Ives 112HD Series User manual

Other Ives Door manuals

Ives

Ives Surface Bolt 43 User manual

Ives

Ives Offset Top Pivot 7212 User manual

Ives

Ives 620 Series User manual

Ives

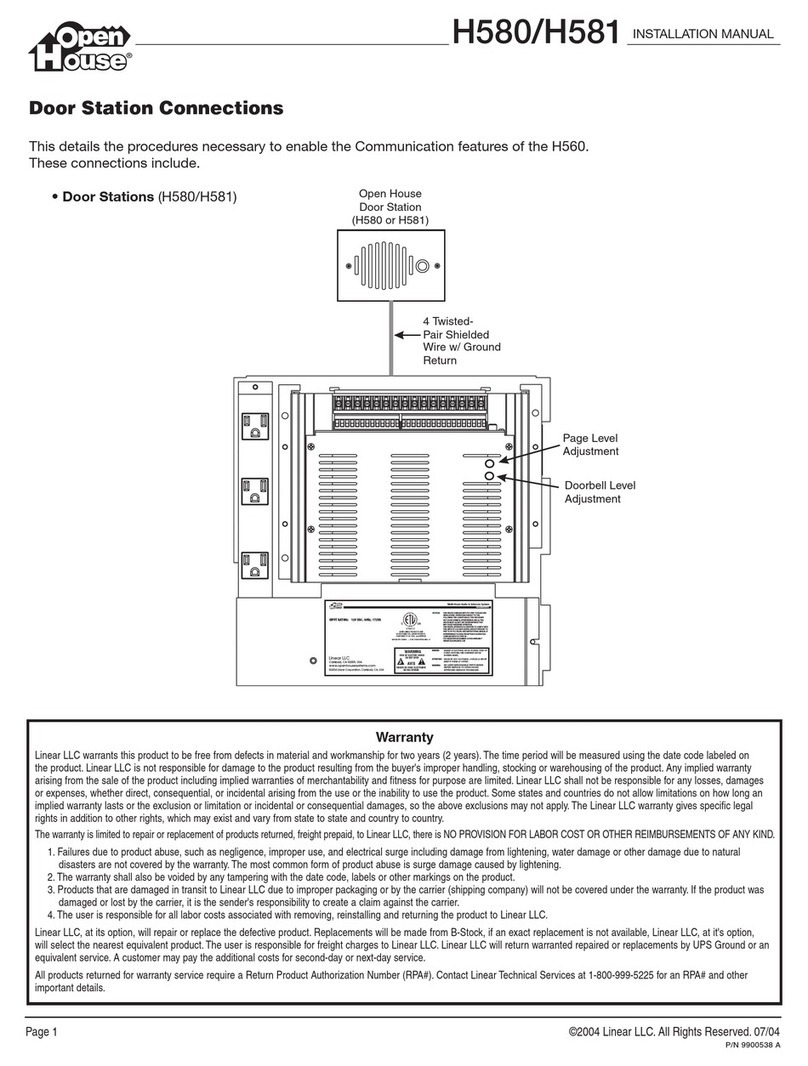

