ii www.teejet.com

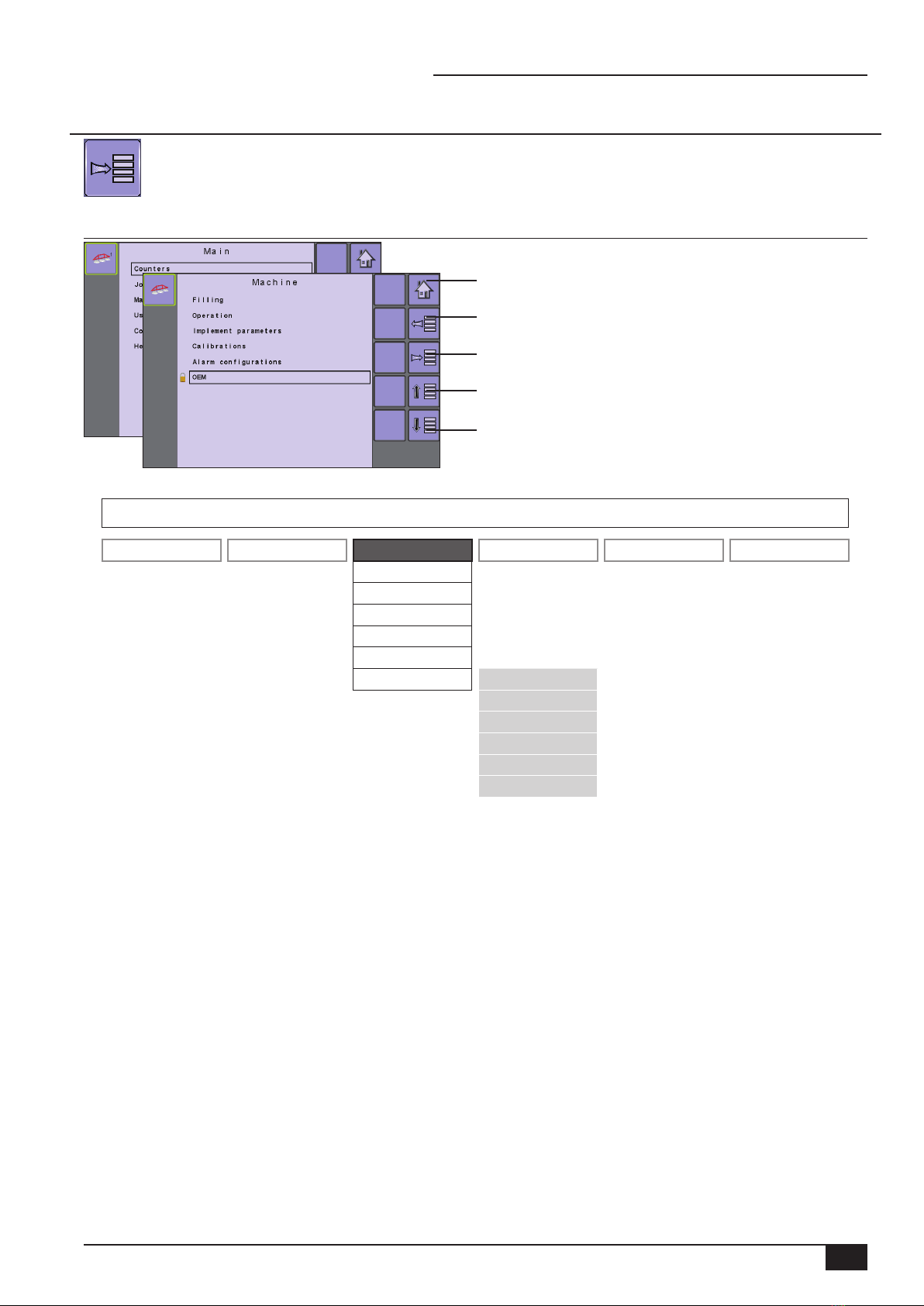

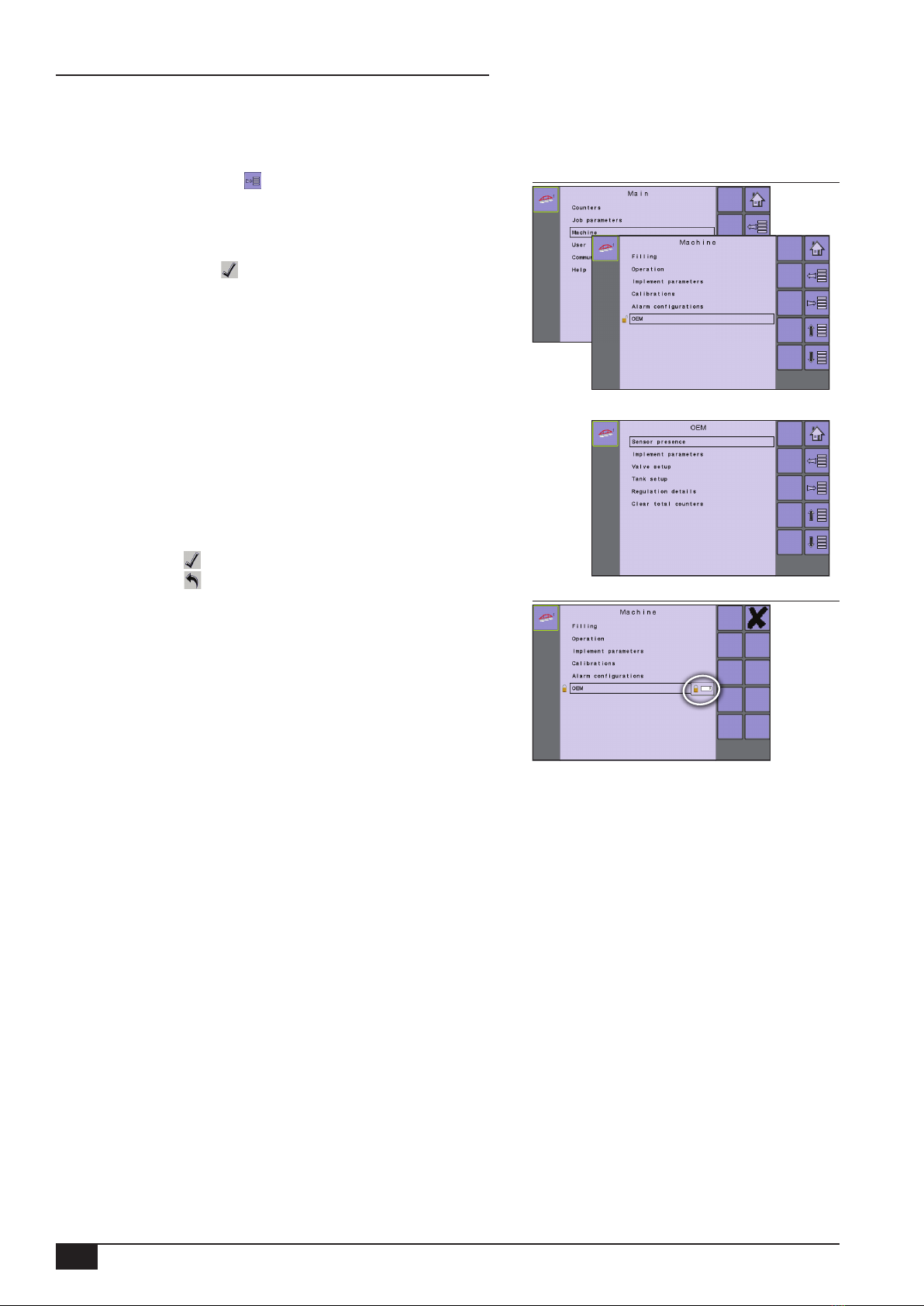

IC18 Sprayer/NH3 OEM options

Table of Contents

OEM SETUP OPTIONS 1

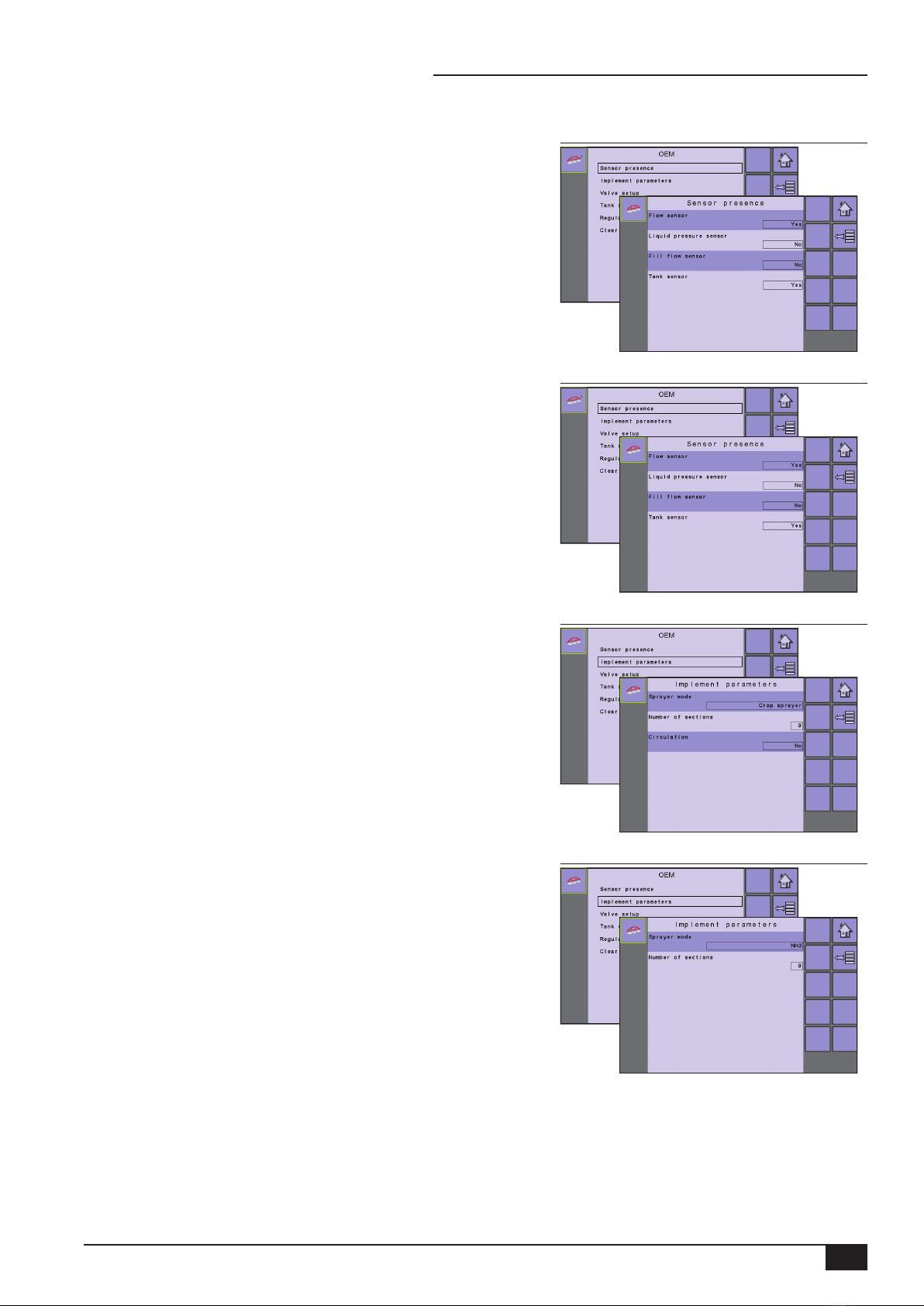

Sensor Presence ..................................................................................................................................................................................... 3

Flow Sensor...........................................................................................................................................................3

Liquid Pressure Sensor..........................................................................................................................................3

Fill Flow Sensor (Sprayer Mode) ...........................................................................................................................3

Tank Sensor (Sprayer Mode).................................................................................................................................3

Implement Parameters........................................................................................................................................................................ 3

Sprayer Mode ........................................................................................................................................................3

Number of Sections ...............................................................................................................................................3

Circulation (Sprayer Mode)....................................................................................................................................3

Valve Setup .............................................................................................................................................................................................. 4

