International Tapetronics Corporation 99B Series User manual

'I

li

'■

!'!■

I'

]

©

o

/

JiTI

‘

I

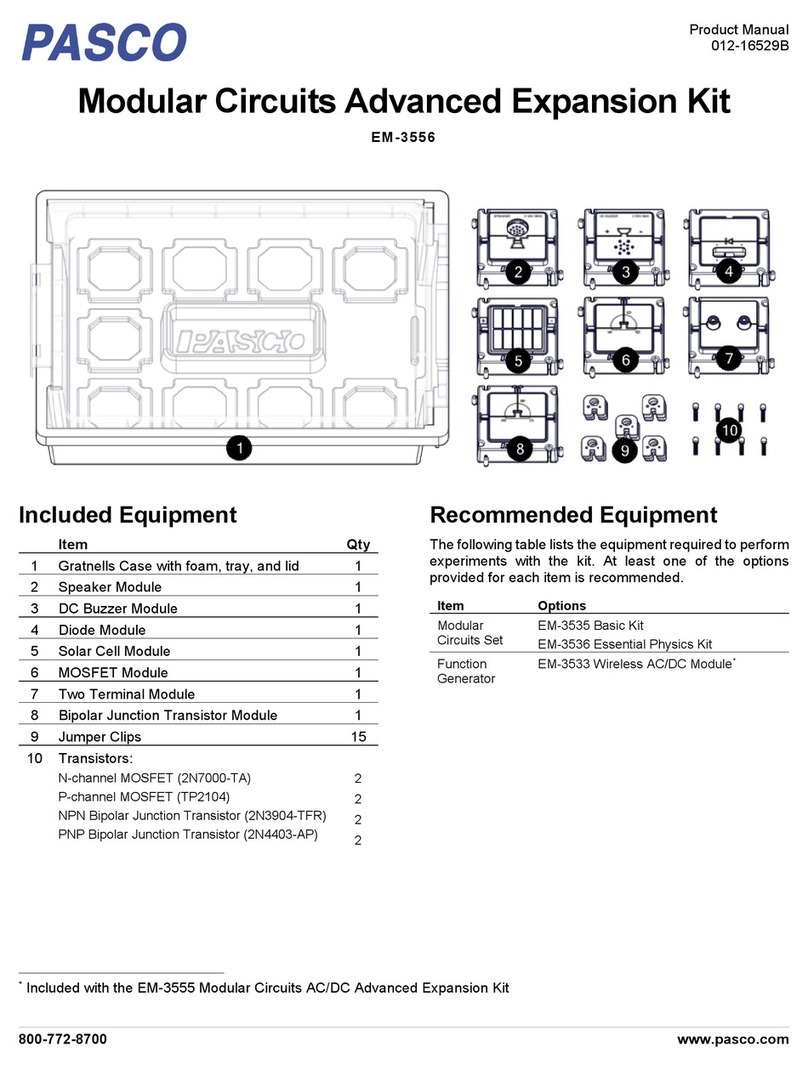

TECHNICAL

MANUAL

SERIES

99B

CARTRIDGE

MACHINE

REPRODUCER/RECORDER

iniGRfiRTIOfiAL

TAPETROAICS

CORPORATOR

'

2425

South

Main

Street

Bloomington,

Illinois

61701

_OOOOOOOOOO

‘

-_

0

SERIES

9W

CAR RIDGE

MACHENE

REPRODUCER/RECORDER

ECHNICAL

MANUAL

(890-0022-000)

IN ERNA IONAL

APE RONICS

CORPORA ION

2425

South

Main

•

Bloomington,

Illinois

elephone:

309/828-1381

©1982

ITC/3M

Printed

in

U. .A.

MADE

UNDER

ONE

OR

MORE

OF

THE

FOLLOWING

PATENT

ira

&38

3.042JM

4.105.934

4.040.114

4.142.221

4.101.937

D248.333

4,153.018

4.221.316

4.219.167

OTHER

PATENT

PENDING

PREFACE

HE

H C

INS RUC ION

MANUAL

International

Tapetronics

Corporation

Manuals

are

written

with

the

intent

of

assisting

the

reader-user

toward

a

better

understanding

of

ITC

equipment.

Most

instruction

manuals

are

seldom

read

except

at

the

time

of

crisis

when

equipment

malfunction

is

suspected.

When

this

happens,

the

manual

is

usually

missing,

or

at

best,

difficult

to

locate.

P EASE

FIND

A

CONVENIENT

SPOT

TO

KEEP

THIS

MANUA .

We

at

ITC

have

tried

to

produce

a

useable

manual.

But,

being

human,

we

are

subject

to

the

frailities

of

be

havior.

Therefore,

should

you

discov

er

any

errors

or

amissions,

or

should

you

wish

to

contribute

any

recommenda

tions,

please

send

us

your

comments.

We

will

be

most

appreciative.

ABLE

OF

CON EN S

Page

SECTION

I

.

INTRODUCTION/SPECIFICATIONS

1-1

INSTA ATION

AND

OPERATION

SECTION

II.

2-1

3-1

SECTION

III.

MECHANICA

ADJUSTMENTS

4-1

SECTION

IV.

MECHANICA

DRAWINGS

5-1

E ECTRICA

ADJUSTMENTS

SECTION

V.

1-1

1-2

A.

General

Description

B.

Specifications

....

A.

General

..

B.

Reproducer

C.

Recorder

.

Installation

..............

External

Audio

Connections

.

External

Control

Connections

Controls

and

Indicators

....

Operational

Options

.......

2-1

2-1

2-2

2-5

2-8

3-1

3-1

3-2

3-5

3-5

3-5

3-6

3-6

3-9

3-9

3-1

2

3-12

3-1

3

A.

B.

C.

D.

E.

A.

B.

C.

D.

E.

F.

E.

F.

G.

H.

I

.

J.

K.

.

M.

J.

K.

.

M.

N.

A.

Important

Considerations

....................

Bo

Pressure

Roller

Shaft/Cross

Shaft

Clamp

Adjust

C.

Capstan

Shaft

(Motor)

Positions

...........

D.

Pressure

Roller

Pressure/Solenoid

Adjustment

.

Solenoid

Dampening

Adjustment

...............

Cartridge

Guidance

System

Alignment

.........

Tape

Guide

Adjustment

.......................

Head

Height

and

Zenith

Adjustment

...........

Monophonic

Head

Azimuth

Adjustment

..........

Stereo

System

Head

Azimuth

Adjustment

.......

Head

Replacement

...........................

Recording

Head

imit

Switch

Adjustment

......

Splice

ocator

Sensor

Adjustment

............

5-1

•

5-1

5-3

Front

Panel

of

Reproducer

with

Dimensions-Figure

4-1

...

