IntelliSAW CAM-5 User manual

User Manual

910.00382.0001

May 2018

IntelliSAW CAM™-5

Condition Asset Monitoring

User Manual

910.00382.0001 May 2018

2

User Manual

May 2018 910.00382.0001

3

Contents

Contents........................................................................................................................................................3

Important Information....................................................................................................................................6

Section 1 Introduction................................................................................................................................7

1.1 Models...........................................................................................................................................7

1.2 Instructions for Use .......................................................................................................................8

1.3 System Inputs and Outputs...........................................................................................................8

1.4 Labeling.........................................................................................................................................9

1.4.1 Back Label.................................................................................................................................9

1.4.2 Serial Number, Safety and Compliance Label........................................................................10

Section 2 Installation...............................................................................................................................11

2.1 Unpacking ...................................................................................................................................12

2.2 Dimensions..................................................................................................................................12

2.3 Connectors..................................................................................................................................13

2.3.1 Power Connector.....................................................................................................................15

2.3.2 Chassis Ground Connector –Protective Earth.......................................................................16

2.3.3 Ethernet Connector.................................................................................................................16

2.3.4USB Mini-B Cable Connector..................................................................................................16

2.3.5 USB Standard-A Connector....................................................................................................16

2.3.6 SD Micro Connector................................................................................................................17

2.3.7 SCADA Connectors.................................................................................................................17

2.3.8 Devices Connector..................................................................................................................18

2.3.9 SMA (RF) Connectors.............................................................................................................18

2.3.10 Humidity Sensor Connector ................................................................................................18

2.3.11 Relay Alarm Connector.......................................................................................................19

2.4 Panel Mounting ...........................................................................................................................20

2.4.1 Installation Location ................................................................................................................20

2.4.2 Panel Cutout............................................................................................................................20

2.4.3 Mounting Bracket Installation..................................................................................................20

Section 3 Wiring ......................................................................................................................................22

3.1 Power Connection.......................................................................................................................24

3.1.1 Input Power Details.................................................................................................................24

3.1.2 Protective Earth (PE) wiring....................................................................................................26

3.2 RS485 Communication (Device and SCADA) ............................................................................26

3.2.1 CAM-5 Connection to Readers...............................................................................................27

3.2.2 CAM-5 Connections to External SCADA ................................................................................28

User Manual

910.00382.0001 May 2018

4

3.2.3 RS485 Cabling........................................................................................................................28

3.2.4 Bus Termination......................................................................................................................29

3.2.5 Bus data rate (baud rate) considerations................................................................................29

3.3 Humidity Sensor Connections.....................................................................................................29

3.4 Air Interface Connections............................................................................................................30

3.5 Alarm Wiring................................................................................................................................31

3.6 Example Wiring Diagram ............................................................................................................33

Section 4 HMI Overview..........................................................................................................................34

4.1 Home Screen ..............................................................................................................................34

4.1.1 Home Screen Segments.........................................................................................................34

4.1.2 HMI Warning & Alarm Indications ...........................................................................................36

4.1.3 Unit Details & Measurement Selection....................................................................................38

4.1.4 Versions ..................................................................................................................................38

4.1.5 Network ...................................................................................................................................38

4.1.6 Capture & Log Files ................................................................................................................39

4.1.7 Reboot.....................................................................................................................................39

4.1.8 Date.........................................................................................................................................39

4.2 Device Specific Detail Screens ...................................................................................................40

4.2.1 Device Detail Screen Overview...............................................................................................40

4.2.2 Temperature Measurements...................................................................................................42

4.2.3 Humidity and Ambient Temperature .......................................................................................44

4.2.4 Partial Discharge.....................................................................................................................46

Section 5 HMI Configuration ...................................................................................................................50

Section 6 Measurement Configuration & Sensor Installation..................................................................51

6.1 Measurement Configuration........................................................................................................51

6.2 Sensor Installation.......................................................................................................................52

Section 7 SCADA System Integration.....................................................................................................53

7.1 Modbus RTU or TCP...................................................................................................................53

7.1.1 MODBUS COMMANDS..........................................................................................................53

7.1.2 MODBUS REGISTERS...........................................................................................................54

7.2 DNP3...........................................................................................................................................57

