AH53/8

EL7 –

AH53/12 GM

EL7

9

5.1. LABEL FORMAT SET UP PROCEDURE

(SEE PICTURES 5 and 7)

The printer retains the label length and the backing

paper transparency in permanent memory.

If changing label format or print media type

you have to use the following procedure to update the

values (see also paragraph 7.2):

1 - Switch the printer off.

2 - Lift the printing head up by rotating lever #25b.

3 - Thread the web between the printing roller and

the printing head #21,105.

4 - Lift the pressure roller up by rotating lever #17b.

5 - Thread the web between the driving roller and

the pressure roller #35,32 up to the rewinding

shaft #102.

6 - Check web has been rightly positioned under the

label photosensor #10.

7 - Lift the printing head and the pressure roller down

by rotating levers #25a and #17a.

8 - Switch the printer on while pushing the print

button.

9 - Printer ejects some labels (depending on their

length) and stores the values of the media.

10 - Release the print button.

11 - The display lits light blue and the printer is ready

to work.

6. PRINTING MEDIA DESCRIPTION

6.1. PAPER SPECIFICATIONS

White coated glossy printing paper

- weight: 65 ÷ 90 g/mq (ISO536)

- caliper: 0,075 ÷ 0,083 mm (ISO534)

ADHESIVE SPECIFICATIONS

- peel adhesion(90° C): 430 N/m

- service temperature: -20° C ÷ + 70° C

LINER SPECIFICATIONS

- BG 40 brown, supercalendered glassine

- weight: 65g/mq (ISO536)

- caliper: 0.057 mm (ISO534)

- transparency: 45%

SUGGESTED MODELS

- Fasson Fasthermal NT

- Kanzaki KPT 86-H

- Fasson Fastransfer MP - S470 (TT models)

- Fasson Fastransfer Extra - S470 (TT models)

LABEL DIMENSIONS See Chapter 1

6.2. THERMAL RIBBON

SPECIFICATIONS

- film thickness 4.5 ÷ 6 micron

- core diameter: 25.4 mm

- width: 32 mm min/ 54 mm max.

- length: about 220 meters

- ink coating outside

SUGGESTED MODELS

- TOIKO C 250 (matt paper)

- TOIKO CR 150 (glossy paper and polypropylene)

- TOIKO R 300 (plastic media)

STORAGE

Keep labels and ribbons in a dry place at temperature

not over 40° C and not exposed to direct sun light.

