GB

3

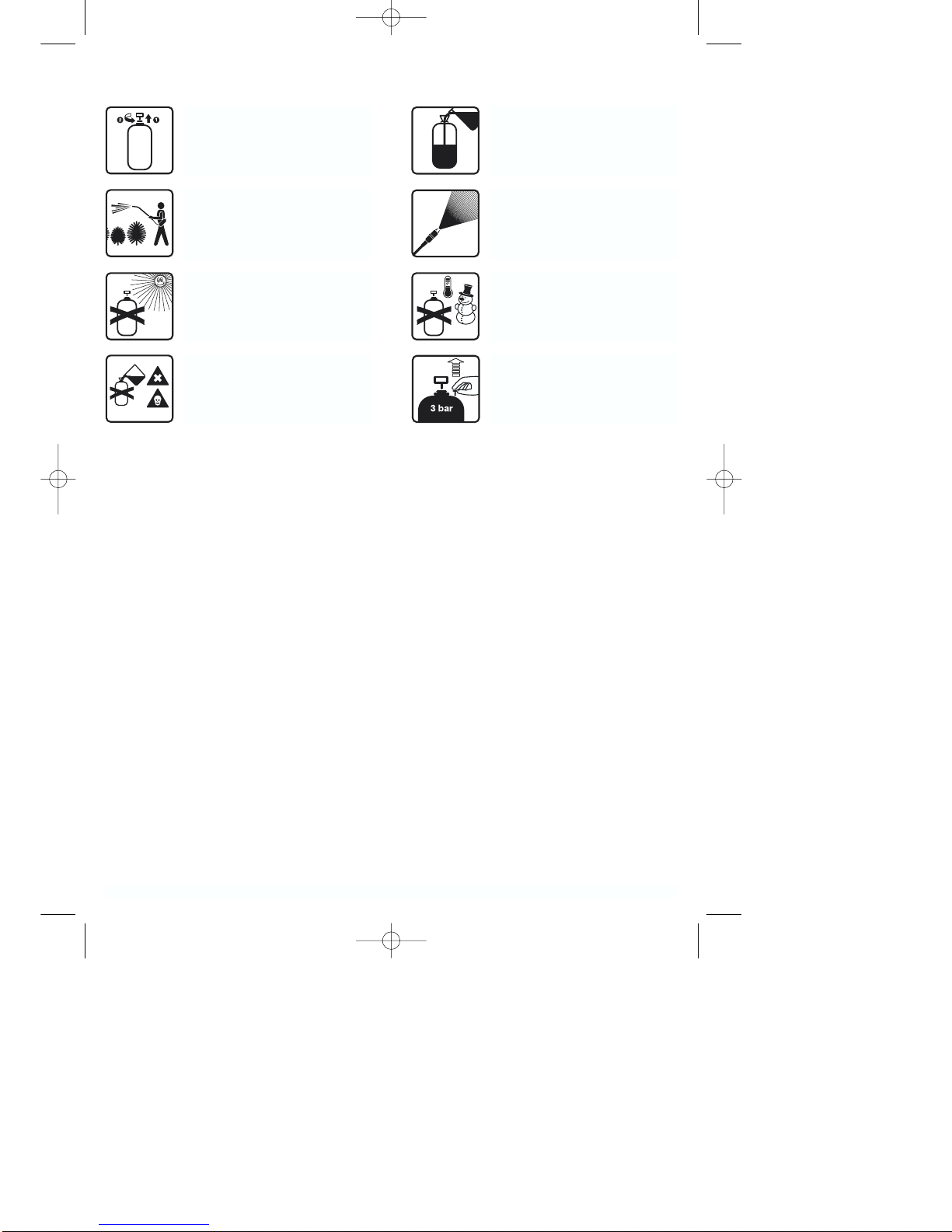

Safety regulations:

Please read these directions for use carefully

and observe the information provided. It is impor-

tant to consult these instructions in order to

acquaint yourself with the unit, its proper use and

safety regulations.

Suitable measures must be taken to keep the

unit out of children’s reach.

The pressure sprayer is designed for spraying

common home and garden solutions. This is pri-

marily meant to include pesticides, weed killers

and liquid fertilizers.

The pressure sprayer is not designed to spray

acidic and caustic liquids. Nor should it be used

to spray impregnating agents.

Only use a suitable nozzle wire or cleaning agent

to clean clogged nozzles.

Do not spray contents of sprayer on persons or

animals.

Always wear protective clothing when spraying

pesticides and insecticides.

Ensure that liquid sprays are not heated beyond

the permitted operating temperature of 40 °C.

When mixing and working with spray solutions,

always follow the manufacturer’s instructions.

Each time the spraying unit has not been used

for an extended period of time it should be

checked for possible damage prior to reusing it.

Immediately replace defective parts.

Use only original replacement parts.

Do not leave the unit (filled or empty) in direct

sunlight.

Before placing the unit in winter storage,

thoroughly clean and dry it out so that it is not

damaged by freezing temperatures.

We will not be liable for any damage that results

from improper repairs and/or improper handling

of the unit (e.g. using the unit in ways for which it

was not intended).

Opening the unit or performing maintenance

work on it is only permitted when the tank is

depressurized.

To relieve the pressure, pull up the funnel-sha-

ped knob connected to the safety valve.

Only use currently approved pesticides.

Please observe COSHH Material Safety Data

Sheets.

Pesticides include - but are not limited to - herbi-

cides, insecticides, fungicides and growth regula-

tors as well as materials that are intended to be

used in conjunction with these agents in order to

modify their properties or effects.

Each time after using the unit and prior to perfor-

ming any maintenance work on the unit, always

relieve the pressure via the overpressure valve

by raising the overpressure valve.

Technical data

Max. filling capacity 5 l

Total filling capacity 7 l

Volumetric flow rate, Vmax = 1.07 litres/min.

Permissible operating pressure 3 bar

Permissible operating temperature + 40°C

Safety valve / vent valve 1

Nozzle hollow cone 1 mm

Nozzle spraying angle max. 60°

Repulsion angle at the nozzle less than 5N

Assembly

Screw the spray tube (Fig. 1/Item 1) to the pistol

grip (Fig. 1/Item 2)).

Do not unscrew the overpressure valve ( Fig.

3/Item 6)!

Check to ensure that the screw connections for

the hose at the spray gun handle and on the tank

are tight!

Starting up and venting

Unscrew the feed funnel from the bottom of the

pressure sprayer (Fig. 2/Item 5).

Before you screw out the pump, raise the over-

pressure valve (Figure 3/Item 6) and let off any

overpressure that may be in the unit.

Press down the pump handle as far it will go and

slowly unscrew the pump (counter-clockwise).

Screw the feed funnel onto the tank (Fig. 3/Item

5).

Fill the container up to no further than the 5 liter

mark with the preparation you want to spray.

Follow the instructions issued by the producer of

the preparation you are using.

Remove the feed funnel from the tank.

Insert the pump, press down the pump handle as

far it will go and screw in the pump (clockwise)

until it is tight again. The pump handle latches

simultaneously into the bayonet lock.