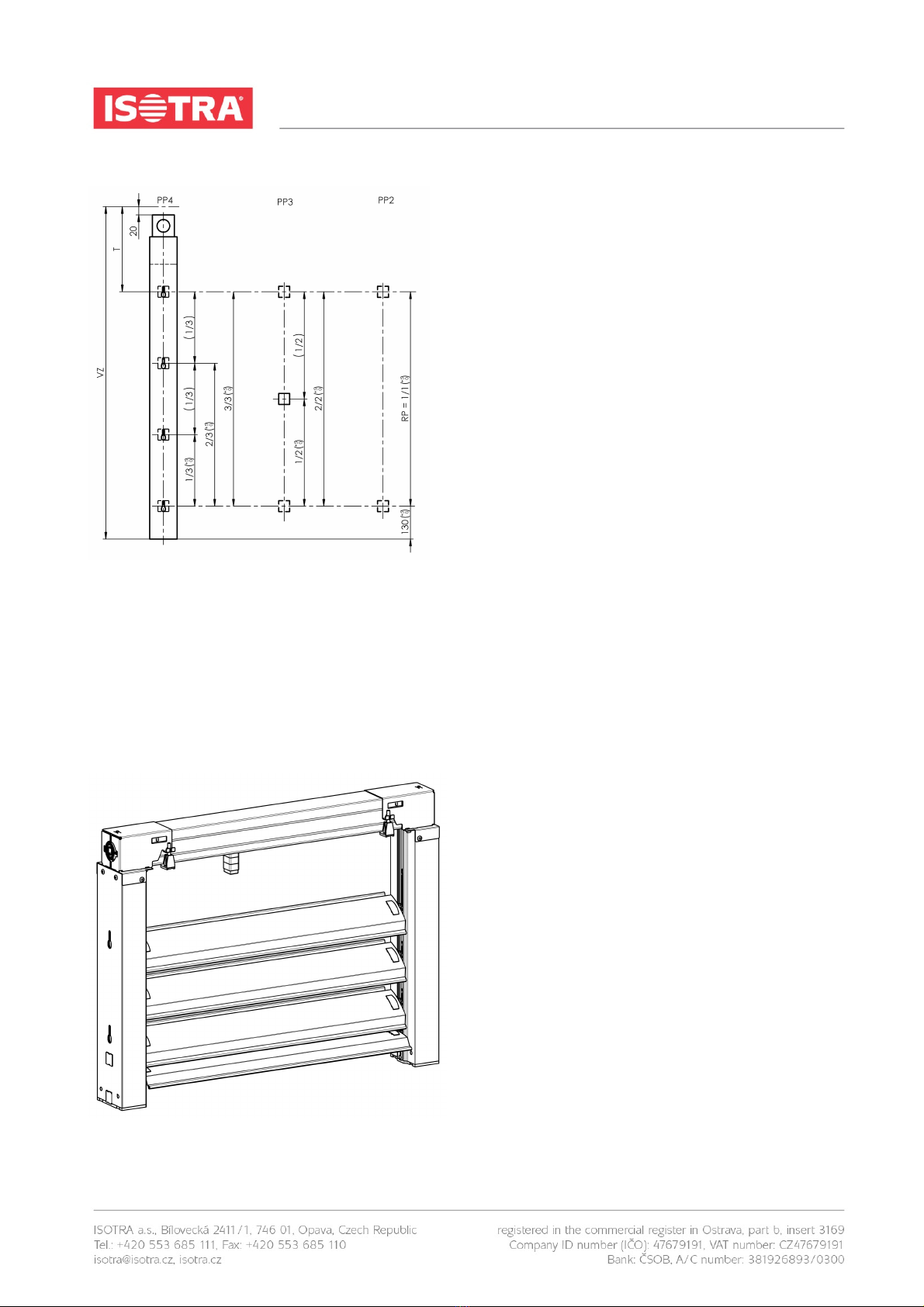

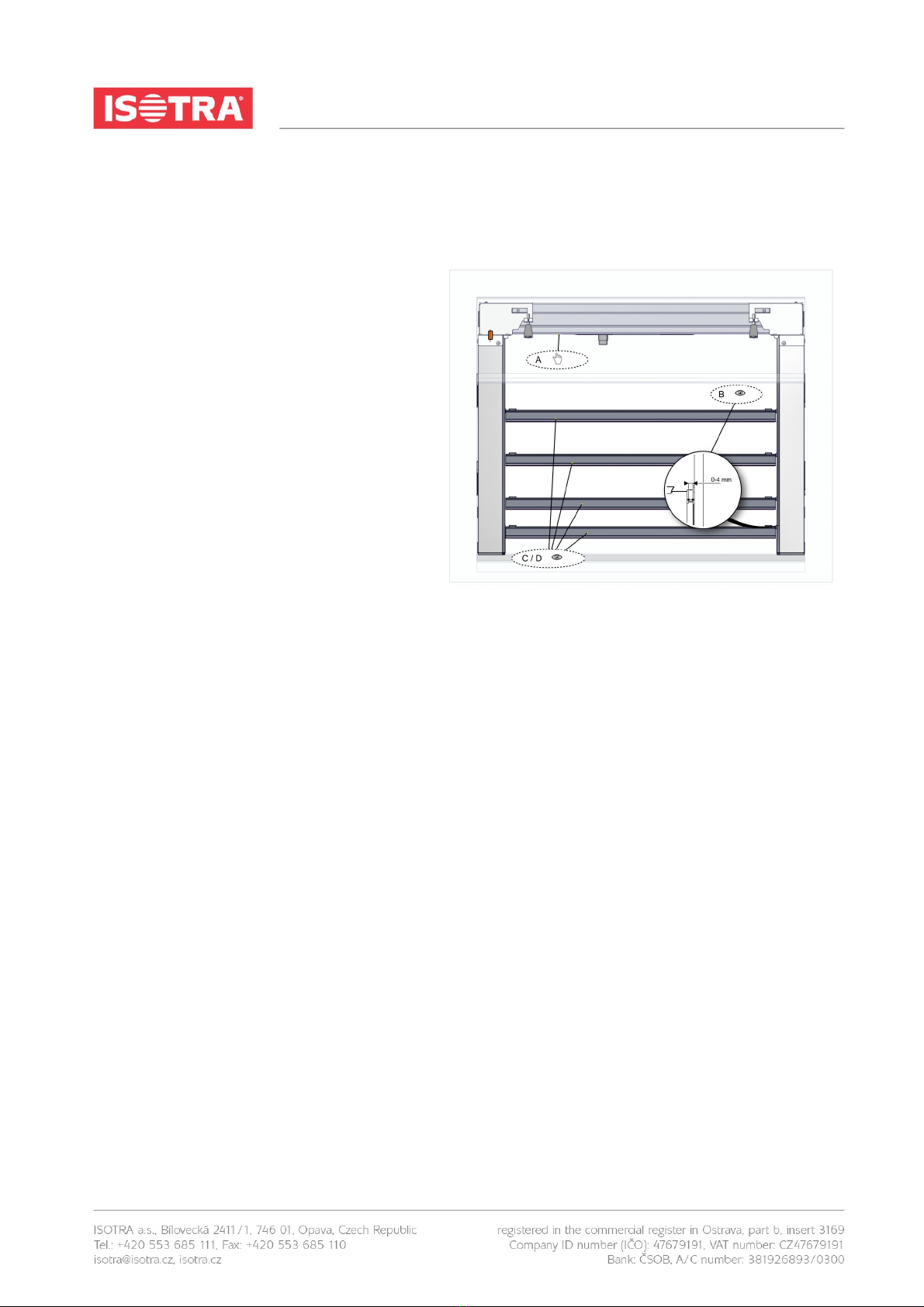

2.5.1. Guiding rails assembly

A – Level the rail into lining.

B – Minimal distance between guiding rail axis and the obstacle is 65mm.

C – Mind the difference between left and right guiding rail, place them correctly.

D – Make marks through the assembly holes for using suitable fixing elements.

E – Screw and insert fixing elements.

2.5.2. Guiding rails attachment

A – Check that you have not misplaced right and left rail.

B – Screw the screws through the guiding rail.