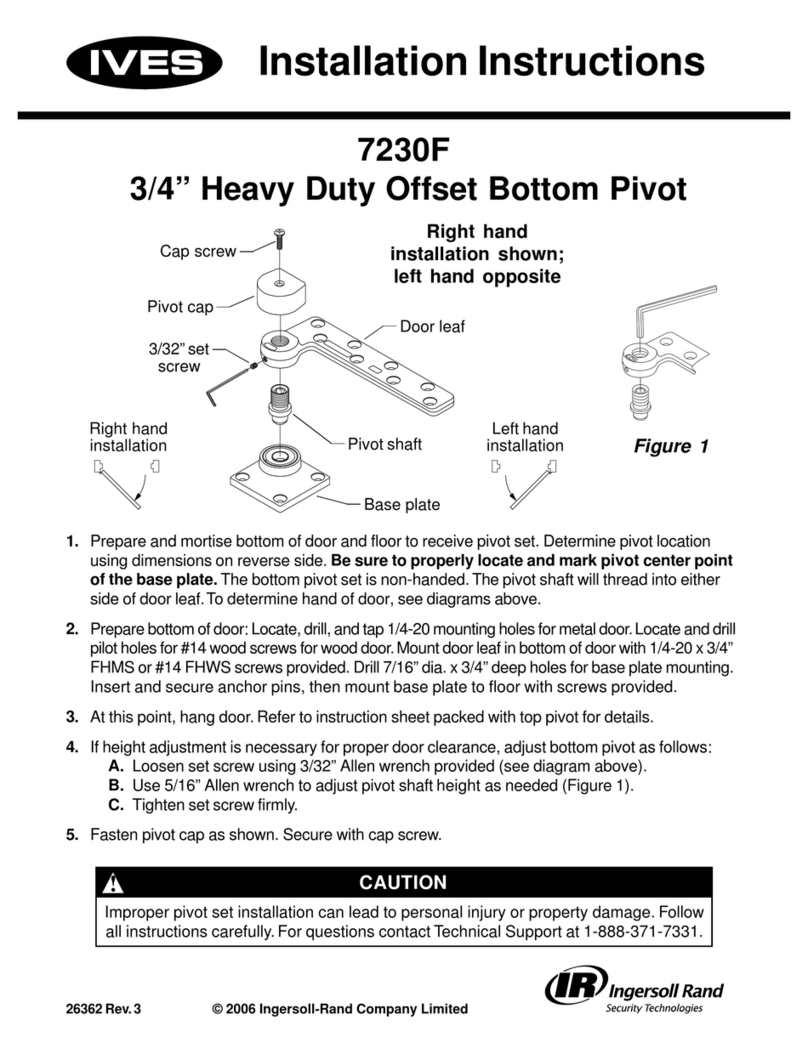

Ives Heavy Duty Offset Top Pivot 7230F User manual

Ives

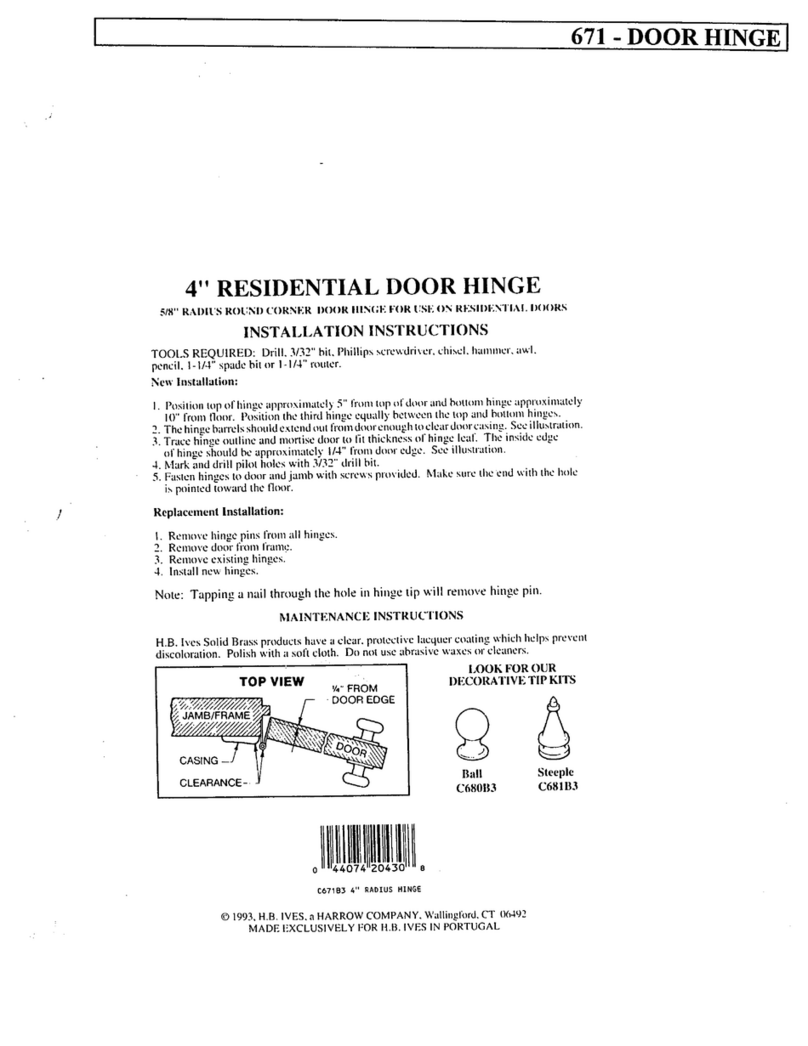

Ives 671 User manual

Ives

Ives Offset Jamb Mount Top Pivot 7212V User manual

