Use and Maintenance manual

4

CHAP.1 –GENERAL INFORMATION

1.1 Introduction

Thank you for having chosen our product.

This piece of equipment has been constructed with the help of the most up to date technology

available to guarantee long lasting use and maximum performance under normal working

conditions.

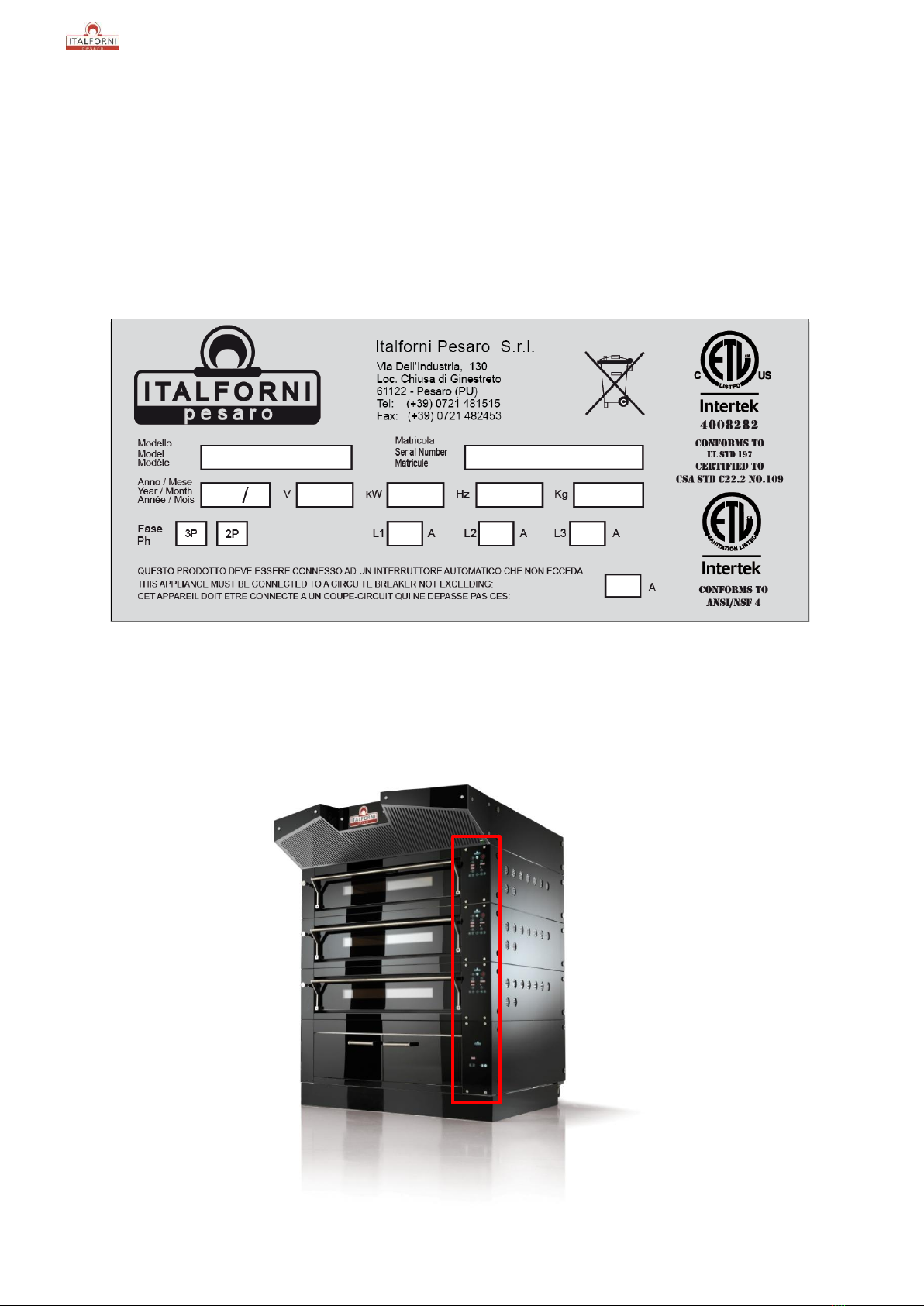

Particular care has been taken in designing the product to ensure that it conforms to ETL safety

regulations and can therefore carry the symbol.

If the recommendations set out in this manual are followed carefully, your oven will maintain

perfect operational efficiency and consequently the value of the investment made.

1.2 Aim of this manual

This manual covers the use and maintenance of electric pizza ovens of the BULL range. It is

intended as a guide for proper and safe operation together with maintenance recommendations.

Each oven comes supplied with a copy of this manual.

In order to understand how to operate the oven in the shortest possible time it is necessary to

READ THIS MANUAL CAREFULLY BEFORE INSTALLING AND OPERATING THE OVEN.

This oven has been designed for cooking foodstuffs and in particular Pizza. Use for any other

purpose is prohibited as it can be dangerous.

Efficient operation of the equipment depends largely on correct periodic maintenance; the

procedures contained in this manual are the minimum required for the oven to work safely.

Due to continual technical improvements and changing safety regulations the oven in your

possession may appear slightly different from the one described in this booklet. That will in no way

effect the validity of the information and illustrations provided.

Any eventual modifications carried out will be described in future revisions of this manual.

The way this oven has been designed makes it an efficient working tool for even the most

demanding of client applications.

WARNING! The manufacturer can accept no responsibility for damage to persons or object due to

improper use and reserves the right to take the necessary legal action in cases where

unauthorized modifications have been carried out to the equipment.

1.3 Warranty

The product is guaranteed for a period of 12 months from delivery date and is limited to the

replacement of any component malfunctions or failures due to manufacturing defects.

The guarantee does not cover any eventual failure or malfunctions caused by transportation by

third parties, installation or maintenance errors, incorrect operating procedures or modifications

carried out by unauthorized persons.

The guarantee does not cover glass, canopies, bulbs, refractive surfaces or any other elements

subject to normal wear and tear.

The guarantee will not be deemed valid if regular payment has not been effected by the purchaser

and if the product has been repaired, modified or dismantled without prior written permission

from the manufacturer.

In order to receive assistance in the quickest possible time it is recommended that a full written

description of the problem together with any other pertinent information be sent immediately to

the manufacturer.