2

IMPORTANT SAFETY AND WARNING

INFORMATION

READ THIS MANUAL IN ITS ENTIRETY AND UNDER-

STAND THESE RULES TO FOLLOW FOR SAFETY.

WARNING

Do not attempt to alter or modify the construction of

the appliance or its components. Any modification

or alteration may void the warranty, certification

and listings of this unit.

WARNING

Improper installation, adjustment, alteration, ser-

vice or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

2. Do not connect this appliance to air ducts or any air distribu-

tion system.

3. DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

4. Do not use class B venting intended for gas appliances as a

chimney or connector pipe on a pellet-fired appliance.

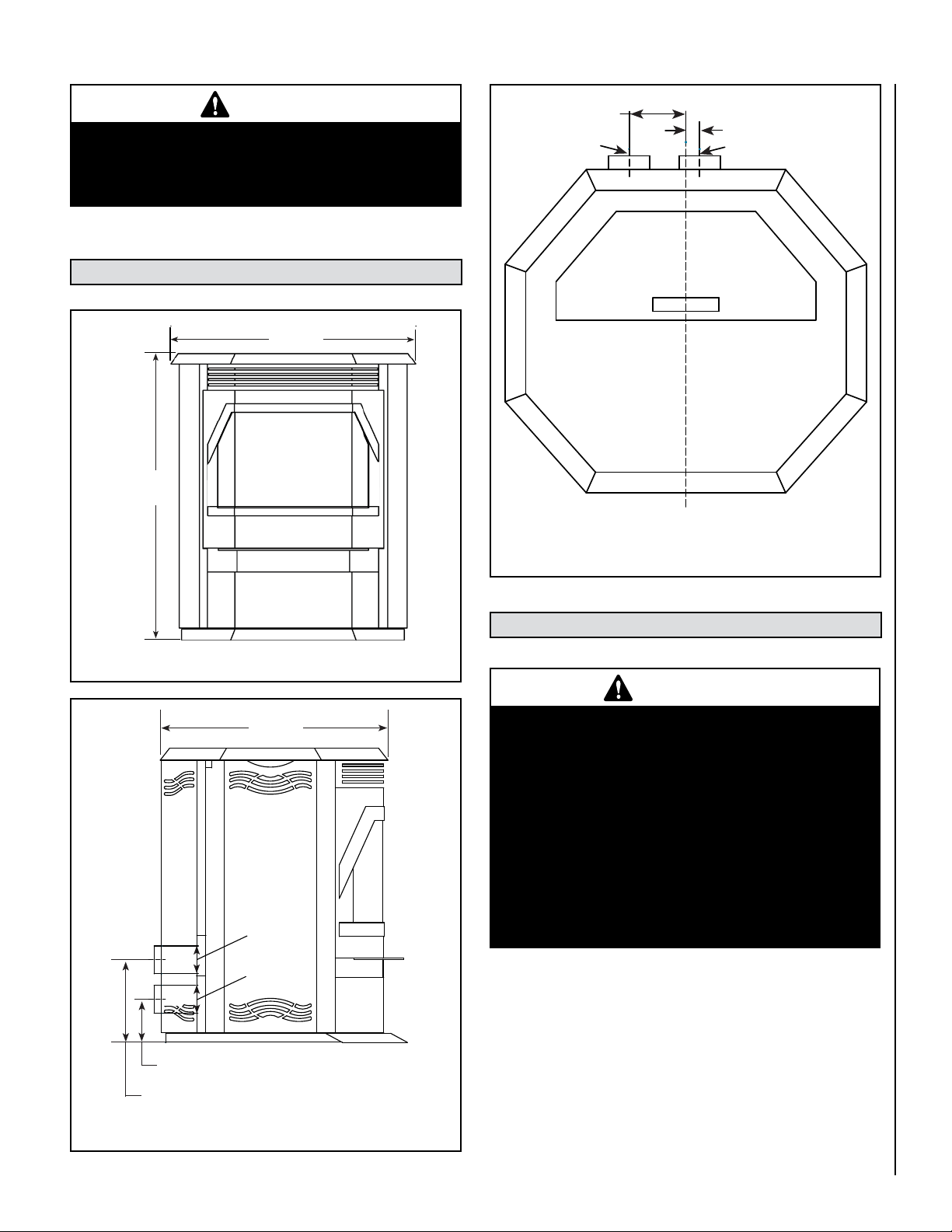

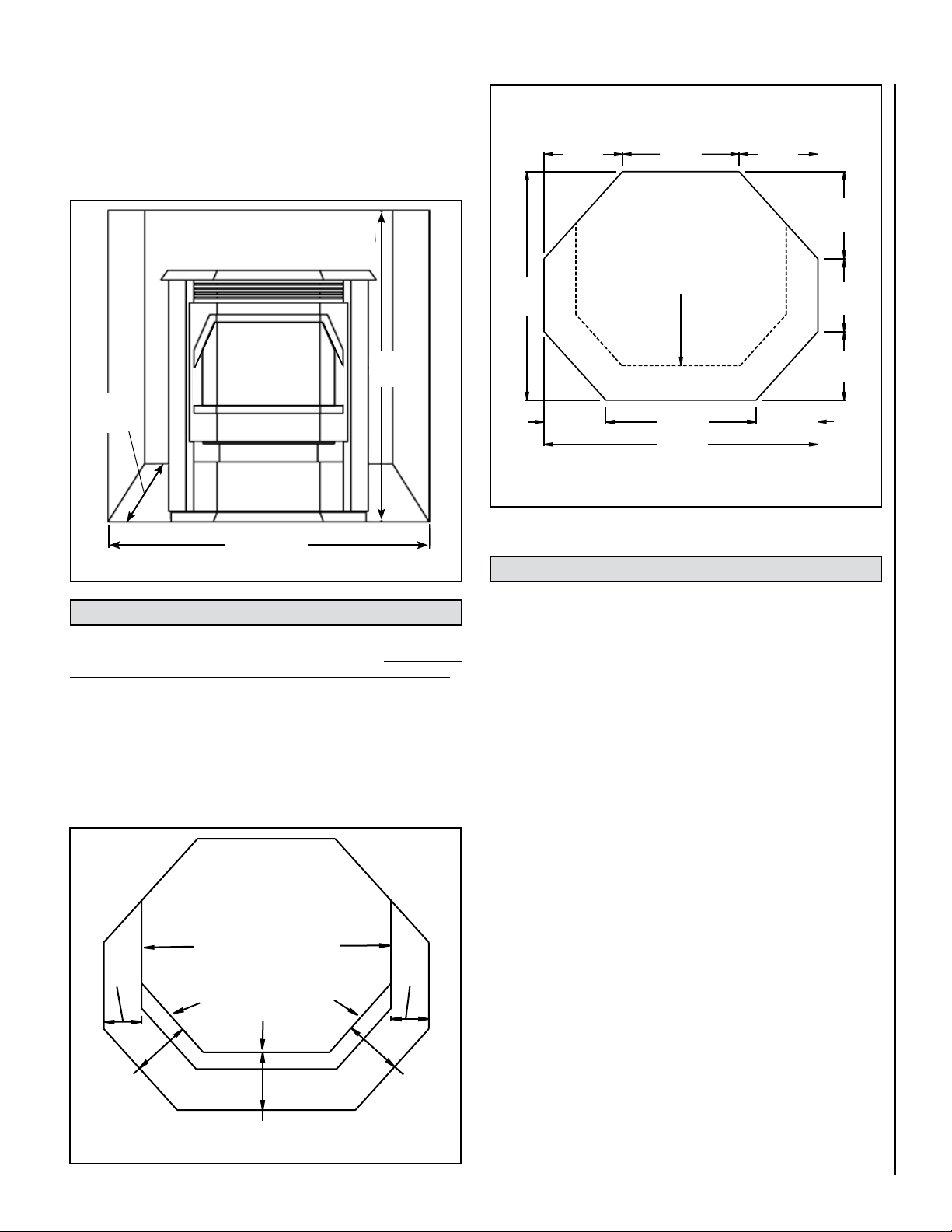

5. The minimum clearances must be maintained for all combus-

tible surfacesand materialsincluding; furniture,carpet, drapes,

clothing, wood, papers, etc. Do not store combustibles within

this clearance space (see Clearances on Pages 8 and 9).