Ives

Ives Magnetic Catch 326 User manual

Ives

Ives Pull Plate 8311 User manual

Ives

Ives Mortise Bolt S48 User manual

Ives

Ives 660 User manual

Ives

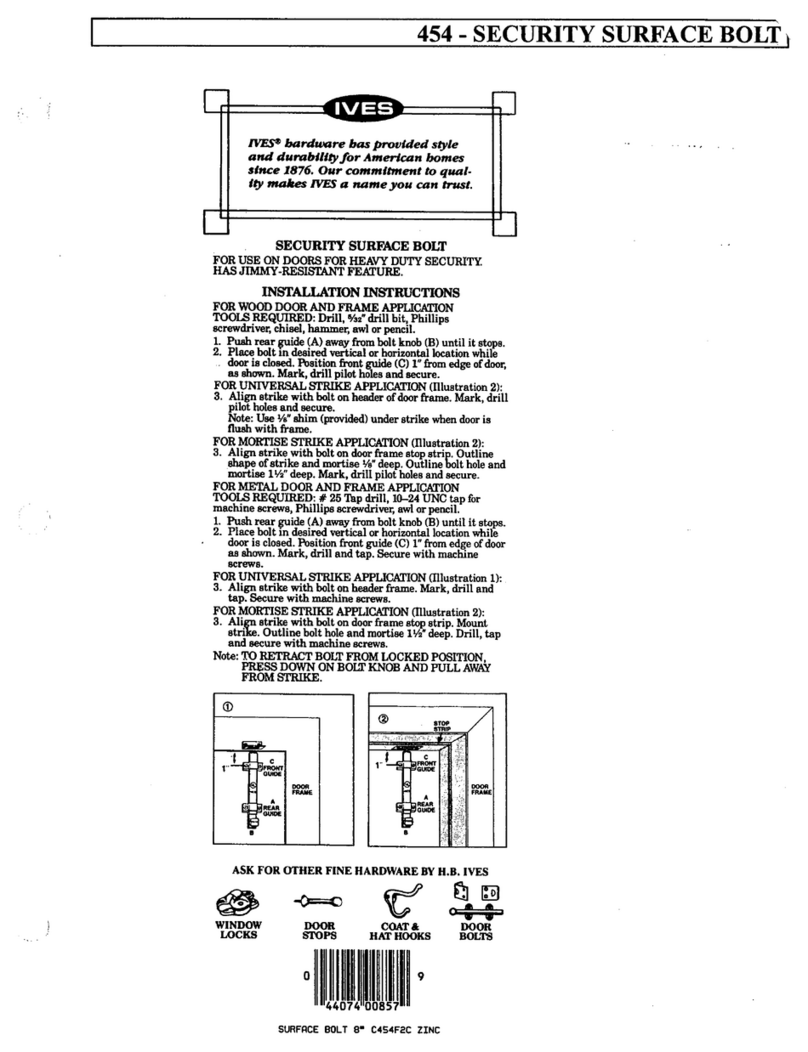

Ives Security Surface Bolt 454 User manual

