For Your Safe Flight Page 5

•Normalize and Percentage View Indicators

•Percentage view: when there is a dash — near the Pat the top of

the display (EDM-700) or NRM is not lighted (EDM-800), the

columns indicate percent of EGT red line. Each column is

composed of a stack of segments. A maximum height column

depicts 100 % of red line and a one segment-high column depicts

50 % of red line. For example, if the red line is 1650°F, a

maximum height column represents 1650°F and a one segment-

high column represents half that value, or 825°F. The

Percentage view permits comparison of EGTs across all

cylinders. Hotter cylinders display higher columns than cooler

cylinders.

•Normalize view: when there is a dash _ near the Nat the top of

the display (EDM-700) or the letters NRM are lighted on the left

side (EDM-800), the EGT columns are displayed normalized.

When you change to the Normalize view, all column peaks are

set to the same half-height level for trend analysis. Any changes

are shown as an increase or decrease in column height. A one-

segment change in column height represents a 10°F change.

The Normalize view permits rapid visualization of EGT trends,

rather than a percentage of red line. You should use normalize in

level cruise and run-up.

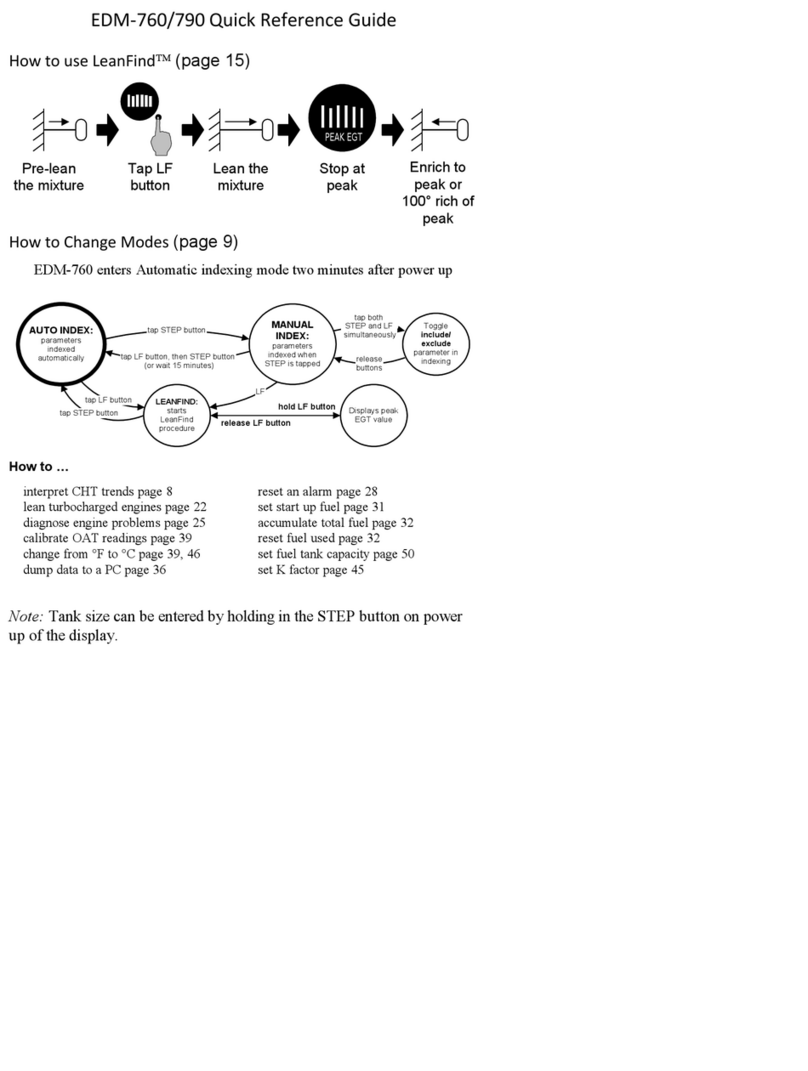

To toggle between Percentage and the Normalize views, hold the LF

button for five seconds until the display changes. The analog display

becomes half height and the display changes to the Normalize view.

Selecting the Normalize view does not affect the digital display nor alter

the parameter sequence. The CHT display—described later—is not

affected by the Normalize or Percentage view.

You may select the Normalize view in either the Manual or Automatic

mode. Normalize view is most helpful for engine trend monitoring of

each cylinder’s operation. For example using the Normalize view during

engine run-up, a fouled spark plug will appear as a higher column.

A common misapplication is to be in the Normalize view and then

change your power setting, causing all columns to go off scale, high or

low. Set to the Percentage view before adding or reducing power.

Always set Percentage View when beginning your descent.