1.1 Table of Figures

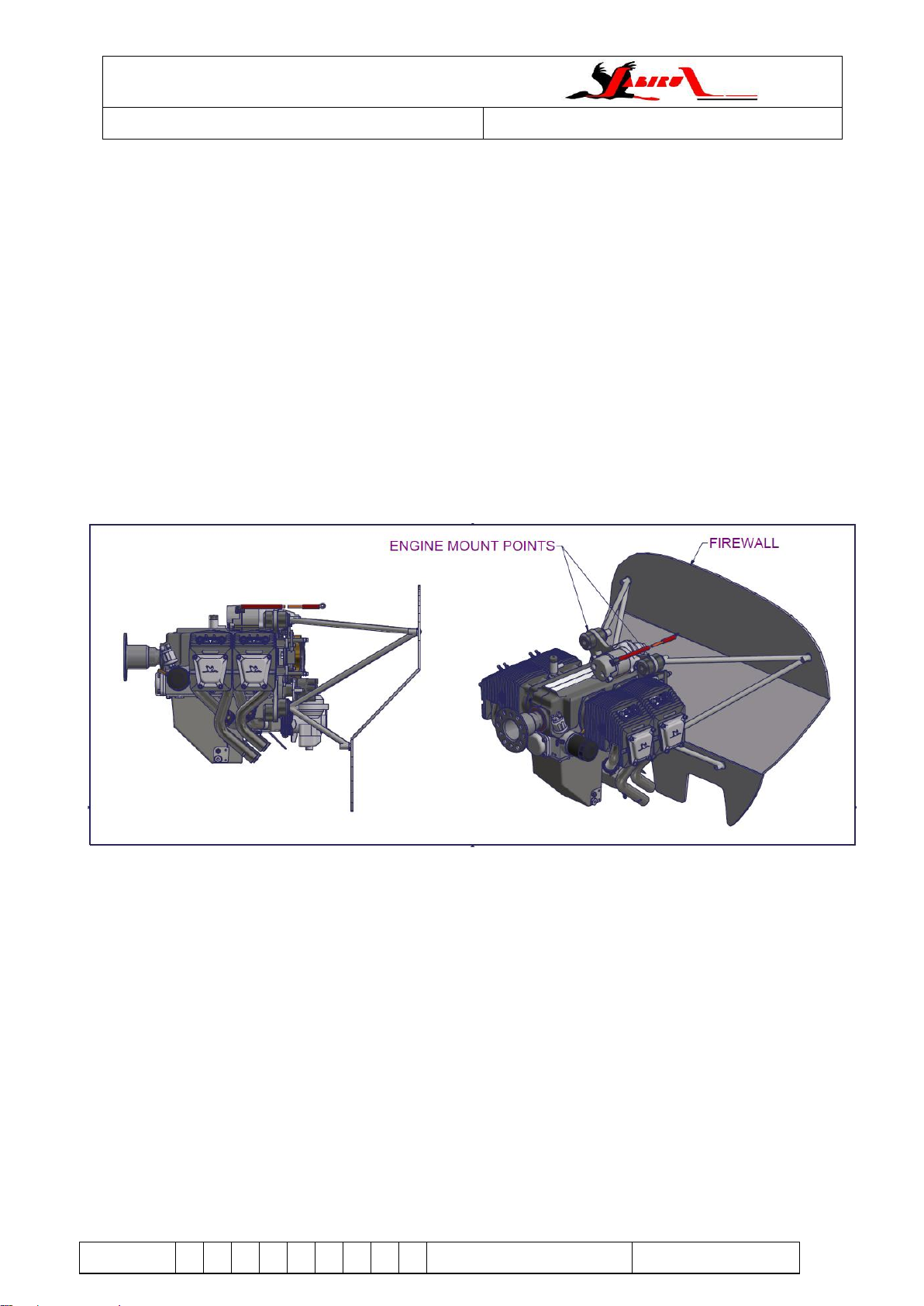

Figure 1. Engine Mount Point Locations....................................................................................................................................6