4-1

Front

Panel

of

Recorder

with

Dimensions-Figure

4-2

....

4-2

Rear

View

of

Reproducer

-

Figure

4-3

..................

4-2

Rear

View

of

Recorder

-

Figure

4-4

....................

4-2

Top

View

of

Reproducer

-

Figure

4-5

...................

4-3

Bottom

View

of

Reproducer

-

Figure

4-6

................

4-4

G.

Top

View

of

Recorder

-

Figure

4-7

.....................

4-5

H.

Bottom

View

of

Recorder

-

Figure

4-8

..................

4-6

I.

NAB

Track

Format

-

Figure

4-9

.........................

4-7

Expanded

View

of

Playback

Deck

-

Figure

4-10

..........

4-9

Expanded

View

of

Playback

Deck

with

E SA

-

Figure

4-11..4-11

Deck

and

Shield

-

Figure

4-12

.........................

4-12

Capstan

Motor

Assembly

-

Figure

4-13

..................

4-12

Solenoid

Assembly

-

Figure

4-14

.......................

4-12

6-1

D.

F.

G.

I.

J.

K.

.

M.

6-3

6-4

6-4

6-5

6-6

6-7

6-7

6-8

6-9

6-9

6-10

6-1

1

6-1

1

6-12

6-13

6-13

6-19

6-20

6-21

6-14

6-1

5

6-15

6-16

6-16

6-16

6-24

6-25

6-25

6-26

6-26

6-26

6-17

6-17

&

6-18

6-18

6-22

6-22

&

6-23

6-23

SECTION

VI.

E ECTRICA

DRAWINGS

A.

Block

Diagram

Series

99B

B.

Servo

1.

Schematic,

Figure

6-1

2.

Component

oading

and

Overlay,

Figure

6-2

3.

Parts

ist

.

.

C.

Play

and

Cue

Amp

1.

Schematic,

Figure

6-4

2.

Parts

ist

3.

Stereo

Component

oading

and

Overlay,

Figure

6-5

4.

Mono

Component

oading

and

Overlay,

Figure

6-6

.

E SA

Control

1.

Schematic,

Figure

6-7

2.

Component

oading

and

Overlay,

Figure

6-8

3.

Parts

ist

E.

Play

ogic

Control

1.

Schematic,

Figure

6-9

.........................

2.

Component

oading

and

Overlay,

Figure

6-10

3.

Parts

ist

Reproducer

Mother

Board

1.

Schematic,

Figure

6-11

2.

Component

oading

and

Overlay,

Figure

6-12

3.

Parts

ist

Flexible

Switch

Board

1.

Schematic,

Figure

6-13

2.

Component

oading

and

Overlay,

Figure

6-14

3.

Parts

ist

H.

Play

Erase

Phase

Card

1.

Component

oading

and

Overlay,

Figure

6-15

2.

Schematic,

Figure

6-16

3.

Parts

ist

Record

and

Meter

Amp

Card

1.

Schematic,

Figure

6-17

.........................................................

2.

Parts

List

3.

Component

oading

and

Overlay,

Figure

6-18

....

Record

Bias

Card.

1.

Schematic,

Figure

6-19

.........................................................

2.

Parts

List

3.

Component

oading

and

Overlay,

Figure

6-20

Record

ogic

Control

1.

Schematic,

Figure

6-21

........................

2.

Parts

List

r

3.

Component

Loading

and

Overlay,

Figure

6-22

..........

Record

Mother

Board

1.

Schematic,

Figure

6-23

........................

2.

Component

oading

and

Overlay,

Figure

6-24

3.

Parts

ist

................

Record

Meter

Board

1.

Component

oading

and

Overlay,

Figure

6-25

2.

Schematic,

Figure

6-26

.......................

3.

Parts

ist

Page

N.

7-1

MAINTENANCE

SECTION

VII.

8-1

WARRANTY

SECTON

VIII.

6-27

6-27

6-28

6-28

6-29

7-1

7-1

7-1

O.

P.

A.

General

..

B.

Mechanical

C.

Electrical

Record

Switch

Board

1.

Schematic,

Figure

6-27

2.

Parts

ist

.

.

.

3.

Component

oading

and

Overlay,

Figure

6-29

.E.D.

Board

Component

oading

and

Overlay,

Figure

6-29

Record

Chassis

(Stereo)

Parts

ist

..............

ILLUSTRATIONS

Figure

Number

Page

Number

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-

9

2-

10

3-

1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-

9

3-

10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

3-

18

4-

1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-

9

4-

10

4-11

4-12

4-13

4-14

5-

1

6-

1

2-1

2-2

2-2

2-2

2-3

2-4

2-4

2-6

2-6

2-

6

3-

1

3-2

3-2

3-3

3-3

3-4

3-5

3-5

3-6

3-7

3-7

3-8

3-

8

3-11

3-12

3-13

3-14

3-

14

4-

1

4-2

4-2

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-

9

4-

12

4-12

4-12

5-

2

6-

1

Reproducer/Recorder

Rack

Mount

Dimensions

Reproducer

Front

Panel

Dimensions

Reproducer

Audio

CUtput

Connections

Recorder

Audio

Input

Connections

Sample

Remote

Control

Schematic

Reproducer

Rear

View

Connectors

...

Recorder

Rear

View

Connectors

....

Front

View

Recorder

Controls

... ....

*

Front

View

Reproducer

Controls

..

..

Recorder

Meter

and

Function

Switches

....

Pressure

Roller

Pressure

Gauge

Solenoid

inkage

...........

Top

View,

Solenoid

inkage

and

Cross

Shaft

Clamp

Setup

Correct

ocation

of

Pressure

Roller

in

Deck

......

Correct

ocation

of

Motor

and

Pressure

Roller

Shaft

..

Proper

Adjustment

for

Solenoid

.... ....

Proper

Adjustment

for

Pressure

Roller

Pressure

Air

Dampening

Adjustment

ypical

NAB

ype

AA

Cartridge

Proper

ocation

of

Cartridge

....................

Proper

Use

of

Tape

Height

Gauge

.

Azimuth

and

Zenith

Adjustment

...................

Zenith

Adjustment

.

E SA

System

Adjustment

Oscilloscope

Pattern

for

Azimuth

Adjustments

.

Head

Seating

Placement

Top

View

Splice

ocate

Adjustment

.

Side

View

ocate

Adjustment

....................

Front

Panel

of

Reproducer

with

Dimensions

.

Front

Panel

of

Recorder

with

Dimensions

Rear

View

of

Reproducer

.

Rear

View

of

Recorder

.

Top

View

of

Reproducer

.

Bottom

View

of

Reproducer

.

