1

Contents

1.Introduction .........................................................................................................................................................................................2

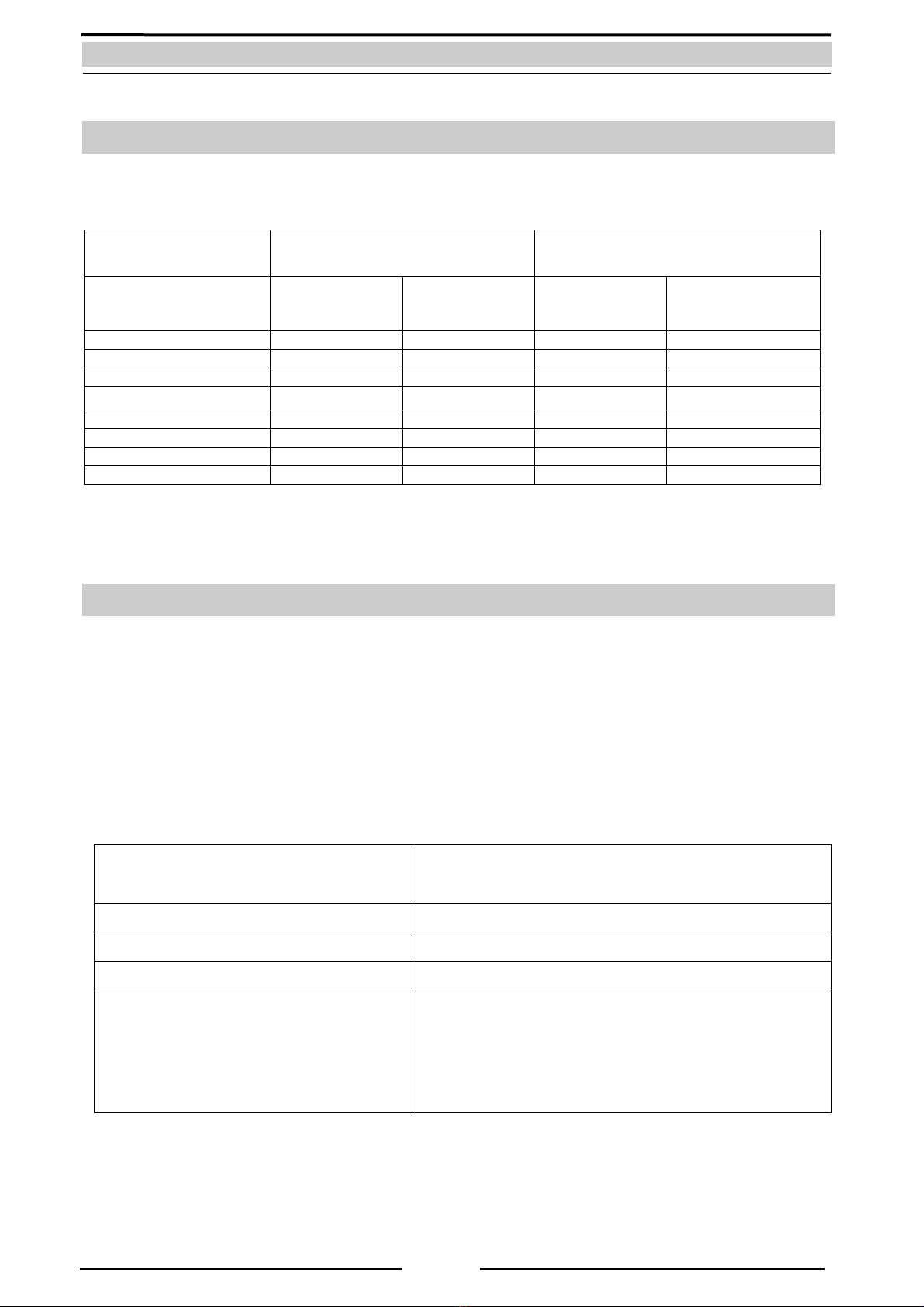

2.Dimensioning and general description for the AQUALOOP GW series ........................................................................... 3

