5

UNIT PERFORMANCES AND FEATURES

This appliance is intended and ce tified fo comme cial and indust ial use

(Technical file, Machine y Di ective 2006/42/EC)

This u it has bee desig ed to recreate the ideal co ditio s of a good atural cellar. I or-

der to recreate such a peculiar atmosphere, IP uses a double automatic “warm/cold” circuit

e suri g that the specified temperature is mai tai ed i side the cellar.

The applia ce is desig ed to operate i ambie t temperature* specified by its temperature

class marked o the rati g plate.

To ensu e maximised functioning, the equipment should be a anged in a well-

ae ated a ea without excessive moistu e which is fa f om heat sou ces, avoiding ex-

posu e to di ect sunlight and keeping equipment clean f om dust o othe sedi-

ments.

A y damage or defects caused by failure to respect these orms are ot covered by the guar-

a tee a d are ot i a y way the respo sibility of the ma ufacturer.

It is also recomme ded to place the machi e i order to e able the use whe lighti g co di-

tio s are “NORMAL” (qua tified i 200 LUX) E.D. 2006/42/EEC.

(*) Ambie t temperature it mea temperature immediate proximity of the cabi et.

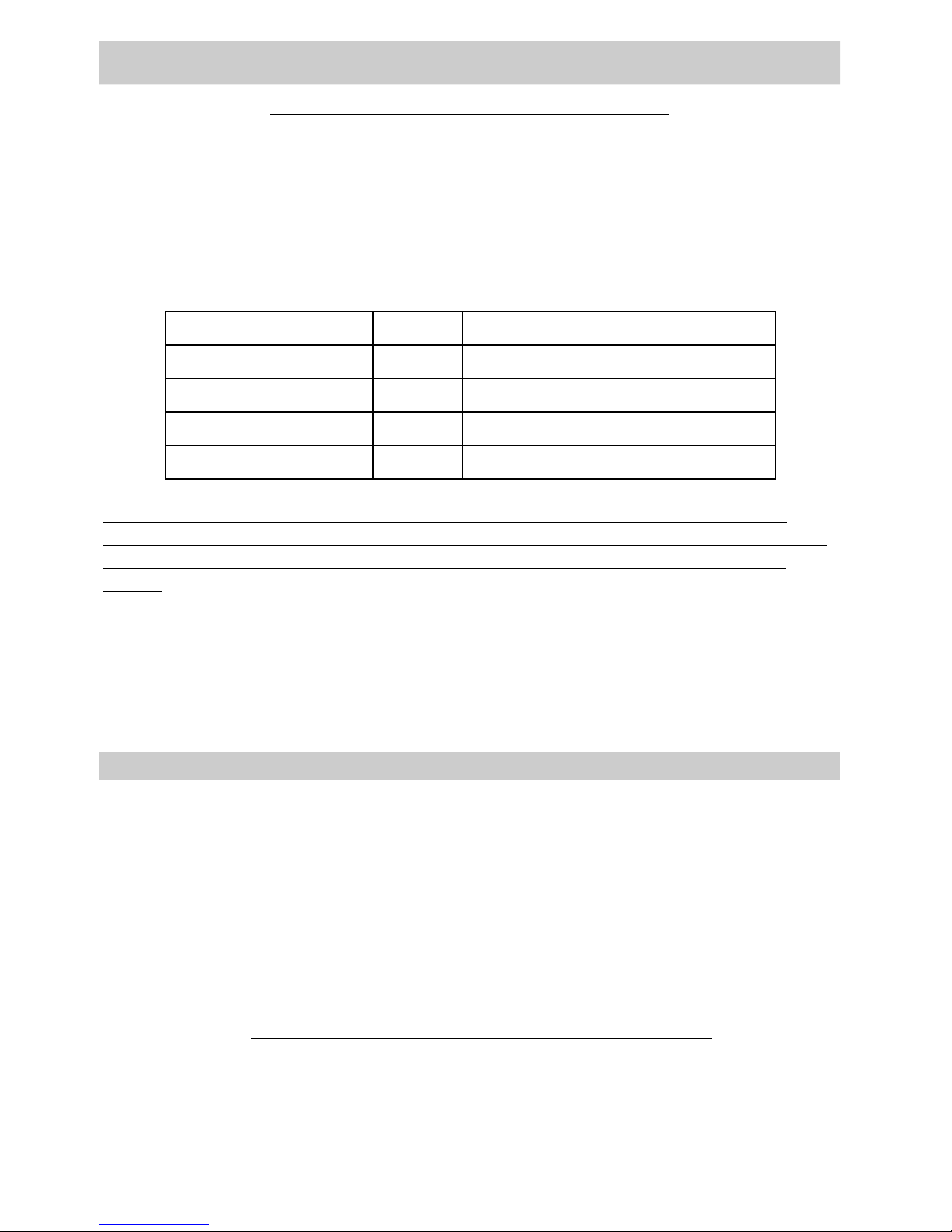

TECHNICAL INFORMATION

Class Symbol Ambient temperature range C°(*)

Extended Temperate SN Da +10 a + 32

Temperate NDa +16 a +32

Subtr pical ST Da +16 a +38

Tr pical TDa +16 a +43

HANDLING AND INSTALLATION

EQUIPMENT INSPECTION UPON RECEIPT

We recomme d immediately u packi g equipme t as soo as the package has arrived i

order to verify its co ditio s a d the abse ce of a y tra sport damage.

A y damage must be immediately reported to the carrier by mea s of a writte ote o

the tra sport docume tatio . I the eve t that damage is detected o ly upo i stallatio ,

report said damage to the ma ufacturer withi 7 days of receipt. Otherwise, the ma u-

facturer decli es all respo sibility for a y tra sport damage requests.

Lower o circumsta ces ca damaged equipme t be retur ed to the ma ufacturer with-

out otice a d without havi g obtai ed prior writte authorisatio .

ACCESSORY CLEANING AND ARRANGEMENT

Before start-up, clea the i side the store-room a d accessories with eutral soap to re-

move the characteristic odour of the ew equipme t.

Set up accessories i side i the most appropriate positio s.