7.2.1 DNP3 flags..............................................................................................................................58

7.2.2 DNP3 Settings.........................................................................................................................58

7.2.3 DNP3 TLS and Secure Authentication....................................................................................58

7.3 IEC 61850 ...................................................................................................................................58

7.3.1 Logical Nodes List...................................................................................................................58

7.3.2 Mapping of Modbus to IEC61850............................................................................................59

7.3.3 Mapping of Digital Output to IEC61850 ..................................................................................61

User Manual

May 2018 910.00382.0001

5

Section 8 Specifications..........................................................................................................................62

Section 9 Product Certifications..............................................................................................................66

9.1 Compliance Testing ....................................................................................................................66

9.2 Wireless Certifications.................................................................................................................67

9.2.1 Telecommunication Compliance.............................................................................................67

9.2.2 Approved Antennas.................................................................................................................67

9.2.3 Federal Communications Commission (FCC) ........................................................................68

9.2.4 Industry Canada (IC)...............................................................................................................68

Contact........................................................................................................................................................70

User Manual

910.00382.0001 May 2018

6

Important Information

This symbol identifies messages in this document related to safety.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or

serious injury.

Failure to follow the instructions given will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

Failure to follow the instructions given can result in death or serious injury

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury.

Failure to follow these instructions can result in personal injury.

NOTICE

NOTICE alerts you to practices unrelated to personal injury, such as those that can cause property

damage.

Failure to follow these instructions can result in property damage.

IMPORTANT

IMPORTANT indicates additional information about making effective use of this product.

User Manual

May 2018 910.00382.0001

7

Section 1 Introduction

The IntelliSAW CAM™-5 provides a local human machine interface (HMI) with remote monitoring

capabilities (temperature, partial discharge, and humidity / ambient temperature), data trending and

alarming, data aggregation, and multiple communication interfaces such as Modbus TCP, DNP-3, and

IEC61850 to integrate into existing SCADA / DCS systems.

The CAM-5 can be a stand-alone system ideal for predictive condition-based monitoring of electrical

power critical assets such as switchgear, generator circuit breakers, and bus ducts.

This manual covers CAM-5 functionality, configuration, safety, and installation.

1.1Models

The following tables outline available CAM-5 models.

Model Number

Description

CAM5B-TPH-AMEU

CAM5 Base:

- Monitoring: Temperature, PD, Ambient Temp &Humidity

- Alarm outputs –6 ch. (NO/NC)

- Multiunit Device Interface (RS485)

- Communication interface: Ethernet

- Standard communication: Modbus TCP

- Universal Input Power (100 to 250 VAC; 120 to 250VDC1)

CAM5B-T00-AMEU

CAM5 Base:

- Monitoring: Temperature

- Alarm outputs –6 ch. (NO/NC)

- Multiunit Device Interface (RS485)

- Communication interface: Ethernet

- Standard communication: Modbus TCP

- Universal Input Power (100 to 250 VAC; 120 to 250VDC1)

CAM5B-000-AMEU

CAM5 Base:

- No Monitoring

- Alarm outputs –6 ch. (NO/NC)

- Multiunit Device Interface (RS485)

- Communication interface: Ethernet

- Standard communication: Modbus TCP

- Universal Input Power (100 to 250 VAC; 120 to 250VDC1)

CAM5B-TPH-AMFU

CAM5 Base:

- Monitoring: Temperature, PD, Ambient Temp & Humidity

- Alarm outputs –6 ch. (NO/NC)

- Multiunit Device Interface (RS485)

- Communication Interface: Fiber Optic (100 base FX)

- Standard communication: Modbus

- Universal Input Power (100 to 250 VAC; 120 to 250VDC1)

CAM5B-T0H-AMEU

CAM5 Base:

- Monitoring: Temperature, Ambient Temp &Humidity

- Alarm outputs –6 ch. (NO/NC)

- Multiunit Device Interface (RS485)

- Communication interface: Ethernet

- Standard communication: Modbus TCP

- Universal Input Power (100 to 250 VAC; 120 to 250VDC1)

1

DC operation has not been evaluated for FCC Part 15 or c/UL/IEC 61010-1.

