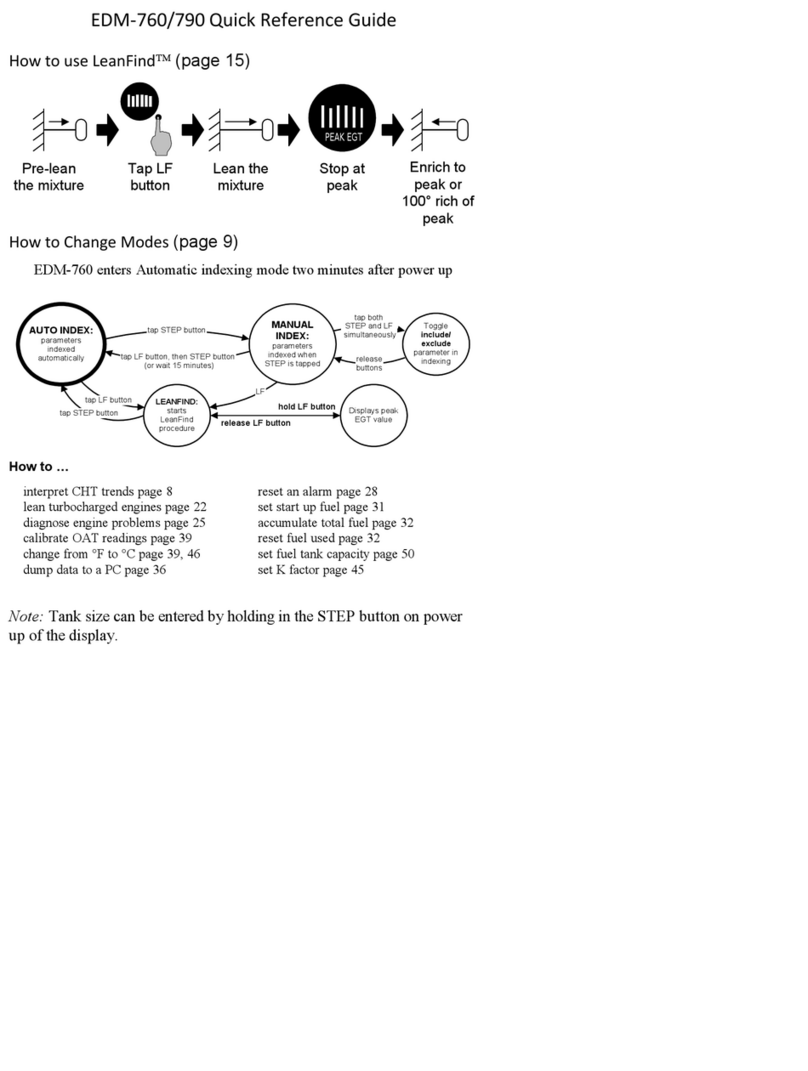

Scanner® Display Basics

The EDM Scanner section is located in the lower left area of the screen.

It consists of a graphical display of EGT and CHT (and TIT if so

equipped) and a digital display that automatically scans the various

parameters. You can select Manual Mode by tapping STEP to lock onto

the parameter of interest. To return to Automatic scan mode, tap LF

followed by tapping STEP.

Lean Find Basics

Simply pre-lean, tap the LF

button (Lean Find) and begin

leaning. The EDM will assist

you in finding the first cylinder

to peak. This example is for

Rich of Peak. See page 21

for a more detailed

description of leaning.

1. Establish cruise at approximately 65 to 75% power and pre-lean the

mixture to 50°F estimated rich of peak EGT on any cylinder.

2. Wait about 30 seconds, then tap the LF button.

3. Begin leaning the mixture smoothly without stopping. Turn the

Vernier about ¼ turn per second; retract the non-Vernier or quadrant

lever so that EGT rises about 10°F per second.

4. Stop leaning when you see LEANEST for two seconds, followed by—

for example—EGT1520 FF13.8. The EGT number is the current

temperature of the first EGT to peak and the FF number is the

current fuel flow.

5. Now tap the PEAK button to display the EGT difference from peak

which is very useful for setting desired degrees below peak.

6. Slowly enrich the mixture noting that the EGT difference diminishes

as EGT climbs back to peak, followed by it going minus again. Stop

enriching at the desired EGT difference (such as ‘EGT -75’).

7. You can also see what the peak EGT was by holding the PEAK

button.

8. Tap STEP to exit the Lean Find Mode.