ITC 44-010 User manual

ESPAÑOL

Cl2SENSOR

CONTENTS

1.-GENERAL DESCRIPTION 4

2.-TRANSPORT AND HANDLING 4

3.-TECHNICAL FEATURES 5

4.-OPERATION 6

5.-INSTALLATION 7

5.1 Installation in the Multifunction Sensor Holder Red. 44-020 7

5.2 Connections 7

6.- START-UP 8

6.1 Sensor Conditioning 8

6.2 Sensor Calibration 8

7.- MAINTENANCE 9

7.1 Cleaning and Calibration 9

7.2 List of Parts 10

7.3 Electrode head replace 11

7.4 Problem-Cause-Solution 12

CE DECLARATION OF CONFORMITY 15

WARRANTY 15

SAFETY RULES

In order to prevent personal risks and damages to the environment and to

ensure the proper operation of the system, the staff in charge of the systems

installation, start-up and maintenance should follow, the instructions of this

manual, paying special attention to the explicitly detailed recommendations and

warning. They should also follow the specific instructions on the chemical

products to be dosed.

1.-GENERAL DESCRIPTION

.

Free chlorine amperometric sensor for drinking water and water treatment. Specifically

designed to determine the residual level of inorganic chlorine in water.

The chlorine sensor is of the open cell type with no intermediate liquids for the electroche-

mical reaction, thus facilitating installation and maintenance. Since it is an open sensor it

can be used in pressure applications and with solids in suspension.

Manufactured from materials that ensure perfect operation in applications such as:

- Drinking water desininfection

- Industrial processes

- Cooling towers

- Wastewaters reuse

The original packaging is designed to ensure that the transport and the storage of the

system can be carried out without causing damages to the systems provided these

processes are performed inside dry ventilated areas and away from sources of heat.

The packagin includes:

Free chlorine sensor

Instruction manual

2.- TRANSPORT AND HANDLING

4

3.-TECHNICAL FEATURES

- Potentiostatic amperometric sensor for measuring free chlorine

- Analyzable products: Cl2, NaClO, Ca(ClO)2

- Four- electrode system:

Working Electrode (Au)

Reference Electrode (Ag/AgCl)

Counter electrode (Au)

GND Electrode (Au)

-Scale reading 0.02-3.00 mg/l

- Precision: ± 2%

- WorKing conditions:

pH 6.5-9.0

Temperature 0-40ºC

Salinity: < 500 ppm Cl-, <500 ppm SO4

2-

Conductivity: 50 - 3000 uS/cm

Maximum pressure: 6 bar

- Polarization time: 30’ approx.

- Electrode cleaning: electrochemichal (WTR PRO control device)

- Protection: IP68

- Materials:

Body: PVC

Hydrodynamic regulator: PMMA

Sealing: FPM

5

Amperometric analysis is based on the measurement

of current intensity. This intensity is produced by the

oxidation or reduction of an analyte when a suitable

voltage is applied.

In the case of free chlorine analysis:

As can be deduced from the above reaction, current intensity is proportional to the

amount of hypochlorous acid which is present in the measured solution.

The chlorine reduction takes place in the gold

working electrode (W) in which the suitable voltage is

applied referred to in the reading we obtain from the

reference electrode (R) Ag/AgCl. The electrical circuit

is completed by using a gold auxiliary electrode

(counterelectrode)(C). Finally, since the intensities

generated are very low (in the nanoampere range), a

fouth electrode in used in order to keep the signal as

stable as possible. This electrodes also made of gold

acts as a ground connection to eliminate any residual

current that might be found in the water.

It is important to bear in mind that hypochlorous acid is a weak acid and thus the

distribution of its species greatly depends on the pH of the water.

At the working voltage, the amperome-

tric sensor responds not only to hypo-

chlorous acid but also to hypochlorite.

For this reason it is fundamental that the

sensor response be compensated in

accordance with the pH of the medium.

With the WTRpro system, this correction

is automatically carried out in the pH

range of 6.5 to 9.0.

Outside this pH range, parasitic reations

on the electrode surfaces make it

impossible to correct the readings

generated.

