We like to remember that, products that use combustion

or electrical energy there is security rule to observe

before operating.

Do not allow children to be near the convector.

It is prohibited to turn on an electrical device if there

is a gas smell.

In this case:

- Open windows and door.

- Close the gas tap.

- Call a Technical Service Assistance.

It is prohibited to touch the convector with wet hand

or other parts of your body.

-Electrical Hazard: Do not touch the convector with

wet feet or other part of your body.

It is prohibited to clean the convector when it is run-

ning.

It is prohibited to pull, remove and wring electric

wires outside the convector also if the electrical

supply is turned off.

It is prohibited place over the convector, towels, tea

clothes and other could be cause of inefficiency or

also source of hazard.

It is prohibited to leave paper, plastic, or other things

of the convector box outside within a childʼs reach.

It is prohibited to disperse and leave packaging com-

ponents for the children handy.

It could be potential source of hazard.

Check if there is everything in the packing. In case of

messing pieces call the Agent that sold you the

apparatus.

The convector installation has to be done by a quali-

fied person or by a qualified enterprise that has

received a qualification. The enterprise has to relea-

se you the installation conformity statement tells you

the work is correctly done, and follows the safety

rules laws, “of the 5 March1990 n 46”.

The convector has to do the work that it has been

projected for; if this is not respected there is no war-

ranty.

If the convector is going to be shut down for a long

period of time, the following steps should be taken:

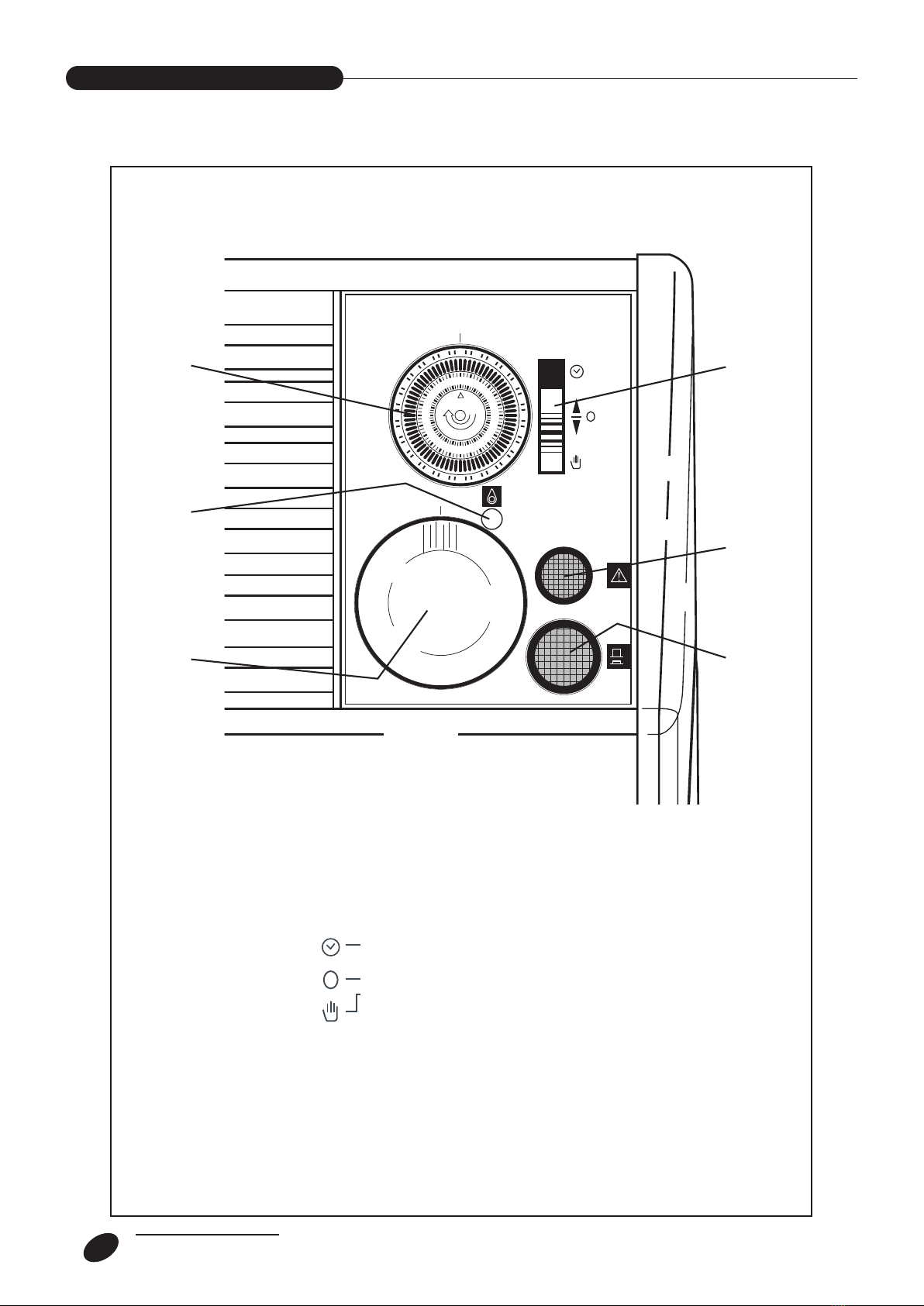

-Position the main switch that is on the control panel

to the “off” position.

-Position the general or wall switch to the “off” posi-

tion and unplug the electrical cord.

Close the gas tap.

This book is a part of the convector, please read and

save all instructions for future reference.

5

GENERAL

GENERAL INFORMATIONS

SAFETY RULES