Intercomp WIM Strip Sensor User guide

intercompcompany.com

ISO 9001:2008 Registered

Strain Gauge Transducer Technology

Weigh-in-Motion Strip Sensor Application Guide

WIM Strip Sensor Application Guide

2

Intercomp strain gauge strip sensors provide accurate dynamic weighing across many applications in installations all over the

world. The performance, reliability and longevity of Intercomp’s WIM strip sensors provide the best return on investment of any

form of precision WIM technology. Strip sensors involve minimally invasive installation in concrete or asphalt, and installations

can be used in low speed (LS-WIM) and high speed (HS-WIM) applications.

WIM strip sensors can be installed in rows depending on the application and required accuracy. Providing the sensors alone,

or with electronics and software, Intercomp sensors are ideal for integration into complete WIM systems. When combined

with cameras, detectors, and data transmission devices, they are capable of serving as standalone virtual remote weigh

stations or work in tandem with commercial weigh stations while operating as pre-selection for enforcement.

In-Ground Strip Sensors for WIM

WIM screening allows transportation

engineers to study traffic characteristics for

the planning and maintenance of roadways.

Data Collection

Vehicle data such as classification

and flagged violations can be remotely

accessed for enforcement efforts

downstream of WIM site.

Screening for Enforcement

Meets or Exceeds ASTM E1318-09

Type I, II, III and COST 323 A(5), B+(7)

or B(10) Performance Requirements

Strip Sensors

Intercomp strip sensor WIM systems

are designed to deliver best-in-class

accuracy across a wide range of

speeds and temperatures.

ACCURACY

Visit us online at intercompcompany.com or call us at +1 763-476-2531 Worldwide

ISO 9001:2008 Registered

3

Traffic can be directed to specific lanes, off

the mainline for further inspection, or to

continue on without further interruption.

Pre-Selection

Data collection to identify and divert

overloaded vehicles for protecting bridges

and infrastructure.

Bridge Protection

Weight based information is used to confirm

vehicle loading or calculate fees. In tolling,

heavier vehicles are charged more than lighter

vehicles due to impact on roadways.

Tolling/Ports of Entry

Intercomp designs and manufactures weighing and measurement solutions to help our customers in WIM product

deployment maximizing system performance and compliance.

Manufactured at our headquarters in the United States, Intercomp products build upon 40 years of global industry

expertise and applications experience to provide our customers superior quality, reliability and certainty in the

products and services we deliver.

INTERCOMP WIM STRIP SENSORS

Worldwide Sites and Distribution

WIM Strip Sensor Application Guide

4

Designed from NTEP/OIML approved scale technology, the sensor measures the magnitude of mechanical quantities

such as force, torque, load, and pressure to provide the benefits customers are accustomed to with precision scale

technology. This enables customers to comply with accepted metrology, standardization, testing, certification and

accreditation used by legal metrology authorities and industries worldwide.

The Intercomp strain gauge strip sensor:

• Not position sensitive to tire placement with consistent linear output along entire length of sensor.

• Designed to measure only vertical force by removing side loads associated with pavement crowding or side

or angle loading.

• Internal temperature compensation adjusts for changes in temperature at sensor. This improves consistency

of output from day to day and season to season and reduces calibration frequency as compared to piezo-electric

and quartz sensors.

• The capacitance of a long cable does not affect the measurement characteristics of the strain gauge sensor,

so there is no need for a charge amplifier.

• Long life span – designed for mainline operation of 5 or more years.

Strain Gauge Technology for Weigh-In-Motion

Intercomp’s GaugeSense™Technology actively senses, corrects, and controls to provide the most

accurate measurement possible. The inherent benefits of this technology are integrated into the

WIM strip sensor with many advantages for in-road use.

Visit us online at intercompcompany.com or call us at +1 763-476-2531 Worldwide

ISO 9001:2008 Registered

5

Strain gauge technology is used in static weighing for direct weight enforcement and is accepted as the most accurate and

reliable means to weigh a vehicle. Intercomp’s strip sensors integrate the same strain gauge technology incorporated into a

compact strip for accurate WIM applications. Offering the lowest cost of ownership of any precision WIM sensor, the price,

durability, and longevity of Intercomp sensors deliver performance to rely on.