Top

View

of

Recorder

...........................

-

Bottom

View

of

Recorder

.

NAB

Track

Format

-

Mono

(top)

and

Stereo

(bottom)

.

Expanded

View

of

Playback

Deck

.

Expanded

View

of

Playback

Deck

with

E SA

Cations

....

Deck

and

Shield

...............................

Capstan

Motor

Assembly

Solenoid

Assembly

Motor

Control

Wave

Form

for

Adjustment

Block

Diagram

Series

99

b

I USTRATIONS

(Continued)

L

Figure

Number

Page

Number

6-1

6-2

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6-11

6-12

6-13

6-14

6-15

6-16

6-17

6-18

6-19

6-20

6-21

6-22

6-23

6-24

6-25

6-26

6-27

6-28

6-29

6-3

6-4

6-5

6-7

6-7

6-8

6-9

6-10

6-11

6-12

6-13

6-14

6-15

6-16

6-16

6-17

6-18

6-19

6-21

6-22

6-23

6-24

6-25

6-26

6-26

6-27

6-28

6-29

Series

99B

Servo

Schematic

...........................

Series

99B

Servo

Component

oading

and

Overlay

..........

Play

and

Cue

Amp

Card

Schematic

.......................

Play

and

Cue

Amp

Cart

Component

oading

and

Overlay

(Stereo).

Play

and

Cue

Amp

Cart

Component

oading

and

Overlay

(Mono)

..

E SA

Corirol

Schematic

...............................

E SA

Control

Component

oading

and

Overlay

..............

Play

ogic

Control

Schematic

.........................

Play

ogic

Control

Component

oading

and

Overlay

.........

Reproducer

Mother

Board

Schematics

..........................................

Reproducer

Mother

Board

Component

oading

and

Overlay

.....

Flexible

Switch

Board

Schematics

......................

Flexible

Switch

Board

Conponent

oading

and

Overlay

......

Play

Erase

Phase

Card

Component

oading

and

Overlay

......

Play

Erase

Phase

Card

Schematic

.......................

Record

and

Meter

Amp

Card

Schematic

...................

Record

and

Meter

Amp

Card

Component

oading

and

Overlay

...

Record

Bias

Card

Schematic

...........................

Record

Bias

Card

Component

oading

and

Overlay

..........

Record

ogic

Control

Card

Schematic

...................

Record

ogic

Control

Card

Component

oading

and

Overlay

...

Record

Mother

Board

Schematic

........................

Record

Mother

Board

Component

oading

and

Overlay

........

Record

Meter

Board

Component

oading

and

Overlay

........

Record

Meter

Board

Schematic

.........................

Record

Switch

Board

Schematic

........................

Record

Switch

Board

Component

oading

and

Overlav

........

.E.D.

Board

Component

oading

and

Overlay

.............

SEC ION

I.

IN RODUC ION

/

SPECIFICA IONS

I.

introduction

/

specifications

1-1

realized

by

mechanical

interaction

between

any

of

the

Steel

ball

pivots

combine

with

a

to

permi

t

much

The

entire

head

nodule

be

relieved

without

destroying

pre

adjustments

thus

allowing

for

and

flexi-

This

serves

to

lower

the

operating

tem

perature.

Faster

tape

stop

time

occurs

because

less

field-to-collapse

in

the

winding

produces

faster

solenoid

plunger

release.

This

results

in

minimal

tape

overshoot.

The

entirely

new

true,

center-pivot

head

module

is

designed

with

rotational

axis

in

the

exact

vertical

and

horizon

tal

centerline

of

the

heads.

Height,

zenith

and

azimuth

adjustments

are

in

dependent

and

individually

lock,

preven

ting

interaction

between

any

of

three,

longer

azimuth

pivot

finer

tuning,

can

vious

adjustments

thus

greater

interchangeability

bility.

Performance

improvements

the

previously

described

changes

can

best

occur

when

the

tape

cartridge

is

positioned

accurately,

con

sistently,

and

without

distortion

to

the

cartridge

material.

ITC,

therefore,

has

designed

a

completely

new

cartridge

pos

itioning

system

which

assures

precise,

rigid

alignment

of

tape

and

head,

even

when

cartridge

insertion

is

hurried

or

somewhat

careless.

Electronically,

the

Series

99B

incor

porates

many

standard

features

made

pos

sible

by

micro-processor

technology.

The

cue

tones

which

are

generated

and

detected

digitally

are

crystal

refer

enced

for

long

term

frequency

stability.

Cue

tones

include

Primary,

Secondary

and

Tertiary.

A

two

speed

(standard

7.5

IPS

and

20.25

IPS

high

speed

cue)

crystal

locked

DC

brushless

servo

motor

dramat

ically

inproves

flutter

performance

and

reduces

heat.

A

specially

designed

reproduce

head,

coupled

with

a

low

inductance

recording

head,

contribute

to

frequency

response

which

equals

open

reel

quality.

High

frequency

bias

(256

kHz)

and

a

unique

bias

and

program

mixing

amplifier

com

bine

to

reduce

intermodulation

distor

tion

to

the

point

at

which

the

magnetic

A.

GENERAL

DESCRIP ION

The

Series

99B

cartridge

equipment

from

International

Tapetronics

Corpora

tion

has

been

designed

and

built

using

the

technology

available

today.

Micro

processor

control

is

the

key

behind

the

innovative

standard

features

of

the

Series

99B.

ow-noise

and

BI-FET

op-amp

circuits

have

provided

the

basis

for

an

audio

system

which

easily

accomodates

the

best

magnetic

tapes

of

today.

One

of

the

guidelines

used

during

the

development

of

the

Series

99B

was

the

December,

1975,

NAB

Standards

for

car

tridge

tape

recordings

and

reproductions.

The

standards

outlined

therein

have

been

met

and

in

many

cases

improved

upon.

The

Series

99B

is

built

on

a

nodular

basis

in

which

the

playback

transport

electronics

and

the

recording

electron

ics

are

each

housed

in

separate

units.

This

allows

greatest

flexibility

in

mounting

the

Series

99B

and

also

makes

the

addition

of

a

recorder

unit

to

an

existing

reproducer

at

a

later

date

a

simple

task.

All

sub-assemblies

such

as

motherboard,

amplifiers,

control

cir

cuits,

power

supplies,

front

and

rear

panels,

and

head

assemblies

are

either

plug

or

bolt-in

place.

This

feature

makes

service

convenient

and

efficient.

Sockets

are

also

used

for

IC's

and

tran

sistors

to

ease

individual

component

re

placement.

Mechanically,

the

Series

99B

is

built

with

the

reliability

of

standards

set

by

ITC.