6. INSTALLATION DISCLAIMER - It is imperative that the exhaust

venting system be installed correctly and sealed gas-tight

(not allowing exhaust to leak). Follow the vent manufacturer's

instructions for proper installation. Since IHP has no control

over the installation of your stove, IHP grants no warranty,

implied or stated for the installation or maintenance of your

stove and assumes no responsibility for any consequential

damage(s).

7. Burning any kind of fuel consumes oxygen. If outside air is

not ducted to the appliance, ensure that there is an adequate

source of fresh air available to the room where the appliance

is installed.

8. The appliance will not operate using natural draft, nor without

a power source for the blower and fuel feeding systems.

9. Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or “freshen

up” a fire in this heater. Keep all such liquids well away from

the heater while it is in use.

10.The authority having jurisdiction such as municipal build-

ing department, fire department, fire prevention bureau, etc

should be consulted before installation to determine the need

to obtain a permit.

11.APPROVED FUEL: This appliance is designed specifically

for use only with pelletized wood pellets or a mixture of up

to 50% corn mixed with a minimum of 50% pelletized wood

pellets. This mixture of wood pellets and corn should be

evenly pre-mixed before being placed in the units hopper.

This appliance is designed and approved for the burning of

wood residue pellets with up to 2% ash content. This appli-

ance is NOT approved to burn cardboard, nut hulls, cherry

pits, etc. regardless if it is in pellet form. Failure to comply

with this restriction will void all warranties and the safety

listing of the stove. Consult with your IHP dealer for more

information on approved pellet fuels.

12.These appliances are designed as supplemental heaters.

Therefore, it is advisable to have an alternate heat source

when installed in a dwelling.

13.CONTINUOUS OPERATION: When operated correctly, this

appliance cannot be overfired. Continuous operation at a

maximum burn can, however, shorten the life of the electri-

cal components (blowers, motors and electronic controls)

and is not recommended. Typical approved operation would

include running at the low tomid range setting with occasional

running on the maximum setting during the coldest periods

of the winter. DO NOT OVER-FIRE THIS STOVE. Follow all

instructions regarding the proper use of this stove.

14.CAUTION: NEVER PUT FINGERSNEAR AUGER. This appliance

is equipped with a hopper lid switch, which is designed to stop

the auger when the hopper lid is opened. NEVER DISCONNECT

OR BYPASS THIS SWITCH FOR ANY REASON. Pellet fuel is fed

to the Burn-Pot by a screw auger. This auger is driven by a

high torque motor. The auger is capable of causing serious

harm to fingers. Keep pellets in the hopper at all times and

keep fingers away from auger. The auger can start and stop

automatically at any time while the stove is running.

15.CAUTION:HOTWHILE INOPERATION. Anappliance hotenough

to warm your home can severely burn anyone touching it.

Keep children, pets, clothing and furniture away. Contact may

cause skin burns. Do not let children touch the appliance.

Train them to stay a safe distance from the appliance.

16.FLY ASH BUILD-UP: For all wood pellet fuel-burning heaters,

the combustion gases will contain small particles of fly-ash.

This will vary due to the ash content of the fuel being burned.

Over time, the fly-ash will collect in the exhaust venting

system and restrict the flow of the flue gases. The exhaust

venting system should be inspected regularly and cleaned

as necessary.

17.SOOT FORMATION: Incomplete combustion, such as occurs

during startup, shutdown, or incorrect operation of the room

heater will lead to some soot formation which will collect in

the exhaust venting system. A precautionary inspection on

a regular basis is advisable to determine the necessity of

cleaning. The exhaust venting system should be inspected

regularly and cleaned as necessary.

18.DISPOSAL OF ASHES: Ashes should be placed in a steel

container with a tight fitting lid and moved outdoors imme-

diately. The closed container of ashes should be placed on

a noncombustible floor or on the ground, well away from

all combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container

until all cinders have been thoroughly cooled.

19.The instructions must be strictly adhered to. Do not use

makeshift methods or compromise in the installation.

20.Do not abuse the door glass by striking, slamming or similar

trauma. Do not operate the stove with the glass removed,

cracked or broken.

21.SAVE THESE INSTRUCTIONS.

22.See the listing label on the appliance.