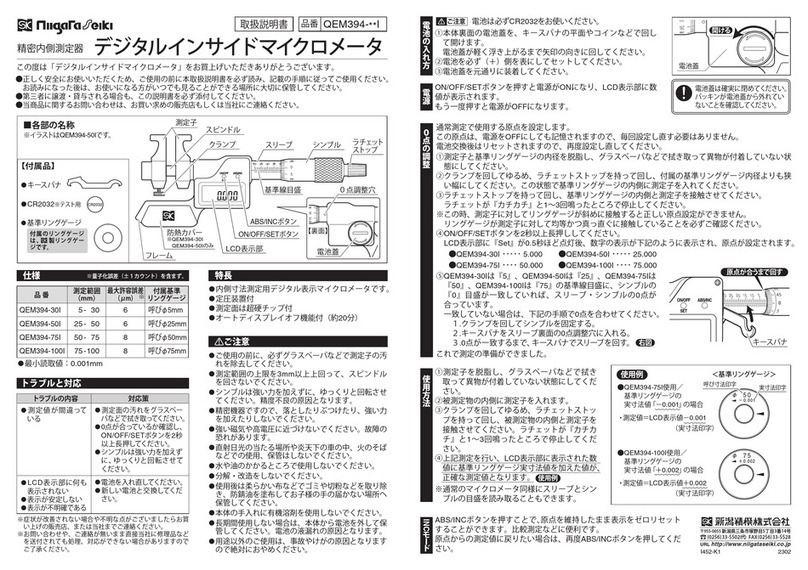

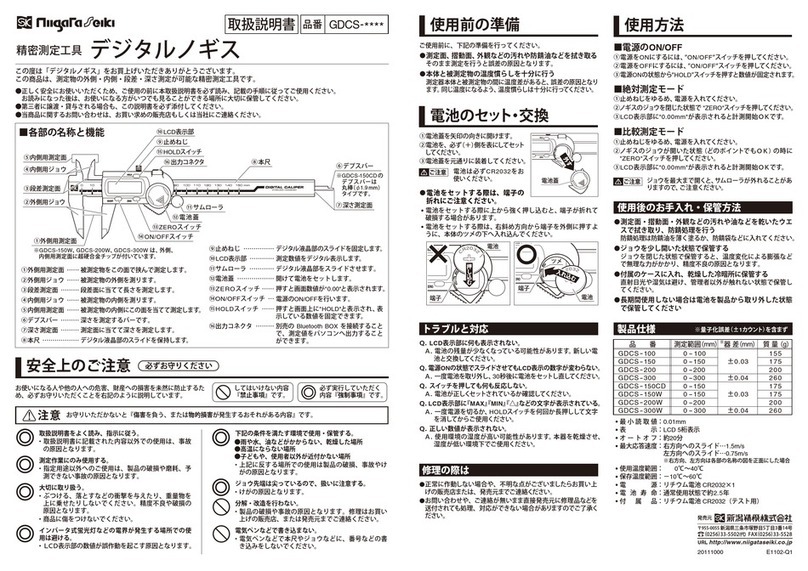

Rotate until origins match

・Meas. = Display value -0.001

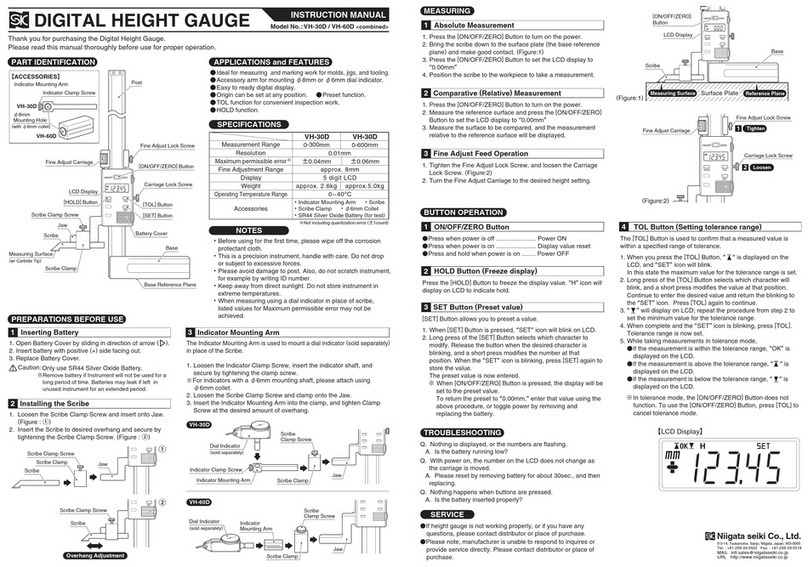

Clamp

[ON/OFF/SET]Btn.

[ABS/INC]Btn.

LCD Display

Scale

Sleeve Thimble Ratchet

Stop

0-Point Adj. Hole

Jaws

Battery

Cover 【Rear】【Rear】【ACCS.】●Spanner

●CR2032

●Ring Gauge

※Model QEM394-50I shown.

ERROR CORRECTIVE ACTION

※If problem persists, or if you have any questions,

please contact distributor.

※

Please note, manufacturer is unable to respond to inquires

or provide service directly. Please contact distributor.

QEM394-30I

QEM394-50I

6

6φ5mm

φ25mm

QEM394-75I

QEM394-100I

8

8

5

25

50

75

-

-

-

-

30

50

75

100 φ50mm

φ75mm ●

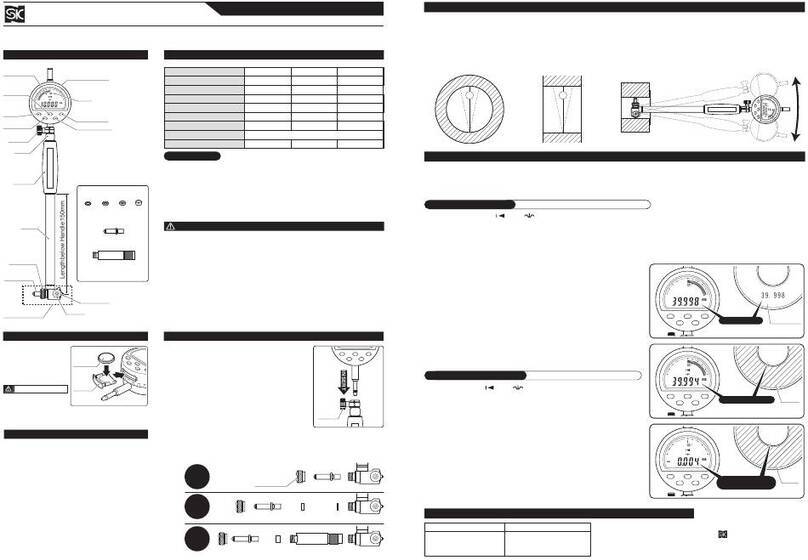

Always clean measuring surfaces with soft cloth before use.

●Do not turn spindle more than 3mm above upper

measurement range.

●When turning Thimble, be gentle and do not apply

force. High force on Thimble will cause inaccuracy.

●This is a precision instrument, handle with care. Do

not drop or subject to excessive forces.

●Keep away form high voltage and strong magnetic

fields. Instrument damage may result.

●Keep instrument away from direct sunlight or high

temperatures such as in a car, or near a stove or

heat source.

●Do not expose to water or oils.

●Do not disassemble or modify.

●After use, wipe with a soft cloth to remove any dirt or

grime, and apply a rust preventative oil before

storage. Keep out of reach of children.

●Please do not use organic solvents to clean the body

of the instrument.

●Remove battery if instrument will not be used for a

long period of time. Batteries may leak if left in

unused instrument for an extended period.

●Only use as directed. Improper use may cause

accident or injury.

