5

Owner’s/Installer Manual Rev 20191216 For Warranty Service Call 866-359-7378

UNPACKING

Unpack the Hot Plate immediately after receipt. Remove the Gas Hot Plate from the crate; remove all

packaging on and surrounding the unit and be certain to remove all protective plastics and residues from all

surfaces. Make sure that all parts provided including the L.P. gas conversion kit are located. Equipment must

have the legs properly installed before use. Before using this equipment it must be cleaned and dried

thoroughly.

INSTALLATION

NOTE: It is vital that the purchaser of this equipment post in a prominent location instructions to be followed in

the event that the user smells gas. This information shall be obtained by consulting the local gas supplier.

1. Read this manual thoroughly before installation and operation. DO NOT proceed with installation and

operation if you have any questions or do not understand anything in this manual. Contact your local

representative or IRON RANGE first.

2. Select a location for the Open Burner that has a level, solid, nonskid surface that is nonflammable

and away from water hazards or sinks, and is in a well-lighted work area away from children and

visitors.

3. This equipment must be installed under proper ventilation as required by local code.

Local codes regarding installation and ventilation vary greatly by area. The National

Fire Protection Association states in its NFPA 96 latest edition (see NFPA page at the

beginning of this manual) that local codes are “authority having jurisdiction” when it comes to

requirements for installation of equipment. Therefore, installation should comply with all local

codes.