Ives

Ives 56 User manual

Ives

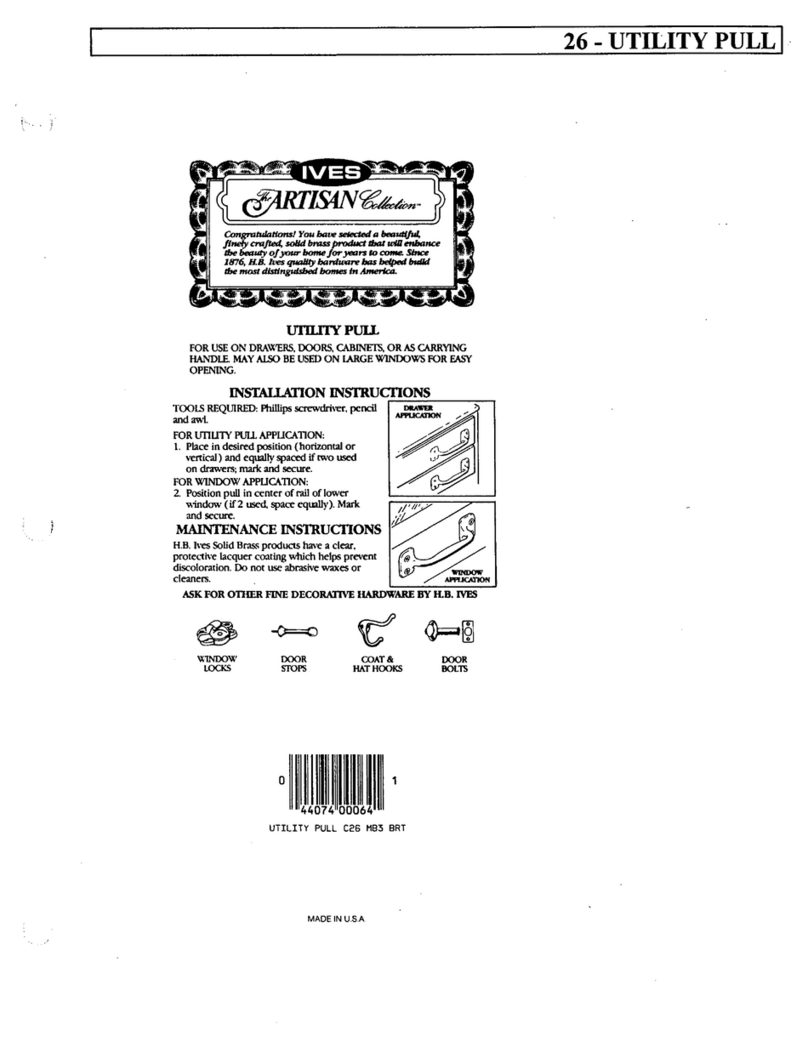

Ives Utility Pull 26 User manual

Ives

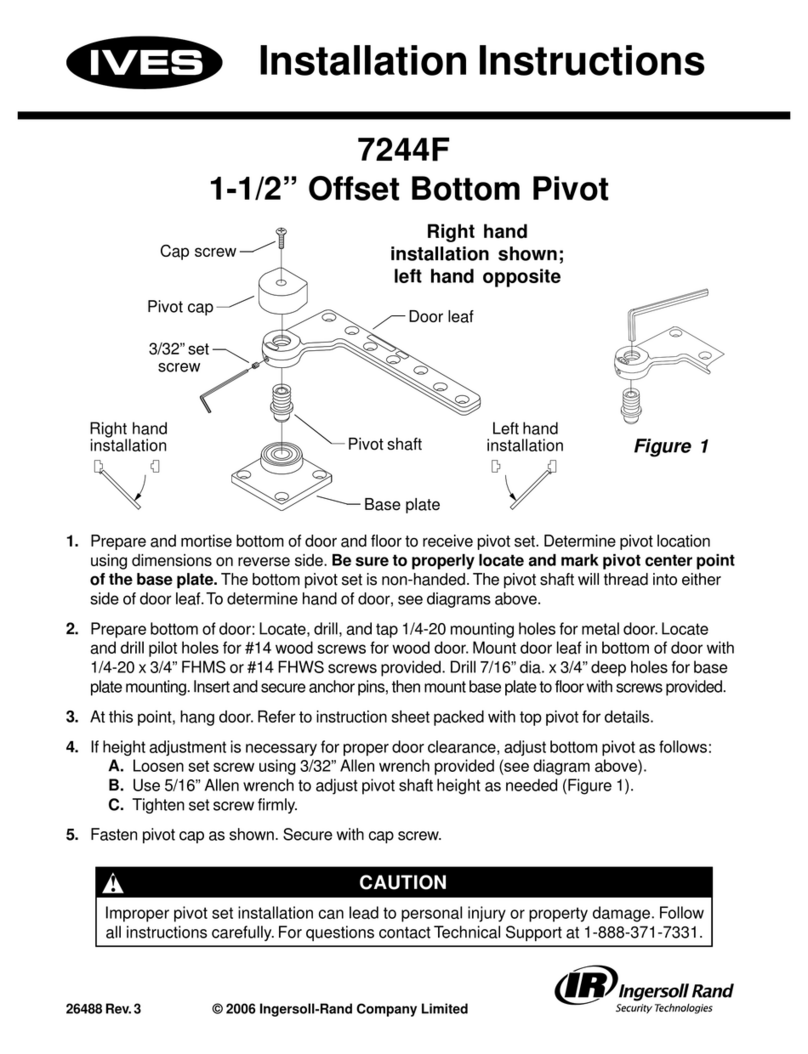

Ives Offset Top Pivot 7244F User manual

Ives

