Instructions for use and maintenance

4

CAP.1 - INTRODUCTION AND OVEN DESCRIPTION

The ITALFORNI Pesaro s.r.l. company wishes to thank you for having chosen this oven.

The tunnel ovens are part of the belt oven series, specifically designed for the automatic baking of pizza,

bread, biscuits and related products.

The baking can be carried out either directly on the refractory plan or using baking trays or moulds.

These tunnel ovens may be included in any automatic production line.

Improper use of the oven as well as any attempt at dismantling or modifying can lead to accidents and

therefore the manufacturer ITALFORNI S.r.l. declines all responsibility for any damage to persons or

property caused by such tampering. For any faults encountered, contact the nearest authorised service

centre or the manufacturer directly.

The manufacturer declines all responsibility in the following cases:

-Improper use of the oven by staff not suitably trained.

-Use not complying with the laws in force in the country of use.

-Lack of or incorrect routine maintenance.

-The use of non original spare parts.

-Total or partial failure to observe the instructions.

-Failure to send off the guarantee certificate.

The electric-gas conveyor oven Mod. TS GAS carries the CE symbol issued by an authorised agency,

entrusted with and responsible for assessing compliance with the essential requisites set out by gas

Directive 2009/142/CEE. The oven or the quality of the production system are subjected to periodic

monitoring through inspection checks in order to ensure their conformity with the type of certificate as

stated in the above Directive.

The ovens conform to product standards EN 203-1, EN 203-2 and EN 437.

The appliance in addition conforms to the following European Directives:

Low Voltage Directive 2006/95/CEE.

Electromagnetic Compatibility Directive 2004/108/CEE.

Machinery Directive 89/336/CEE.

The appliance may be sold in all European countries whose symbol appears on the Technical Data Plate. It

must be installed in accordance with the rules in force governing the installation of gas-electric appliances

for collective use, with the accessories and the adaptations required by the country of use as described in

the use and maintenance manuals printed in the original and official languages of the different countries.

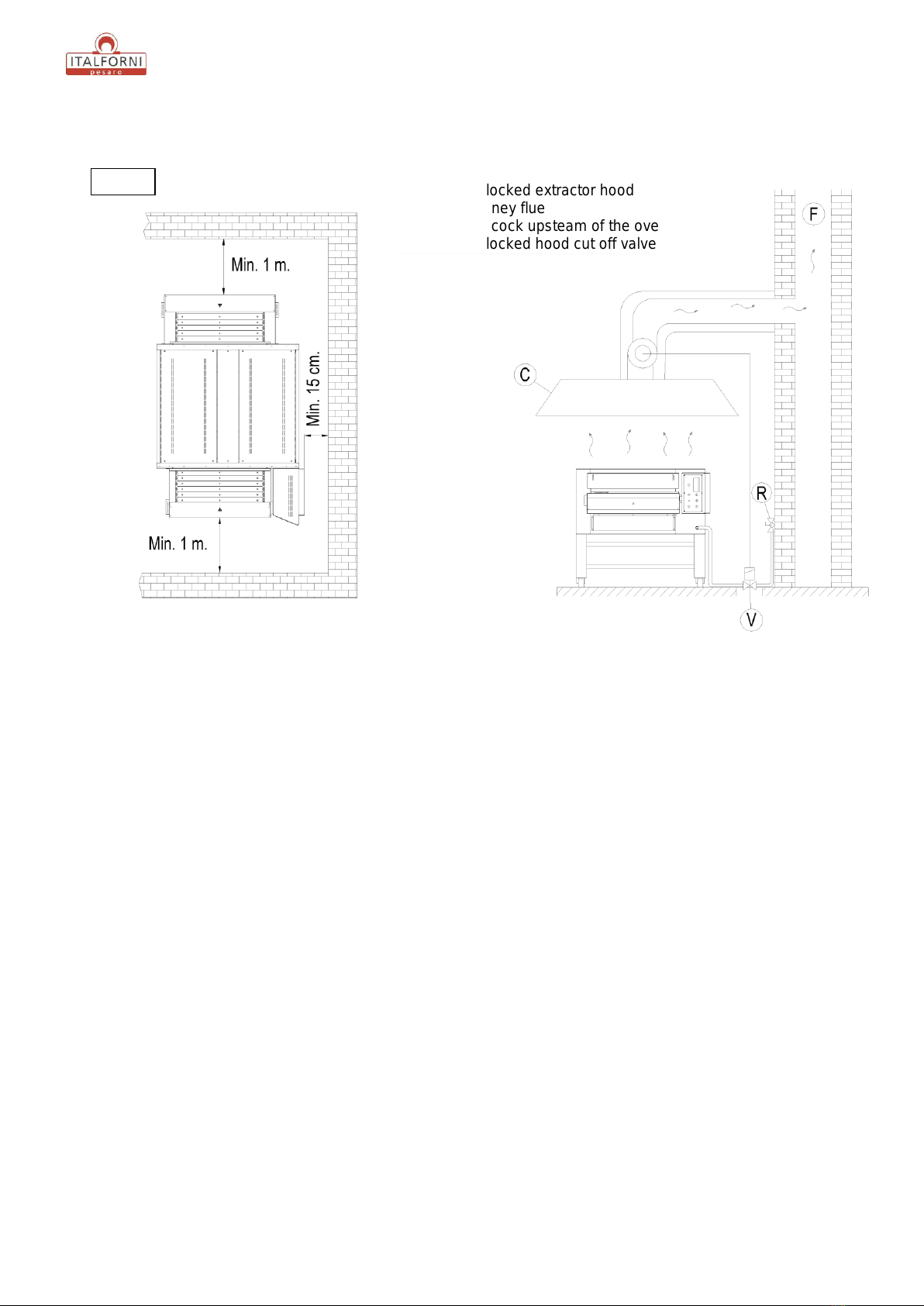

More precisely, the oven must be installed on a suitable stand or sufficiently solid surface which is perfectly

horizontal in a room with sufficient ventilation and must be used by trained staff only.

The oven must be palced under a suitable extractor hood in order to divert the cooking vapours and

combustion fumes outdoors; the extractor hood must be an interlocked one, able to interrupt the gas

feeding if the discharge of the removed combustion fumes from the room is lower than certain

parameters. The burner power can be set on two values.

If the burner should fail to ignite, a red warning light comes on and then ignition can be attempted again by

pressing the reset button. In the event of excessive or irregular heating of the cooking chamber, a safety

thermostat with automatic re-enabling is triggered; in order to signal th anomaly, on the control panel the

“over temperature” warning light comes on.