8

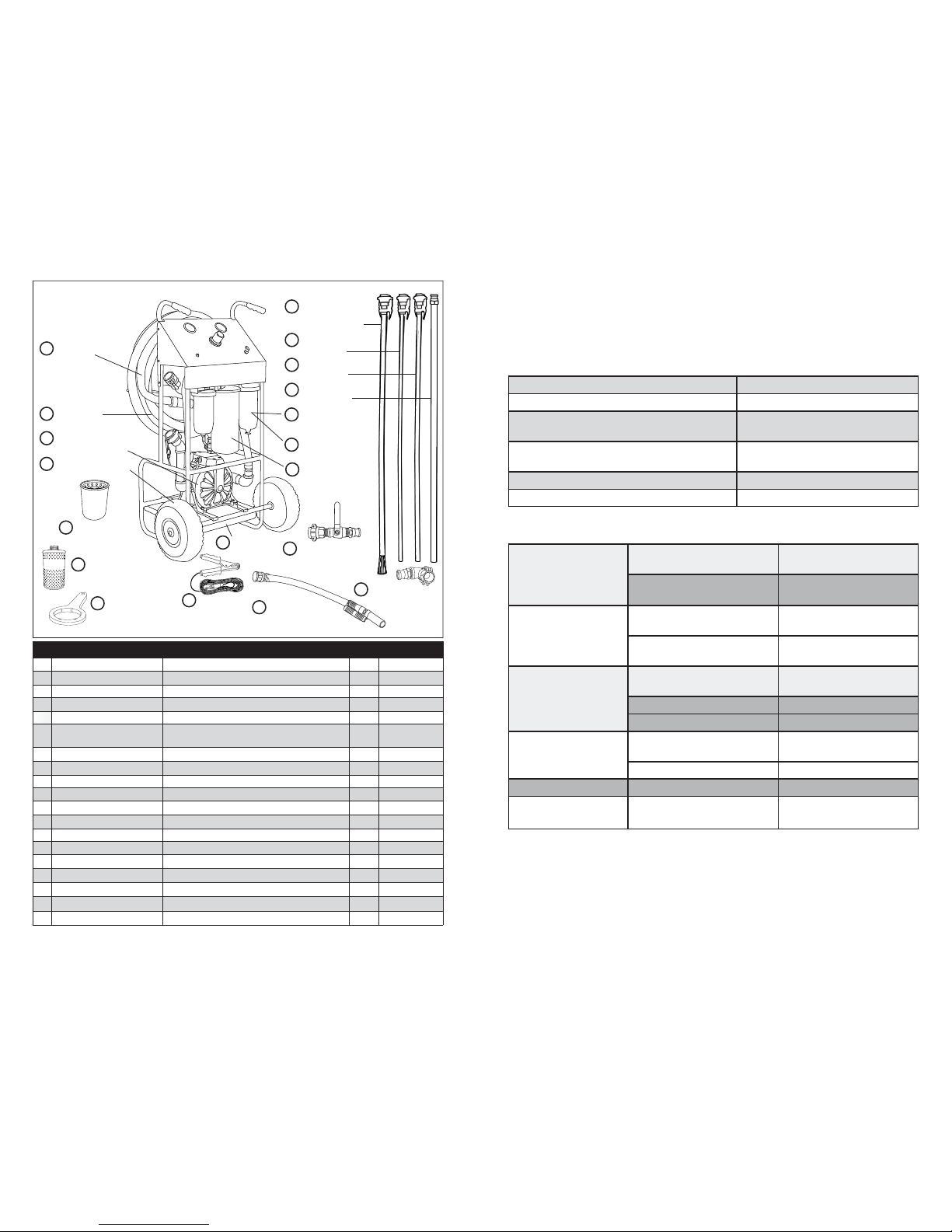

OPTIONAL FILTERS

(A) #FIL00003 30-Micron Particulate-Blocking Filter

(A) #FIL00010 10-Micron Water-Blocking Filter

(A) #FIL-02WB 2-Micron Water-Blocking Filter

(A) #FIL-02PT 2-Micron Particulate-Blocking Filter

(B) #FIL00001A 17-Micron Water-Blocking Filter

(C) #FIL00004 381-Micron Wire Mesh Filter

(C) #FIL00013 178-Micron Wire Mesh Filter

NOTE: Each unit includes one extra filter for each option available to that unit.