Regulation Valve Type ...........................................................................................................................................4

Section Valve Behavior..........................................................................................................................................4

Section Valve Type (Sprayer Mode).......................................................................................................................4

Tank Setup................................................................................................................................................................................................ 4

Maximum Content..................................................................................................................................................4

Minimum Content...................................................................................................................................................4

Auto Filling (Sprayer Mode) ...................................................................................................................................4

Auto Filling Offset (Sprayer Mode).........................................................................................................................4

Regulation Details ................................................................................................................................................................................. 5

Minimum Regulation Pressure...............................................................................................................................5

Maximum Regulation Pressure..............................................................................................................................5

Regulation Valve Time ...........................................................................................................................................5

Minimum Regulation Voltage .................................................................................................................................5

Regulation Dead Band...........................................................................................................................................5

Regulation Backlash ..............................................................................................................................................5

Anticipation Factor .................................................................................................................................................5

Default Valve Position............................................................................................................................................5

Regulation Valve Capacity.....................................................................................................................................5

Regulation Start Delay...........................................................................................................................................6

Minimum Speed.....................................................................................................................................................6

Manual Regulation Speed......................................................................................................................................6

Restrictor Plate Flow (Sprayer Mode)....................................................................................................................6

Clear Total Counters.............................................................................................................................................................................. 6

