1

Table of contents

1. Introduction and scope of application ........................................................................................................................................ 2

1.1Modes of operation ................................................................................................................................................................. 3

2. Safety instructions .............................................................................................................................................................................. 4

3. Scope of delivery ................................................................................................................................................................................ 5

4. Technical Data ..................................................................................................................................................................................... 6

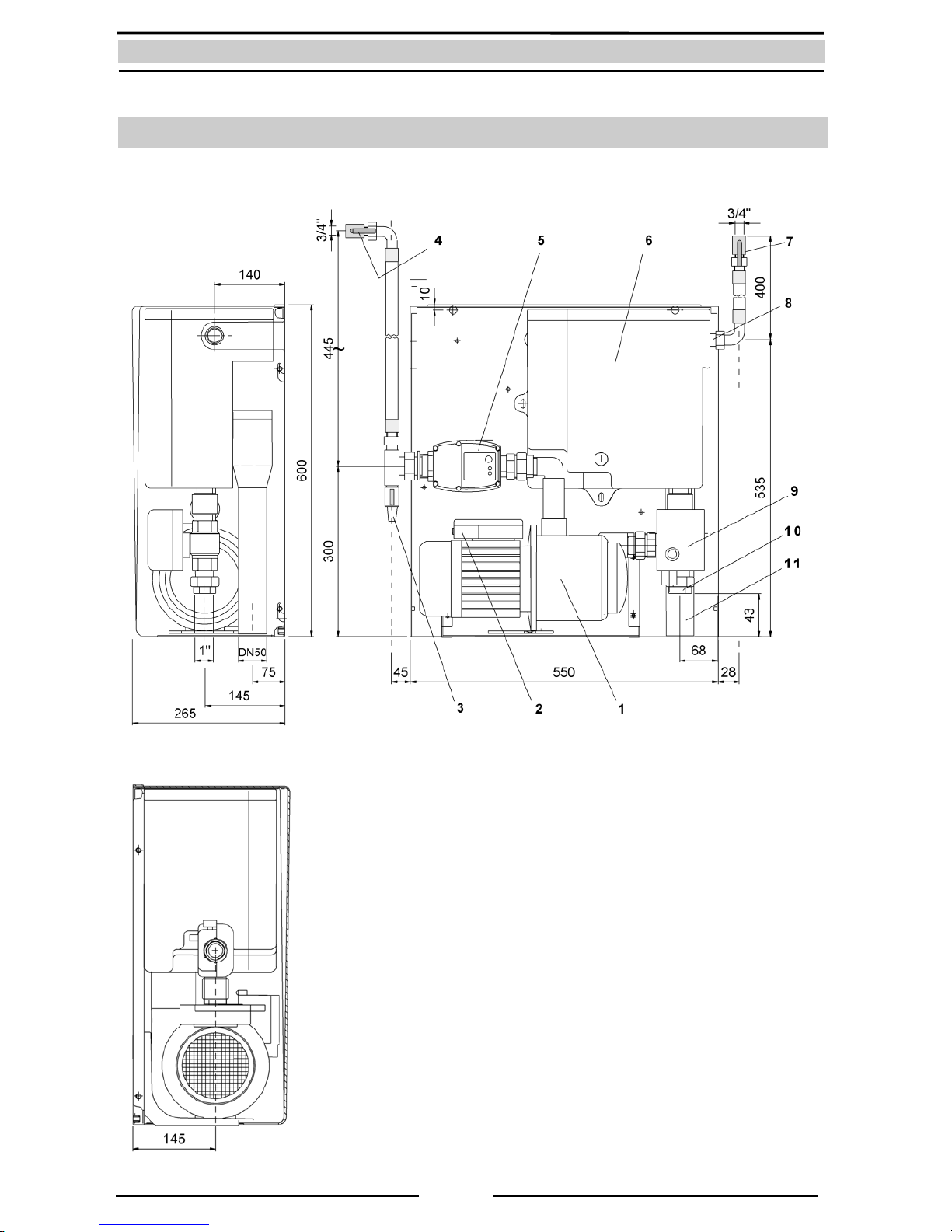

4.1Device overview and dimensions ....................................................................................................................................... 7

4.2.Dimensions of the intake line .............................................................................................................................................. 8

4.3Standards, Directives, tests ................................................................................................................................................... 9

5. Overview of components ............................................................................................................................................................... 10

5.1Components of the pump-controller ............................................................................................................................... 10

5.2Components of the basic controller ................................................................................................................................. 11

5.2Components of the multistage pump ............................................................................................................................. 13

5.3Components of the supplemental supply container .................................................................................................. 15

5.4Components of the electronic 3/2-way ball valve ....................................................................................................... 15

6. Installation instructions ................................................................................................................................................................... 16

6.1Wall mounting .......................................................................................................................................................................... 16

6.2Connection to the mains water line .................................................................................................................................. 17

6.3Installation on the intake side ............................................................................................................................................. 18

6.3.1Installation of a protective conduit pipe ............................................................................................................ 18