Additional quantities are available.

ACCESS WANDS

The #9046 Pneumatic Tank Sweeper®series offers four wands for input and output

depending on the unit. See below for a description of each wand.

1. 5' Long x 1" Dia. Rigid Wand: Should be used on the input side for accessing

55-gallon drums and other stationary tanks.

2. 5' Long x ¾" Dia. Flex Wand: Can be used on either input or output side.

3. 5' Long x ½" Dia. Flex Wand: Only used on the output side to avoid restricting

flow to the pump. The ½" wand is traditionally used for blasting the inside of tank

walls with a higher pressure.

4. 5' Long x ¾" Dia. Flex Wand w/ Flow-Through Brush: The flow-through brush is

removable and should only be used with extreme caution to avoid losing the brush

inside a fuel tank. Be sure to securely tighten the brush to the wand before use.

(Comes with #9046F and #9046FH only. Available separately for #9046H.)

ABC

CHANGING FILTERS

1. If output flow stops while pump is still active, the filters may be clogged. Verify

the filters are clogged by disconnecting the air supply and observing OUTPUT/

FILTER PRESSURE Gauge. If the filters are clogged, the gauge will continue

displaying a high-pressure reading.

2. Prior to changing filters, be sure the drain pan is in place. Dissipate any remaining

pressure in the system by opening the petcock at the base of the clear filter housing and

Valves 2 and 3.

Valve 2

Valve 1

Valve 3

5

MUST READ BEFORE USE

This diaphragm pump is meant for use with liquids only. DO NOT suck up leaves,

gravel or other solids. Doing so will void the warranty.

SUMMARY

The Pneumatic Tank Sweeper®is a portable system designed for recovering and

salvaging hydraulic/diesel fuel and oil. This system is offered in three model types:

#9046F - for filtering diesel and fuel oil, #9046H - for filtering hydraulic oil, and

#9046FH - for filtering diesel fuel, fuel oil and hydraulic oil. Specific options such as

filters, wands and adapters are included for each model type. Each model utilizes

diverter valves, which allow the user to bulk transfer without filtering for removing

contaminants from the bottom of the tank where the majority of the sludge, water

and debris settle. It also transfers through the filters for the purpose of polishing

the fuel/oil, which is typically performed as a scheduled preventative maintenance

procedure. The provided input and output wands are specifically built for these

applications.

SET-UP INSTRUCTIONS

1: ASSESSING THE CONDITION OF THE FUEL/OIL

It is recommended that you visit the site 48 hours before tank sweeping to prepare

the tank and assess the site condition. Using the optional IPA®#9042 Sample Stick,

insert the tool all the way down to the bottom of the tank you are cleaning. Draw the

piston shaft up enough to get a good sample of the fuel (approximately 12"). Remove

the Sample Stick and note the amount of water and crud at the bottom of the tank.

It is recommended that you transfer the sample into a glass jar and allow the various

contaminants to settle and separate for 24 hours. This will give you an idea of the

fuel condition inside the tank and the amount/type of the contaminated fuel.

2: KILLING MICROBIAL GROWTH

Add an algae biocleaner or equivalent to the tank in appropriate amounts. Using the

Sample Stick, stir the tank briskly to mix the algae cleaner into the oil. After 48 hours,

the algae should be killed off and the tank is now ready for sweeping. If convenient

and safe, you may use a small jack to elevate the tank a few degrees on one side to

allow the majority of contaminates to collect on one end of the tank. This is the end

you will choose to sweep.

3: REMOVING SLUDGE AND DEBRIS FROM BOTTOM OF TANK

WARNING: Do NOT hook up air to cart until set-up is complete!

1. Set up your Tank Sweeper®near the tank to be cleaned, allowing enough room

for the input hose to reach the tank.

2. Install the output hose to the bulk/unfiltered output quick-disconnect fitting

located on the side of the Tank Sweeper®.

3. Attach the output wand to the other end of the hose and insert into a 55-gallon

drum (Note: Use a clean and leak-free 55-gallon drum).

4. Connect the desired wand to the input hose via couplers.

WARNING: Be sure to use the locking pins on all the quick-disconnect

fittings so that the locking levers do not vibrate loose.

5. Insert the wand all the way down to the bottom of the oil/fuel tank you are cleaning.