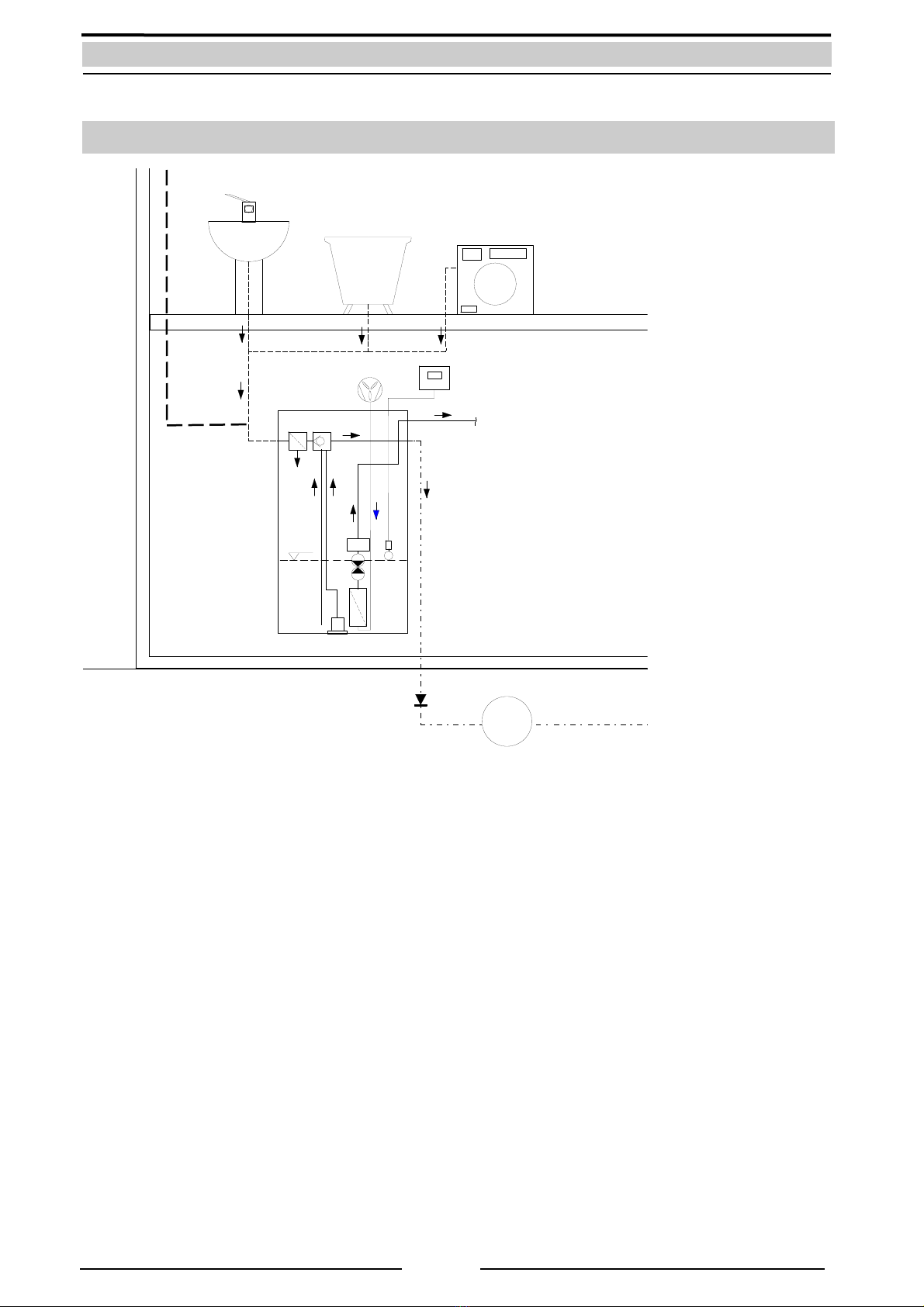

2.1Functional description.............................................................................................................................................................. 4

2.2Influent quality ........................................................................................................................................................................... 5

2.3Effluent quality ........................................................................................................................................................................... 6

