pump discharge to insure optimum performance.

Using undersized pipe may dramatically reduce the

flow and therefore waste energy. Your pump supplier

can suggest the correct pipe for your installation.

3.2. Install a threaded pipe adapter, matched to the pipe

type you are using, into the threaded pump

discharge. One end will have a male thread and the

other end will have a barbed connector, compression

fitting or solvent weld connector. Use Teflon® tape

on all threaded joints. If using solvent welded pipe

and fittings it is best to dry fit them first and after

verifying the fit, solvent weld. A union installed just

above the sump or basin cover will facilitate future

maintenance and replacement. See Chart 1 for

discharge sizes.

3.3. Install a line check valve within 2 feet of the pump.

Install per valve manufacturer’s instructions.

IMPORTANT – Drill a 1⁄8" (3.2mm) relief hole in the

discharge line approximately 2" (51mm) above the

pump discharge connection but below the check

valve and within the sump. This “relief” hole allows

trapped air to escape from the pump and prevents

air-locking the pump. Failure to drill this hole is a

major cause of sump pumps failing to pump after

long periods of inactivity such as seasonal use.

4. INSTALLATION IN SUMP

4.1. The pump can be placed directly on the bottom of a

poly or fiberglass sump basin or a concrete sump

bottom. If the bottom is packed gravel the stones

must be larger than

1⁄2" (13mm) in diameter and the pump should be

placed on bricks for support.

4.2. After connecting the discharge pipe to the pump it

can be lowered into the sump (basin). Always lower

the pump by the handle and the pipe, never by the

power cord. Place the pump against the basin wall

so the switch is to the center. See Figure 1.

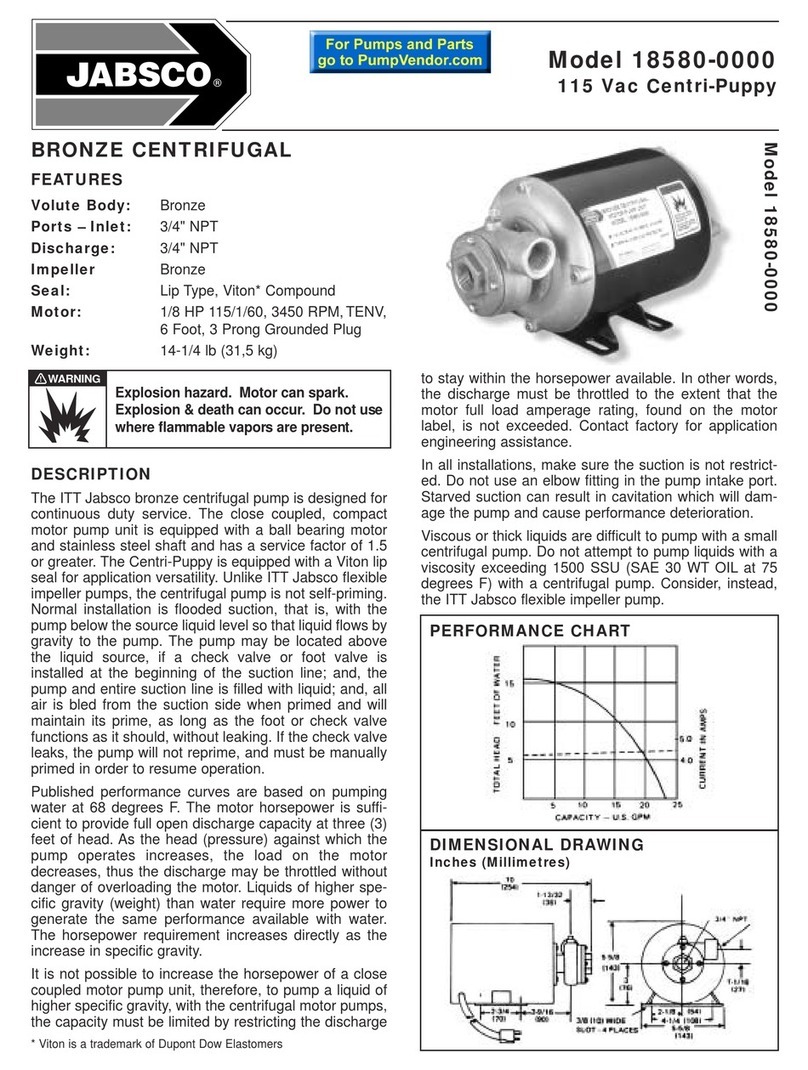

MODEL INFORMATION

(Chart 1)

Min. Min. Min. Min. Max. Shipping

Circuit Float Cord Discharge On Off Basin Solids Weight

Model No. HP Volts Amps Breaker Phase Switch Style Length Connection Level Level Dia. Size lbs/kg

JSP03 1/3 115 2.8 10 1 Piggyback Wide Angle 20' 1-1/2" 11" 5" 12" 3/8" 11/5

JSP07 3/4 115 6.6 10 1 Piggyback Wide Angle 20' 1-1/2" 12.5" 6.5" 12" 3/8" 15/6.8

1. GENERAL INFORMATION

1.1. Sump pumps are designed to operate intermittently

and usually seasonally. It is recommended that you

test the pump before your rainy season begins to

insure that the pump and switch are operating properly.

1.2. We suggest installing a high water alarm system

and a battery back-up pump system for finished

basements or areas where flooding will cause

property damage. A back-up generator is another

option you can discuss with your pump installer.

Most power outages occur during rain storms, just

when you need your sump pump the most! Pump

manufacturer's warranties cover only the pump.

Labor and incidental damage such as flooding is not

covered.

2. PRE-INSTALLATION CHECKS

2.1. Open all cartons and inspect for shipping damage.

Report any damage to your supplier immediately.

2.2. Verify that all equipment is the correct voltage.

Warranty does not cover damage caused by

connecting pumps and controls to incorrect voltage.

2.3. Is your basin sized correctly and the proper type for

the location?

Diameter – It must be wide enough to allow the

pump and switch to physically fit and provide room

for the switch to operate freely. See “min. basin

diameter” in Chart 1.

Depth – It must be deeper than the

minimum depth at which the switch

turns the pump On. As an example, if the pump turns on

at 15" you want to use a basin deeper than 15".

See "On level" in Chart 1.

Style – There are several sump basin

styles available. The location of the

sump determines if you require a cover and what type

you require. It is important to keep debris from entering

the sump and clogging the pump. An open sump in a

traffic area such as a basement is dangerous. If children

or pets will be playing in the area a bolt-on or child-proof

cover is recommended.

3. PIPING

3.1. Discharge pipe should be the same size as the