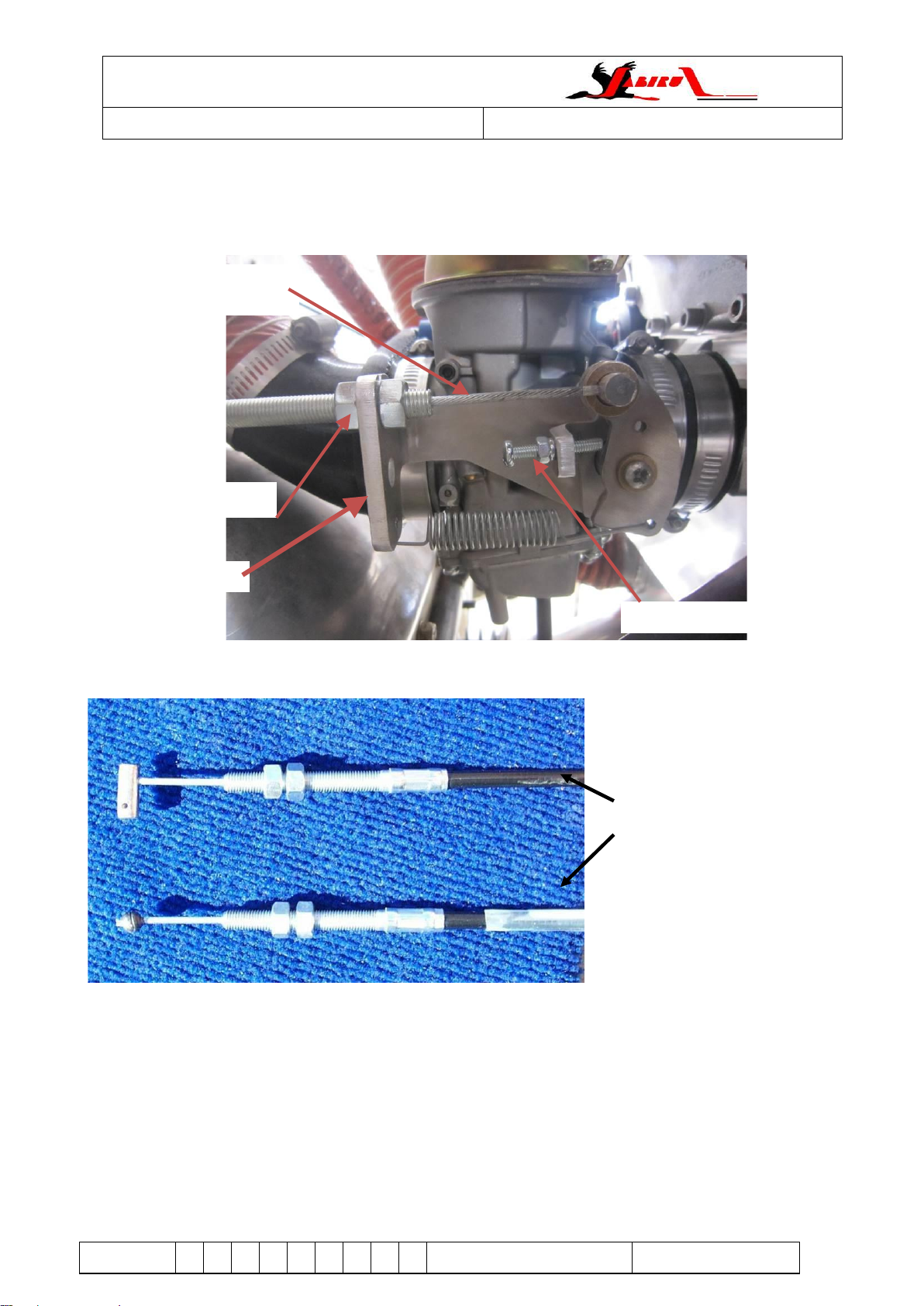

Figure 2: Throttle cable connections. ........................................................................................................................................7

Figure 3: Choke cable fitted ......................................................................................................................................................8

Figure 4: Choke cable end drawing...........................................................................................................................................8

Figure 5: Choke cable end parts in order of assembly..............................................................................................................8

