6

13. On units equipped, remove seal housing wear ring (5)

if excessively worn.

DISASSEMBLY OF BEARING FRAME OR

SAE BEARING FRAME

1. Remove deflector (123) from shaft.

2. Remove bearing cover (134).

3. Remove shaft assembly from frame.

4. Remove lip seals (138, 139) from bearing frame (228) and

bearing cover (134) if worn. Discard.

5. Remove retaining ring (361).

6. Use bearing puller or arbor press to remove ball

bearings (112, 168).

Reassembly

• All parts should be cleaned before assembly.

NOTICE: O-RING SHOULD BE REPLACED AFTER ANY

DISASSEMBLY OF UNIT.

BEARING FRAME

1. Replace lip seals if removed.

2. Replace ball bearings if loose, rough or noisy when rotated.

3. Check shaft (122) for runout. Maximum permissible is

0.002" (0.05 mm) TIR.

4. Refer to the “MAINTENANCE” section of this manual

for M-group bearing frame regreasing instructions.

LIQUID END

1. Inspect shaft removing any debris or burrs.

2. Treat shaft with LOCQUIC®Primer “T”, or equivalent,

following manufacturer’s instructions carefully.

3. When replacing shaft sleeve, spray new shaft sleeve’s bore

with LOCQUIC®Primer “T”, or equivalent. Let parts dry

and then apply LOCTITE®#262 on the same surfaces.

Slide new sleeve over shaft with a twisting motion, wipe

off excess. Let cure according to instructions.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY. FOR PACKED

BOX PUMPS SEE “PACKED BOX

INSTRUCTIONS”.

4. Replace seal housing wear ring, if removed.

5. For mechanical seal pumps, stationary seal seat may be

dipped in water to ease installation. Place stationary seal

seat squarely into seal housing bore. Cover the polished

face of the seat with a thin piece of cardboard or paper

towel. Press seat firmly into bore using a round piece of

plastic or wood that disperses the force over the entire

seal face. NOTE: If mechanical seal is supplied with a

spring retainer, remove and discard the retainer.

6. Place adapter, concave face pointing up, over motor

shaft and lower it onto the motor.

7. Replace seal housing o-ring. This o-ring may be lubricated

with water or glycerin to ease in installation. Install seal

housing on adapter. Exercise care in that the motor shaft

does not dislodge or damage seal seat.

8. Fully and squarely install the rotary assembly of seal

against the stationary seat.

NOTICE: REPLACE IMPELLER BOLT AND WASHER

WHENEVER IMPELLER IS REMOVED.

9. Install impeller key in shaft keyway. Mount impeller on

shaft and push until it bottoms. Hold in place. For SAE

units, apply LOCTITE 271 to the impeller bore, keyway

and shaft. Mount impeller on shaft and push until it

bottoms. Hold in place.

10. Install new impeller washer. Impeller washer not used for

SAE units..

11. Apply LOCTITE

®

#271 or equivalent, to new impeller bolt

threads and tighten to:

3⁄8"-16 bolts 20 lbs.-ft. (27 N.m)

1⁄2"-13 bolts 38 lbs.-ft. (51 N.m)

Impeller bolt not used for SAE units.

12. For SAE units apply LOCTITE

®

#271 to the external

threads of the shaft and internal threads of the impeller

nut (22). Tighten impeller nut to the following:

1⁄2"-Impeller Nut (SAE M-Group) 80 lbs.-ft. (107 N.m)

3⁄4"-Impeller Nut (SAE L-Group) 100 lbs.-ft. (134 N.m)

13. For SAE units, after impeller nut (22) has been installed,

apply

LOCTITE

®

#271 to set screw (22A). Install impeller

set screw into face of impeller nut (22) and tighten

hand-tight.

14. Replace casing wear ring, if removed.

15. Replace casing bolts and tighten, in a crossing sequence,

to torque values indicated below:

3⁄8"-16 bolts (bronze casing) 25 lbs.-ft. (34 N.m)

1⁄2"-16 bolts (cast iron casing) 37 lbs.-ft. (50 N.m)

1⁄2"-13 bolts (cast iron casing) 90 lbs.-ft. (122 N.m)

3⁄4"-10 bolts (cast iron casing) 175 lbs.-ft. (237 N.m)

16. Check reassembled unit for binding by rotating shaft with

appropriate tool from motor end.

