0A–1

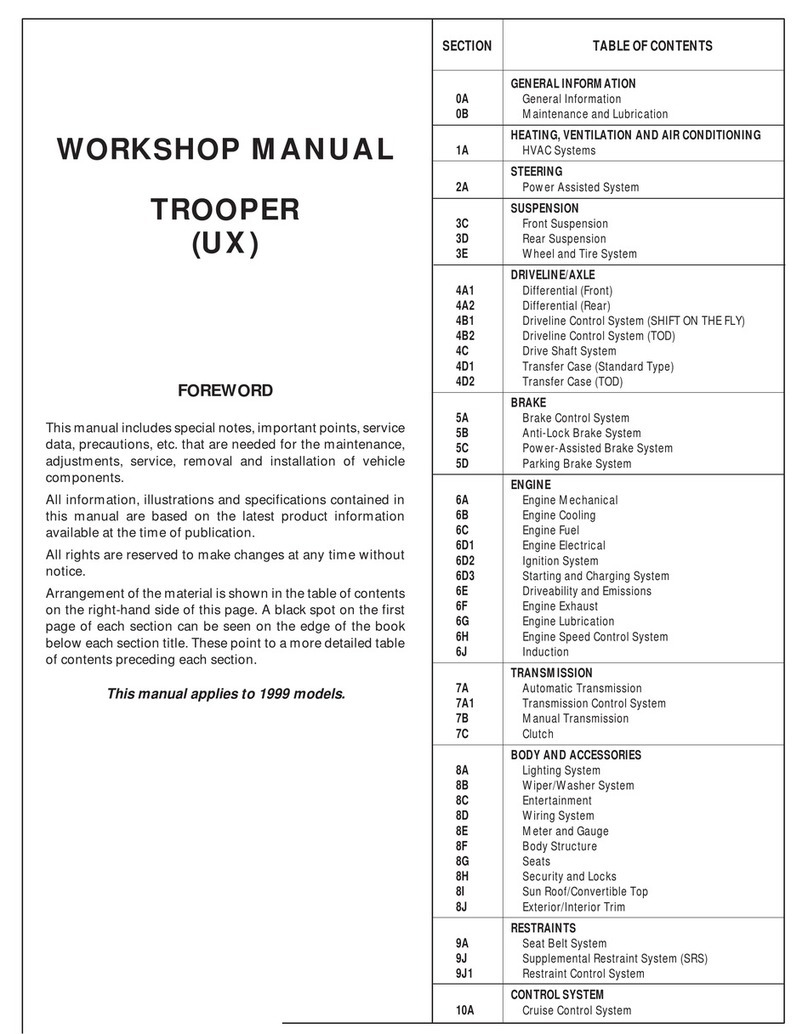

GENERAL INFORMATION

TROOPER GENERAL INFORMATION

CONTENTS

General Information 0A. . . . . . . . . . . . . . . . . . . . .

Maintenance and Lubrication 0B. . . . . . . . . . . . .