Weigh-in-Motion Strip Sensors Patent pending

The sensors are installed within 3"

wide (75mm) channels cut into the

existing asphalt or concrete road

surface. Installation can be

completed in a single day.

Flexibility—Integration from Sensor

Replacement to Full Systems

Maintenance—Can be Ground Flush

with Changing Road Conditions

Accurate— Across Variety of Speeds

& Temperature Extremes

Durability—Field Proven Through

Millions of Cycles

Installation—In a Single Day with

Minimal Traffic Interruptions

Variable Sizes—

Sensor comes in 59", 69",

79"(1.5, 1.75, 2m) Lengths

Capable of meeting or exceeding

ASTM E1318-09 Type III and COST

323 A(5) performance requirements

WIM Strip Sensor Application Guide

6

Transportation officials rely on Weigh-In-Motion

(WIM) sensors for collecting vehicle data at high

speeds for highway data and traffic monitoring.

Traffic volume, speed, vehicle classifications,

and vehicle weights are all part of monitoring

current usage and highway planning for the future.

Strip sensors for data collection incorporate strain gauge sensor technology:

• WIM Site Installation employs Two to Four Sensors, Loop & Electronics

• Provides Accurate Data for Roadway Monitoring & Planning

• Detection of Overloaded Vehicles & Incidence

• Integrate Sensors in Existing Pavement or during Site Replacement

Performance of WIM site has a Gross Vehicle

Weight (GVW) accuracy for data collection

which meets or exceeds ASTM 1318 Type I

and COST 323 B(10) WIM requirements.

DATA COLLECTION

Typical Sensor Configurations

DATA COLLECTION | CASE STUDY

NETHERLANDS: DATA COLLECTION

Just outside of Rotterdam in the Netherlands, Intercomp strip sensors are

installed in multiple lanes to gather traffic and vehicle data in the mainline.

As Rotterdam is one of the busiest shipping ports in the world, gathering

traffic and vehicle data supplies the Ministry of Infrastructure and the

Environment valuable information for roadway planning and utilization.

Sensors were installed in four lanes, with two sensors per lane for this mainline application. The WIM site

experiences high speed vehicle traffic, with significant heavy vehicles due to the commercial traffic for the port.

Additionally, one lane of traffic required bi-directional capability, so monitoring traffic in both directions was enabled

for that lane.

Delivering GVW accuracy of better than COST 323 B+(7) requirements with the bi-directional and single lanes, the

Intercomp strip sensors satisfied the requirements to provide excellent traffic and weight data for this high traffic

volume WIM site.

As the Intercomp sensors were integrated with the local operator’s electronics and software, this adds to the variety

of electronics platforms that are currently capable of working with Intercomp WIM sensors.

Visit us online at intercompcompany.com or call us at +1 763-476-2531 Worldwide

ISO 9001:2008 Registered

7

IN-GROUND

Weight Enforcement is vital to minimize the damage

caused by overloaded vehicles to roads and highways,

and to increase safety for the operators. Detection of

these vehicles at high speeds (HS-WIM) is an efficient

and effective method for screening for enforcement

or pre-selection of vehicles for static weigh stations.

Strip sensors for pre-selection or enforcement incorporate strain gauge

sensor technology:

• WIM Site Installation Employs Four to Six Sensors, Loop & Electronics

• Consistent Accuracy for Selection of Vehicles from Screening

• Improve Vehicle & Operator Safety

• Simple Integration of Sensors into Existing Enforcement Systems

Regions can have different requirements for accuracy

of systems employed in screening for enforcement

WIM systems. COST 323 A(5) and COST 323 B+(7)

are commonly referenced for these screening for

enforcement sites. Six sensors (three pairs) have

been used in some countries for these applications.

Performance of WIM sites have a Gross Vehicle Weight

(GVW) accuracy for screening for enforcement meeting

or exceeding ASTM 1318 Type III and COST 323 B+(7)

WIM requirements.

ENFORCEMENT & PRE-SELECTION

Typical Sensor Configurations

ENFORCEMENT & PRE-SELECTION | CASE STUDY

OREGON DOT: PRE-SELECTION

The state of Oregon in the US has used pit-type Weigh-In-Motion scales

for pre-selection in the mainline for many years. Though pleased with the

accuracy the scales delivered, the cost of installation and the ongoing

maintenance required led the state to evaluate different HS-WIM options.