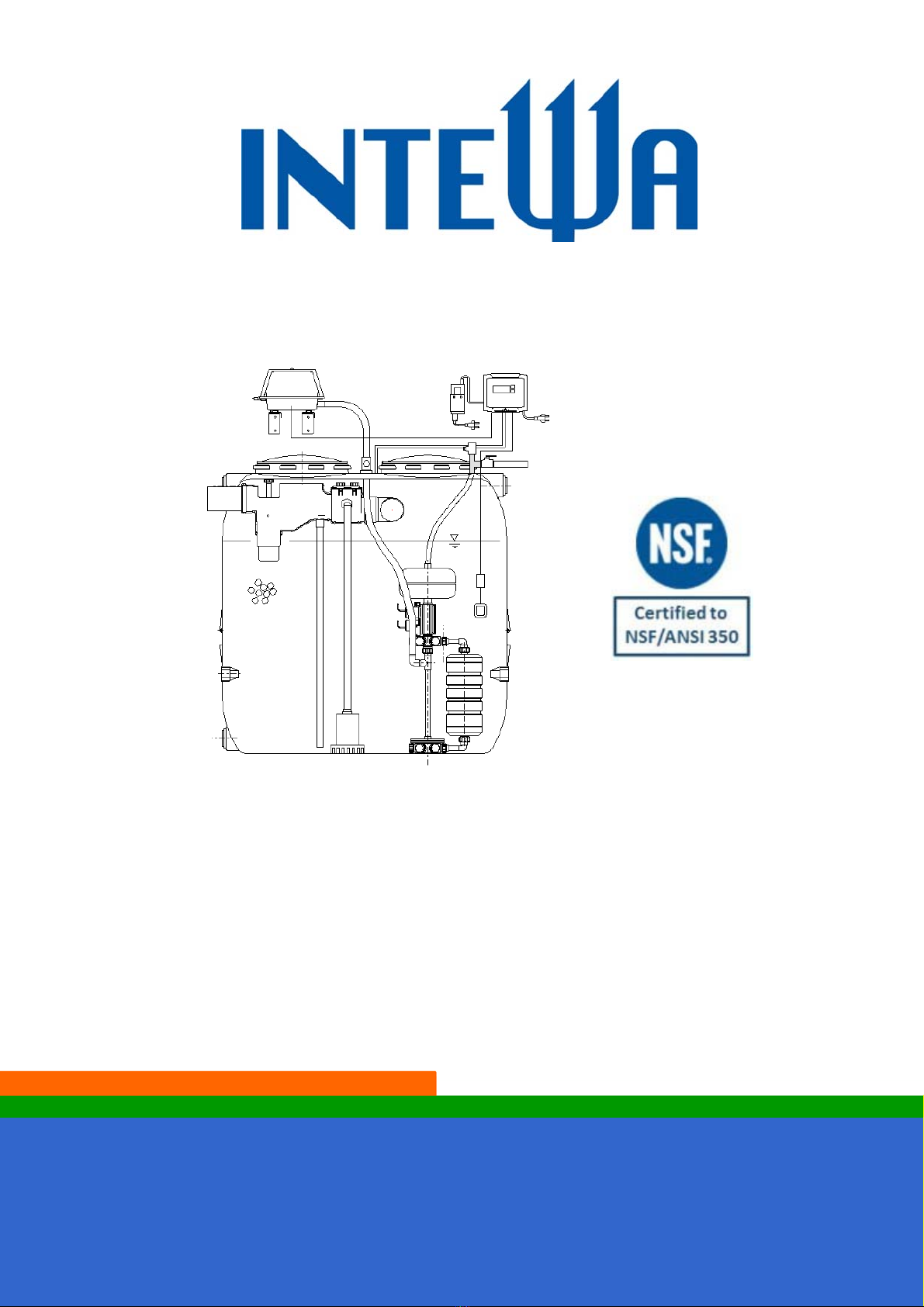

2.4Certification NSF/ANSI 350 -2014 .......................................................................................................................................... 6