These

include

solid

1/2

inch

thick

anodized

aluminum

deck,

full

swing

chain

driven

pressure

roller

assembly,

heavy

duty

air-damped

solenoid,

and

a

preci

sion

micro-adjust

head

assembly.

A

long

lasting

high

adhesion

pressure

roller

material

which

pulls

better

with

less

pressure

is

standard.

Solenoid

operation

provides

for

stable

tape

travel

path,

lower

operating

temperature,

and

minimal

tape

overshoot.

The

tape

path

has

greater

stability

due

to

consistent

plunger

location

under

all

temperature

variations.

The

coil

cur

rent

is

also

reduced

after

engagement

as

a

result

of

the

true

positioning

feature.

with

Monophonic

Stereophonic

Squelched

74

dB

or

greater

74

dB

or

greater

S/N

53

dB

or

greater

50

dB

or

greater

B.

SPECIFICATIONS

Hum

&

Noise

58

dB

or

greater

56

dB

or

greater

Capstan

Motor:

Among

pro-

1-2

-18

to

-

1

dBm

-10

to

+

7

dBm

-

5

to

+12

dBm

+

1

to

+18

dBm

Power:

VA.

Reproducer:

0.5%

harmonic

distortion,

or

less

Record

to

*

or

less

Measured

1975

NAB

tape

and

cartridge

become

the

limiting

factors.

Group

delay

compensation

is

used

in

the

recording

amplifier

to

improve

square

wave

performance

and

transient

response.

Peak

indicators

which

follow

tape

saturation

are

conveniently

mounted

in

the

meters.

Meters

may

be

used

to

monitor

input,

output,

program

and

cue

bias

and

cue

playback.

These

functions

are

all

selectable

from

the

front

panel.

Input

monitoring

(NORM

REC)

is

automati

cally

switched

to

output

monitoring

(PGM

P AY)

when

the

machine

is

not

recording.

The

primary

cue

tone

may

be

recorded

at

any

time

from

the

front

panel

1

kHz

cue

control

switch.

A

new

standard

feature

with

Series

99B

recorders

is

CUE

ERASE.

Selective

erasure

of

any

material

on

the

cue

track

is

possible

using

this

function.

Another

operational

feature

especially

useful

in

machine

maintenance

is

the

multi-func

tion

test

tone

generator.

A

complete

frequency

response

test

can

be

made

in

less

that

five

minutes

without

taking

the

machine

out

of

service

.

The

output

of

the

tone

generator

is

accessible

from

the

remote

connector

for

external

use.

The

RPSE

(Stereophonic)

and

RPME

(Monophonic)

units

incorporate

all

the

features

of

the

Series

99B.

These

in

clude

stereo

or

mono

recording

and

re

producing;

automatic

erase,

azimuth

(phase)

alignment

of

the

recording

head,

and

splice

location

(E SA);

brushless

DC

servo

motor

and

previously

described

features.

Variations

of

these

units

are

available

and

may

be

obtained

by

con

tacting

ITC

Sales

Department.

Amplifier

Distortion:

or

less

total

0.1%

or

less

third

harmonic

distor

tion.

Recorder:

0.5%

or

less

total

harmonic

di

stortion

,

0.1%

third

harmonic

distortion,

in

accordance

with

the

standard.

System

Distortion:

0.8%

or

less

total

harmonic

distortion,

0.5%

third

harmonic

distortion.

playback

at

+4

VU

recording

level.

Noise:

*,

**,

***

IPS

(51.4

cm/s).

Normal

operating

speed

may

be

changed

by

jumper

to

3.75

or

15

IPS

(9.5

or

38

cm/s).

Wow

&

Flutter:

Playback:

0.12%

or

less

DIN

weighted.

Record/play:

0.15%

or

less

DIN

weighted.

Speed

Accuracy:

0.1%

maximum

deviation.

Rated

Output

Load

Impedance:

600

ohms

balanced.

May

be

strapped

for

150

ohms.

Measured

at

1

kHz

in

accord

ance

with

1975

NAB

standard.

Audio

Output

Capability:

+25

dBm

maxi

mum

before

clipping.

May

be

strapped

to

provide

the

following

operating

ranges

without

deteriorating

the

signal-to-noise

ratio.

Preamplifier

Hea

Room:

*****

Reproducer:

+25

dB

Recorder:

+24

dB

Crosstalk

Between

Channels:

*

gram

and

cue

channels.

120/240

volts

AC,

50/60

Hz;

40

800

VA

during

erase

cycle

of

E SA

equipped

units.

Selectable

taps

for

accommodating

varying

line

volt

age

conditions.

Taps

at

105V,

120V,

210V,

225V,

and

240V.

Direct

drive,

crystal

referenced,

brushless

DC

servo,

cap

stan

motor

with

ceramic

shaft

and

permanently

lubricated

ball

bearings.

Tape

Speed:

7.5

IPS

(19

cm/s):

High

speed

cue

standard

on

models

at

20.25

Cue

to

Program

Program

to

Program

150

Hz 52

dB

50

dB

40

Hz

1

kHz

50

dB

48

dB

1

kHz

8

kHz

40

dB

45

dB

10

kHz

ease

and

Frequency

150

36

dB

Hz

1

kHz

8

kHz

(tape

F).

1-3

(Specification

limited

for

record/play

by

noise

of

tane,

NOT

electronics.)

Metering:

scale,

to

ring:

Cue

Track

Erase

Depth

Input

and

output

compatible

with

256

for

40

dB

50

dB

(limited

by

tape

noise

)

program

an

in-

20

K

ohm

bal-

600

ohm

and

loads

"A

”

for

moni-

(

automatic

Record

to

playback

*

+/-1.0

-20

dBm

-10

dBm

0

dBm

+10

dBm

Taut

band

movement

with

Switch

selection

Recording

input

switching

to

program

playback

when

machine

is

not

recording):

playback;

program

bias;

cue

bias;

cue

playback.

Built

in

ED

peak

dicators

follow

tape

saturation.

Bias

Amplifier:

Crystal

referenced

kHz

for

program

track(s),

83

kHz

cue

track.

Cue

Erase:

*

‘

‘

*'

or

detection

kHz

or

any

NAB

size

AA

100

milliseconds

movement)

.

150

milliseconds

(to

audio

on)

.

Stop

ime:

75

millisconds

(transport

and

electronics).

ape

travel

after

stop

signal

varies

according

to

type

of

cartridge

used

and

length

of

tape.

Ambient

Operating

emperature

Range:

10°

C

to

55°

C.

(50°

F

to

131°

Square

Wave

Response:

At

1

kHz*

phase

distortion

compensation

in

recorder

to

minimize

overshoot.

ape

Capacity:

Start

ime:

Frequency

Response:

at

-14

VU

recording

level.

dB

from

31.5

Hz

to

16

kHz.