Ives 670 User manual

Ives

Ives Top Center Pivot 7253 User manual

Ives

Ives Magnetic Catch 327 User manual

Ives

Ives Heavy Duty Offset Top Pivot 7237F User manual

Ives

Ives Offset Top Pivot 7215/15F User manual

Ives

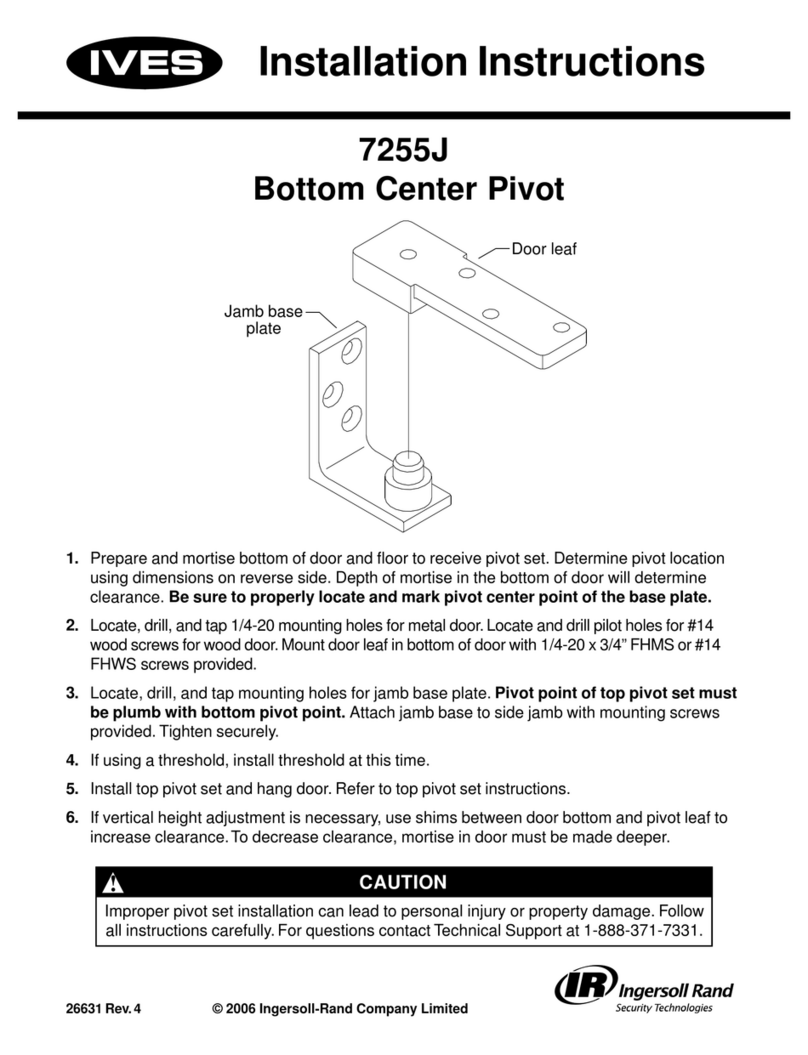

Ives Bottom Center Pivot 7255J User manual

Popular Door manuals by other brands

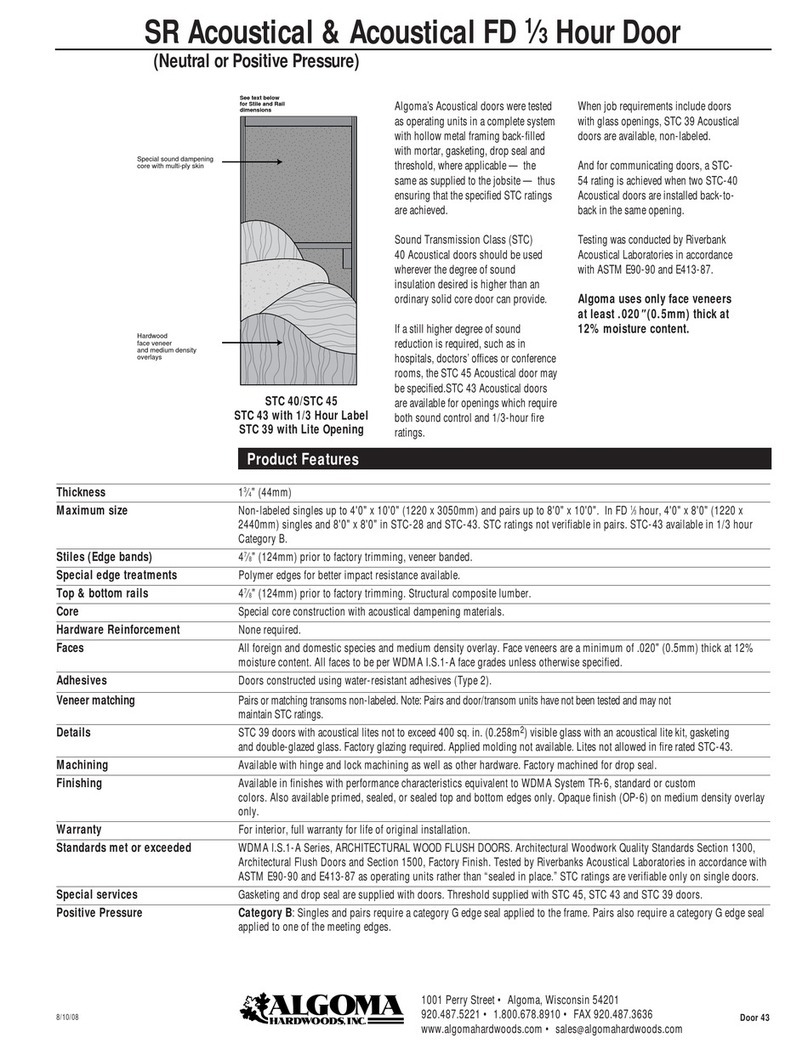

Algoma Hardwoods

Algoma Hardwoods STC 39 Specification sheet