7. THERMAL RIBBON AND LABEL ROLL REPLACEMENT

7.1. THERMAL RIBBON REPLACEMENT

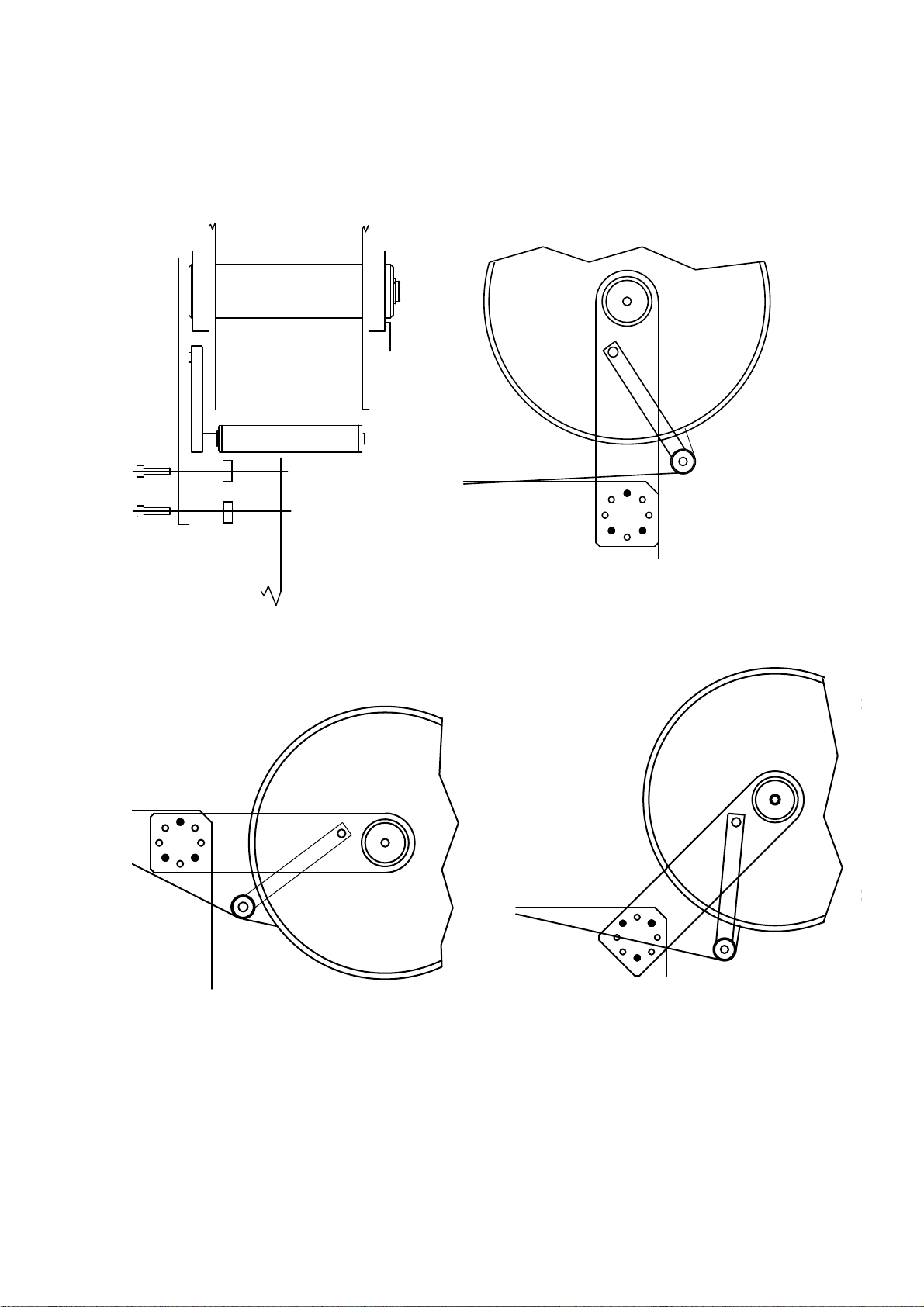

(SEE PICTURE 7)

Remove the used roll. Remove the core #47 from the

shaft #30 and put it on the rewinder #29.

By rotating the lever #25b, lift the printing head #105

from the printing roller #21, setting the movement

of the ribbon free.

Slide new ribbon #43 onto shaft #30 and thread it

under the ribbon photosensor #48 and the threaders

#108, 107 and 37 and up round to the rewinder #29.

Attach the ribbon leader with label/tape to core #47.

Return head lever to closed position #25a

7.2. LABEL ROLL REPLACEMENT

(SEE PICTURE 5)

In case of changing of label format or printing media type, remember to follow the "Label format set up

procedure" shown on paragraph 5.1.

Remove the movable flange by rotating the lever #41.

Remove the empty label roll.

Insert new label roll onto roller #45

Reassemble the movable flange and push it tightly

against the side of the label roll; lock lever #41.

By rotating the lever #25b, lift the printing head #105

from the feed roller #21, setting the movement of

labels and ribbon free.

By rotating the lever #17b, lift the pressure roller #32

from the driving roller #35.

Remove clip #28 from the rewinding shaft #102.

Remove backing paper from the rewinding shaft.

Remove the first 50 centimetres from liner of the new

roll labels.

Hold pressure clip #33 up and feed the liner through

the path, thread the web between the printing roller

and the thermal head #21,105, then around the

driving roller and under the pressure roller #35,32,

finally slide the liner on the rewinder unit #102 and

fasten it with the clip holder #28.

Turn the rewinder to stretch the paper.

Turn head lever and toggle lever back to closed

positions #25a,17a.

Check paper has been rightly positioned under

the label photosensor #10.