Equalization:

1975

NAB

standard,

(50

us)

adjustable

for

CCIR

(70

us).

1964

NAB

standard

may

be

accomodated

by

strap

removal

in

recorder

(3180

us,

50

us).

High

frequency

equalization

control

included

in

recording

ampli

fier,

with

both

high

and

low

fre

quency

controls

in

reproducer.

Head

Configuration:

NAB

-

two

for

mono

(0.080"

track

width),

tracks

for

stereo

(0.043"

width)

.

other

combination,

to

cue

system

are

1975

NAB

standards.

Audio

Input

Impedance:

anced

bridging

standard.

150

ohm

balanced

terminating

may

be

selected

by

jumper.

Audio

Input

Capability:

+28

dBm

@

0.5%d

HD

(recorder).

Strappable

for

the

following

mid-range

(level

control

knob

position)

sensitivity

levels

to

facilitate

front

panel

adjustment

optimize

signal-to-noise.

tracks

three

for

stereo

(0.043"

track

Separate

record

and

repro

duce

heads

permit

playback

monitoring

while

recording.

Cue

Signals:

NAB

-

primary

(1

kHz),

sec

ondary

(150

Hz)

and

tertiary

(8

kHz)

all

standard.

Open

collector

tran

sistor

switching

for

external

control

available

for

150

Hz

and

8

kHz

in

ac

cordance

with

1975

NAB

standard.

Op

tional

relays

available.

Secondary

cue,

150

Hz,

and

tertiary

cue,

8

kHz

may

be

applied

during

recording

pro

cess

or

during

playback.

150

Hz

and/

or

8

kHz

tones

are

strappable

to

in

itiate

high-speed

cue

upon

conclusion

of

detection

of

tone

(playback

or

re-

cord/playback

mode)

.

Individual

and/

or

simultaneous

tone

generation

and

detection

are

available

for

1

kHz,

150

Hz,

and

8

kHz.

•

Logging

Signals:

External

input

to

the

cue

recording

amplifier

and

external

output

from

the

cue

reproducer

ampli

fier

are

available

for

recording

and

reproducing

logging

signals

at

-10

VU

between

3.3

kHz

and

6.5

kHz.

Exter

nally

applied

cue

tones

are

not

for

simultaneous

generation

with

1

kHz,

150

Hz,

8

Monophonic

and

50

Hz

ine

60

Hz

ine

Average

Rack

Specification

Pending

Peak

Width

Height

Depth

90

mm

133

mm

216

mm

394

mm

(.354

in)

(5.25

in)

(8.5

in)

(15.5

in)

1-4

Add

for

Feet

*****Referenced

to

160

nW/m

as

specified

in

the

1975

NAB

Cartridge

Recordings

and

Reproductions

Standard.

****Referenced

from

NAB

cue

tone

repro

duce

levels.

Automatic

Erase:

Stereophonic*

(Erase

mode

not

intended

for

contin

uously

repeated

operation.

)

*A11

measurements

made

using

3M

Scotch

cart

tape

and

referenced

to

1

kHz

re

corded

at

250

nW/m,

4

dB

higher

than

the

160

nW/m

reference

of

the

1975

NAB

Cartridge

Recordings

and

Reproductions

Standard.

***

Audio

measurements

band

limited

to

20

Hz

to

20

kHz.

A

Specification

Pending

audio

and

Mating

con-

Weight:

Playback:

13.6

kg

(30

pounds),

wi

th

ELSA

14.1

kg

(31

pounds

).

Re

cord!

ng

amplifier:

6.8

kg

(15

pounds).

E SA

System:

Splice

ocate:**

Detect

one

mil

thick

splicing

tape

thickness

minimum,

square

and

diagonal

ended

cut.

Automatic

Phase

Alignment:**

Monophonic:

1.0

dB

or

less

azimuth

loss

at

10

kHz.

Stereophonic:

+/"

20

degrees

or

less

difference

between

left

and

right

program

chan

nels

at

10

kHz

(

to

be

measured

under

steady

state

conditions

after

application

of

E SA

se

quence)

.

Remote

Control:

All

front

panel

con

trols

and

indicators

plus

cue

erase,

1

kHz

record

and

defeat

and

external

cue

tones

record

input

and

enable

lines.

External

Connectors:

X R

latching

remote

control,

nectors

are

furnished.

Mounting:

Table

top

mounting,

mount

housing

optional.

Dimensions

(Maximum):

**A11

measurements

-

3M

Scotchcart

AA

cartridge

with

3.5

minutes

tape

load

running

at

7.5

IPS.

SECTION

II.

INSTALLATION

AND

OPERATION

.

IL

INS ALLA ION

AND

OPERA ION

A.

INSTALLATION

housing

accommodates

mount

See

Figure

B.

EX ERNAL

AUDIO

CONNEC IONS

(101.

Ontm.)

Figure

2-1

2-1

(4

82.60

mm

An

appropriate

combination

of

plugs

and

sockets

is

provided

with

each

Series

6

IS/1

e

In

(176.

21mm.)

I

I

5/32in

”

1""

RACK

MOUNT

OEPTH

FROM

ALLOW

2

ADDITIONAL

INCHE

(50.

80

mm.)

It

is

inportant

to

note

that

the

+

(plus)

and

-

(minus)

signs

are

indica

tions

of

proper

phase

relationships

only

and

do

not

reflect

DC

voltage

potential.

It

is

necessary

to

connect

the

+

lines

of

both

channels

to

the

corresponding

+

(or

equivalent)

terminal

of

the

external

source

in

order

to

prevent

phase

rever

sals.

MOUNTING

URFACE

I

1

5.

3

9

4

in.

(

391.0

I

m

m

.

)

FOR

CONNECTOR

CLEARANCE.

Adjustments

outlined

within

this

section

are

made

at

the

factory

to

a-

chieve

optimum

performance

from

Series

99B

cartridge

machines.

At

the

time

of

installation,

three

adjustments

may

be

required:

program

reproduce

level,

re

corder

input

level

strap,

and

internal

test

tone

generator

"0"

VU

level

cali

bration.

99B

machine

for

connecting

audio

inputs

and

outputs.

Refer

to

Figures

2-6

and

2-7

for

proper

location

of

connectors.

Inputs

and

outputs

are

balanced;

it

is

therefore

recommended

that

two-conductor

shielded

cable

be

used

for

each.

Attach

the

shield

only

at

either

the

ma

chine

end

or

the

console

to

prevent

any

potential

ground

loop.

Figure

2-3

shows

a

proper

method

of

connection

for

the

playback

output

lines.

Figure

2-4

illus

trates

the

connections

required

for

the

recorder

inputs.