Therma-Tru

Therma-Tru Double-door Specifications

Erreka

Erreka PREMIS 200 user manual

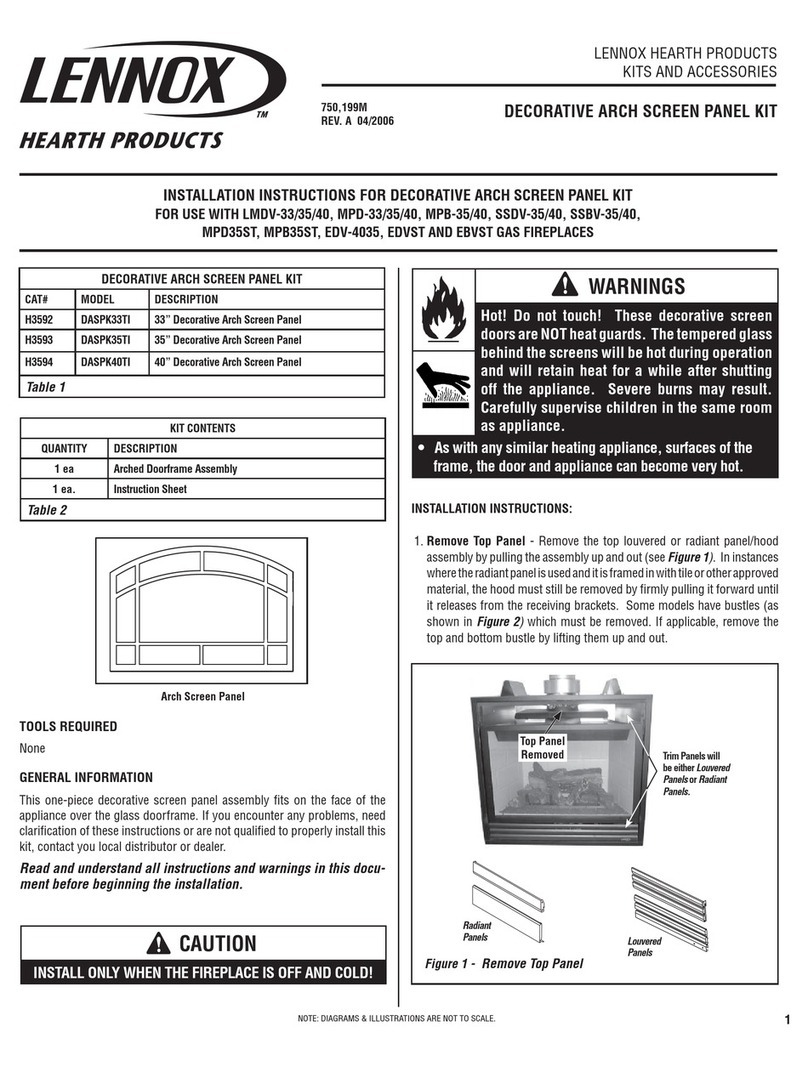

Lennox Hearth Products

Lennox Hearth Products MPB-35 installation instructions

KitchenAid

