Isotherm SP Installation instructions

General

Isotherm SP is a sea water cooled refrigeration system for

sailing yachts and power boats. This unique system means

reduced power consumption and noise level. It has no fan

or pump. The sea water cooled skin fitting/heat exchanger

replaces the air cooled condenser and cooling fan. The

heat is transferred directly to the surrounding water instead

of being circulated as hot air inside the boat.

Description

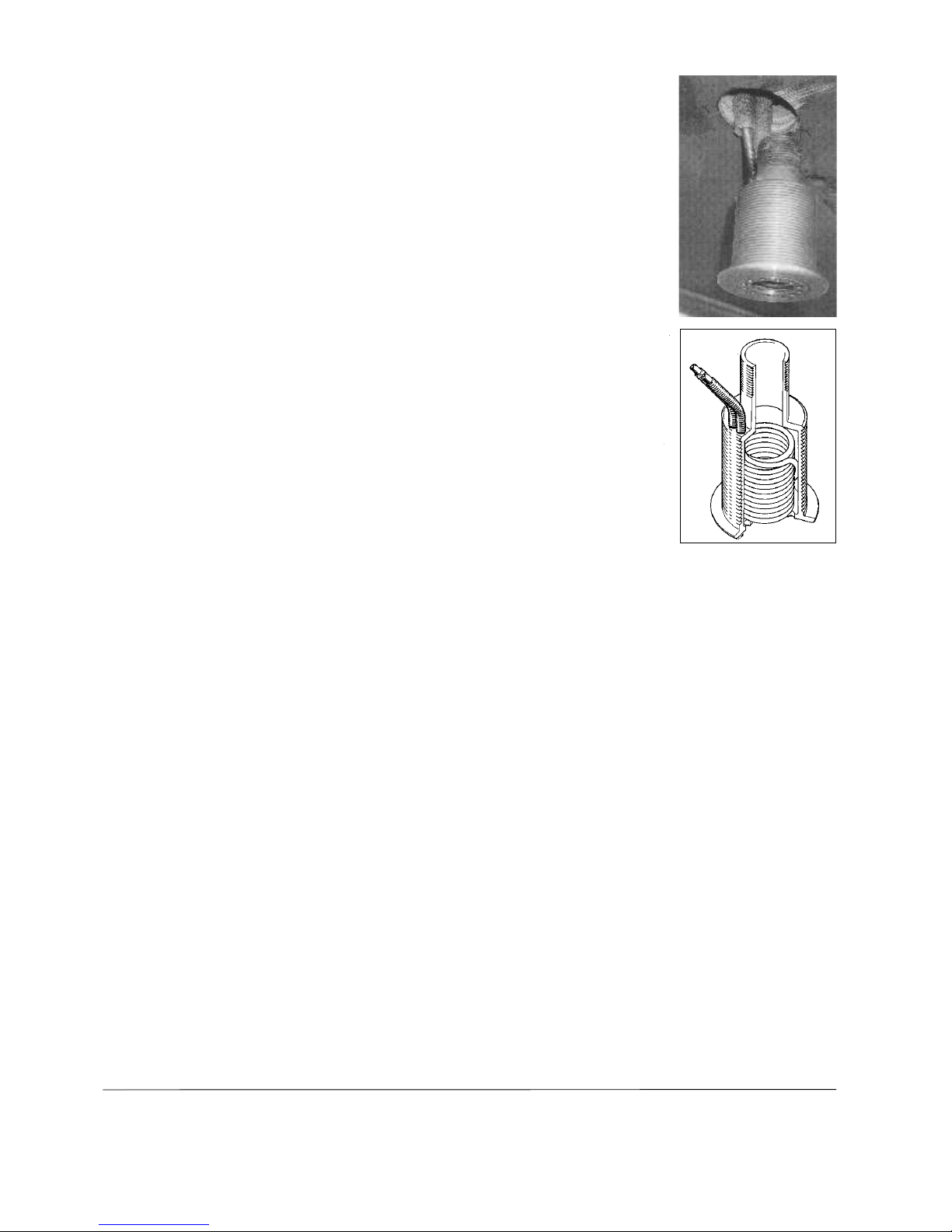

The special skin fitting with its integrated condenser/heat

exchanger is mounted in the hull and is made of salt water

resistant brass with the heat exchanger coil in copper-nickel

alloy and replaces the existing skin fitting for the sink drainage.

The connection pipes to the compressor have a length of 1

meter and are equipped with quick couplings. The couplings

can be opened and closed without loss of refrigerant. A filter

dryer is mounted approx. 20 cm (7¾”) above the skin fitting

on the return pipe. A 1¼” ball valve should be mounted on

the skin fitting.

Important! The hose between the sink and the ball valve shall be a minimum

of ø 38 mm (1½”). The skin fitting is normally kept clean due to the constant

movement of the water and lack of sunlight. During sailing or motoring the

water will flash the fitting and the heat exchanger coil rapidly, which will keep

it clean from marine growth. The skin fitting shall be equipped with the zinc

anode on the outside and which is included in the delivery.

Operation

Always keep the ball valve open to ensure a satisfactory function.

If the ball valve is closed and the boat is in harbour, the fridge will operate at

a reduced cooling level.

During sailing or motoring the fridge will operate better but not to its full

potential with a closed valve. When the boat is on shore, the fridge system

will operate at a reduced level, in this case the ball valve must be kept open

to allow air ventilation through the hose and the sink.

Maintenance

When necessary clean the through hull fitting, do not use sharp or hard tools, a brush will be enough. In a tropical

environment, cleaning of the fitting has to be made more often. If necessary, the threaded bottom entrance

washer can be removed for better access to the heat exchanger coil.

Corrosion: Galvanic corrosion can often take place on board when the boat is surrounded by salt water and

should be carefully checked. This type of corrosion takes place depending on various electrical potential between

different devices. When two different metals are placed under water and connected to each other, electricity will

start to run. To prevent metal damages on parts under water, sacrificed anodes made of zinc are installed. Zinc is

a less noble metal compared to other materials used and will therefore be sacrificed.

All Isotherm refrigeration units have the plus and minus power supply separated from all chassis parts. Isotherm

SP has a skin fitting in direct contact with the sea water and has as standard a zinz anode. The brass in the fitting

is dezincification and salt water resistant as well as the Cu/Ni condenser pipes and the soldering silver. The zinc

anode on the fitting shall be inspected regularly and replaced as soon as half or more of the zinc is used.

Zinc anode part no: SBE00006AA

Pleas note! Important, use only original screws for the zinc anode.

If it is affected to a high degree and not lasting more than one season or part of a season, the electrical system

on board must be carefully checked to find the reason for the galvanic or stray-current corrosion.

Make sure that the refrigeration system is connected to the electrical system in such a way, it cannot be

connected to the shore grounding when shore power is connected.

It is strongly recommended to use an insulation transformer in the shore power system, to always be sure, boat

and shore grounding is separated.

When the boat is equipped with a central bonding system, the SP skin fitting shall be connected to this with a 6

mm² copper cable. On the skin fitting, there is a M5 hole for this purpose.