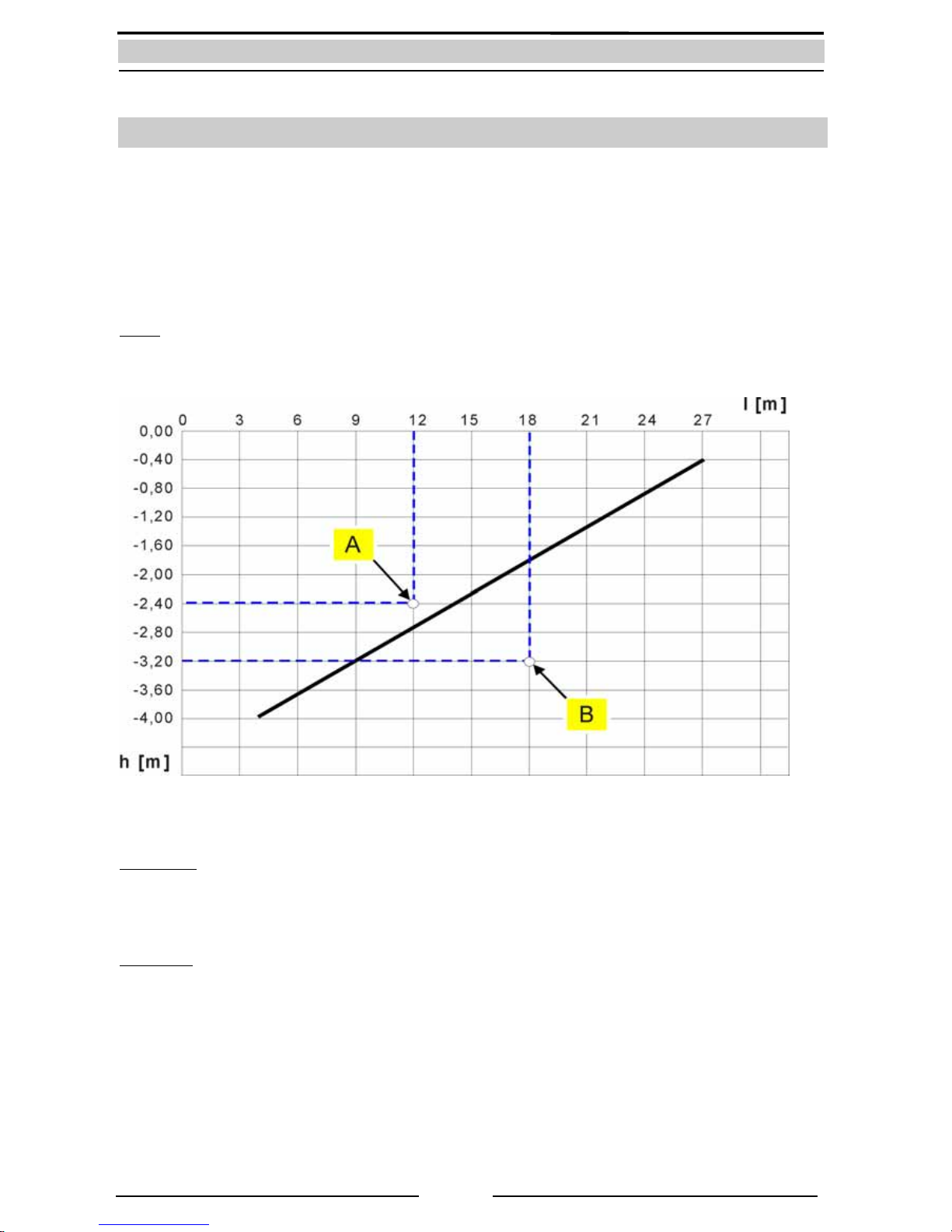

6.3.2Layout of the intake line .......................................................................................................................................... 19

6.3.3Intake line connection .............................................................................................................................................. 20

6.3.4Installation of the floating intake ......................................................................................................................... 20

6.4Installation of the pressure line set ................................................................................................................................... 21

6.5Connecting the emergency overflow .............................................................................................................................. 21

6.6Installation and adjustment of the float switch ............................................................................................................ 23

7. Start up and use ................................................................................................................................................................................. 24

7.1Start-up in mains water mode ............................................................................................................................................ 24

7.2Start-up in rainwater mode .................................................................................................................................................. 25

7.3Modes of operation and display ........................................................................................................................................ 26

7.3.1Automatic mode (Switching position I ) ............................................................................................................ 27

7.3.2Maintenance mode (Switch position II )............................................................................................................. 27

8. Trouble shooting in case of problems ........................................................................................................................................ 28

9. Maintenance ....................................................................................................................................................................................... 29

10.Spare parts ........................................................................................................................................................................................... 29

11.Optional Accessories ........................................................................................................................................................................ 29

12. Guarantee............................................................................................................................................................................................. 30

13. Contact / Unit serial number ......................................................................................................................................................... 30