C – Before tightening put the distance pad on the screw between lining

and the rail.

D – Tighten the screws and check the level of rails again.

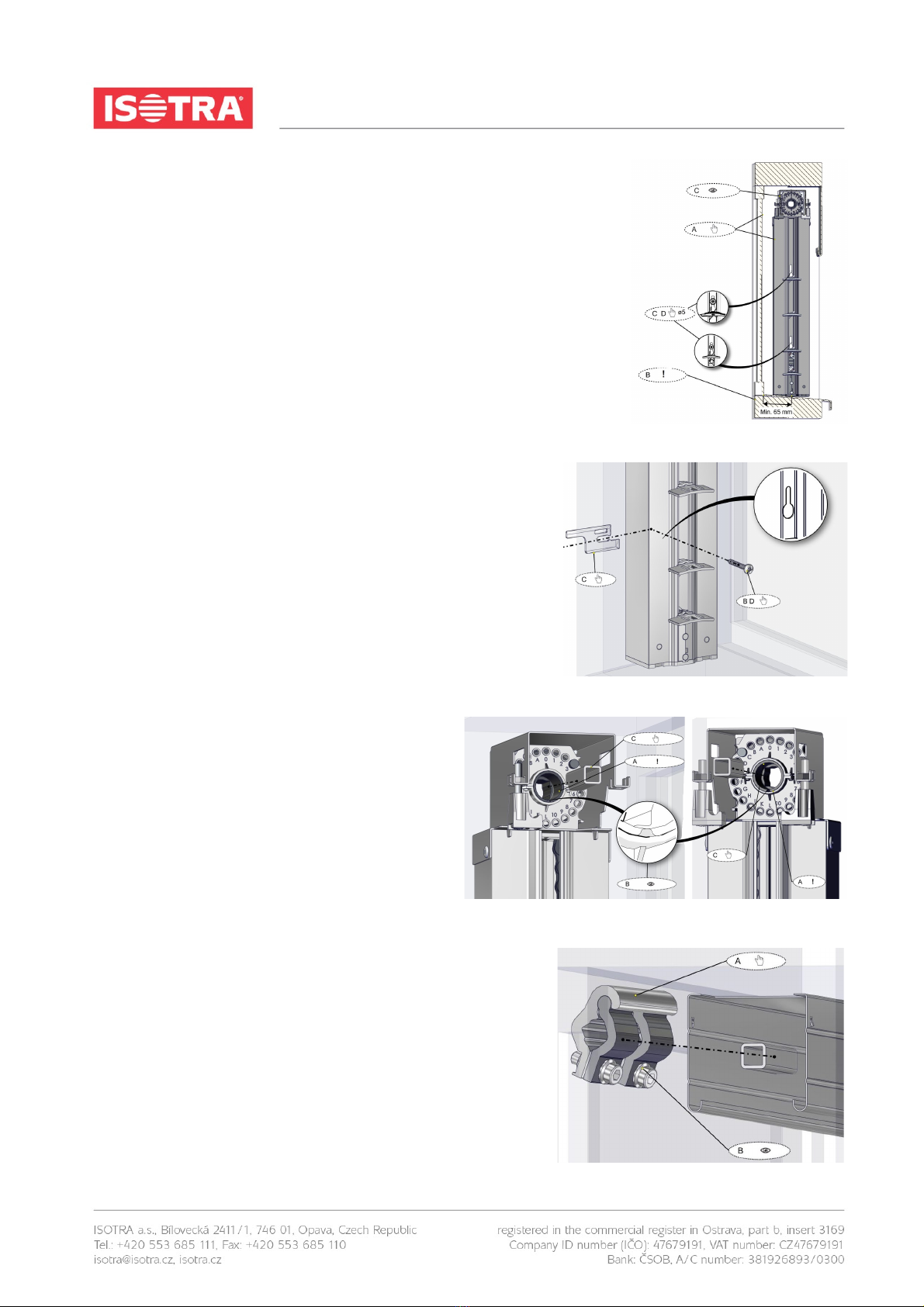

2.5.3. Check the bearing position

A – Do not turn the bearing in any case. Default setting

can be lost.

B – Ensure that bearing marking are facing down on

both guiding rails.