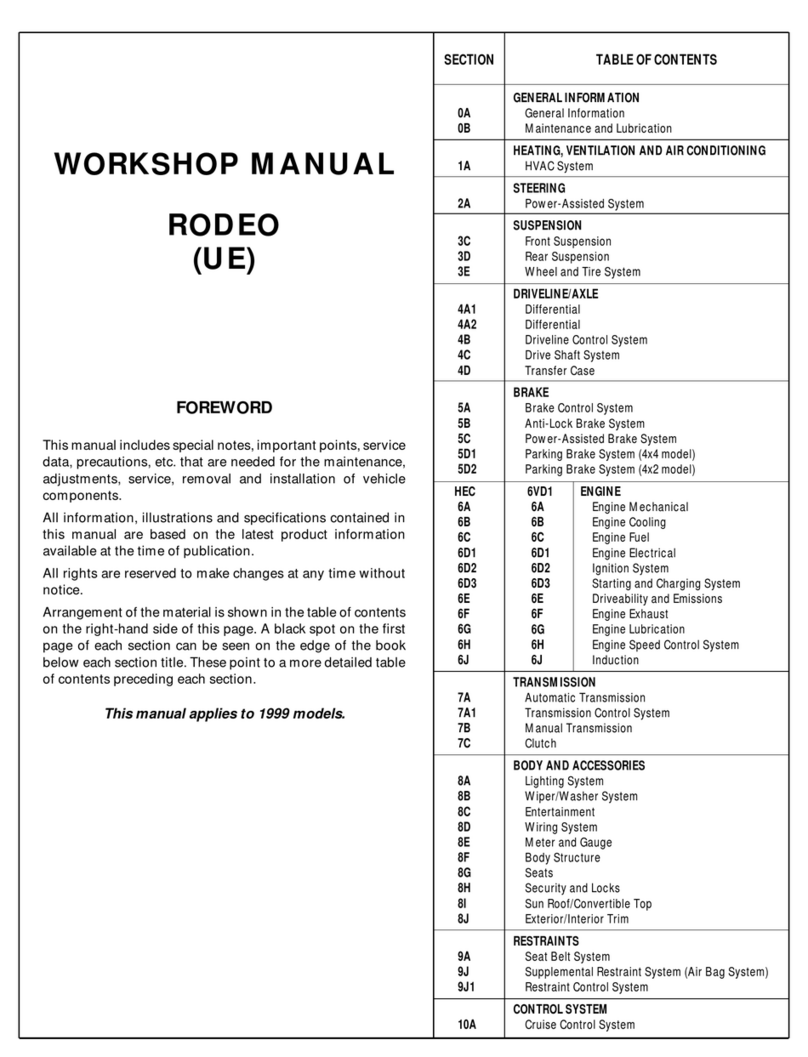

GENERAL INFORMATION

CONTENTS

General Repair Instruction 0A–1. . . . . . . . . . . . . . . .

Illustration Arrows 0A–2. . . . . . . . . . . . . . . . . . . . . . .

Identification 0A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theft Prevention Standard 0A–5. . . . . . . . . . . . . . . .

Lifting Instructions 0A–10. . . . . . . . . . . . . . . . . . . . . . .

Standard Bolts Torque Specifications 0A–13. . . . . .

Abbreviations Charts 0A–14. . . . . . . . . . . . . . . . . . . .

Service Parts Identification Plate 0A–15. . . . . . . . . .

General Repair Instruction

1.If a floor jack is used, the following precautions are

recommended.

Park vehicle on level ground, “block” front or rear

wheels, set jack against the recommended lifting

points (see “Lifting Instructions” in this section), raise

vehicle and support with chassis stands and then

perform the service operations.

2.Before performing service operations, disconnect

groundcablefrom thebatterytoreducethechanceof

cable damage and burning due to short circuiting.

3.Use a cover on body, seats and floor to protect them

against damage and contamination.

4.Brake fluid and anti–freeze solution must be handled

with reasonable care, as they can cause paint

damage.

5.The use of proper tools and recommended essential

and available tools, where specified, is important for

efficient and reliable performance of service repairs.

6.Use genuine Isuzu parts.

7.Used cotter pins, plastic clips, gaskets, O–rings, oil

seals, lock washers and self–locking nuts should be

discarded and new ones should be installed, as

normal function of the parts cannot be maintained if

these parts are reused.

8.To facilitate proper and smooth reassembly

operation,keepdisassembledpartsneatlyingroups.

Keeping fixing bolts and nuts separate is very

important, as they vary in hardness and design

depending on position of installation.

9.Cleanthepartsbeforeinspectionorreassembly.Also

clean oil ports, etc. using compressed air, and make

certain they are free from restrictions.

10.Lubricate rotating and sliding faces of the parts with

oil or grease before installation.

11.When necessary, use a sealer on gaskets to prevent

leakage.

12.Carefully observe all specifications for bolt and nut

torques.

13.When removing or replacing parts that require

refrigerant to be discharged from the air conditioning

system, be sure to use the Vehicle Refrigerant

Recovery and Recycling Equipment (VRRRE) to

recover and recycle Refrigerant–134a.

14.When a service operation is completed, make a final

check to be sure the service has been done properly

and the problem has been corrected.

15.SUPPLEMENTAL RESTRAINT SYSTEM

The vehicle is equipped with a Supplemental

Restraint System. (SRS)—Air Bag.

This system is not to be serviced without consulting

the appropriate service information.

Consult Sections 9J1 and 9J “SRS System” if work is

tobedone onthefront of thevehiclesuch asbumper,

sheet metal, seats, wiring, steering wheel or column.

Also review SRS system information if any arc

welding is to be done on the vehicle.

The SRS system equipped vehicle can be identified

by:

1. “AIR BAG” warning light on the instrument panel.

2. A Code “J” or “K” for fifth digit of vehicle

Identification Number.