Shielded

cables

are

recommended

for

all

remote

audio

functions

(cue

amp

out

put,

square

wave

output,

test

tone

gen

erator,

cue

amp

input).

The

Series

99B

machines

are

design

ed

for

table

top

mounting.

Machines,

including

recording

amplifiers,

may

be

safely

stacked

3

to

4

high

if

desired.

Vertical

space

requirement

for

each

Series

99B

machine

is

7

inches

when

rack

mounted

in

the

ITC

rack

mount

housing.

The

rack

either

two

playback

units

side

by

side

or

one

recorder/playback.

2-1

and

2-2

for

additional

mounting

in

formation.

□

□

UcuTI

m

o

Figure

2-2

C.

EXTERNAL

CON ROL

CONNEC IONS

Additional

remotes

available

are:

rr

n

7)

2

LEFT

+

RIGHT

RIGHT

REPRODUCER

AUDIO

OUTPUT

CONNECTIONS

RECORDER

AUDIO

INPUT

CONNECTIONS

Figure

2-4

Figure

2-3

2-2

2

I

2

I

TO

P2

TO

PI

TO

LOAD

TO

2

5

7/32

In.

(132.56

mm.)

Of

ready

(see

front

lamp

page

A

—

t-

8

9/16

In.

(

2

17.49

mm.)

panel

is

2-8)

TO

3

2

1

---------

►

GND

NOTE

:

CONNECT

SHIELD

AT

ONE

END

ONLY

(CONSISTENT

WITH

STATION

WIRING)

---------------- -

+

I

-------

►

ONO

NOTE

:

CONNECT

SHIELD

AT

ONE

END

ONLY

(CONSISTENT

WITH

STATION

WIRING)

-►GND

V-*-

l

—

—

►

GND

1.

Secon ary

cue

open

collector

output

—

—

pin

40

—

200

ma.

switching

FROM

S-

AUDIO

SOURCE

All

remote

control

functions

are

accessible

through

one

connector,

J1,

located

on

the

playback

rear

panel.

Fig

ure

2-5

illustrates

many

of

the

common

remotes

used

and

the

proper

method

for

making

the

connections.

Insome

cases,

unshielded

lines

may

be

tolerated

for

remote

switch

functions

However,

it

is

recommended

that

shield

cables

be

used

in

all

installations.

current

(sinking),

maximum

25

VDC

open

circuit

voltage,

switches

to

ground

upon

sensing

of

secondary

cue.

2.

ertiary

cue

open

collector

output

—

—

pin

37

—

switches

to

ground

upon

sensing

of

tertiary

cue.

3.

Auxiliary

Start

Pulse

—

pin

28

—

momentary

(100

msec)

pulse

to

ground

upon

start

of

cartridge

—

open

collector.

May

be

used

to

start

an

external

clock

or

timer.

Maximum

25

VDC

open

circuit

voltage,

at

200

ma.

4.

Ready

Ground

—

pin

3

—

follows

ready

lamp

function,

when

lamp

is

on,

ready

ground

signal

is

at

ground.

When

lamp

is

off,

signal

is

open

collector.

Caution:

ready

ground

follows

condition

ready

lamp.

If

strapped

to

flash

ready

ground

will

change

states

syn

chronous

with

front

panel

ready

All

switches

shown

are

momentary

action,

single

pole.

Typical

switching

current

is

5

ma.

DC

at

a

maximum

5

VDC.

SAMP E

REMOTE

CONTROL

CHEMATIC

0

T

ART

REMOTE

TART

WITCH

©

WITCH

COMMON

r

0

RUN

/

I

0

+

O

VDC

I

TOP

0

REMOTE

TOP

WITCH

X--

READY

( TOP)

0

0

+

O

VDC

I

0

CUE

Notes

REMOTE

CUE

WITCH

0

CUE

1.

REMOTE

CUE

LAMP

'

I

I

"cannons"

together

2.

0

+

O

VDC

3.

0

DIGITAL

COMMON

together

between

other

0

+

O

VDC

4.

any

i

0

ECONDARY

OPEN

COLLECTOR

5.

0

DIGITAL

COMMON

6.

0

TERTIARY

OPEN

COLLECTOR

7.

and

RECORD

ET

WITCH

0

REMOTE

RECORD

ET

WITCH

0

WITCH

COMMON

and

0

RECORO

LAMP

REMOTE

RECORD

ET

LAMP

0

+

30

VDC

0

COMMON

DIGITAL

0

EL A

EL A

WITCH

REMOTE

I

KHi

CUE

RECORD

0

I

KHi

CUE

DEFEAT

0

X

RECORD

I O

Hz

0

X

Figure

2-5

8

KHI

RECORD

0

2-3

Use

shielded

cable

runs

where

pos

sible.

the

electrical

this

Technial

REMOTE

150

Hl

CUE

RECORD

WITCH

I

I

I

I

I

8

KHI

(

TERTIARY

)

DETECT

I O

Hi

( ECONDARY)

DETECT

RELAY

WITH

DIODE

ie

shields

and

only

at

the

machine

end.

REMOTE

RUH

AMP

(

RUN

GROUN

D

)

j^i

'

v

r

02

-o

o

32-

o

ci-

02

o

o

_y

2T

Do

not

"mix"

digital

ground,

switch

cannon,

or

audio

ground

circuits,

to

prevent

digital

or

DC

ground

loops.

For

other

JI

connections

not

noted

here,

refer

to

the

reproducer

mother

board

schematic

in

drawings

section

of

Manual.

24

VO T

IN4OO5

REMOTE

STOP

AMP

(READY

GROUND

)

~1^

7?/

Keep

all

switch

and

lamp

circuits

"above"

any

ground

at

all

points

outside

the

machine.

Do

not

tie

cannons,

shields,

or

+30

volt

lines

t

*~

’

~*'

t

machines.*

*For

"Daisy

Chain"

operation,

I C

recan

mends

the

use

of

the

optional

plug-in

relays

for

absolute

ground

and

power

supply

isolation

between

machines

peripheral

interface

gear.

