6

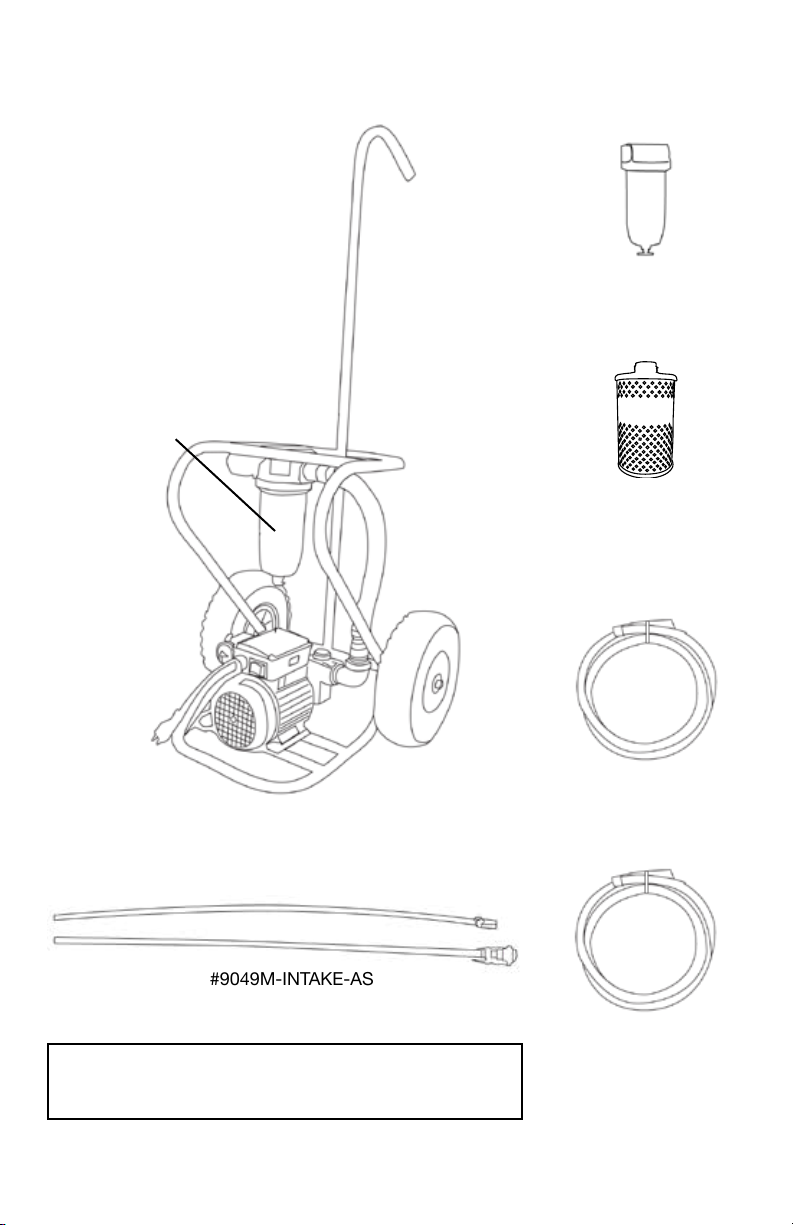

TANK SWEEPING

1. Once all safety precautions have been complied with and you are certain of good

and proper connections with the output hose rmly in the holding drum or tank,

plug the AC pump into a grounded 12-volt AC socket. When ready, turn on the

pump via the switch. This begins to actuate the pump assembly and the suction

through the input ex wand. The input and output ex wands can be cut to

accommodate your custom needs.

2. Keep the ex wand at the bottom of the tank and slowly sweep back and forth,

collecting all contaminants from the bottom of the tank.

3. The Tank Sweeper®will remove the bottom contents of the tank where the majority

of fuel contaminants exist, i.e., water, crud, algae and rust. If a badly contaminated

tank is expected, you must run the cleaning through the lter housing with the lter

installed. The Tank Sweeper® operator should move the ex wand back and forth

across the bottom of the tank moving the stick when the diesel is clear in the lter

housing. You should now move the wand to another spot at the bottom of the tank.

Repeat this sweeping function until only clean fuel is removed.

FILTERING AND BLENDING THE FUEL

A great feature of the Tank Sweeper®is its ability to return the contaminated fuel clean

and ltered to the same or a new diesel tank.

1. Install the output hose in the tank into which you want to transfer the clean fuel.

NOTE: Observe above warnings.

2. Insert ex wand into one hole at the top of the tank and insert the output hose into

another hole at the top of the tank.

NOTE: Depending upon what contaminants are present when using the hose and

how well it is cleaned afterwards determines how long the lter housing remains

clear.

NOTE: After transferring or ltering the fuel, drain both the input and the output

hoses. Cleaning of the hoses after use is necessary to maintain its longevity.

When ready, allow the hoses to gravity drain. Once the hoses have been drained,

hang them away from the sun over a pail or a bucket to catch any additional

residue.

#9042 SAMPLE STICK (OPTIONAL)

The Sample Stick is designed to remove a small sample of diesel fuel from the bottom

of a fuel tank so the operator can see what contaminants are present.

TO OPERATE

1. Insert the Sample Stick through one of the cap openings at the top of the tank until

it contacts the bottom of the tank.

2. Slowly withdraw the piston via the handle until the desired amount of fuel is drawn

into the Sample Stick.

3. Remove the Sample Stick from the tank, keeping a fuel absorbent towel ready.

Allow the Sample Stick to drip drain onto the towel.

4. Have a suitable container made of glass or material that will not be affected by the

fuel ready for the sample fuel.

5. Slowly withdraw the piston until it is removed completely from the Sample Stick.

Place the piston on a towel to drip drain.

6. Pour the remaining contents of the Sample Stick into the sample jar.