Familiar with the benefits of strain gauge technology, Oregon DOT (ODOT)

chose to test Intercomp strip sensors as a WIM sensor replacement integrated

into their current electronics and software.

Pilot sites with four sensors in two rows were installed to conduct evaluations of possible WIM replacement scales

and sensors. Vehicles crossed the mainline WIM sites at speeds ranging from 40-80mph (65-130kph), and these

vehicle records were compared to weights gathered with static scales at weighstations downstream from the

WIM sites.

These sites were operated by the ODOT, and when comparing the data from WIM to static scales, performance

of 3-4% GVW error were found in diverse weather conditions over time.

This confirmed ODOTs previous positive experience with strain gauge WIM technology, but Intercomp supplies this

performance in a smaller, easier to install strip sensor. In the future, when replacing current or creating new WIM

sites, the State of Oregon has committed to use Intercomp strip sensors for their High-Speed WIM mainline technology.

WIM Strip Sensor Application Guide

8

Typical Sensor Configurations

Tolling based on weight or axle configurations

is done with Weigh-In-Motion (WIM) technology.

Integrated into existing lanes in the mainline or

slower traffic areas, vehicles can be measured

rapidly without stopping. Automated systems

provide accurate information in real-time for

vehicle processing.

Strip sensors for tolling incorporate strain gauge sensor technology:

• WIM Site Installation Employs Four to Eight Sensors, Loop & Electronics

• Automate Tolling Process

• Detection of Vehicle Weights for Weight Based Tolling

• Detection of Axle Configuration for Vehicle Classification Based Tolling

• Use Sensors in Low or High Speed tolling Applications,

including Mainline Installations

Performance of these WIM sites for tolling

applications have a Gross Vehicle Weight (GVW)

accuracy meeting or exceeding ASTM 1318 Type

III and COST 323 A(5) WIM requirements.

TOLLING (ETC)

TOLLING | CASE STUDY

THESSOLONIKI, GREECE: FEE COLLECTION

Gathering WIM Gross Vehicle Weights (GVW) in individual traffic lanes allows

for revenue determinations to be made for weight based vehicle transactions.

Customers in the Greek area of Macedonia required a WIM system capable

of obtaining vehicle weight data in existing vehicle lanes and to integrate

into their current system.

Highly accurate performance was required for this site, with 4 rows of sensors installed in each lane of traffic.

Speeds at this WIM site are 5-10mph (8-16kmh), and the Intercomp products were ideal for the site as they do not

require drains compared to other strain-gauge based technology. The sensors were integrated into systems with

other peripheral equipment, increasing site efficiency by working to process transactions without vehicle stoppage.

WIM performance at installation was consistent across all vehicle lanes, demonstrating under 1% GVW error

compared to a test vehicle with a known static weight. This allows the operators to calculate and manage fees

rapidly and accurately with the strain gauge strip sensors. As a result of this experience, operators in Greece are

looking into integration of the Intercomp strip sensors into additional locations in the region.

Visit us online at intercompcompany.com or call us at +1 763-476-2531 Worldwide

ISO 9001:2008 Registered

9

Typical Sensor Configuration

Screening for vehicle and cargo weights allows for

identification of unloaded, loaded, and overloaded

vehicles. When integrated into existing processes,

dynamic weighbridges with Weigh-In-Motion

technology allows for rapid processing of vehicles

without stoppage and delays.

Strip sensors for ports and gates incorporate strain gauge

sensor technology:

• WIM Site Installation Employs Eight Sensors, Loop & Electronics

• Weigh Vehicles & Cargo without Stopping

• Integrate Sensors into Existing Automated Process

• Couple Sensors with Gate Arms, RFID & Camera Technology

• Installation does not Require Pits or Drains

Performance of these WIM sites meets or exceeds OSHA

requirements in the U.S., ASTM 1318 Type III and COST

323 A(5) Weigh-In-Motion (WIM) requirements, and IMO

and SOLAS Verified Gross Mass (VGM) in regions around

the world.

PORTS/GATES

PORTS & GATES | CASE STUDY

PUERTO CORTEZ, HONDURAS: SEAPORT

Safety standards defined by the International Maritime Organization (IMO)

include a verified gross mass specification for cargo as part of Safety Of Life

At Sea (SOLAS) requirements. As port systems are also increasing automation

throughout all stages of the supply chain of goods, WIM technology is an

excellent fit to achieve the required accuracy by the government without

interrupting the flow of cargo into and out of the port.