Figure 6: Choke cable end assembled......................................................................................................................................9

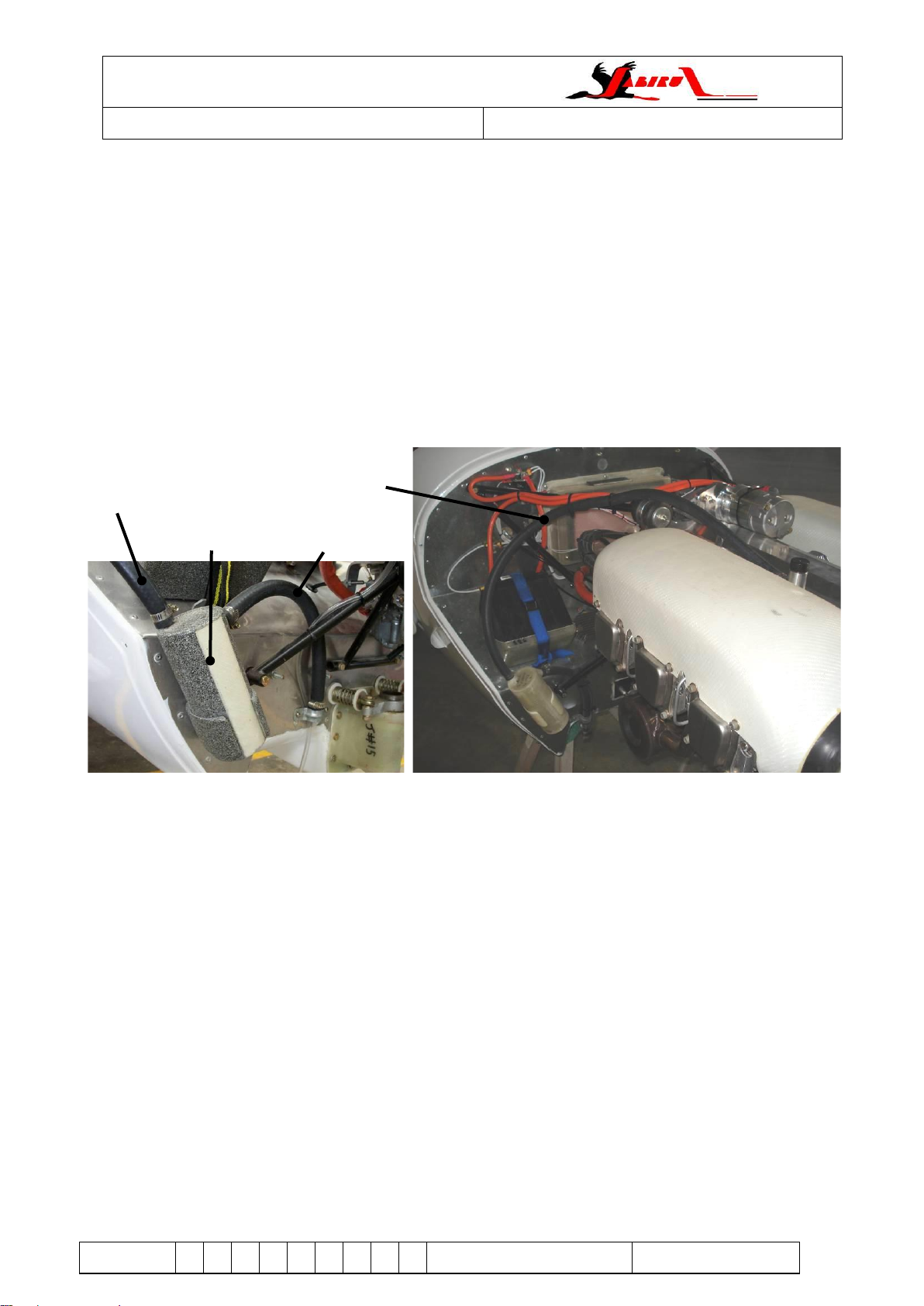

Figure 7. Crankcase Breather Installation...............................................................................................................................10