User Manual

910.00382.0001 May 2018

8

1.2Instructions for Use

The CAM-5 is intended to be installed in the Low Voltage compartment of switchgear or in similar types of

assets. The CAM-5 is intended for use at a maximum altitude of 5km, between -25°C to +70°C (+55°C at

250VAC input) and between 10 - 95% non-condensing relative humidity.

WARNING

THE CAM-5 IS INTENDED ONLY FOR INSTALLATION IN LOW VOLTAGE CONTROL

COMPARTMENTS.

ONLY SENSORS AND AIR INTERFACES ARE INTENDED FOR INSTALLATION IN MEDIUM / HIGH

VOLTAGE COMPARTMENTS.

ONLY WIRELESS SENSORS ARE INTENDED FOR CONTACT WITH ENERGIZED CONDUCTORS

ABOVE 300VRMS.

Failure to follow the instructions given can result in death or serious injury

1.3System Inputs and Outputs

The maximum system inputs and outputs are as follows:

Inputs

Outputs

12 SAW wireless temp sensors

Communications:

Modbus RTU (SCADA)2

Modbus TCP

DNP3

IEC61850

Email alarms3

SMS alarms4

4 air interfaces (TMP or TPD)

8 humidity sensors (series connected)

Modbus RTU (Devices)

Power: 100 to 250V AC 50/60 Hz (20W)

120 to 250V DC1

Alarms: 6 Form C (NO / NC) relays with a

shared common (COM)

2

MODBUS RTU output requires a non-standard model with RS485 communications card.

3

Email alarms require connectivity to a user-supplied SMTP server and valid email account for sending data.

4

SMS is only supported via a compatible cellular gateway device with a user-supplied SIM card and plan.

User Manual

May 2018 910.00382.0001

9

1.4Labeling

The CAM-5 has two identification labels. The back label provides model number and device specific

connections. The safety and compliance label on the top provides product serial number, certification

information and installation ratings.

1.4.1Back Label

The back label is unique per model number as the connectors will change. Each label identifies the unit

model number.