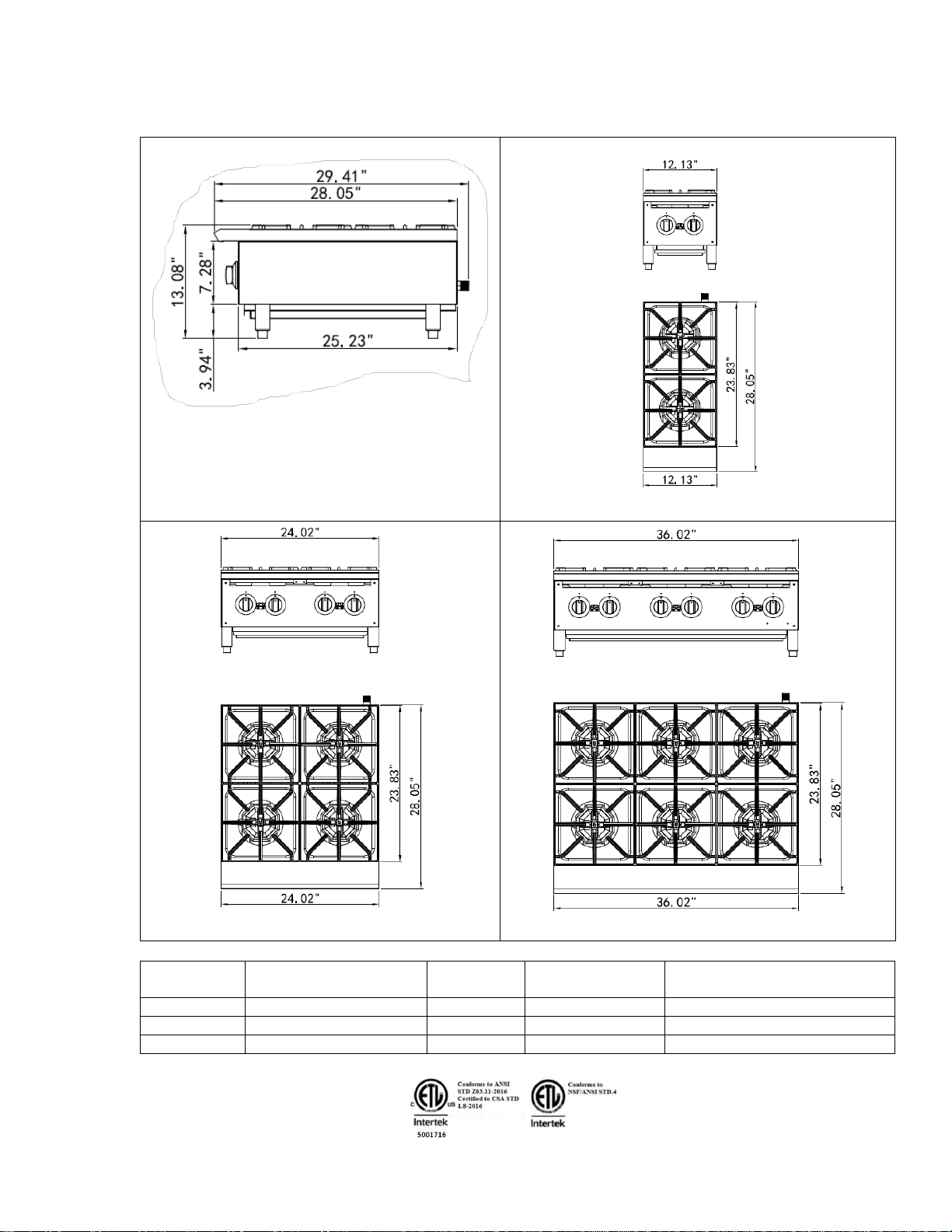

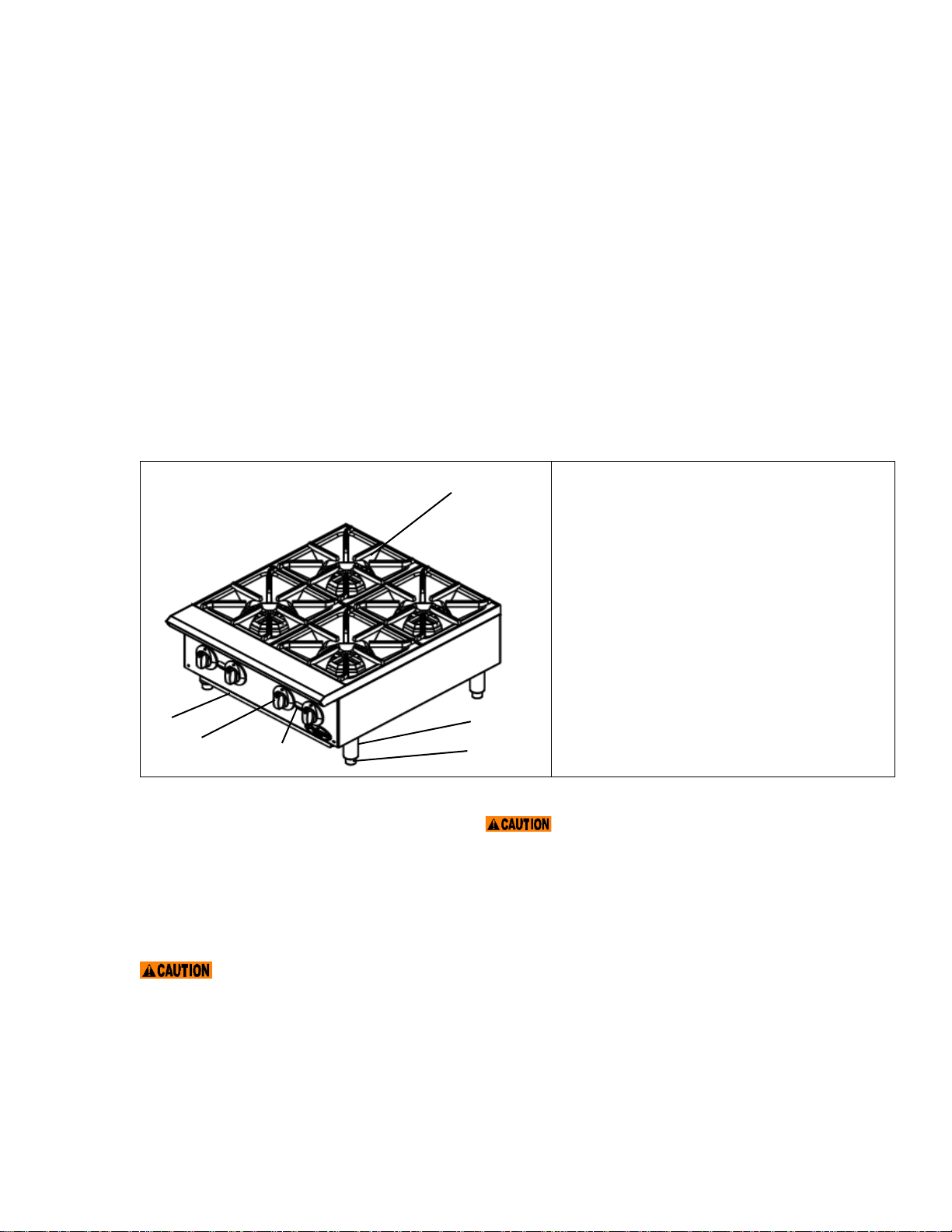

4. Screw legs into (A) the permanently fastened nuts on the four corners of the unit and tighten by hand.

Legs must be installed to adequately provide proper ventilation to the unit. (See Figure 1)

5. Level unit by adjusting the four feet and tighten securely. The adjustable feet have an adjustment of

one inch. Do not slide unit with legs mounted, lift if necessary to move unit.