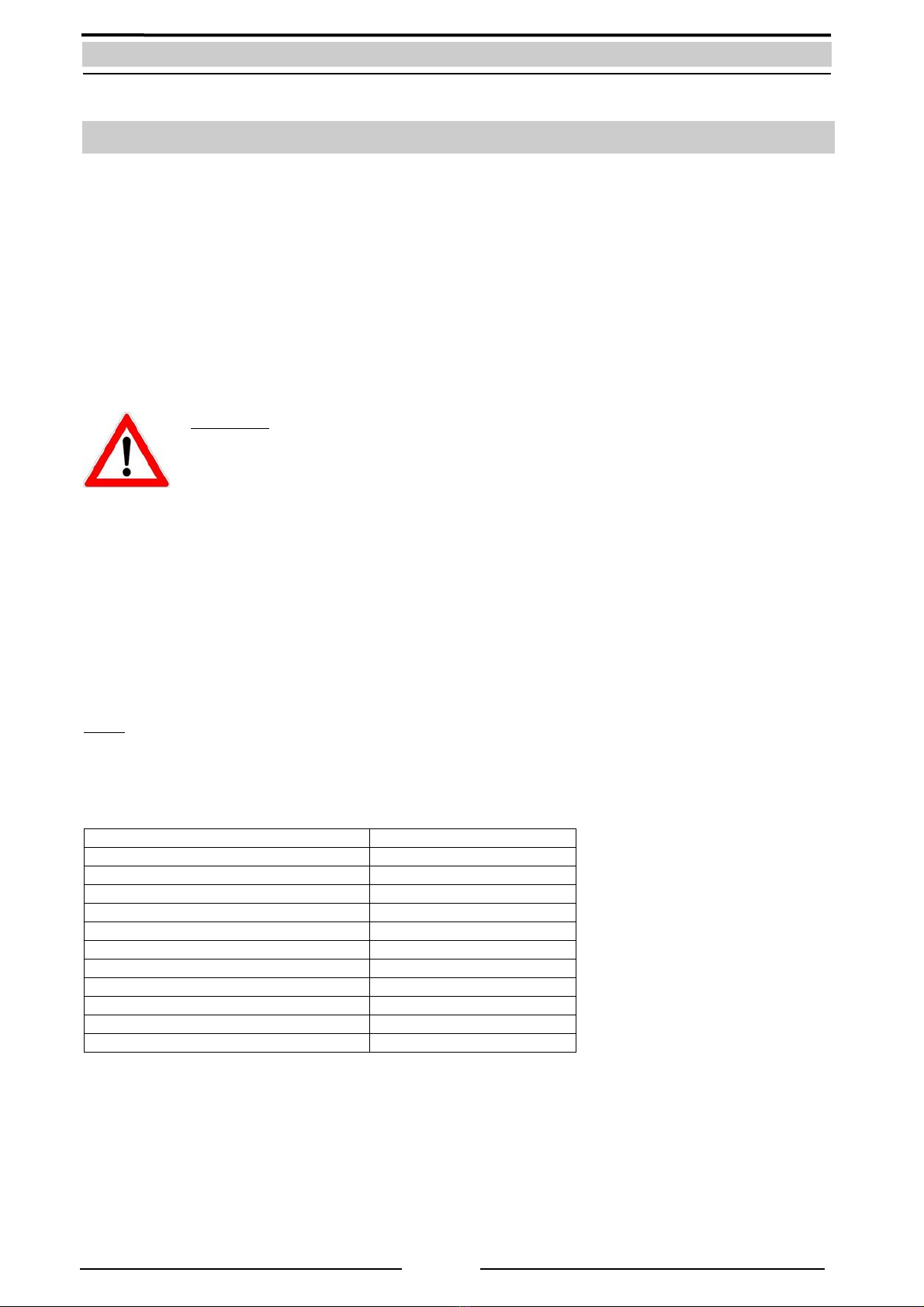

3.General safety instructions.............................................................................................................................................................. 7

4Declaration of conformity, electrical standards, approvals.................................................................................................. 8

5.Scope of delivery, Transporting, Storage ...................................................................................................................................9

6.Technical data and installation details......................................................................................................................................10

6.1Membrane station control unit............................................................................................................................................ 10

6.2Membrane station...................................................................................................................................................................12

6.3Membrane cartridge............................................................................................................................................................... 14

6.4Pre-filter......................................................................................................................................................................................16

6.5Blower.........................................................................................................................................................................................17

6.6Growth bodies .......................................................................................................................................................................... 17

6.7Pressure sensor aeration........................................................................................................................................................18

6.8Sludge pump.............................................................................................................................................................................18

7.Electrical function and operation of the control unit...........................................................................................................19

7.1Electronic connections ...........................................................................................................................................................19

7.2Menu overview .........................................................................................................................................................................22

7.2.1Operating mode display.........................................................................................................................................26

7.2.2Menu settings and description ............................................................................................................................27

8Installation and connection ..........................................................................................................................................................31

8.1Data plate and labelling of the control unit ............................................................................................................................33

9.System start-up .................................................................................................................................................................................34

9.1Tightness test ............................................................................................................................................................................34

9.2Start-up phase of the bioreactor..........................................................................................................................................34

9.3Starting the bio reactor ..........................................................................................................................................................35

9.4References: Bio reactor in process........................................................................................................................................35

10.Trouble shooting ..............................................................................................................................................................................36

11.Maintenance and replacement instructions ...........................................................................................................................38

11.1Pre-filter......................................................................................................................................................................................38

11.2Suction and Back flush pump...............................................................................................................................................39

11.3Floating switch.........................................................................................................................................................................39

11.4Pressure sensor .........................................................................................................................................................................39

11.5Blower.........................................................................................................................................................................................40

11.6Membrane .................................................................................................................................................................................41

11.6.1Mechanical cleaning of the membrane.............................................................................................................41

11.6.2Chemical cleaning ....................................................................................................................................................42

11.6.2.1In-Situ cleaning in the bioreactor.................................................................................................42

11.6.2.2Intensive cleaning in an separate cleaning tank.....................................................................45

11.6.3Cleaning solution......................................................................................................................................................46

11.7Bio reactor ................................................................................................................................................................................. 47

11.7.1Collecting effluent samples...................................................................................................................................48

12.Spare parts..........................................................................................................................................................................................48

13.Optional accessory...........................................................................................................................................................................49

14.Limited Warranty / Service policy / Contact............................................................................................................................50