Figure 1: Example CAM-5 back label

User Manual

910.00382.0001 May 2018

10

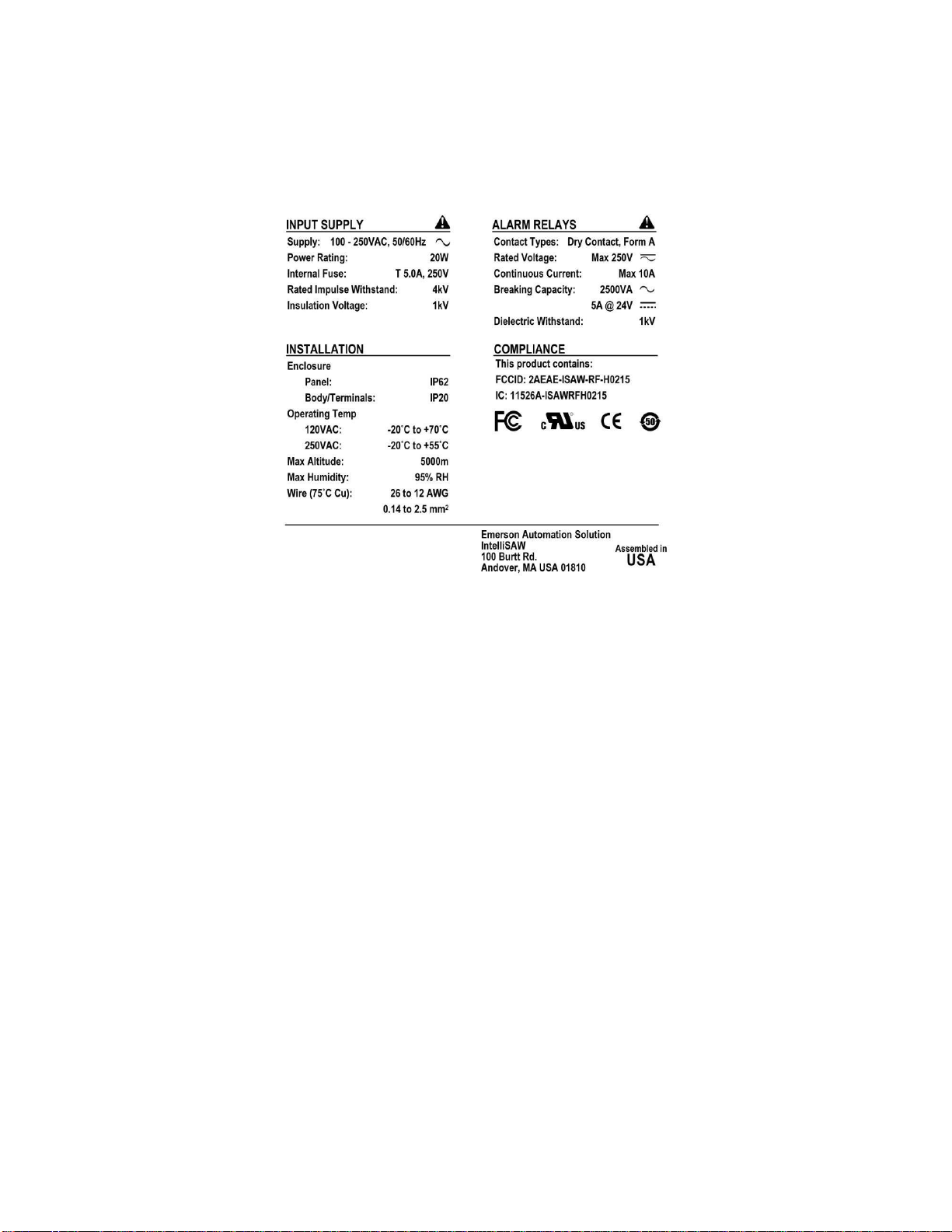

1.4.2Serial Number, Safety and Compliance Label

The safety and compliance label located at the top of the unit provides the product serial number,

manufacturer information, compliance information, along with input supply, installation, and alarm relay

ratings.

Figure 2: CAM-5 Safety and Compliance Label

User Manual

May 2018 910.00382.0001

11

Section 2 Installation

WARNING

INSTALLATION AND CONFIGURATION SHOULD BE PERFORMED ONLY BY PERSONNEL WHO

ARE TECHNICALLY COMPETENT AND AUTHORIZED TO DO SO. LOCAL REGULATIONS

REGARDING ELECTRICAL INSTALLATION AND SAFETY MUST BE OBSERVED.

Failure to follow the instructions given can result in death or serious injury

WARNING

THE USE OF THIS EQUIPMENT IN A MANNER NOT SPECIFIED IN THIS MANUAL OR BY THE

MANUFACTURER MAY IMPAIR PROTECTION OF THE USER AND EQUIPMENT.

Failure to follow the instructions given can result in death or serious injury

CAUTION

THIS EQUIPMENT IS DESIGNED FOR INSTALLATION IN AN ENCLOSURE THAT PROVIDES

ADEQUATE PROTECTION AGAINST ELECTRIC SHOCK.

Failure to follow these instructions can result in personal injury.

NOTICE

The product is recognized as a component under c/UL/IEC 61010-1 and c/UL/IEC 61010-3 and has

been evaluated under IEC61000-6-5 in type 4 interface applications. The 61010-1 and -3 component

recognitions assume the following, which were not specifically evaluated for the product as a

component:

•Spacing of all wired components from energized conductors meets the greater of double

insulation under c/UL/IEC61010 or the BIL requirements of the host equipment.

•Wired sensors are installed and cabled in accordance with instructions.

Note that introduction of a recognized component into a previously recognized system requires

evaluation of the modified system for c/UL recognition.

Failure to follow these instructions can result in operation outside the c/UL recognition of the

product and/or host equipment.

User Manual

910.00382.0001 May 2018

12

2.1Unpacking

1. Remove the product from its packing. Retain the packing for future use, to transport the

instrument to a different site or to return it to the supplier for repair/testing.

2. Examine the delivered items for damage or defects. If any are found, contact the courier

immediately.

