6 Extension module connection

6.1 Extension bus connection

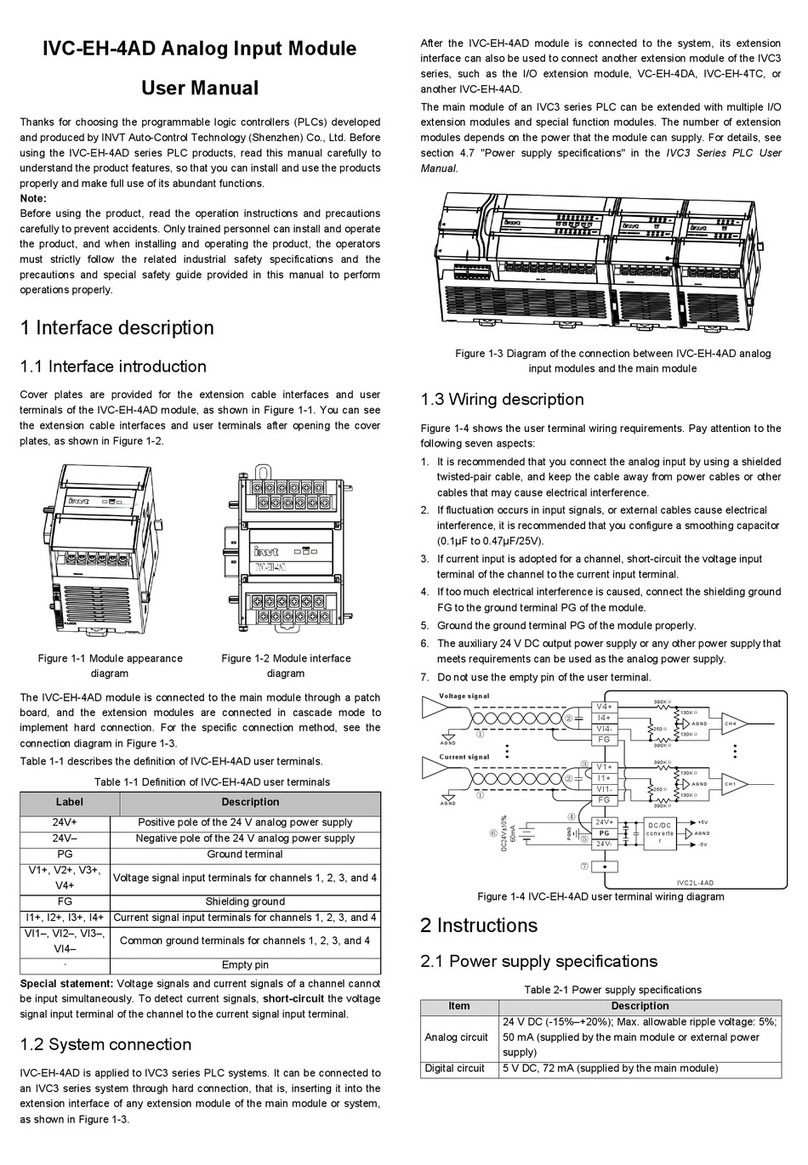

Ensure that the main module is not powered on. Remove the

small cover of the extension cable socket on the right side of the

main module, and then insert the bus cable terminal of the

extension module to the socket. If multiple extension modules are

to be connected, you can connect them in sequence. Note that

extension cable socket covers are detachable parts. Do not lose

themafter removing them fromthe main module.

Figure 6–1 Diagram of extension module connection in series

mode

6.2 Extension module addressing

IVC3 series PLCs automatically identify extension modules that

are connected to them and automatically perform sequential

addressing on the extension modules. No user operation is

required.

Automatic addressing is performed once after the PLC is properly

powered on, and then the addresses of all the extension modules

do not change in the running. Do not insert or remove any I/O

extension module or special function module when the PLC is

running. Otherwise, the PLC may be damaged or operation

exceptions may be caused.

Extension modules with power supplies must be powered on

simultaneously with or before the main module to ensure effective

addressing on the extension modules.

The octonary system is adopted for numbering I/O points, for

example, 0, 1, 2, 3, 4, 5, 6, 7, 10, 11, 12, 13, 14, 15, 16, 17, 20,

21, … The digits 8 and9 are not used.

Input ports of the main module and extension modules are

numbered X0, X1, X2, … X7, X10, X11, …; and output ports are

numbered Y0, Y1, Y2, …Y7, Y10, Y11, … The point numbers are

grouped with 8 number in one group, and the groups with less

than 8 point number are left out.

For example, IVC3-1616MAT provides 16 input points, which are

numbered X0 to X17. No terminal is numbered X24 to X27. The X

terminal of a subsequent extension module is numbered from

X30. In the same way, if 12 output points are provided, they are

numbered Y0 to Y13, and no terminal is numbered Y14 to Y17;

and the Y terminals of subsequent extension modules are

numbered from Y20.

The X terminals and Y terminals of I/O extension modules are

numbered in ascending mode based on the sequence they are

connected to the extension connectors of the main module.

The following table describes logical numbering examples of the

ports of the main module and extension modules.

User notice

1. The warranty covers only the PLC machine.

2. The warranty period is 18 months. We provide

free-of-charge maintenance and repairs for the product if it

is faulty or damaged during proper operation within the

warranty period.

3. The warranty period starts from the ex-factory date of the

product. The machine No. is the only basis for determining

whether the machine is within the warranty period. A device

without the machine No. is deemed out-of-warranty.

4. Maintenance and repair fees are charged in the following

scenarios even the product is within the warranty period:

•Faults are caused due to misoperations. Operations

are not performed following the instructions provided in

the manual.

•The machine is damaged due to causes such as fire,

flood, or voltage exceptions.

•The machine is damaged due to improper use. You

use the machine to perform some unsupported

functions.

5. The service fees are calculated based on the actual fees. If

there is a contract, the provisions stated in the contract

prevail.

6. Keep this warranty card. Show it to the maintenance unit

when you seek maintenance services.

7. Contact the local dealer or directly contact our company if

you have any questions.

Customer Service Center (China)

INVT Auto-Control Technology (Shenzhen) Co., Ltd.

Address: Gaofa Technology Park, Longjing, Nanshan District,

Shenzhen

Postal code: 518055

Company website: http://www.invt-control.com/en/index.html

All rights reserved.

The content of this manualis subject to change without prior

notice.