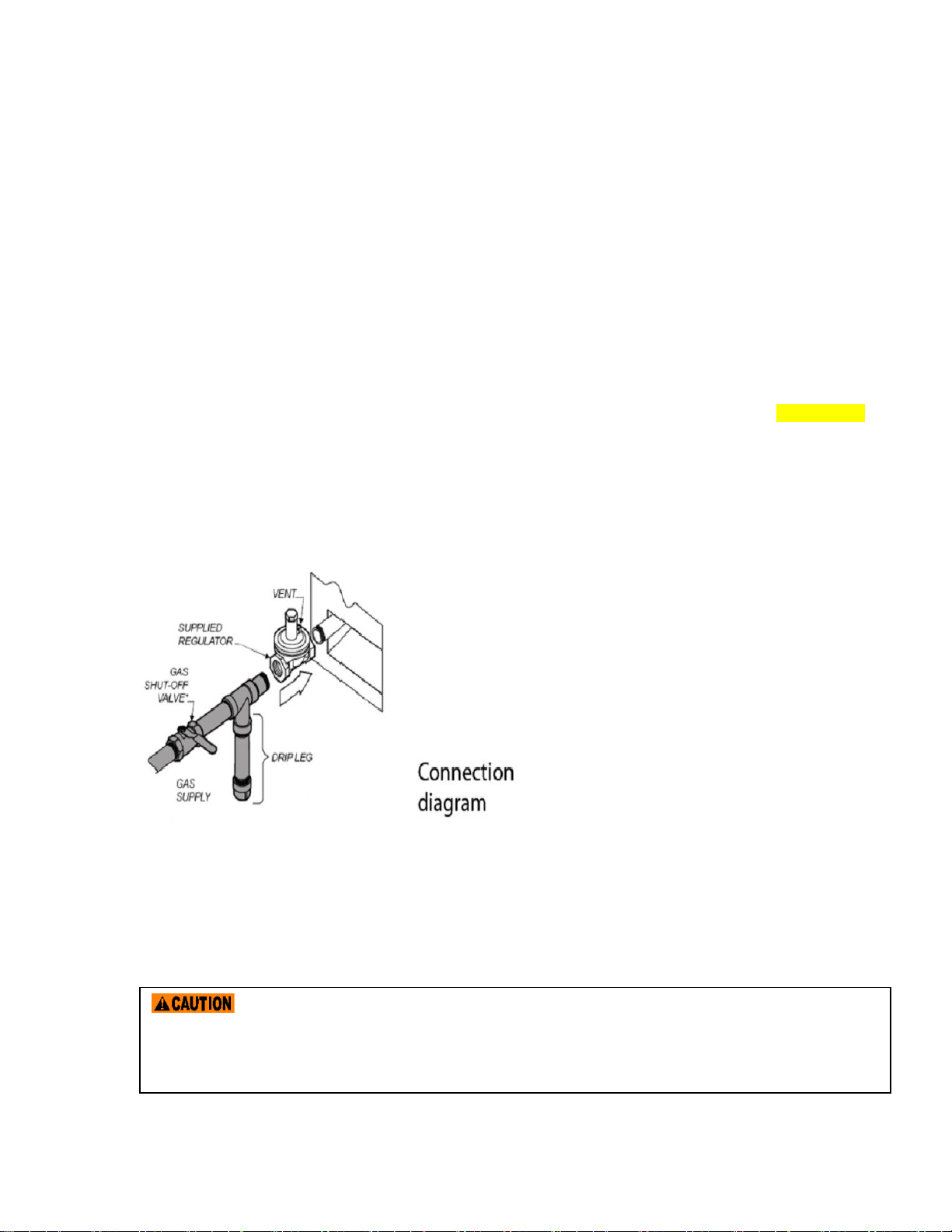

6. The supplied gas pressure regulator is factory set at 4” Natural Gas W.C. or 10” Propane Gas

7. THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON-COMBUSTIBLE SURFACE ONLY.

Noncombustible clearances: 6” sides (152 mm), 6” rear (152 mm), 4” floor (102 mm).

8. Do not obstruct the flow of combustion and ventilation air under the unit by the legs or behind the unit

by the flue. Do not place objects between the bottom of the unit and the counter top.

9. There must be adequate clearance for removal of the front panel. All major parts except the burners

are removable through the front if the gas is disconnected.

10. It may be necessary to adjust the balance of gas volume and air supply to each burner. This must be

done by an authorized service technician.

11. Pipe threading compound must be resistant to the action of liquefied petroleum gas. DO NOT USE

TEFLON TAPE.

The installation of this appliance must conform to local codes, or in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA

B149.1, as applicable.

•The appliance and its individual shut off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of ½ PSI (3.5kPa)