3. In the Box:

a. CAM-5 Unit

b. Power terminal block (2 position 7.62mm Plug)

c. Devices terminal block (6 position 3.5mm Plug) if option exists

d. SCADA terminal block (6 position 3.5mm Plug) if option exists

e. Alarm terminal block (5 position plug) if option exists

f. 16GB USB Flash Drive

g. (4) Mounting Clips

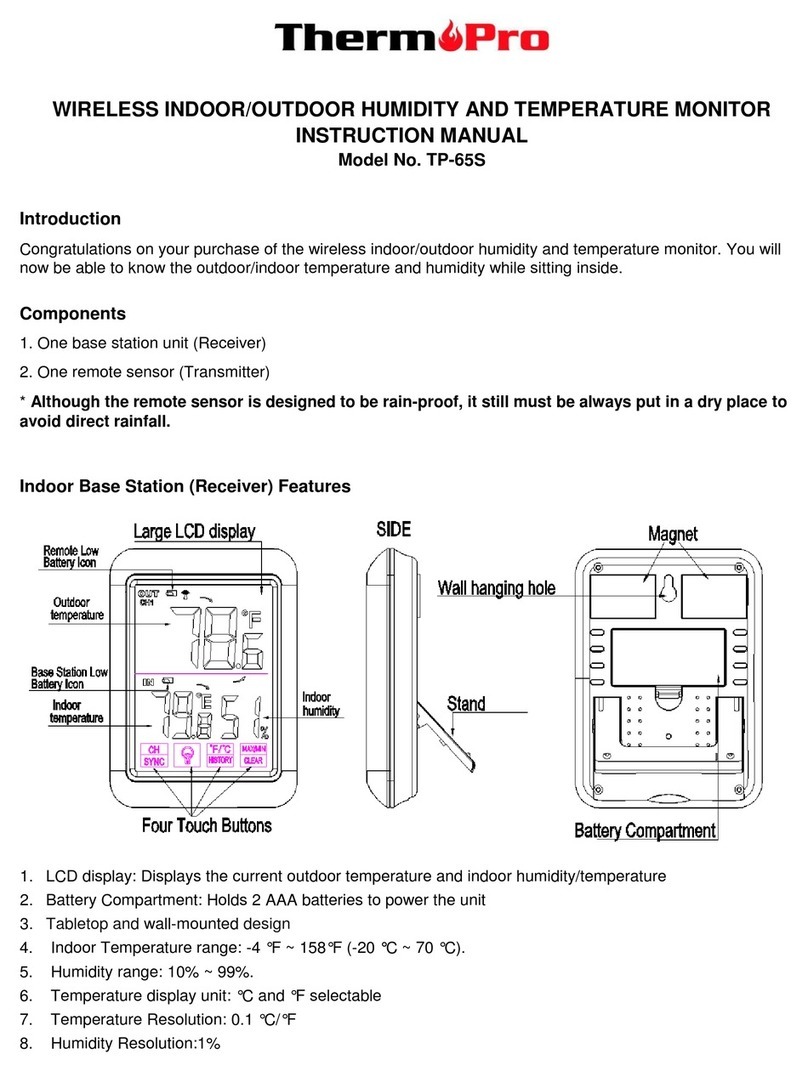

2.2Dimensions

The CAM-5 HMI instrument has front screen dimensions of 153.4 mm W x 110.2 H with a face depth of

3.14 mm. The Body dimensions of the CAM-5 are 143.6 W x 100.25 H x 101.6 mm D.

Figure 3: CAM-5 Dimensions (in mm)

User Manual

May 2018 910.00382.0001

13

2.3Connectors

The product has up to fourteen connectors (depending on model):

Standard Connectors:

•(1) Input Power Connector

•(1) USB connector (Mini-B) –used for measurement configuration

•(1) USB connector (Standard-A) –used for data logging

•(1) SD Micro card –for factory and future use.

•(1) Ethernet Connector (system)

•(1) Ground lug –chassis ground

Optional Connectors:

•(4) SMA (RF) connectors –used for air interface connections

•(1) Alarms Connector

•(1) Devices (RS485) Connector –Reader Input through Modbus RTU

•(1) Humidity connector

•(1) SCADA Connector

oRS485 - integration through Modbus RTU

oFiber Connector

oEthernet Connector

Figure 4: CAM-5 Back View

DEVICES

Humidity

Ground Lug

Power

SMA (RF)

Ports

SCADA

Alarms

USB-Standard-A

USB-Mini-B

Ethernet (system)

User Manual

910.00382.0001 May 2018

14

Figure 5: CAM-5: Left Side View

IMPORTANT

External radio frequency energy sources located close to the RF ports can reduce the sensitivity of

partial discharge measurements.

