2

IMPORTANT SAFETY INSTRUCTIONS

UNPACKING AND INSPECTION:

Do not use this range as a supplement to your furnace/

heater. It is not designed to heat up the kitchen nor

any other room. Using this appliance other than its

intended use could be dangerous.

Check that the container is upright. Check for visible

damages on the carton. If there is damage to the car-

ton, contact the carrier, and request an inspection. Do

not refuse shipment but file the appropriate freight

claims. Responsibility for shipping damage is with the

carrier and dealer or end user.

Cut the shipping straps and carefully lift the carton up

from the range. Check the range for visible damage.

If the range is to be installed on an area covered with

linoleum or any other floor covering, make sure that

the floor covering can withstand 90°F (65°C) above

room temperature without warping, shrinking or discol-

oring. Do not install the range over carpeting.

Remove, unwrap and temporarily lay aside any part or

accessory shipped with the unit and make sure that

there are no hardware or accessories left in the box for

accidental disposal. Make sure all packing material

and literature are removed from the oven before

connecting gas and electrical supply to the range.

CONTENTS PAGE

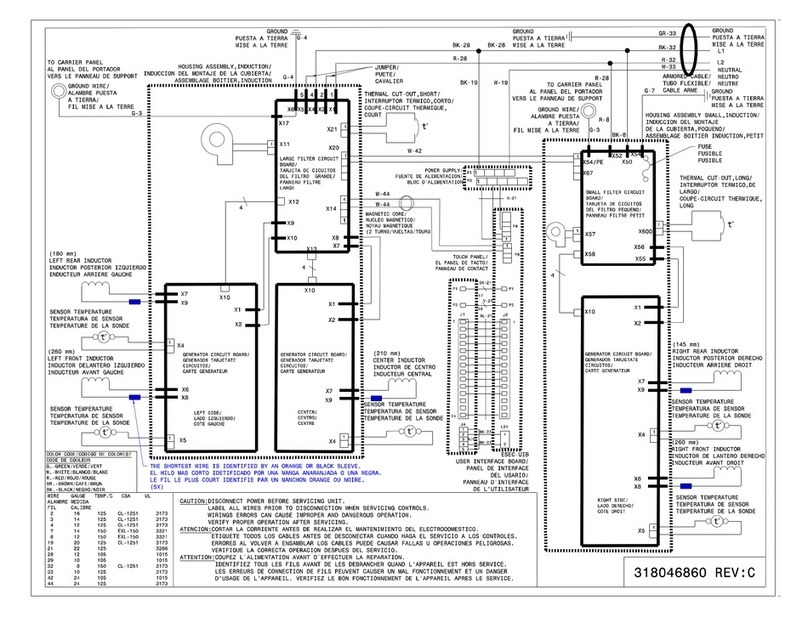

Important Safety Instructions............................................................... 1-2

Unpacking and Inspection................................................................... 2

Range Specifications........................................................................... 3

Legs Installation.................................................................................. 3

Casters Installation.............................................................................. 4

Curb Base Installation......................................................................... 5