Figure 8. Ignition and Alternator Detail....................................................................................................................................11

Figure 9. Electrics Installation to Firewall................................................................................................................................12

Figure 10. Regulator Plug Wiring Details ................................................................................................................................12

Figure 11. Ignition Coil Cooling Tube......................................................................................................................................13

Figure 12. Starter Wiring Details.............................................................................................................................................14

Figure 13: Example of engine wiring connections...................................................................................................................15

Figure 14. Tachometer Sender Installation .............................................................................................................................16

Figure 15. Inductive pickup to VDO Tachometer Connections................................................................................................17

Figure 16: Hall effect sender location on 2200 engine. ...........................................................................................................17

Figure 17: Hall effect sender mounting location on 3300 engine.............................................................................................18

Figure 18: Hall effect sender connections...............................................................................................................................18

Figure 19: Sender position......................................................................................................................................................19

Figure 20. Oil Temperature Sender.........................................................................................................................................20

Figure 21. Oil Pressure Sender...............................................................................................................................................21

Figure 22. Oil Pressure Connections ......................................................................................................................................21

Figure 23: VDO CHT sender...................................................................................................................................................22

Figure 24: CHT Sender (Thermocouple) Installation...............................................................................................................22

Figure 25: EGT sensor installation example............................................................................................................................23

Figure 26. RG400 Co-Axial Antenna Cable.............................................................................................................................24

Figure 27. Mechanical Fuel Pump...........................................................................................................................................25

Figure 28: 3300 cobra head. (other bends are available)........................................................................................................26

Figure 29: Balance tube connection on airbox........................................................................................................................26

Figure 30. Carburettor Installation...........................................................................................................................................27

Figure 31. Carburettor Intake and Balance Tube Detail..........................................................................................................27

Figure 32. Needle Jet (Jabiru Needle) ....................................................................................................................................28

Figure 33. Air Intake Connections...........................................................................................................................................30

Figure 34. Air Filter Box Plumbing –Incorrect.........................................................................................................................31

Figure 35. Air Filter Box Plumbing –Correct...........................................................................................................................31

Figure 36. Typical “Cobra Head” Installation on a Jabiru Aircraft ............................................................................................31

Figure 37. Ram Air Bleed........................................................................................................................................................32

Figure 38. Engine Accessory Pack Contents..........................................................................................................................36

Figure 39 Upper and Lower Engine Mount Detail ...................................................................................................................36

Figure 40. Engine Mount Detail...............................................................................................................................................37

Figure 41. Fuel Connections General .....................................................................................................................................38

Figure 42. SCAT Hose Detail..................................................................................................................................................38

Figure 43. Cowl Airflow (Best Viewed in Colour).....................................................................................................................41

Figure 44. Cowl Airflow (Black and White Version).................................................................................................................41

Figure 45. Flow Visualisation ..................................................................................................................................................42

Figure 46 - Position ram-air duct on engine ............................................................................................................................43

Figure 47 - Mark, Drill and sand holes and reliefs...................................................................................................................44

Figure 48 - Fitting stainless steel tags.....................................................................................................................................44

Figure 49 - Front tag installation..............................................................................................................................................45

Figure 50: Ignition coil cooling tubes.......................................................................................................................................45

Figure 51. Air Dam Installation...............................................................................................................................................46

Figure 52 - Attach insertion rubber strip..................................................................................................................................47

Figure 53. Oil Cooler Duct Design...........................................................................................................................................48

Figure 54. Oil Cooler Installation.............................................................................................................................................48

Figure 55: Lip to aid cooling as installed on a Jabiru...............................................................................................................49

Figure 56. Effect of Angle of Attack on Cowl Outlets...............................................................................................................49

Figure 57. Cowl Outlet Geometry............................................................................................................................................50

Figure 58. Outlet Restriction Caused By Flange On Lower FirewallCooling System Testing and Evaluation.........................50

Figure 59: Cooling pressure measurement.............................................................................................................................51

Figure 60: Ram Air duct pressure tapping...............................................................................................................................52

Figure 61. Augmentor Exhaust System...................................................................................................................................53