REMOTE

8

KHI

CUE

RECORD

WITCH

REMOTE

I

KHi

CUE

RECORD

WITCH

REMOTE

I

KHt

CUE

DEFEAT

WITCH

Keep

all

interface

cabling

segre

gated

fran

high-power

cables

(such

as

A.C.

runs

and

speaker

leads).

o

HEAD

INTERCONNECTION

CABLE

TO

RECORDER

CONNECT

HERE

PZ

RIGHT

n

•••••

Figure

2-6

not

to

be

less

than

5K

o

CONTROL

INTERCONNECTION

CABLE

FROM

PLAYBACK

CONNECT

HERE

I

Figure

2-7

2-4

Tl

POWER

TRAN FORMER

Connect

across

CONTROL

INTERCONNECTION

TO

REPRODUCER

and

logging

recorded

on

the

©

AUDIO

OUT

RECORD

HEAD

P5

CONTROL

TO

RECOR

RECORD

HEAO

P3

INTERCONNECTION

CAB E

DER

CONNECTS

HERE

5)®

JI

REMOTE

LINE

CORD

PLUG

IN

HERE

output

avail

-

For

monitoring,

HEAD

INTERCONNECTION

CABLE

FROM

PLAYBACK

CONNECT

HERE

(shield)

to

Nominal

pin

8

16)

with

(normally

open

rangement

)

for

erasure

information

previously

cue

track.

Active

-

switch

to

a

momentary

contact

ar-

of

cue

tone

connect

ground

lead

pin

45

—

audio

ground,

voltage

is

.5V

r.m.s.

b.

Square

Wave

output

(analog

signal

from

tape

converted

to

square

waves)

is

accessible

on

pin

44.

This

output

must

be

referenced

to

the

digital

ground

on

pin

48

in

order

to

prevent

interaction

with

analog

circuitry.

Voltage

swing

is

+15

volts

(peak

to

peak).

oad

impedance

ohms.

7.

Cue

Erase

—

ground

(pin

switch

lamp.

Maximum

open

circuit

voltage

25

VDC,

maximum

current

at

200

ma.

5.

External

Fade

Control

—

pin

21

—

this

is

a

DC

control

point

for

vary

ing

playback

output

level,

a

potentiometer

(25K

ohms)

+15V

and

ground

(pins

13

and

16),

connect

the

wiper

arm

of

the

poten

tiometer

to

pin

21.

When

the

wiper

potential

is

+15

VDC

audio

is

ON,

at

0

VDC

audio

is

OFF.

CAUTION

—

with

potentiometer

in

OFF

position,

in

ternal

audio

ON

circuit

is

disabled.

Both

channels

on

a

stereo

machine

are

controlled

simultaneously

with

one

potentiometer.

6.

Cue

Amplifier

Outputs:

a.

Cue

preamplifier

able

on

pin

11.

©•

©

®

P6

INTERCONNECT

switch

D.

CON ROLS

AND

INDICA ORS

E.

2-5

internal

are

to

Out-

VAC

The

READY

has

Enables

the

oper-

1

kHz

primary

cue

as

in

the

Automatic

On

when

in

a

RUN

mode.

5.

Power

Indicator

—

Red

LED

located

between

the

yellow

and

green

cue

tone

ED

’

s

on

the

playback

front

panel.

6.

Cue

Switch

—

Used

for

high

speed

cue

and

audio

mute

from

STOP,

START,

or

RECORD

(cancels

record

set)

modes.

Pressing

CUE

while

in

high

speed

mode

causes

audio

to

turn

on

for

duration

1.

Stop

Switch

—

Active

when

cartridge

is

loaded

properly.

Overrides

all

other

operations

within

the

machine.

On

when

cartridge

is

Flashes

(as

sup-

after

cartridge

For

optional

see

Operational

Options.

Active

whenever

a

a

switch

is

held.

CUE

is

also

used

in

conjuction

with

E SA

switch.

7.

Cue

amp

—

On

when

in

a

CUE

mode.

8.

ELSA

(Erase,

Locate

Splice,

Azimuth)

Switch

—

Pressed

and

held

in

conjunction

with

CUE

causes

automatic

cartridge

pre

paration

cycle

to

begin.

NOTE:

the

E SA

switch

must

be

pressed

first

and

held

while

the

cue

switch

is

pressed.

Pressing

only

the

E SA

switch

during

any

E SA

cycle

sets

up

an

automatic

stop

at

the

end

of

that

particular

cycle.

Simultaneous

illumination

of

RUN,

CUE,

and

READY

AMPS

verifies

that

the

machine

has

accepted

this

command.

Pressing

and

holding

both

E SA

and

CUE

switches

until

first

flash

of

the

CUE

lamp

will

automatically

skip

the

automatic

azimuth

cycle

(for

erase

and

splice

locate

only).

Allowing

CUE

lamp

to

flash

twice

before

releasing

switches

will

automatically

skip

the

azimuth

and

erase

cycles

(for

splice

locate

only)

.

9.

Record

Set

Switch

the

READY

mode.

NOTE:

IN

ORDER

TO

PREVENT

POTENTIA

OPERATIONA

PROB EMS,

EXTERNA

OAD

COMBINED

CURRENT

DRAIN

MUST

NOT

EX

CEED

0.2

AMPERES.

2.

Ready

amp

—

1

oaded

properly

.

plied

from

factory)

has

played

and

cued

.

operation

of

the

Ready

function,

SECTION

II.

3.

Start

Switch

—

cartridge

is

loaded

properly

or

in

CUE

mode.

4.

Run

amp

—

Active

only

in

When

pressed,

exter

nal

audio

signals

are

switched

into

the

recording

amplifier

circuit.

Pressing

START

causes

the

recording

process

to

begin.

10.

Record

Set

amp

A

visual

indication

showing

that

the

machine

is

either

ready

to

record

or

in

the

process

of

recording.

11.1

kHz

Cue

Record

—

ator

to

record

a

tone

at

any

desired

time

case

of

editing

a

tape,

timing

of

the

tone

length

is

control

led

by

the

micro-processor.

The

switch

is

active

in

a

playback

or

re

cording

mode.

The

1

kHz

cue

detector

is

defeated

while

switch

is

depressed.

(See

Figures

2-8,

2-9,

and

2-10.)

12.

1

kHz

Cue

Defeat

-

Active

only

in

a

RECORD

preset

mode

(no

tape

running

—

READY

and

RECORD

lamps

on)

.

When

pres

sed,

ED

(directly

above

switch)

latches

on

as

an

indication

that

the

1

kHz

cue

tone

will

not

record

automat

ically

when

the

cartridge

is

started.

(See

Figures

2-8

through

2-10.)

13.

Secondary

C e

Switch

—

Active

in

either

record

or

playback

modes.

Used

to

record

a

secondary

cue

tone

only

in

playback

mode

after

the

first

1.5

seconds

of

tape

has

play

ed.

Erases

only

when

switch

is

closed.

(RECORDER

ON Y).

8.

External

Cue

Tone

Record

—

Other

auxiliary

tones

may

be

recorded

onto

the

cue

track

by

connecting

the

sig

nal

to

pin

2

(cue

record

input)

and

pin

45

(audio

ground)

and

enabling

the

cue

recording

system

by

switch

ing

pin

26

to

ground

(pin

16).