Area .......................................................................................................................................................................6

Volume...................................................................................................................................................................6

Time .......................................................................................................................................................................6

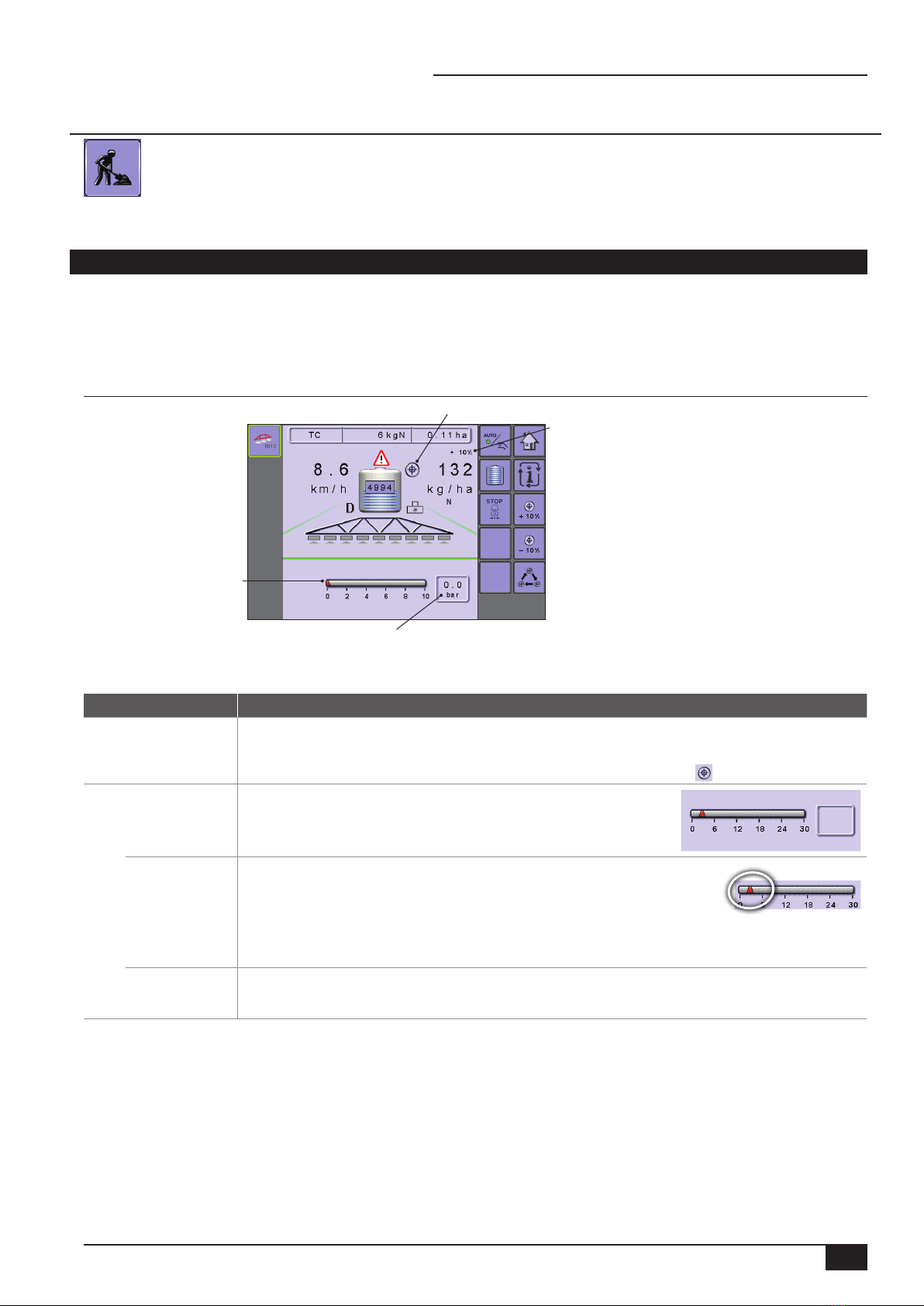

CHANGES ON OPERATION SCREEN 7

LIQUID PRESSURE SENSOR ACTIVATED (NH3 MODE) 7

Operation Mode Overview ................................................................................................................................................................ 7

Section and Icon Descriptions .........................................................................................................................................7

Application Rate Options.................................................................................................................................................................... 8

Target Rate Percentage Increase/Decrease....................................................................................................................8

Target Rate ......................................................................................................................................................................8

With Switchbox ......................................................................................................................................................8

Without Switchbox .................................................................................................................................................8