17. If rubbing exists, loosen casing bolts and proceed with

tightening sequence again.

18. Replace motor hold-down bolts and motor end plug or

cover on close-coupled units.

19. Replace coupling, spacer, coupling guard and frame

hold-down bolts on frame-mounted units.

NOTICE: ALWAYS RECHECK BOTH ALIGNMENTS

AFTER MAKING ANY ADJUSTMENTS.

20. Refer to the “COUPLING ALIGNMENT” section of

this manual to realign shaft.

21. Assembly is complete.

Packed Box

1. Make sure stuffing box is free of foreign materials and

clean before beginning packing of packed box. Refer to

Sectional Assembly in the repair parts section.

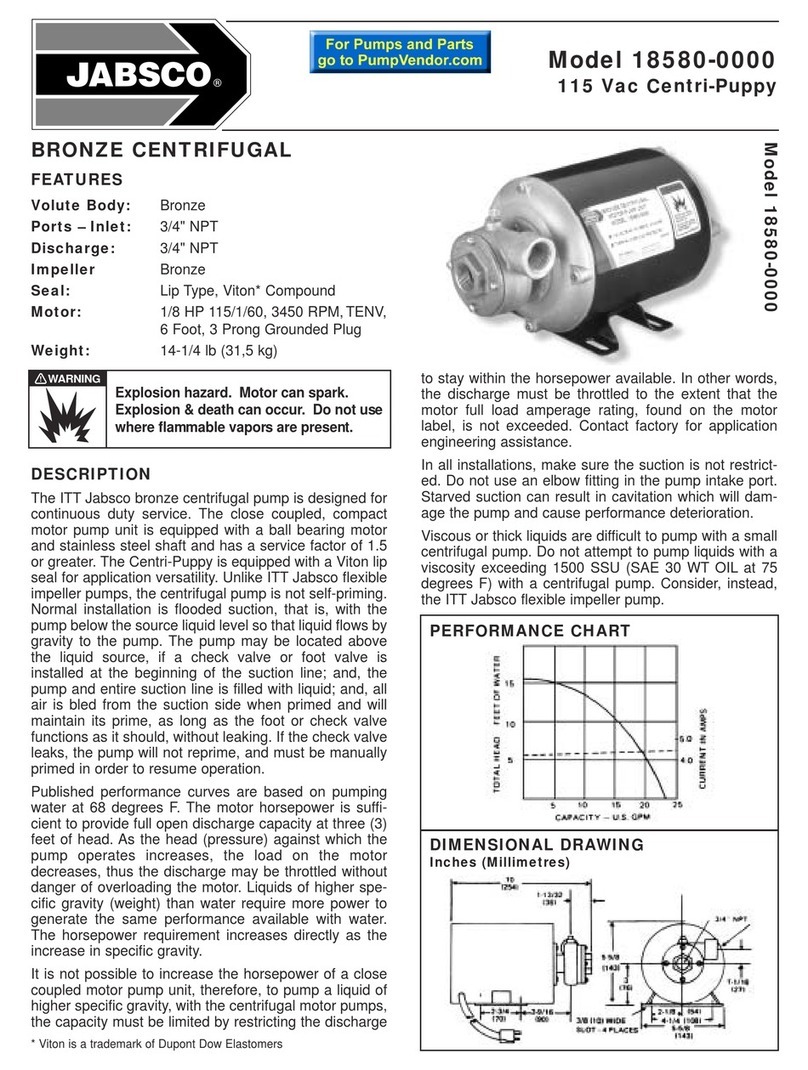

2. Take special care during installation of packing rings

because they are die-formed. To install, twist the ring

sideways just enough to fit it around the shaft sleeve.

DO NOT ATTEMPT TO PULL RINGS STRAIGHT

OUT. See Figure 7.

Figure 7

CORRECT WRONG