1

Tableofcontents

1.Introductionandscopeofapplication................................................................................................2

1.1Modesofoperation.....................................................................................................................................3

2.Safetyinstructions..........................................................................................................................4

3.Scopeofdelivery.............................................................................................................................5

4.TechnicalData................................................................................................................................6

4.1Deviceoverviewanddimensions.................................................................................................................8

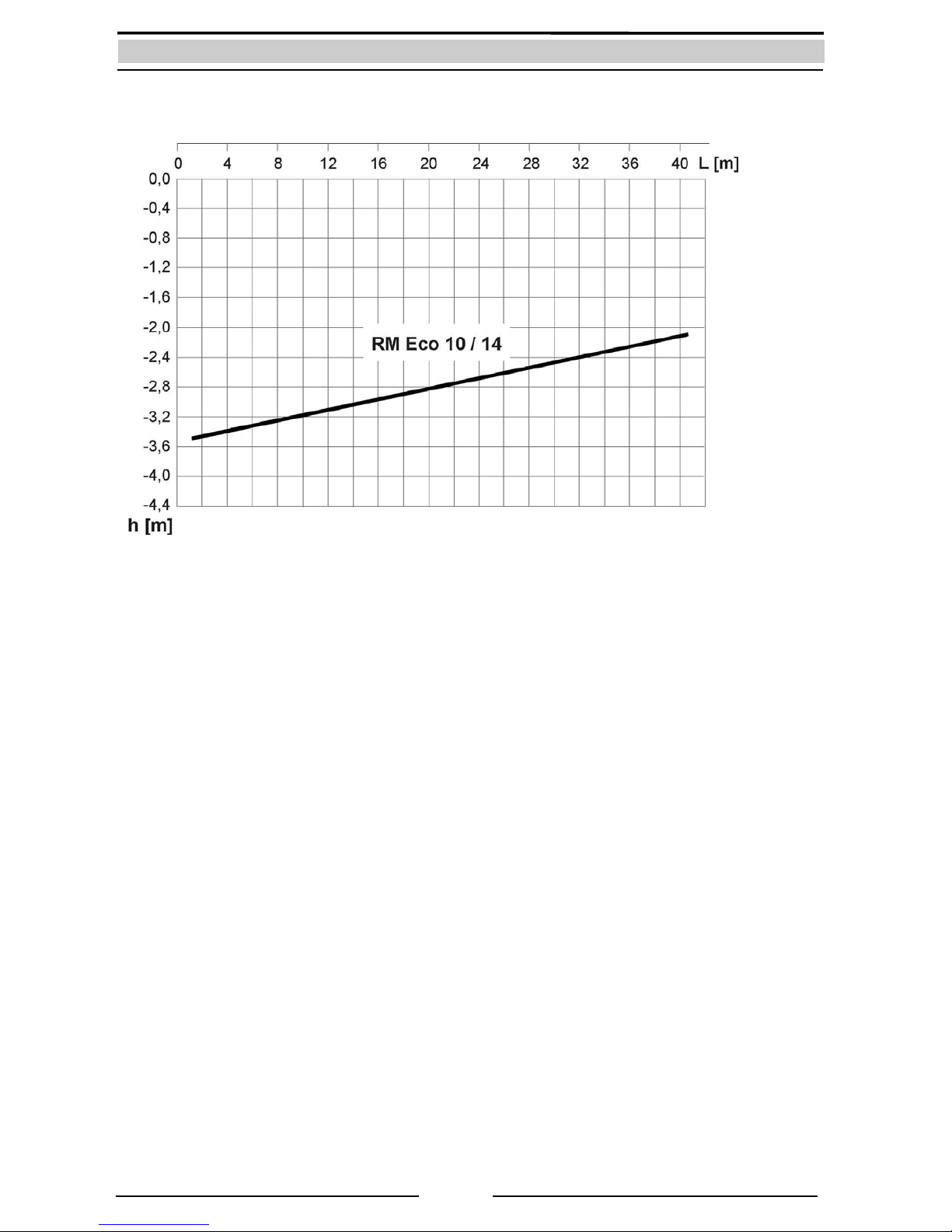

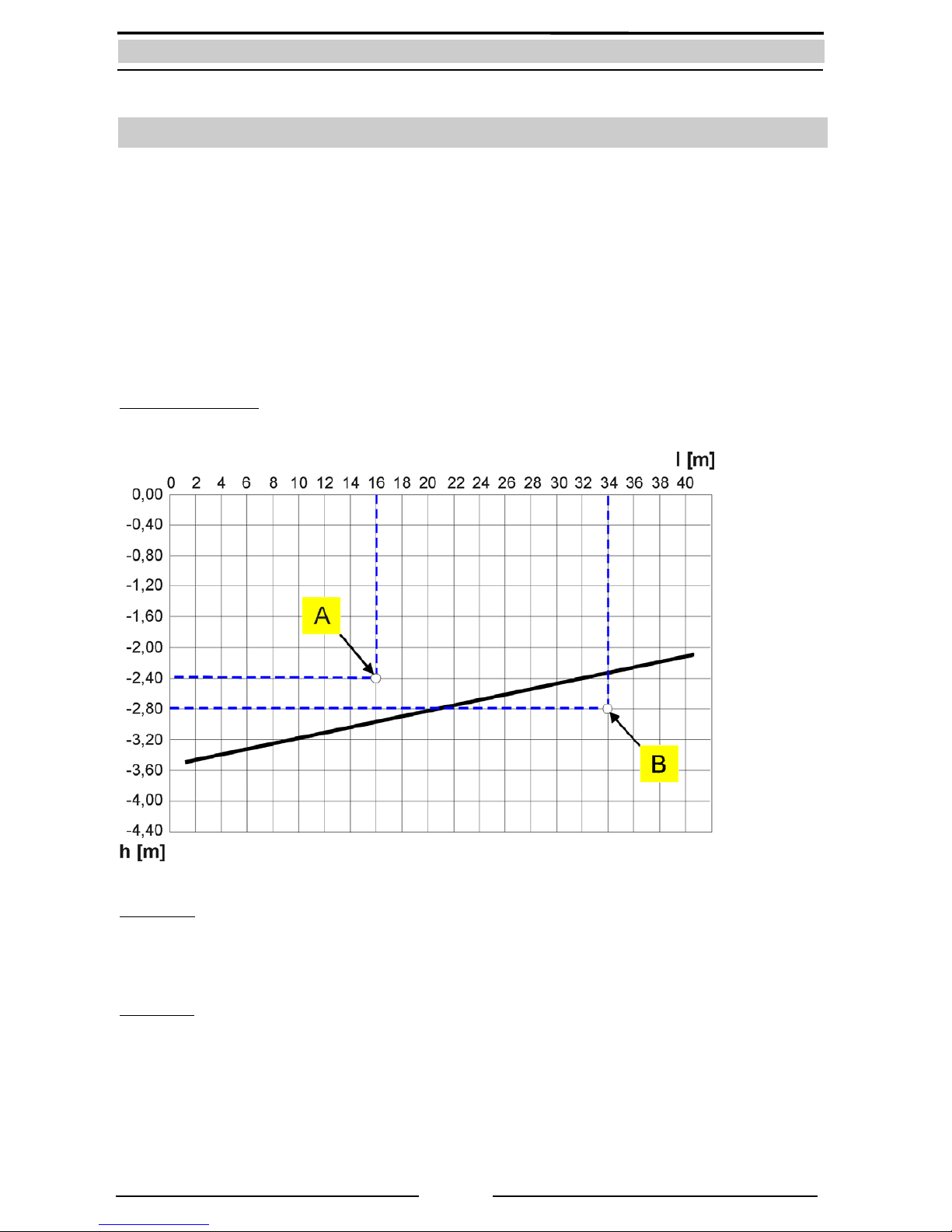

4.2.Dimensioningoftheintakeline.................................................................................................................9

4.3Standards,Directives,tests.......................................................................................................................10

5.Overviewofcomponents.................................................................................................................11

5.1Componentsofbasiccontroller..................................................................................................................11

5.2Componentsofdiaphragmpump...............................................................................................................12

5.2.1Membranpumpe.....................................................................................................................................12

5.2.2Fan................................................................................................................................................14

5.3Componentsofthesupplementalsupplycontainer.....................................................................................15

5.4Componentsofelectronic3/2‐wayballvalve..............................................................................................15

5.5Componentsofthepressurelineset...........................................................................................................16

6.InstallationinstructionsforRAINMASTEREco..................................................................................17

6.1Wallmounting...........................................................................................................................................17

6.2Connectiontothemainswaterline.............................................................................................................18

6.3Installationontheintakeside....................................................................................................................19

6.3.1Installationofaprotectiveconduitpipe.........................................................................................19

6.3.2Layoutoftheintakeline...............................................................................................................20

6.3.3Intakelineconnection...................................................................................................................21

6.3.4Installationofthefloatingintake..................................................................................................21

6.4Installationofthepressurelineset.............................................................................................................21

6.5Connectingtheemergencyoverflow...........................................................................................................23

6.6Installationandadjustmentofthefloatswitch...........................................................................................24

7.Startupanduse..............................................................................................................................25

7.1Start‐upinmainswatermode....................................................................................................................25

7.2Start‐upinrainwatermode........................................................................................................................26

7.3Modesofoperationanddisplay..................................................................................................................27

7.3.1Automaticmode(SwitchpositionI)..............................................................................................27

7.3.2Maintenancemode(SwitchpositionII).........................................................................................27

8.Troubleshootingincaseofproblems................................................................................................28

9.Maintenance..................................................................................................................................29

10.Spareparts.....................................................................................................................................30

11.Optionalaccessories.......................................................................................................................30

12.Guarantee......................................................................................................................................31

13.Contact/Devicenumber..................................................................................................................31