Singer 321C 131M-04 User manual

Other Singer Sewing Machine manuals

Singer

Singer 320K2 Installation and operation manual

Singer

Singer Futura Quartet User manual

Singer

Singer 160 User manual

Singer

Singer 2639 User manual

Singer

Singer 211G146 User manual

Singer

Singer 246K43 Troubleshooting guide

Singer

Singer 17 pattern User manual

Singer

Singer 2662 User manual

Singer

Singer 460K20 Assembly instructions

Singer

Singer 221K Installation and operation manual

Singer

Singer 140G2 Quick start guide

Singer

Singer 240W User manual

Singer

Singer 2277 User manual

Singer

Singer Futura CE-250 User manual

Singer

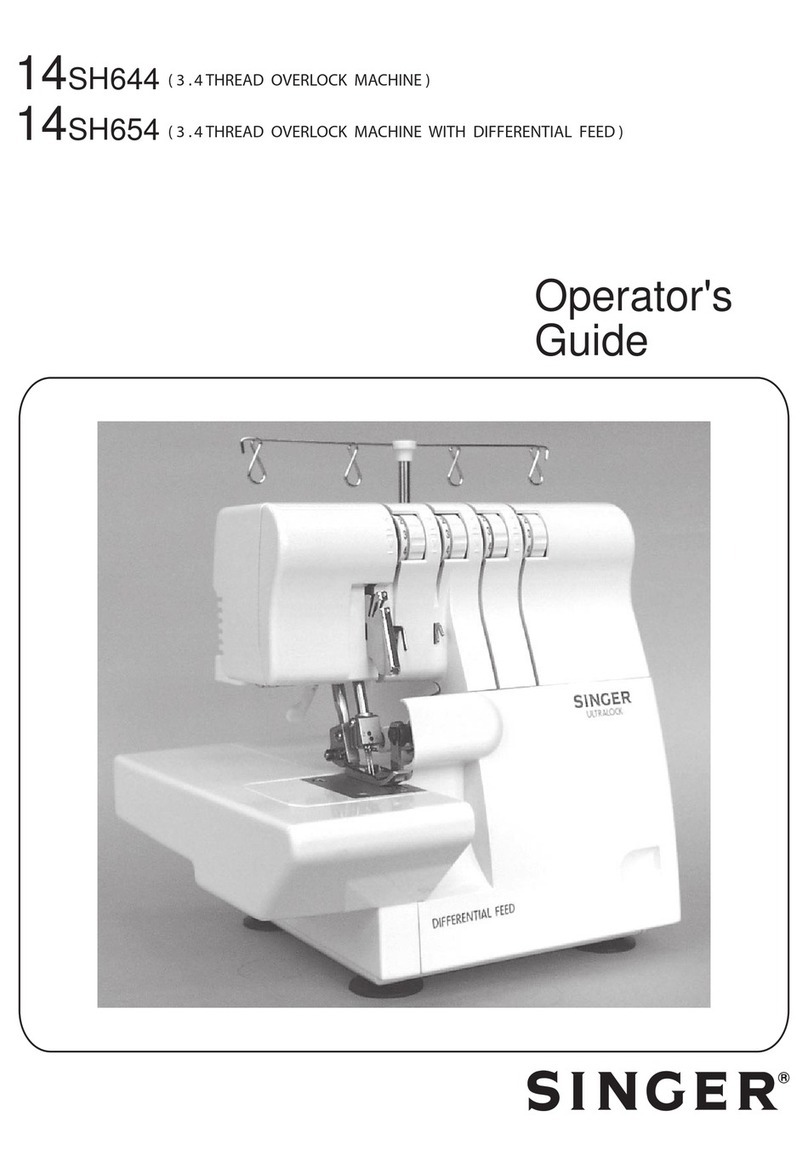

Singer 14SH644 Manual

Singer

Singer 144W305 Quick start guide

Singer

Singer 151K1 Quick start guide

Singer

Singer 11W6 Quick start guide

Singer

Singer 2000A User manual

Singer

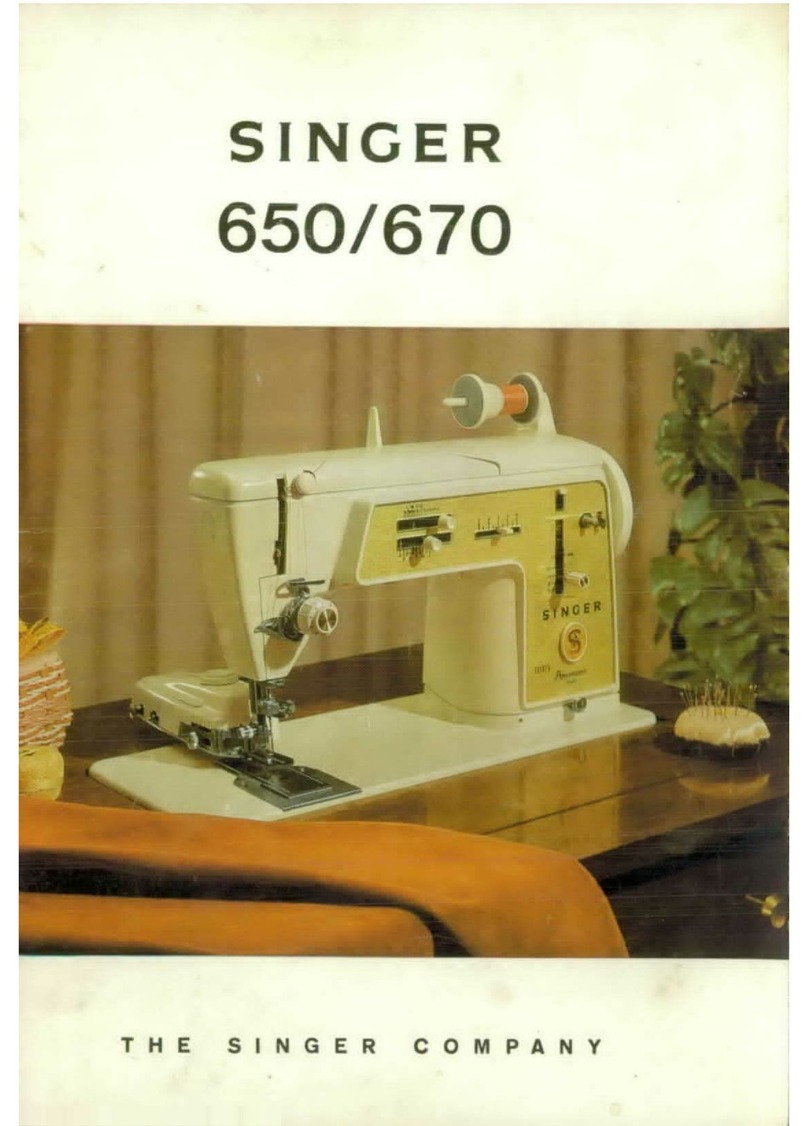

Singer 650 User manual