4.-OPERATION

+ - -

HClO + H + 2e Cl + H O

2

E

RE CEWE

A

ClO-Cl-

H2O O2

RE CEWERE CEWE

A

ClO-Cl-

H2O O2

V

0

10

20

30

40

50

60

70

80

90

100

4 5 6 7 8 9 10 11

pH

%

% HClO

%ClO-

R

CW

GND

6

5.- INSTALLATION

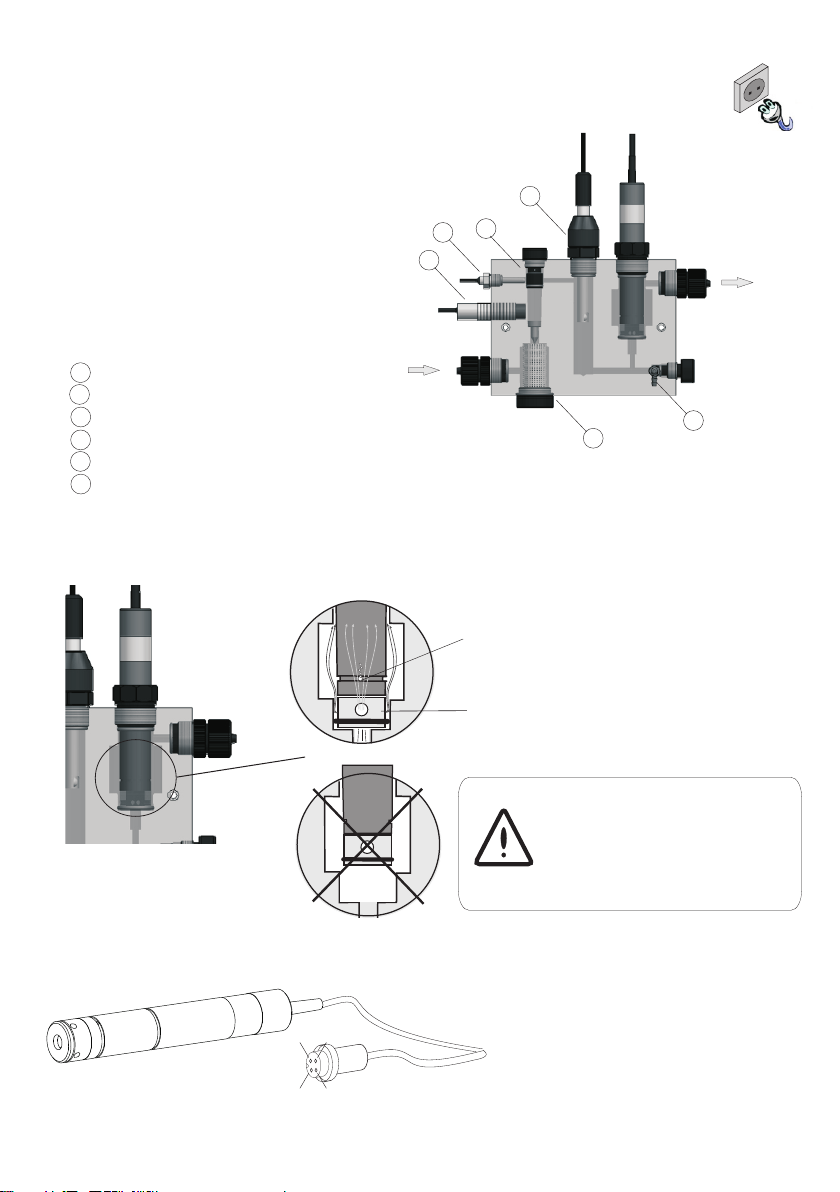

1

2

3

4

5

6

1 Flow regulator

2 Cavity for temperature sensor

3 Flow detector

4 Input filter

5 Sampler

6 pH sensor cavity

ok

no

5.1 INSTALLATION IN MULTIFUNCTION SENSOR HOLDER REF. 44-020

HYDRODYNAMIC REGULATOR

AIR OUTLET

5.2 CONNECTIONS

1

2

4

3

Working electrode

Reference electrode

GND

Counter electrode

12

3

4

The sensor must be installed where it is

possible to ensure a constant flow of

water with no chance of air bubbles

forming in the measuring cell.

It is recommended that it be installed in

the Multifunction Sensor Holder (Ref.

44-020), especially designed for this

application, and equipped with the

following:

Make sure there are no air

bubbles at the bottom of

the chlorine sensor.

7

If it has not been used recently or if it is being connected for the first time, the sensor will

require a conditionning time. Prior to sensor calibration, insert the sensor correctly into the

sensor holder and let the water containing free chlorine flow for 24 hours to ensure that the

cell is properly polarized. If the system start up can not be delayed 24 hours, wait one hour

before calibration, and repeat the calibration after 24 hours.

First point calibration: 0 mg/l

Once the sensor is properly conditioned let the water flow at 0 ppm until a stable

reading is achieved.

To facilitate the calibration at 0 mg/l, the user should have an active carbon filter

in by-pas before the sensor holder. This makes it possible to easily have the

qater at 0 ppm.

Second point calibration:

Let the water with free chlorine flow for ten minutes.

Take a sample of the water, do a DPD-1 analysis in order to determine the free

chlorine level of the sample, and introduce this value into the control device.

6.- START-UP

6.1 SENSOR CONDITIONING

6.2 SENSOR CALIBRATION

8

Cleaning interval:

Every 8 hours and after working for several hours without flow, with water without free

waste chlorine, or over 3 mg/l. This cleaning frequency is maintained automatically with

the WTR PRO control device.

Calibration interval:

The first time, after 24 hours.

This will subsequently depend on the water conditions: 1-4 weeks

After disconnecting the system, wait 60 minutes for the correct polarization

of the sensor. Calibrate, and after 24 hours repeat the calibration.

If the sensor has been working at 0 mg/l, without water flow, or without

water, for 1 hour or more, an electrochemical cleaning will have to be

Carried out. Then condition and calibrate the sensor once again.

The sensor can be passivated if it has been working for hours

over 3 mg/l. Clean the sensor introducing it into a HCI 0.1M solution for

20 seconds. Then conditioning and calibrate again the sensor.

7.- MAINTENANCE

7.1 CLEANING AND CALIBRATION

9

62300

64349

64410

44106

44104

CODE NAME

44-015 Chlorine sensor electrode head

44-016 Chlorine sensor body

44104 Ring holder for electrodes base

44106 Hydrodynamic regulator

62300 O-Ring 19x3 FPM

64349 O-Ring 14x2.5 FPM

64410 O-Ring 19x2 FPM

44-016

44-015

7.2 LIST OF PARTS

10

Table of contents