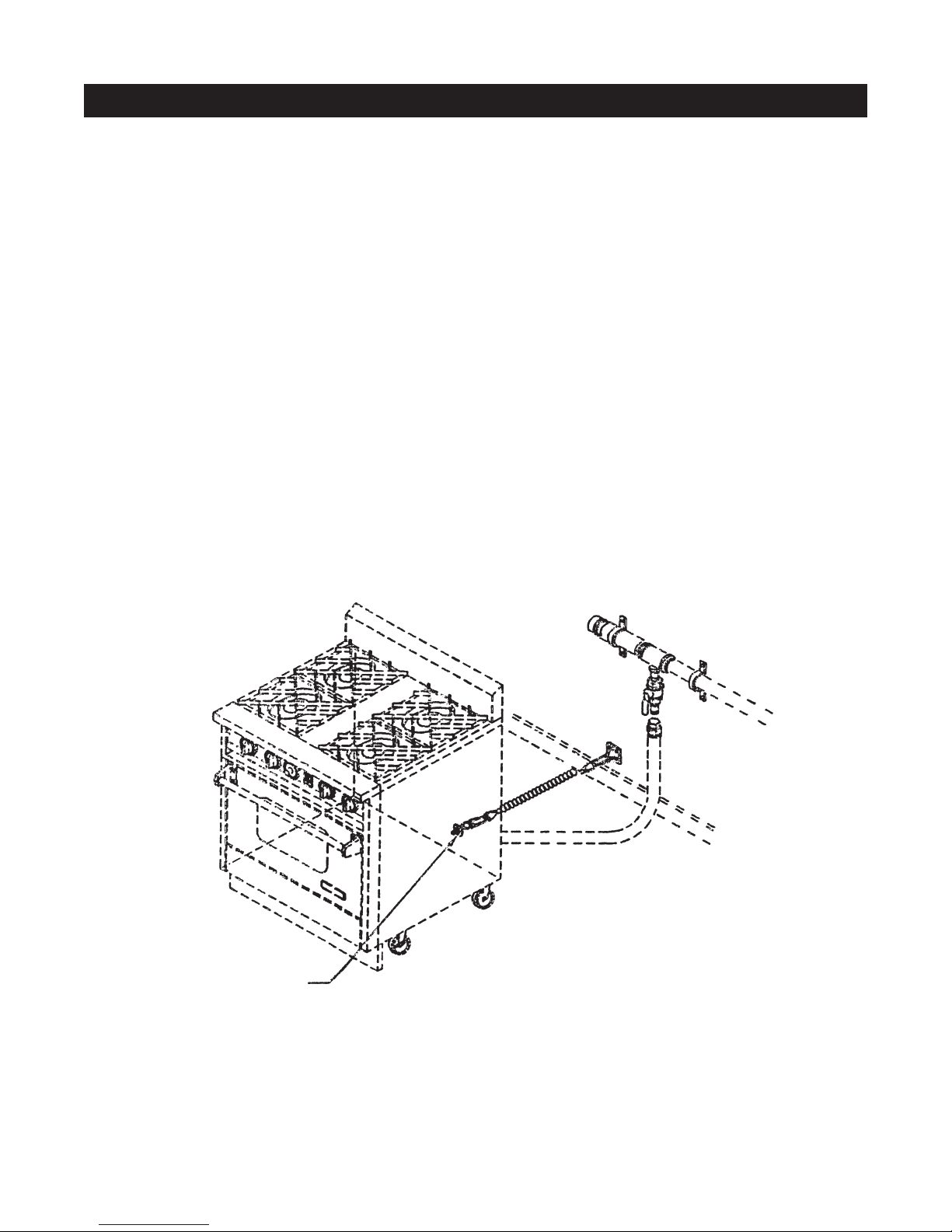

Stub Back Installation......................................................................... 6

Clearances Against Combustible Surfaces......................................... 7