●Resolution:0.001mm

●Measured value

is wrong. ●Clean measuring surfaces

with cloth.

●Confirm 0-Point setting and

re-zero with long press of

[ON/OFF/SET]

Button (>2 sec.)

●

When turning Thimble, be

gentle and do not apply force.

●LCD does not

display.

●Displayed value is

unstable.

●Display is not clear. ●Cycle power by removing

and replacing battery.

●Replace battery with new

one. ●Inside Micrometer with digital display

●Constant pressure mechanism (Ratchet Stop)

●Carbide measuring surfaces

●Auto-display-off function (approx. 20 minutes.)

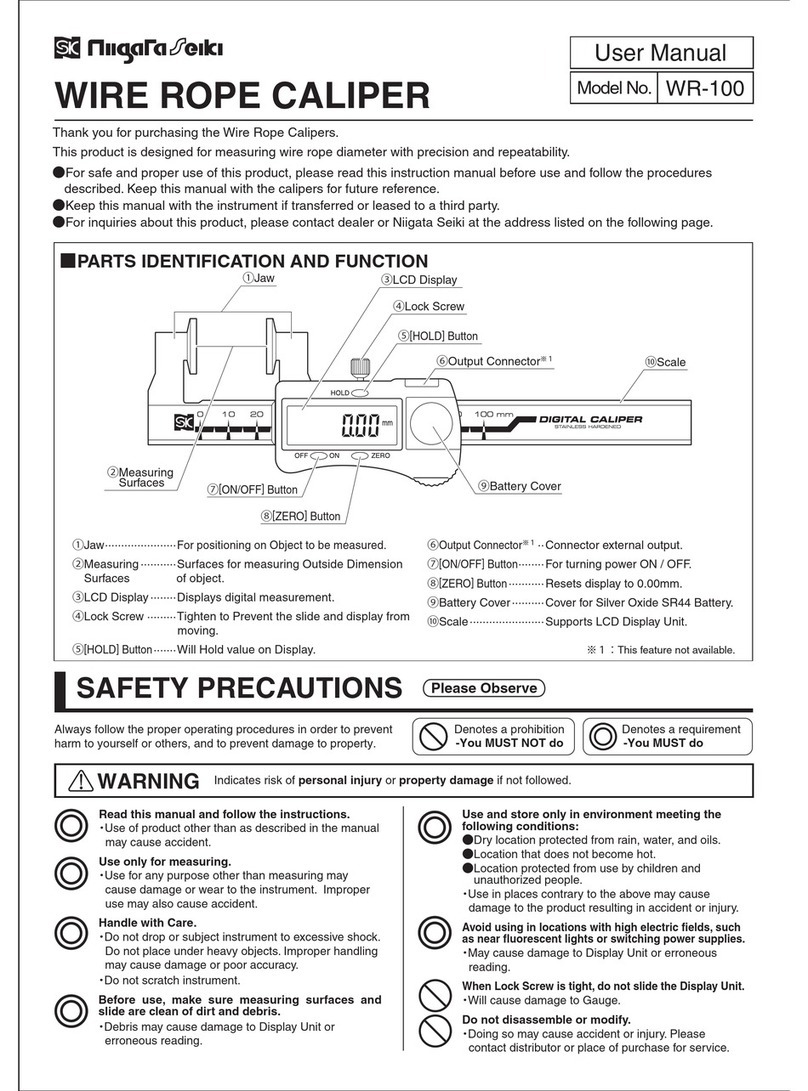

Setting the origin used for normal measurements.

Once set, even when power is off the origin is saved and does not have to be reset with each use.

When battery is replaced, origin will go to default setting. Please reset.

①Remove any grease or dust from the measuring surfaces and Ring Gauge using a clean cloth, such as

a lens cleaning cloth. Make sure no foreign matter is adhered to the measuring surfaces.

②

Loosen the Spindle Clamp and turn the Ratchet Stop to allow the Jaws to fit inside the supplied Ring Gauge.