WIM sites within the terminal were installed in existing vehicle traffic lanes, with 4 rows of sensors to provide the

accuracy at low speeds of 5-10mph (8-16kmh). The Intercomp sensors were coupled with RFID vehicle identification,

stoplights and gate separation, and the terminal integrated the WIM system data into their gate operating system.

The systems weigh vehicles upon entry and within the terminal for Gross Vehicle Weights, and use tare weights to

obtain cargo weights.

The Intercomp strip sensor WIM system provides weighing accuracy with an error of less than 2% with loaded

vehicles. These systems and their performance comply with Honduran regulations regarding automated cargo

weighing in terminals. As a result, further ports in the region are integrating WIM technology for gate operations.

WIM Strip Sensor Application Guide

10

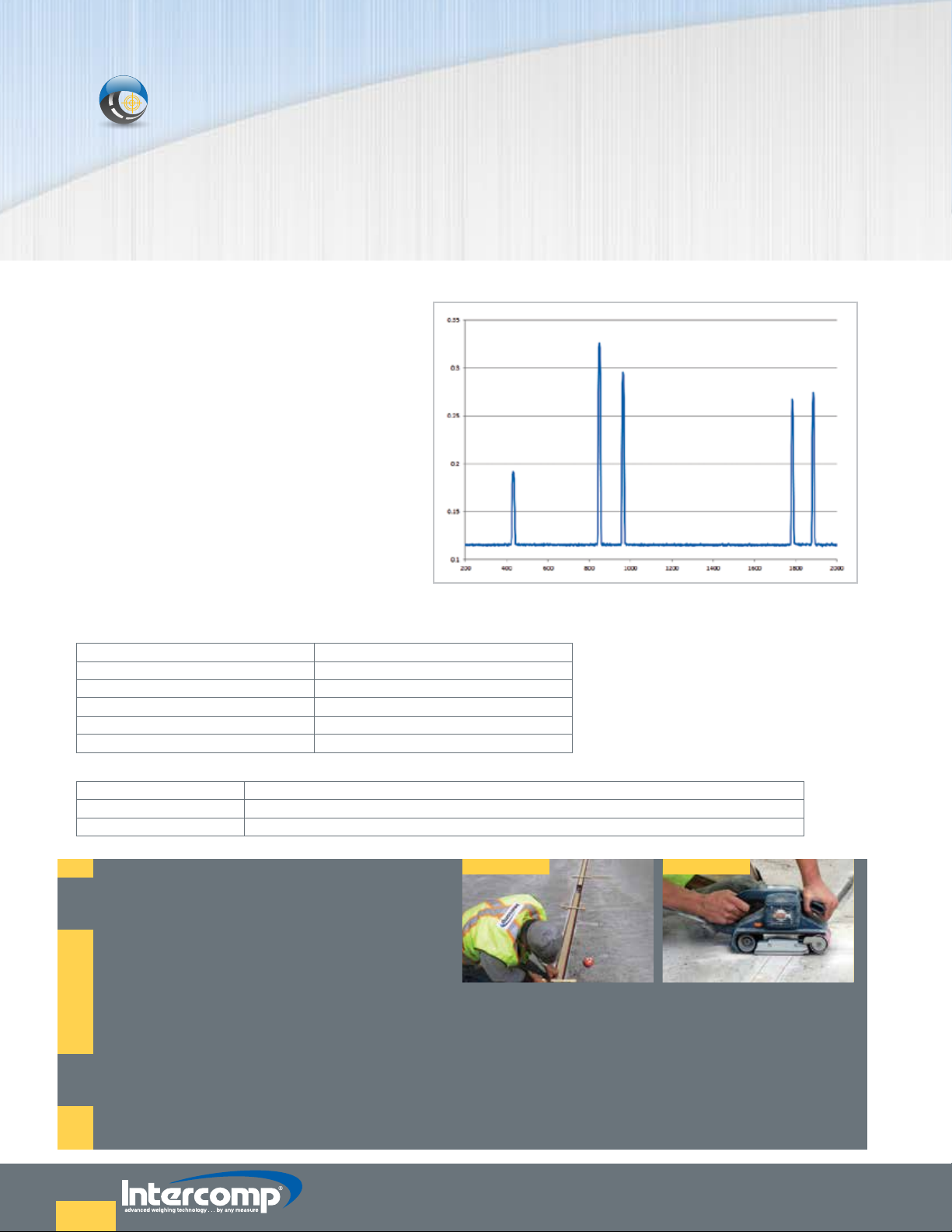

Installation Notes

Installation of the Strip Sensors is a straightforward

process that takes a single day in the existing roadway.