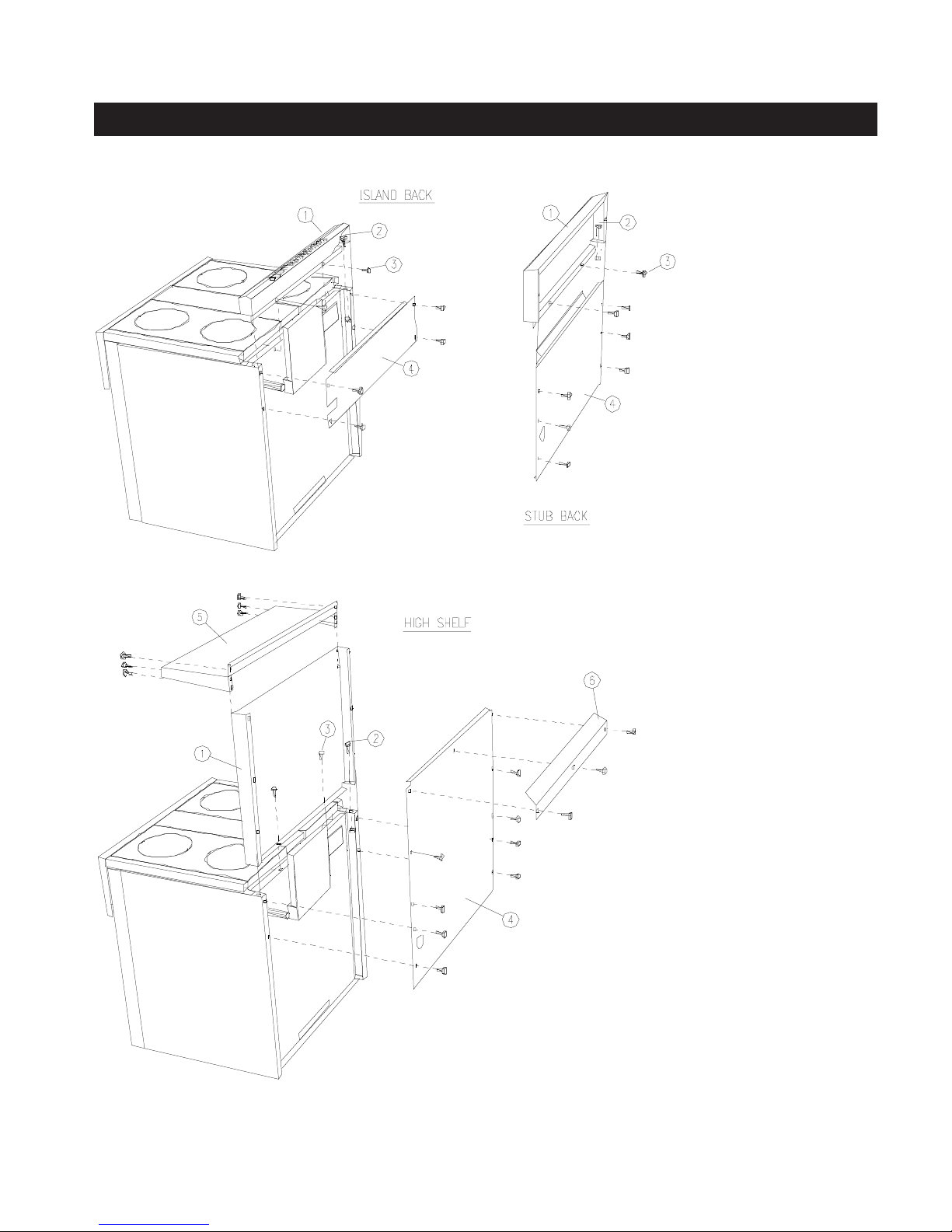

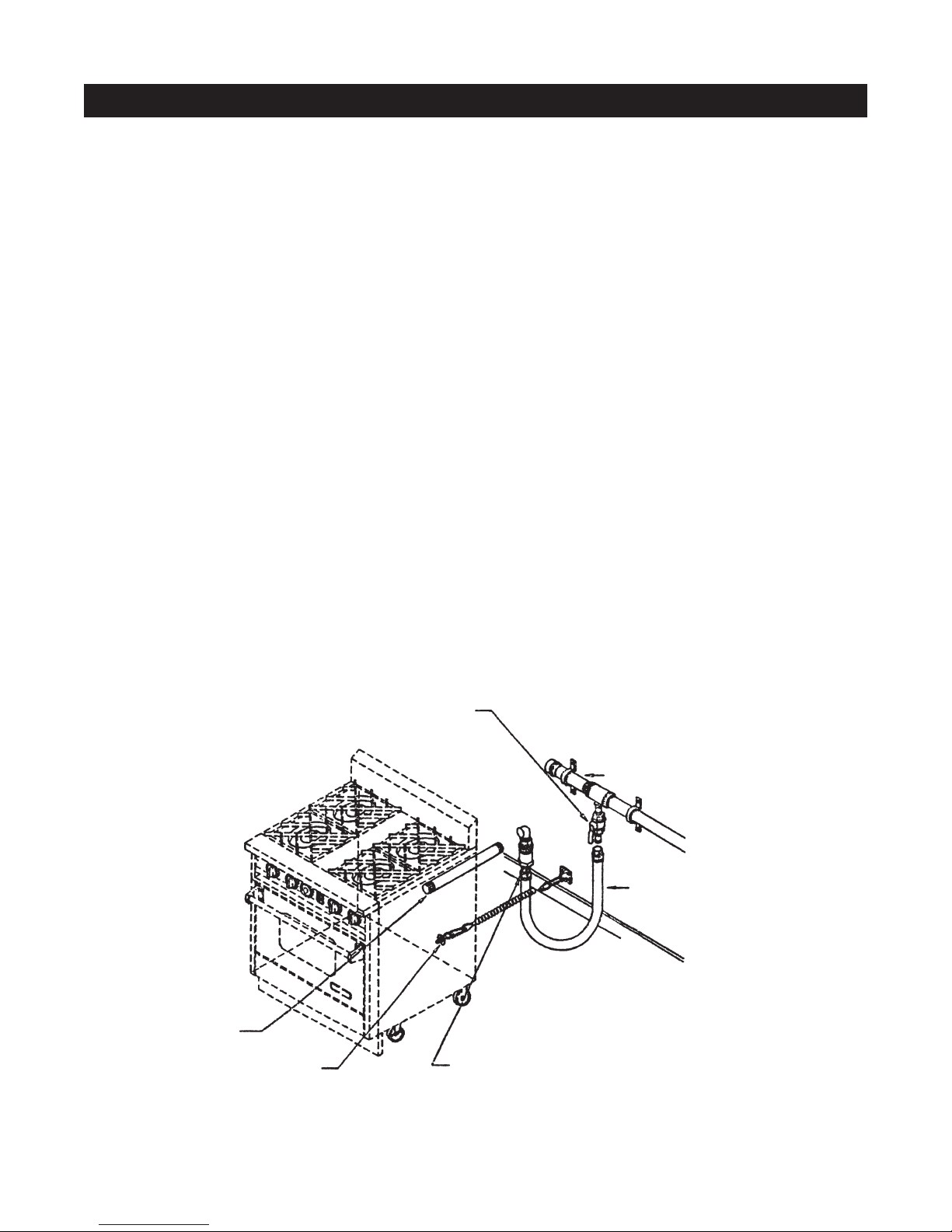

Gas Connection.................................................................................. 8

Gas Conversion For RJGR Series .................................................. 9-10

Electrical Connection.......................................................................... 11

Initial Start-up and Burner Adjustment

Open top / Simmer ................................................................ 12

Infrared Broiler....................................................................... 13

Oven...................................................................................... 13

Wok........................................................................................ 14

Charbroiler.............................................................................. 14

Griddle.................................................................................... 14

Installation of Anti-Tip Bracket............................................... 15-16