KitchenAid KBAU181V Installation instructions and use and care guide

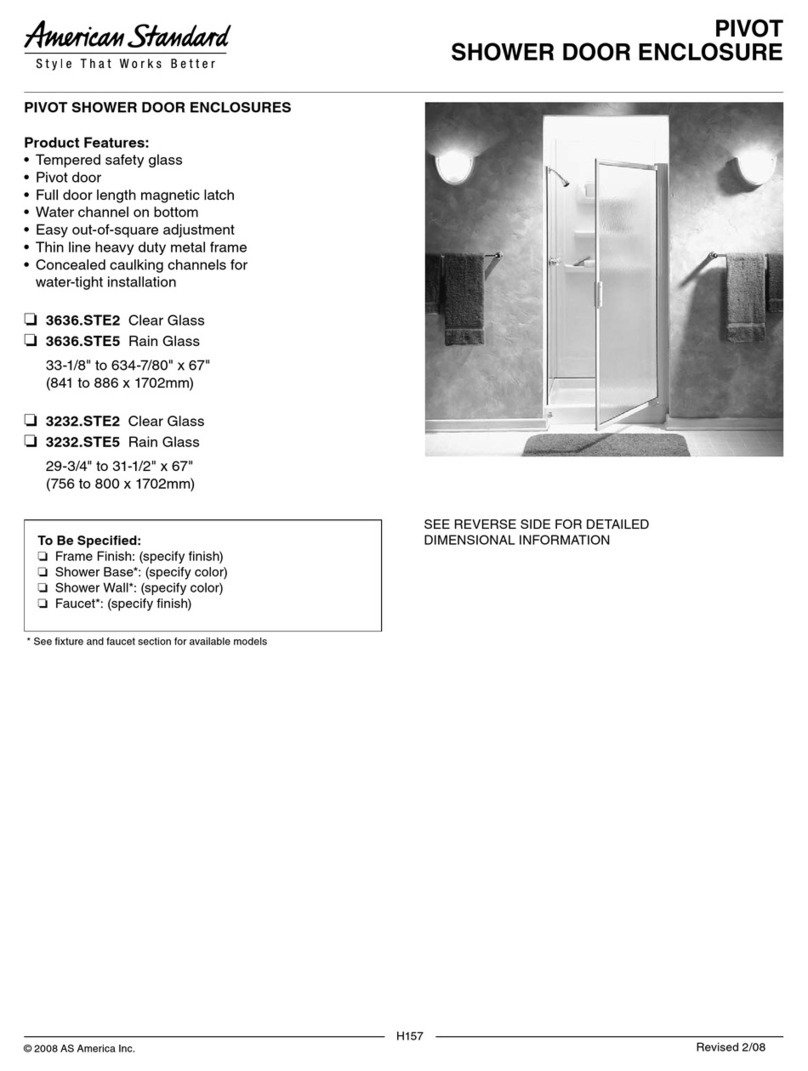

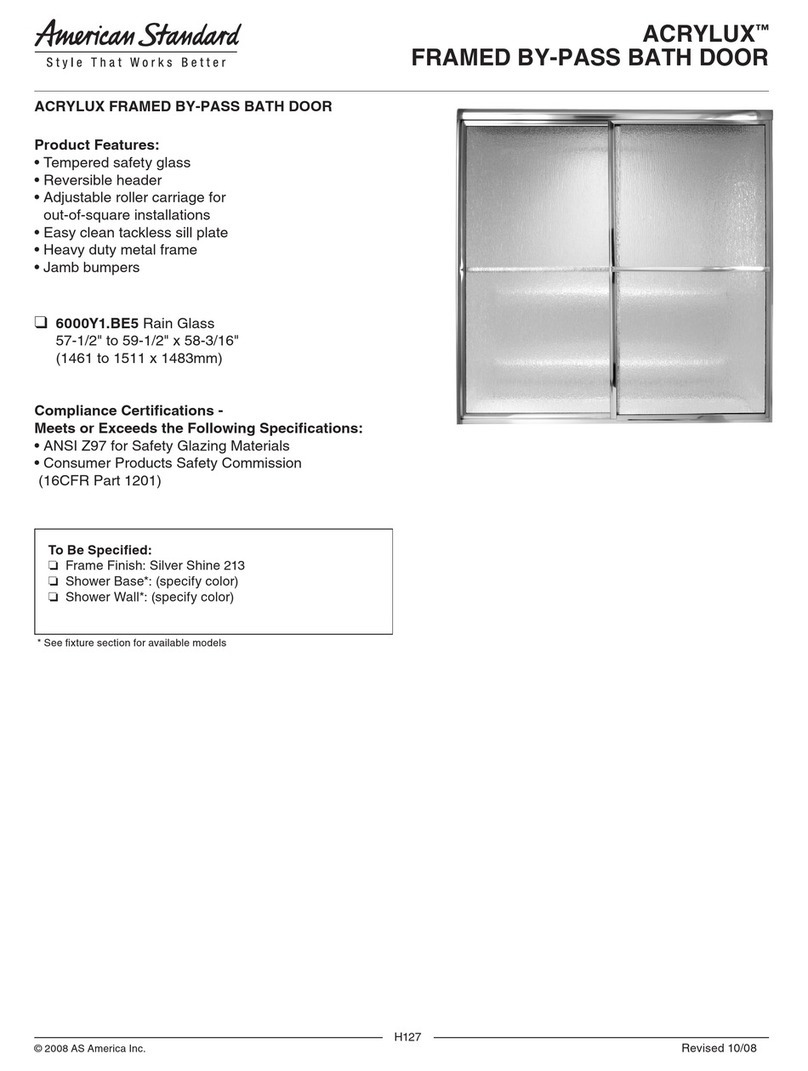

American Standard

American Standard Acrylux 6000Y1.BE5 Specifications