Performance of any WIM system is dependent on the

quality of the installation and condition of the adjacent

roadway surface. Intercomp recommends site conditions that comply with ASTM1318-09 section 6 and COST 323 section 5

standards when selecting the proper site in order to achieve optimal performance.

The Intercomp WIM system is less susceptible to poor road conditions like rutting. Strip sensors have been installed in

asphalt with significant rutting yet can still exceed ASTM Type III or COST A(5) accuracy standards. Regular inspection of

the road service should be made and rutting progression may require additional grinding of the sensors to match the road

surface followed by recalibration. Intercomp recommends adherence to local WIM standards.

Placing Sensor Sanding Flush

Sensor

Sensitivity (Nominal) 0.75 (0.825)m V/V at 6000lb (3000kg)

Output Variance over the Length of Sensor <0.5±%

Linearity <0.1±% FSO

Hysteresis <0.2±% FSO

Operating Temperature Range -40 to 175 ˚F (-40 to 80˚C)

Temperature Coefficient of Sensitivity 0.002 (0.0036) ±% of Load/˚F (˚C)

Electrical Specifications

6-Conductor Cable: ± Excitation, ± Signal, ± Sense, plus Shield Ratiometric mV/V output, 1mV/V @ 8,000lb Typical

Bridge Resistance: 150 to 205 ohms

Recommended Excitation: 5-10V

Strip Sensors Only with Analog Output

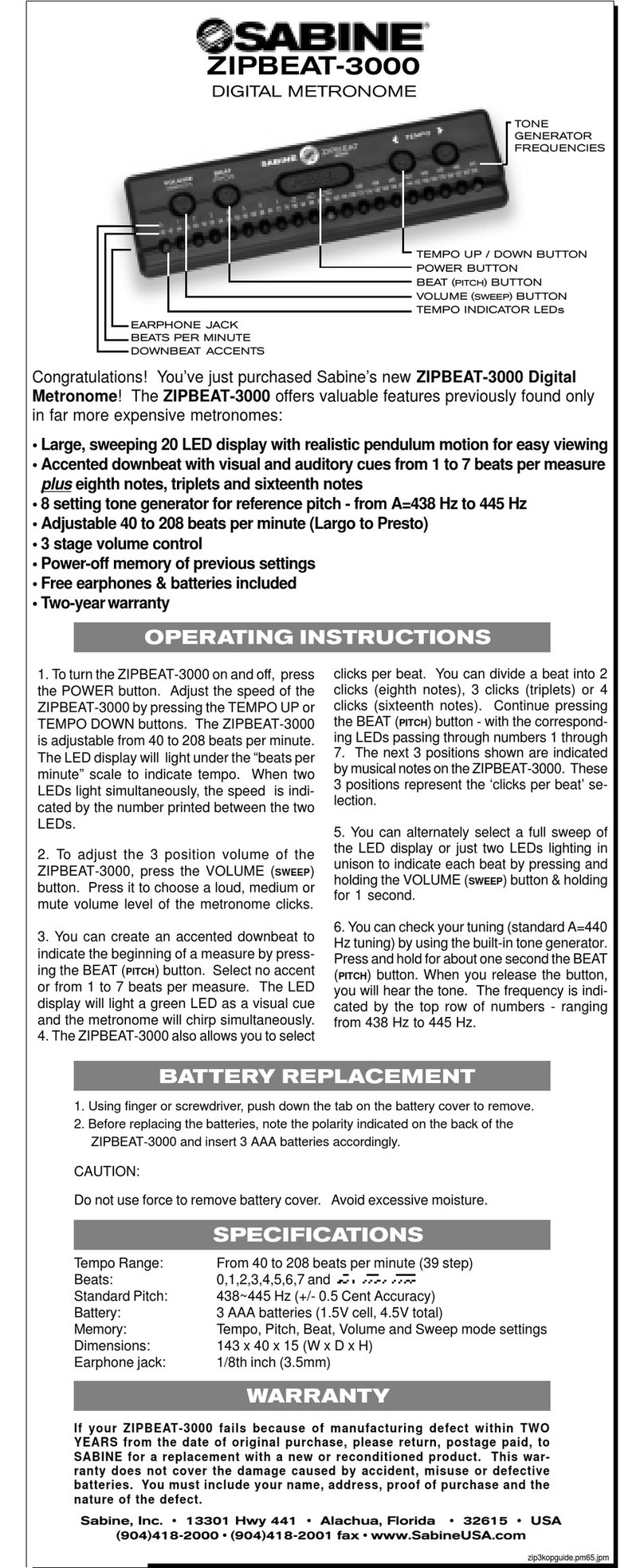

The strain gauge strip sensors are designed to be

used in pairs and can be integrated directly into

customers’ electronics. The sensors are shipped

with variable length cables attached.

The analog output is a mV/V output ratiometric to the

excitation voltage used. In the waveform for a 5 axle

vehicle (see example), the signal is proportional to

the wheel weights experienced by each sensor.

For this option, the customers’ electronics needs

to provide signal conditioning and transmission of

the differential signal to an Analog/Digital Converter.

Intercomp Strip Sensors are offered as Components to be Integrated

with Third-Party Electronics or as Part of a Complete WIM System

Example: 5 Axle Tractor Trailer Vehicle

Visit us online at intercompcompany.com or call us at +1 763-476-2531 Worldwide

ISO 9001:2008 Registered

11

Strip Sensor Signal Converters and CPUs