IMPORTANT

The status LED of the RF card is visible through the ventilation slots.

LED States:

•No Illumination: No Power to RF measurement card

•Solid Green: Power, no measurements

•Green / Amber toggle: Automated measurements enabled

•Fast flashing Amber: Rebooting

SD Card

Mounting Clip

Slots

Ventilation

RF Card LED

Mounting Clip

Slots

User Manual

May 2018 910.00382.0001

15

Figure 6: CAM-5: Right Side View

WARNING

INSERTION OF WIRES OR FINE TOOLS INTO THE VENTILATION SLOTS COULD RESULT IN

HAZARDOUS CONDITIONS.

Failure to follow the instructions given can result in death or serious injury

2.3.1Power Connector

Pin

Name

Description

Line / (+)

Line 1, DC+

Input power range:

100 to 250V AC and 120 to 250V DC1.

2-Phase AC uses (N / -) as Line 2

Neutral / (-)

Neutral, Line 2, DC-

Line and Neutral are symmetric in the CAM™-5 and DC power may be applied at either polarity.

Line and Neutral have differential mode filtering and clamping to PE stud and have common

mode filtering and isolation to the remainder of the unit.

Mounting Clip

Slots

Ventilation

User Manual

910.00382.0001 May 2018

16

2.3.2Chassis Ground Connector –Protective Earth

Interface

Name

Description

Lug

Protective Earth

Chassis ground / protective earth lug connection, required for

safety when air interfaces are near energized conductors.

2.3.3Ethernet Connector

Interface

Name

Description

RJ45

Ethernet (ETH-1)

Used for configuration and Ethernet communication (10/100

BASE-T)

2.3.4USB Mini-B Cable Connector

Interface

Name

Description

Mini-B

CNFG

USB Mini-B used for unit configuration

2.3.5USB Standard-A Connector

Interface

Name

Description

Host-A

USB

USB Host-A used for image capture and data storage. Also used

for software and configuration file uploads.

WARNING

THE CAM-5 IS DESIGNED TO ISOLATE THE USB PORTS FROM HAZARDOUS CONDITIONS

INTRODUCED FROM INCOMING CABLES AND THE ENERGIZED EQUIPMENT.

IT IS NOT ADVISED TO USE THESE PORTS OTHER THAN AS FOLLOWS.

•USB-MINI-B: SHORT TERM USE FOR CONFIGURATION AND VERIFICATION. NOT FOR

LONG TERM DATA COLLECTION.

•USB-HOST-A: LONG TERM DATA LOGGING WITH INFREQUENT REMOVAL AND

REPLACEMENT FOR DATA COLLECTION.

Failure to follow the instructions given can result in death or serious injury

User Manual

May 2018 910.00382.0001

17

2.3.6SD Micro Connector

Interface

Name

Description

SD Micro

SD Micro

SD card for factory use only

2.3.7SCADA Connectors

SCADA interface is determined by model number.

2.3.7.1Modbus RTU Connector

Pin

Name

Description

DATA-

DATA Negative

Negative Input for Modbus RTU (RS485)

DATA-

DATA Negative

Redundant Negative Input for Modbus RTU (RS485)

DATA+

DATA Positive

Positive Input for Modbus RTU (RS485)

DATA+

DATA Positive

Redundant Positive Input for Modbus RTU (RS485)

D-COM

DATA Common

Common input for Modbus RTU (RS485)

D-COM

DATA Common

Redundant Common input for Modbus RTU (RS485)

2.3.7.2Ethernet Connector

Interface

Name

Description

RJ45

Ethernet (ETH-2)

Used for SCADA communication (10/100 BASE-T)

2.3.7.3Fiber Connector

Interface

Name

Description

LC

FIBER (100Base-FX)

Used for SCADA communication

User Manual

910.00382.0001 May 2018

18

2.3.8Devices Connector

Redundant terminals are provided for ease of use, for daisy chaining RS-485 where the CAM-5 is not the

last device on the network. Where it is the last device, a ½ Watt 120 Ohm resistor should be placed

between one Data+ and Data–.