C – Insert short connection shafts into the bearings.

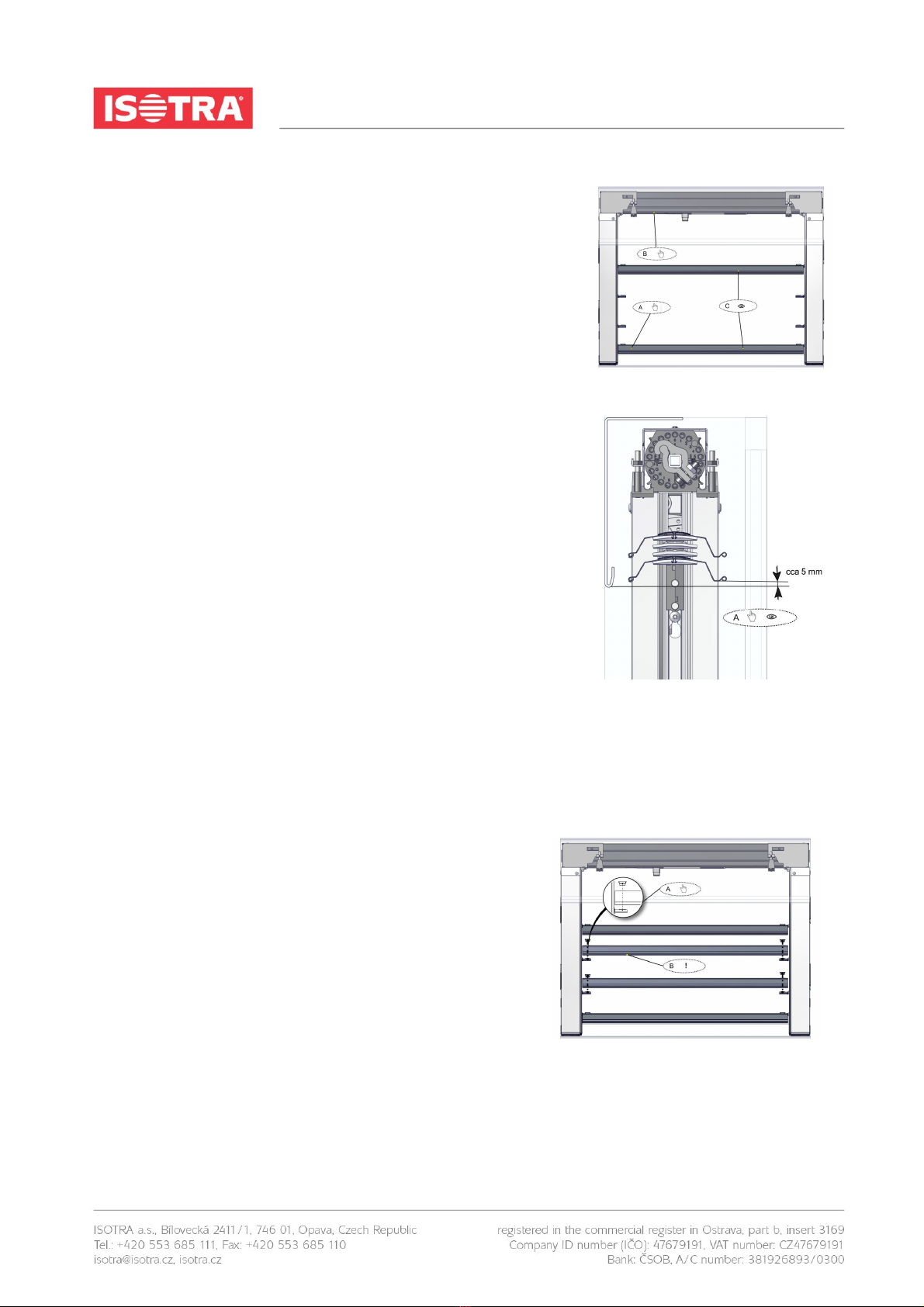

2.5.4. Head-rail with engine - preparation

A – Slide the connectors onto four-square shaft into the head-rail. One

from the left and one from the right side.

B – Screw heads are facing always down.