6

SAFETY

•TRAINING

WARNIG! The use f the machine is all wed exclusively t auth rized staff pr perly

trained.

For a proper and safe use of the machine it is necessary to have entirely read and understood the

present manual and the attached instructions.

•SAFETY INSTRUCTIONS

Do not try to operate the machine until its functioning hasn’t been clearly understood. Anyway

the use of the machine is allowed exclusively to authorized staff properly trained. Do not allow

unauthorized people and especially children to get near the machine.

Before starting the machine, the operator must check the presence of clear faults on the safety

devices and on the machine and immediately report what found to the person in charge.

The only working position suitable for the operator is the fabric loading position, that is behind

the fixed safety bar. Do not occupy other positions different from the above mentioned one

during the machine functioning.

Never start the machine before having advised and averted anyone present nearby it.

Do not use the machine while wearing clothes, ornaments or accessories which can get caught on

any moving part. Gather up long hairs under a cap. Wear clothes which allow to bear objects and

tools in closed pockets.

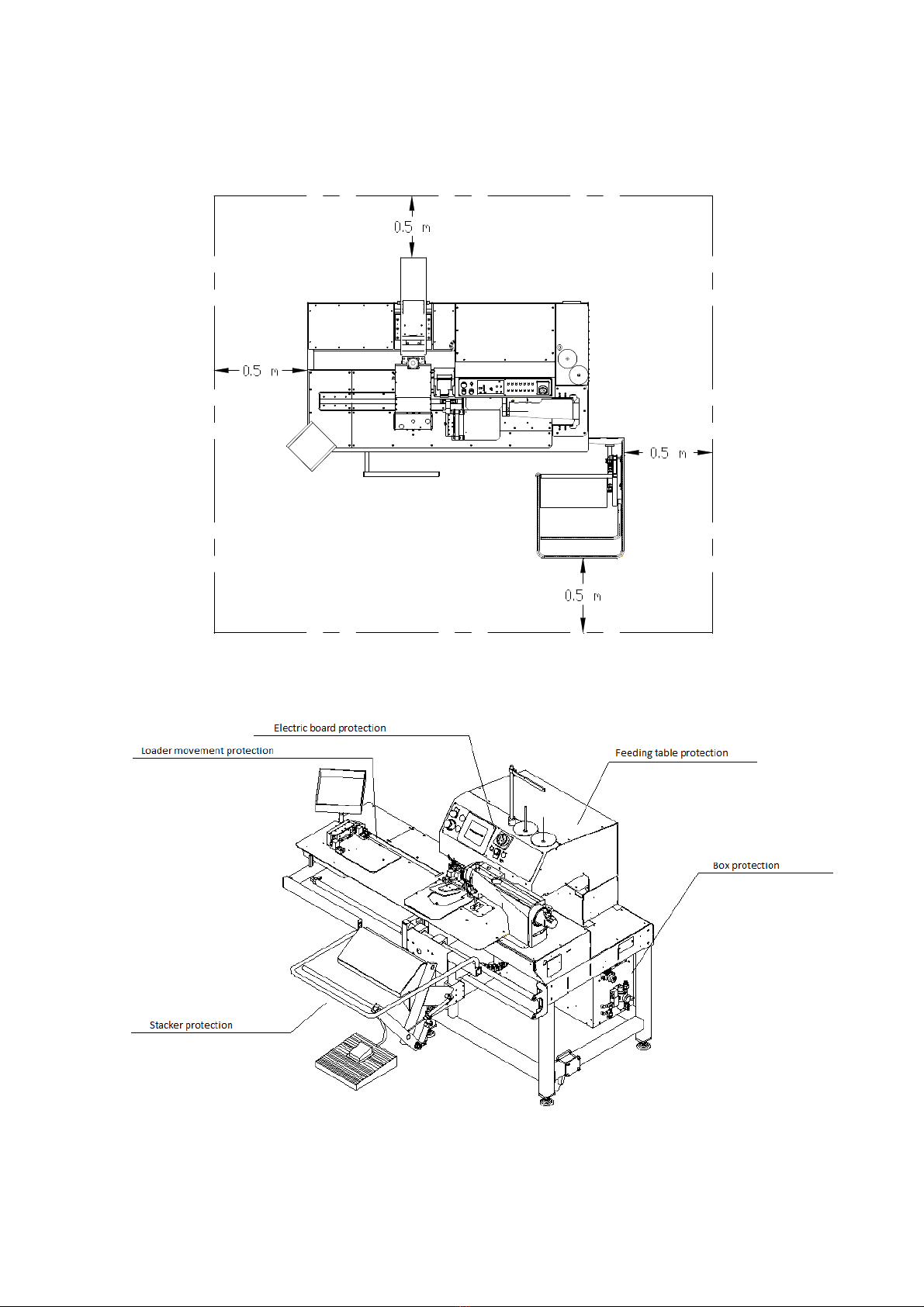

The machine user must know the safety devices installed on it, as well as the respective proper

modalities of use. Check daily the proper functioning of the emergency buttons and of the safety

devices. Never use the machine without its safety devices properly installed and working.

Pay the maximum attention to every danger and prohibition symbol existing on the machine.

Keep every plate with danger and prohibition symbols in perfect conditions, clearly visible and

readable. In case of tear replace them quickly.

Do not operate the machine with damp hands and objects when it is connected to the electric

system.

Replace the parts considered damaged with original ones or in any case authorized by the

manufacturer. Never try hazardous solutions.

It is extremely dangerous to use the machine without its safety devices (emergency button, belt

protection and so on). Never use the machine without the safety devices.

The safety devices rem val is all wed exclusively during the machine maintenance and must be

d ne exclusively buy specialized staff