Pin

Name

Description

DATA-

DATA Negative

Negative Input for Modbus RTU (RS485)

DATA-

DATA Negative

Redundant Negative Input for Modbus RTU (RS485)

DATA+

DATA Positive

Positive Input for Modbus RTU (RS485)

DATA+

DATA Positive

Redundant Positive Input for Modbus RTU (RS485)

D-COM

DATA Common

Common input for Modbus RTU (RS485)

D-COM

DATA Common

Redundant Common input for Modbus RTU (RS485)

2.3.9SMA (RF) Connectors

Pin

Name

Description

P1

RF Port 1

Air Interface Radio Frequency Port 1

P2

RF Port 2

Air Interface Radio Frequency Port 2

P3

RF Port 3

Air Interface Radio Frequency Port 3

P4

RF Port 4

Air Interface Radio Frequency Port 4

2.3.10 Humidity Sensor Connector

Pin

Name

Description

H-PWR

Humidity Power

Humidity Cable Power Input from Humidity Sensor

H-DAT

Humidity Data

Humidity Cable DATA Input from Humidity Sensor

H-CLK

Humidity Clock

Humidity Cable Clock Input from Humidity Sensor

H-COM

Humidity Common

Humidity Cable Common Input from Humidity Sensor

User Manual

May 2018 910.00382.0001

19

2.3.11 Relay Alarm Connector

Pin

Name

Description

A-COM

Alarm Common

Common output for Alarms Connector

A-NO1

Alarm Output 1

Normally Open Alarm Output 1

A-NC1

Alarm Output 1

Normally Closed Alarm Output 1

A-NO2

Alarm Output 2

Normally Open Alarm Output 2

A-NC2

Alarm Output 2

Normally Closed Alarm Output 2

A-NO3

Alarm Output 3

Normally Open Alarm Output 3

A-NC3

Alarm Output 3

Normally Closed Alarm Output 3

A-NO4

Alarm Output 4

Normally Open Alarm Output 4

A-NC4

Alarm Output 4

Normally Closed Alarm Output 4

A-NO5

Alarm Output 5

Normally Open Alarm Output 5

A-NC5

Alarm Output 5

Normally Closed Alarm Output 5

A-NO6

Alarm Output 6

Normally Open Alarm Output 6

A-NC6

Alarm Output 6

Normally Closed Alarm Output 6

A-COM may be high side with grounded loads (current source through relays) or may be low side with

powered loads (current sink through relays).

User Manual

910.00382.0001 May 2018

20

2.4Panel Mounting

CAUTION

ENSURE THE INSIDE OF THE PANEL IS WITHIN THE CAM-5 OPERATING

TEMPERATURE AND THERE IS ADEQUATE AIR FLOW TO PREVENT OVERHEATING.

2.4.1Installation Location

The CAM-5 is intended for indoor use and installation in weather protected enclosures such as

switchgear low voltage compartments or low voltage control boxes. If CAM-5 is being used as a

measurement device, location must be such that it does not exceed the maximum air interface cable

length (assuming cable routing). Reference the (910.00379.001) IntelliSAW Sensor Installation

Manual for more details. The CAM-5 can only be mounted horizontally.

2.4.2Panel Cutout

The CAM-5 requires a 144.9 mm W x 101.65 mm H panel cutout.

2.4.2.1Recommended Spacing

It is recommended to allow at least to 5 cm (2 in.) the rear of the CAM-5 HMI for connectors. Spacing on

the sides and below the unit should be at least 5cm (2 in.) for ventilation and should be increased if

adjacent meters also require ventilation. The spacing requirements should be considered to be additive

between instruments.

2.4.3Mounting Bracket Installation

Do not affix the mounting screws and brackets until the CAM-5 is inserted into the panel cut-out. The

CAM-5 will hold itself in the panel cut-out while the mounting clips are prepared and inserted. Insert the

clip into the pair of retention slots and tighten the retention screw.

Figure 7: CAM-5 lower two mounting clips.

This manual suits for next models

5

Table of contents