Page 7 of 19

and grounded in accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PROVIDED PLUG. If it will not fit the receptacle, have the proper

receptacle installed by a qualified electrician.

CHECK with a qualified electrician or service person if you do not completely understand the

grounding instructions, or if you are not sure the tool is properly grounded.

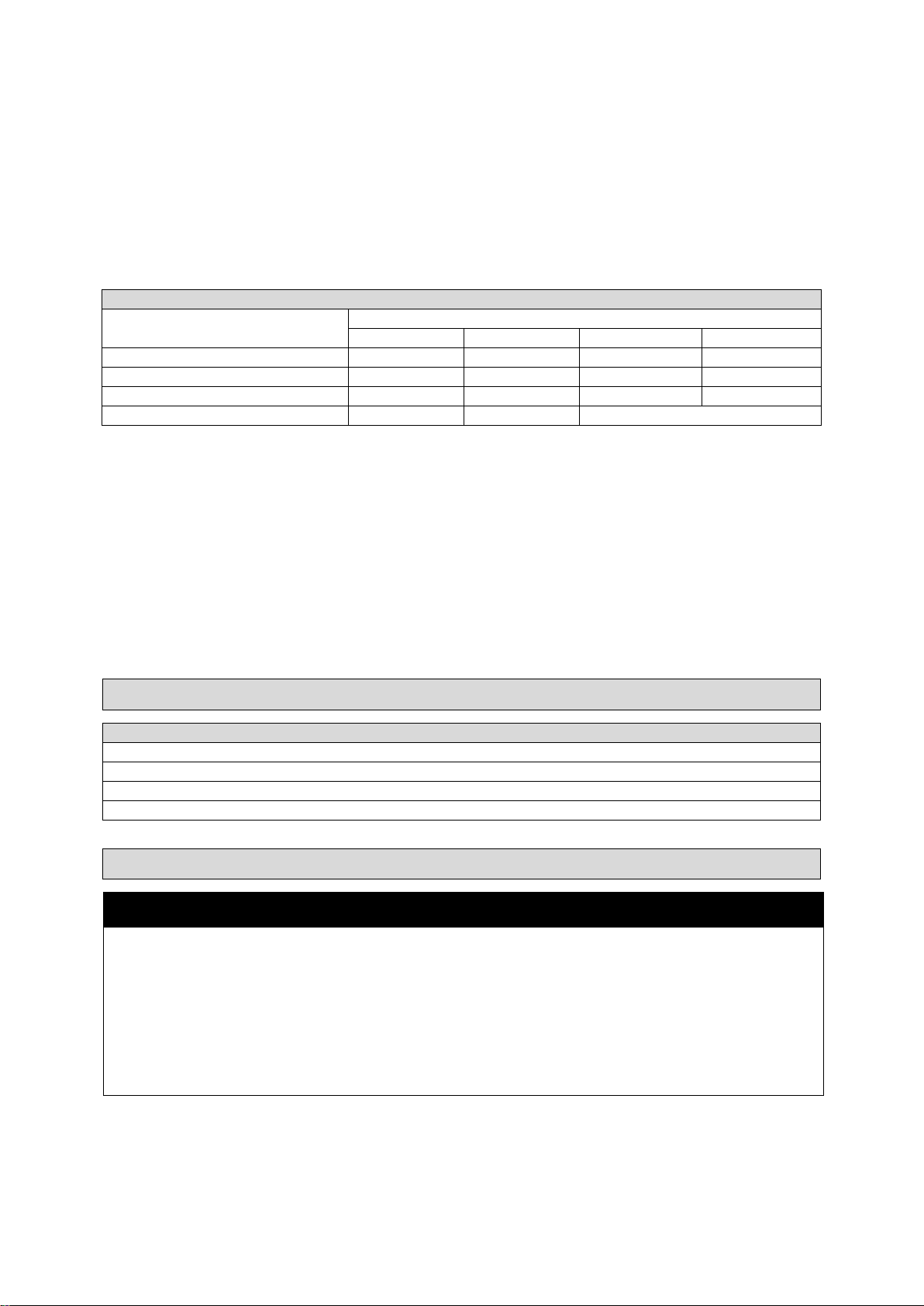

Grounded Tools: Tools with 3-Prong Plugs

Tools marked with Grounding Required have a 3-wire cord and 3-prong grounding plug. The plug

must be connected to a properly grounded outlet. If the tool should electrically malfunction or break

down, grounding provides a low resistance path to carry electricity away from the user, reducing the

risk of electric shock. (See Figure A.)

The grounding prong in the plug is connected through the green wire inside the cord to the grounding

system in the tool. The green wire in the cord must be the only wire connected to the tool’s grounding

system and must never be attached to an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed and grounded in accordance

with all codes and ordinances. The plug and outlet should look like those in the following illustration.

Double Insulated Tools: Tools with Two-Prong Plugs

Tools marked Double Insulated do not require grounding. They have a special double insulation

system which satisfies OSHA requirements and complies with the applicable standards of

Underwriters Laboratories, Inc., the Canadian Standard Association, and the National Electrical Code.

(See Figure B.)

Double insulated tools may be used in either of the 120 volt outlets shown in the following illustration.

Extension Cords

USE A PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage, resulting in loss of power and cause

overheating.

Be sure your extension cord is properly wired and in good condition. Always replace a damaged

extension cord or have it repaired by a qualified person before using it. Protect your extension

cords from sharp objects, excessive heat and damp or wet areas.