A/D signal processing and data communication for software or web applications

WIMLOGIX Standard

Output Protocol API SOAP Data Logs

Wheel Load

Axle Load

Gross Vehicle Weight

Speed

Center-to-Center Spacing

Vehicle Class (via Axle Arrangement)

Site Identification Code

Lane & Direction of Travel

Date & Time of Passage

Sequential Vehicle Order

Violation Code

Axle-Group Load

Equivalent Single-Axle Loads (ESALs)

User-Definable Weight Violations

System Requirements ANY .NET ANY ANY

Time Frame REAL TIME REAL TIME REAL TIME DAILY

*Data Fields & Output Format are Customizable

Fully Provided

Handled by Customer Software

WIMLOGIX Standard WIMLOGIX Pro

Strip Sensors with WIMLogix Electronics

Intercomp strip sensors connect to the WIMLOGIX module,

which provides signal conditioning, data acquisition, and basic

processing. The table below illustrates data and communication

options for the WIMLogix modules.

WIMLOGIX MODULE

The WIMLogix Standard performs the A/D

signal conversion, and data from multiple

inputs are passed directly via protocol, or

communicated via Windows™ based API

to separate operating software.

The WIMLogix Pro performs A/D conversion,

and creates and stores vehicle records for

output. Multiple inputs are synchronized, with

onboard processing and storage enabling

operation as a data logger. Data may also be

passed into separate operating software or

web applications hosted on or off-site.

2.8˝

(70mm)

3.0˝

(75mm)

59, 69˝, 79˝

(1,500mm), (1,750mm), (2,000mm)

2.8˝

(70mm)

3.0˝

(75mm)

59, 69˝, 79˝

(1,500mm), (1,750mm), (2,000mm)

2.8˝

(70mm)

3.0˝

(75mm)

59, 69˝, 79˝

(1,500mm), (1,750mm), (2,000mm)

Weight

1.5m Sensor 50lb (22kg)

1.75m Sensor 62lb (28kg)

2.0m Sensor 71lb (32kg)

Dimensions

Length 59, 69, 79in (1.5,1.75,2.0m)

Width 2.80in (70mm)

Height 3.0in (75mm)

General Data for Sensor

Cable Length 100 to 328ft (30 to 100m), Custom Lengths Available

Connector MIL-C-26482 (8-pin Metal Cylindrical Connector, Bayonet Quarter Turn Lock)

Degree of Protection IP 68EN60529

Made In U.S.A.

ISO 9001:2008

Registered

© 2017 Intercomp Company 700733Printed in the U.S.A.

info@intercompcompany.com

Worldwide: +1 763-476-2531

Toll Free: 800-328-3336

Specifications subject to change without notice.

WIM Strip Sensor Application Guide

Table of contents