③Place the Jaws inside the Ring Gauge and turn the Ratchet Stop until the measurement surfaces make

contact and the Ratchet Stop clicks 1~3 times.

※Make sure the Measurement Surfaces are flat against the Gauge. If they are at an angle or misaligned

the measurement reading will not be accurate.

④Press the [ON/OFF/SET]Button for more than two seconds.

LCD will display “SET”for 0.5 seconds. The origin is now set and display will read as shown below:

●QEM394-30I ・・・・・5.000 ●QEM394-50I ・・・・・25.000 ●QEM394-75I ・・・・50.000 ●QEM394-100I ・・・・75.000

Press [ON/OFF/SET]Button to turn power ON; measurement will display on the LCD.

Press a second time to turn power OFF.

For comparative measurements, the display reading can be

zeroed at any position by pressing the [ABS/INC]Button. In this

mode, the zero point is retained in memory.

Press the [ABS/INC]Button again to return to absolute mode.

①Remove any grease or dust from the measuring

surfaces using a clean cloth, such as lens

cleaning cloth. Make sure no foreign objects

are adhered to the measuring surfaces.

②Loosen the Spindle Clamp and position the

Jaws inside the object to be measured.

③With the Jaws inside the part to be measured,

turn the Ratchet Stop until the measuring

surfaces are in contact and the Ratchet Stop

clicks 1~3 times.

④After performing the above measurement, the

accurate measurement is the value displayed on

the LCD display plus the value printed on the Ring

Gauge (the actual dimension deviation)

※Measurement can also be read off Thimble and

Sleeve Scale as with a standard micrometer.

CAUTION

Make sure the Battery

Cover is closed securely.

Please make sure the

gasket is in the proper

place on the Battery

Cover.

●Ex:QEM394-75I

The actual size of the

reference Ring Gauge

shown is "-0.001"

●Ex:QEM394-100I

The actual size of the

reference Ring Gauge

shown is "+0.002"

<Reference Ring Gauge>

・Meas. = Display value +0.002

Spindle

Insulating Cover

Frame※QEM394-30I

QEM394-50Ionly

Spanner

⑤Check to see if the Thimble Scale aligns with the “0”line on the

Sleeve according to the above values.

To align the Thimble Scale 0-Point reference lines.

1. Lock Spindle using Spindle Clamp.

2. Insert the spanner into 0-point Adjustment Hole on rear of

Thimble.

3. Use spanner to rotate Sleeve to align the 0-Point lines.

The gauge is now ready to take measurements.

QEM394-***

Model

No.

INSTRUCTION MANUAL

DIGITAL INSIDE MICROMETER

PRECISION INSIDE MEASURING INSTRUMENT

Thank you for purchasing the Niigata Seiki DIGITAL INSIDE MICROMETER.

●For safe and proper use of this product, please read this instruction manual before use and follow the procedures

described. Please keep manual where it is accessible to user for future reference.

●Keep this manual with the instrument if transferred or leased to a third party.

●For inquiries about this product, please contact dealer or Niigata Seiki.

Niigata Seiki Co., Ltd.

5-3-14, Tsukanome, Sanjo, Niigata, Japan, 955-0055

Tel. : +81-256-33-5522 Fax. : +81-256-33-5518

MAIL intl.sales@niigataseiki.co.jp

URL http://www.niigataseiki.co.jp

Included Ring Gauge

Reference is

Ring Gauge

meeting JIS standards.

Included for test.

Please insert a new battery

before use.

Maximum

permissible

error※

(µm)

Included

Ring Gauge

(

Nom.Size.

)

BATTERY SETTING THE ZERO-POINT OPERATION

POWER

INC MODE

①Rotate the Battery Cover on rear

using coin or Spanner.

②Insert battery with “+”side up.

③Replace Battery Cover.

Only use CR2032 type

battery.

Battery

Cover

Open

Act.

Dimension

(deviation)

Nom. Size

Meas. Range

(mm)Model No.

(actual size)

(actual size)