Nomi

nal

input

voltage

—

1

VAC

r.m.s.

Input

impedance

approximately

15K

ohms.

(RECORDER

ON Y)

.

9.

est

one

Generator

—

All

test

tone

generator

frequencies

available

at

pin

27

referenced

ground

at

pin

45

(unbalanced),

put

level

is

nominally

2.5

(r.m.s.)

into

a

600

OHM

load,

output

is

directly

coupled

to

an

OP

AMP,

therefore,

a

slight

DC

offset

voltage

of

no

more

than

20

mv

may

occur

.

RIGHT

METER

PEAK

INDICATOR

ECONOA

CUE

WITCH

Figure

2-8

FUNCTION

,

ITCHE

AND

TART

WITCH

AND

RUN

LAMP

POWER

INDICATOR

TOP

WITCH

AND

READY

LAMP

||CUE

||

s

Figure

2-9

CUE

0000000000

®

e

5

V

V

Figure

2-10

2-6

ACCE

DOOR

-

HOWN

IN

OPEN

PO ITION

^-EL A

WITCH

(WORK

IN

CONJUNCTION

WITH

CUE

WITCH)

I

KHZ

CUE

CONTROL

DEC

INC

WITCHE

EVEN

EGMENT

READOUT

INDICATE

TONE

GENERATOR

FUNCTION

ELECTED

RIGHT

CHANNEL

INPUT

LEVEL

CONTROL

V

METER

MONITOR

ELECT

WITCHE

1

‘

lsTQpfl

ARY

CUE

WITCH

AND

LAMP

.

—

RECORD

ET

WITCH

AND

LAMP

TERTIARY

CUE

TONE

EN E

INDICATOR

ECONDARY

CUE

TONE

EN E

INDICATOR

CUE

ERASE

TONE

GENERATOR

FUNCTION

SE ECT

LEFT

PEAK

INDICATOR

CUE

WITCH

AND

LAMP

ACCE

DOOR

TO

METER

ADDITIONAL

CONTROL

W

INDICATOR

LED

"ON"

-------

INDICATE

IKHZ

WILL

NOT

RECORD'

4

(for

fine

6

used

7

2-7

secondary

Jumpers

located

tone

and

0

—

OFF

(readout

blank)

1

—

1

kHz

at

OVD

reference

level

2

—

1

kHz

at

-10

dB

3

—

10

kHz

at

-10

dB

(nodes

2

and

3

may

be

used

for

bias

calibration,

rough

azi

muth

and

equalization

mainten

ance)

.

Pressing

the

RECORD

switch

will

automatically

reset

modes

5

or

7

to

the

beginning

step

frequency

of

50

Hz.

(150

Hz)

on

the

cue

track.

The

sec

ondary

ED

(green)

on

the

playback

chassis

illuminates

and

a

remote

switching

signal

occurs

upon

sensing

of

the

cue

tone.

As

supplied

from

the

factory,

high

speed

recue

is

in

itiated

at

the

end

of

secondary

cue

tone

when

the

unit

is

in

playback

mode.

Jumpers

provided

on

Play

ogic

Card

to

defeat

high-speed

cue

if

desired.

14.

Tertiary

Cue

Switch

—

Active

in

either

record

or

playback

modes.

Used

to

record

a

tertiary

cue

tone

(8

kHz).

Illumination

of

the

ter

tiary

ED

(yellow)

on

the

playback

chassis

and

a

remote

switching

signal

occurs

upon

sensing

of

the

tone.

Reproducer

can

be

program

med

(jumper

optional)

to

initate

high-speed

recue

at

the

end

of

ter

tiary

tone

rather

that

tone,

if

desired,

on

Play

ogic

Card.

15.

Cue

Erase

Switch

—

The

reference

level

of

the

tone

generator

is

internally

adjustable

as

well

as

variable

through

the

use

of

the

front

panel

level

controls.

The

factory

setting

of

the

1

kHz

O

VU

reference

tone

is

matched

to

an

equivalent

0

dBm

input

signal.

To

make

optimum

useage

of

the

tone

gen

erator

reference

level

it

is

recom

mended

that

the

internal

level

ad

justment

be

made

to

match

the

buss

reference

level

commonly

used

in

the

user

’

s

application.

In

this

manner,

the

front

panel

level

controls

can

always

be

easily

recalibrated

using

the

internal

reference

tone

gener

ator,

eliminating

the

need

to

"patch-in"

an

external

tone

oscil

lator.

See

Section

V

for

informa

tion

regarding

this

adjustment.

17.

Peak

Indicators

—

ocated

on

the

lower

right

hand

side

of

the

level

meters,

used

to

indicate

peaks

(which

the

meters

cannot

follow

due

to

ballistics)

and

also

to

indicate

tape

saturation.

The

peak

circuitry

monitors

the

audio

information

as

it

is

fed

to

the

recording

head,

there

by,

"seeing"

the

contouring

effects

of

the

amplifier

and

giving

a

rela

tively

true

indication

of

when

tape

is

being

saturated.

The

factory

setting

is

+8

VU,

but

may

be

reset

to

almost

any

desired

trip

point,

depending

on

the

saturation

point

on

—

14.5

kHz

at

-10

dB

azimuth

adjustment).

5

—

Slow

frequency

step

including

50

Hz,

63

Hz,

125

Hz,

250

Hz,

500

Hz,

1

kHz,

2

kHz,

4

kHz,

8

kHz,

10

kHz,

12.5

kHz,

14.5

kHz

and

ends

with

a

continuous

3150

Hz

tone

for

use

in

measuring

wow

and

flutter.

All

tones

(except

3150

Hz)

are

8

seconds

long.

Hold

—

indefinitely

holds

any

of

the

frequencies

used

in

modes

5

or

7.

Same

as

5

except

duration

of

frequencies

is

4

seconds

each.

Active

only

in

playback

after

first

1.5

seconds

of

tape

travel.

This

prevents

acciden

tal

erasure

of

primary

cue

tone

which,

if

desired,

can

be

erased

when

tone

appears

again

at

end

of

tape.

Erases

cue

track

data

only

during

the

time

the

switch

is

pres

sed.

See

Figure

2-10.

16.

Decrement

and

Increment

—

Test

tone

generator

control,

active

in

Record.

Pressing

and

holding

either

switch

will

automatically

clock

the

seven

segment

readout

from

1-7

(INC)

or

7-1

(DEC).

Releasing

the

switch

stops

the

clocking,

causing

the

readout

to

remain

in

the

selected

mode

(number).

Starting

the

trans

port

then

causes

the

selected

tone

(tones)

to

record.

The

output

of

the

generator

is

also

accessible

through

the

remote

connector

described

ear

lier.

The

seven

functions

include: