SELECTION OF SITE

ØProper space should be there for placement and opening of doors of the

Silent DG set.

ØThere should be atleast 1.5 meter free space around the DG set for

proper operation and maintenance.

ØThere should be cross ventilation of air to ensure proper cooling of DG

set. Exhaust gases and hot air discharge should not re-circulate inside

the acoustic enclosure (canopy).

Ø If Genset is to be installed in the room, please ensure proper cross

ventilation and surrounding space.

ØThere should be no restriction for fresh air suction and hot air discharge.

If 2 nos. DG sets are installed at the site, ensure that hot air outlet of the

one DG set does not become the fresh air intake of the 2nd DG set.

Ø If Genset is to be installed in the basement, please ensure ventilation

with respect to Air requirement and clear space for every maintenance.

ØDistance between two SDG set should be minimum 1.5 meters.

ØA low height shelter for the Silent DG Set should be avoided. It should

not obstruct the hot air outlet, shelter height minimum 1.5 meter or

equal to height of genset

ØIt is preferable to install the DG set in an open area. No shade (roof) is

required over it. However, if the AMF Panel is outside the Acoustic

Enclosure, then a shelter is recommended for the AMF Panel.

ØFor Roof Top Installation, ensure that the civil structure is capable to

bear the static and dynamic load of DG set. The load of the Silent DG set

should be borne by Columns and Beams of the building.

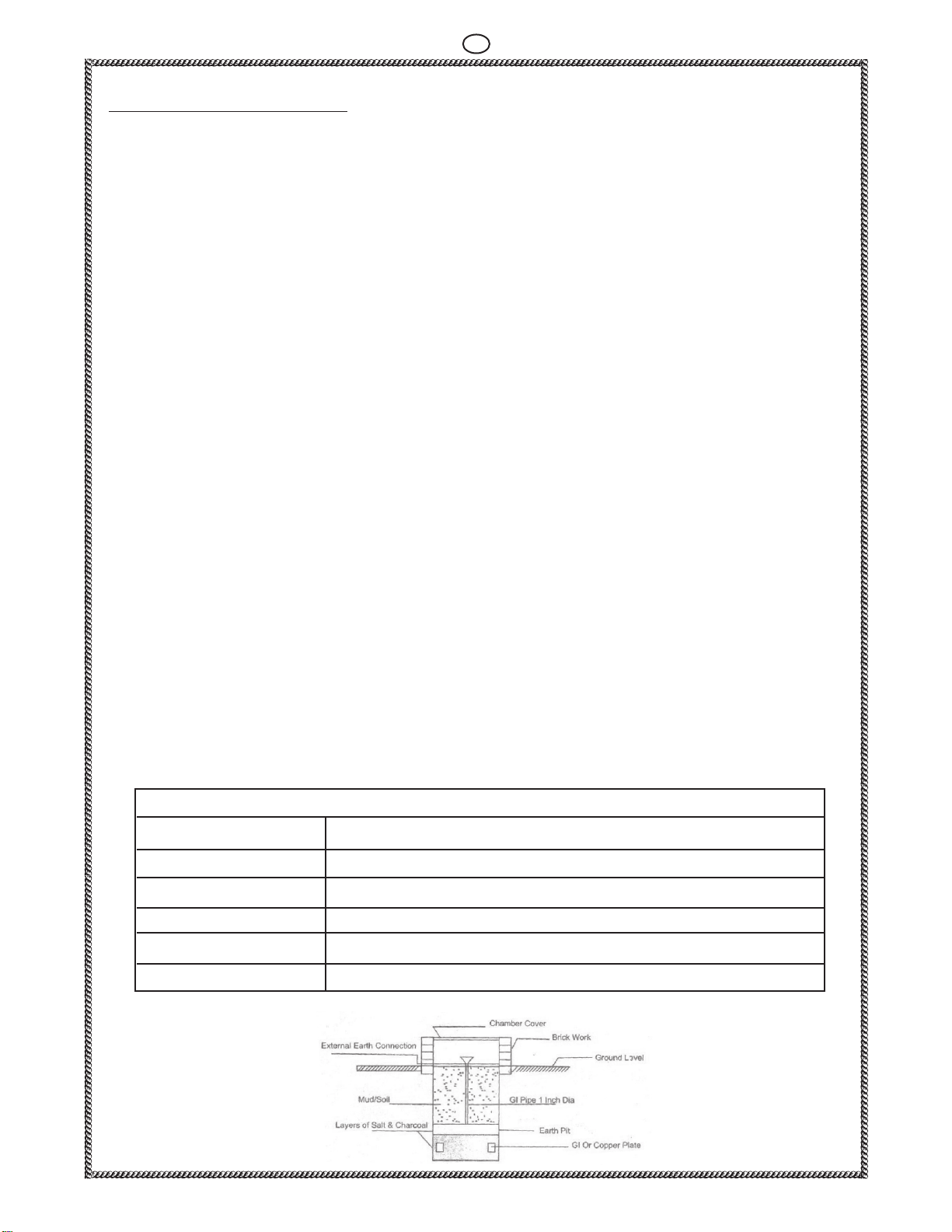

ØProper space should be there for Earthing.

ØIf there are no space constraints, the DG set should be placed near the

distribution panel.

ØThe DG set should be located away from polluted surroundings such as

corrosive fumes, cement dust, fibres, cotton and toxic chemicals to

avoid overheating of the D.G. Set.

Ø There should be sufficient space around the Genset to avoid resonance

and echo effect which contributes to abnormal sound from Genset.

Ø The space should be open without any obstacles.

1

JAKSON & CO.