Oxygen Technical Manual

Oxygen Description

Intelligent, healthy energy-efficient IAQ control

Jaga Oxygen is an energy-efficient, intelligent and fully programmable heating and ventilation solution

which creates a fresh, healthy and comfortable indoor climate in buildings of any age or type.

Particularly suited for rooms with high occupancy such as classrooms, offices and care homes, Oxygen

delivers clean, healthy, fresh air on demand and in a highly energy efficient way.

In schools, poor indoor air quality (IAQ) has long been an issue and has been proven to have a detrimental

effect on educational performance. Similarly in an office environment, good indoor climate is essential for

productivity and to reduce sickness and absenteeism. In care homes the need is even more acute as

poor IAQ, due to excess CO2, is a real threat to healthy living and occupants’ comfort.

How Does it Work?

The Oxygen system works by monitoring and measuring the air quality in a room and cutting in

automatically when required. This ensures that an adequate supply of fresh, clean outside air is

introduced into the room and the contaminated, stale air is removed.

As the Oxygen’s intelligent demand controlled (heating and) ventilation system only vents fresh air when

required it is more efficient than natural ventilation and eliminates the drawbacks of draughts, stuffiness

and security risks. During the hot summer months Oxygen’s boost function can be used to deliver effective

secure night-time air purging. This cools the building fabric down so that the environment is more

comfortable first thing in the morning.

The Oxygen system can be specified with a wide range of Jaga wall-mounted heating solutions. Oxygen

systems can be linked to an existing building management system, centrally controlled in a stand-alone

system, or even controlled simply through a panel on the radiator.

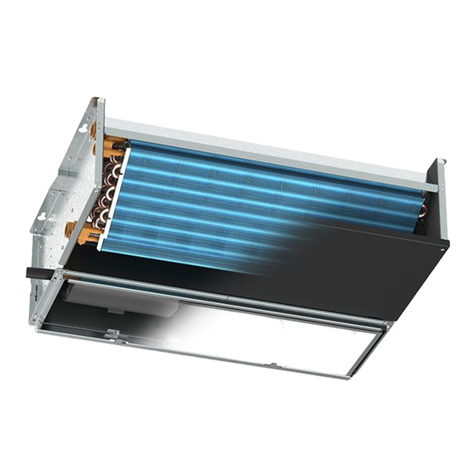

The system features Oxygen Refresh fans built into Jaga’s patented Low H2O radiators. The refresh unit

draws in outside air and filters it before discharging it through the radiator and into the space.

The Jaga Master controller regulates and balances inlet (and exhaust if installed) air. The exhaust unit

directs stale air outside or into central corridors to provide a degree of heat recovery. The Oxygen CO2

sensor controls the whole system, continuously measuring the air quality and reacting accordingly by

replacing stale air with fresh clean air. As the ventilation demand changes the Low H2O radiator is able

to respond instantly offering excellent fast response heating control.

The fresh air, depending on the requirements of the CO2 sensor, will vary from 30 m3/hr on 1.0 vdc output

from main oxygen control panel to 200 m3/hr on 4.5 vdc output from main oxygen control panel, which

will be boosted up to 400 m3/hr on 7.0 vdc output once the ‘BOOST’ button has been depressed on the

smart switch.

When using The Jaga Oxygen control system, remote access can provide real-time monitoring of room

conditions including, CO2, temperature and air volumes.

Also, with the ‘Cloud Service’ the current status can be monitored and changed remotely – ideal for

Facility Managers.