J&D MAnufacturing IS275-17L User manual

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com T.O.C.

HPF Stainless Steel Lines

with 12”, 18”, 24”, or 48”

Nozzle Spacing

HPF Stainless Steel

Panel Fan Ring Kit

with 12 Nozzles

High Pressure Fog System

Table of Contents

Warranty & Recommended Tools

Water Quality Requirements

Pump & Filter Kit Location

Requirements & Recommendations

Parts Identification

Guidelines for Assembling Components

Filter System Assembly & Installation

Motor/Pump Shelf Assembly & Installation

Motor & Pump Assembly & Installation

Hanging & Connecting Stainless Steel Lines

J&D Panel Fan Ring Kit Installation

Ring Kit Installation for (36” and Larger) Basket Fans

Cross Kits Installation for Basket Fans

Auto Drain Kit Installation & Assembly

A:

B:

C:

D:

E:

F:

G:

H:

I:

J:

K:

L:

M:

Connecting Pump to Filter and Fogging System/s

Flushing System

Filter Installation

Nozzle Installation

Test & Adjust System

Maintenance

End of Season & Winterizing

Maintenance Checklist

N:

O:

P:

Q:

R:

S:

T:

U:

• Reduces temperatures quickly and uniformly with minimal

energy use

• Minimizes heat stress which improves feed conversion

for increased production

• Easy to retrofit your current ventilation system

• Made from corrosion resistant materials for long life

• Anti-drip brass nozzles with end of line auto drain valve

help keep your floor dry

• Reduces heat stress mortalities

WARRANTY

One year is our standard warranty unless specified on our literature or in the installation instructions/user manuals, for pump warranty see pump manual.

J&D Mfg. warrants all products are free from defects in materials and workmanship under normal use for the period of one year from date of purchase, warranty does not cover normal or regular wear

and tear. J&D Mfg can repair or replace at our option, any product or part of the product that is found to be defective. Our warranty applies to materials only and does not include return freight, delivery,

loss or damage to personal property, cost of removal or installation, any incidental or consequential damages or labor. This warranty does not apply to products which are misused, abused, altered,

improperly installed or subject to negligence. All warranties must be approved through our warranty department. The original purchaser must present a copy of the invoice for the defective product.

INSTALLATION

Please read over all instructions carefully before you begin. If you have any questions please call your local dealer, or contact

J&D Manufacturing at 1-800-998-2398.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section A - Page 1/1

Section A

Warranty & Recommended Tools and SuppliesSection A

RECOMMENDED TOOLS & SUPPLIES FOR INSTALLATION AND ASSEMBLY (NOT PROVIDED)

Safety Glasses

Measuring Tape

Socket Wrench

1/2”

9/16”

Sockets

PVC

Primer / Cleaner

PVC

Glue / Cement

PTFE

Tape

PVC Primer & PVC Glue/Cement

Brushes or Swabs for

PVC Primer & PVC Glue/Cement

if not provided with product

3/8”

Drill Bit

Drill

#3 Phillips

Driving Bit

Flat Head Screwdriver

Crescent Wrench 1/2”

9/16”

3/4”

Combination Wrenches

3 MM Hex Key

Nylon Tube Cutter

IN

OUT

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section B & C - Page 1/1

Section B

Water Quality RequirementsSection B

Section C

Filter & Motor Location Requirements & RecommendationsSection C

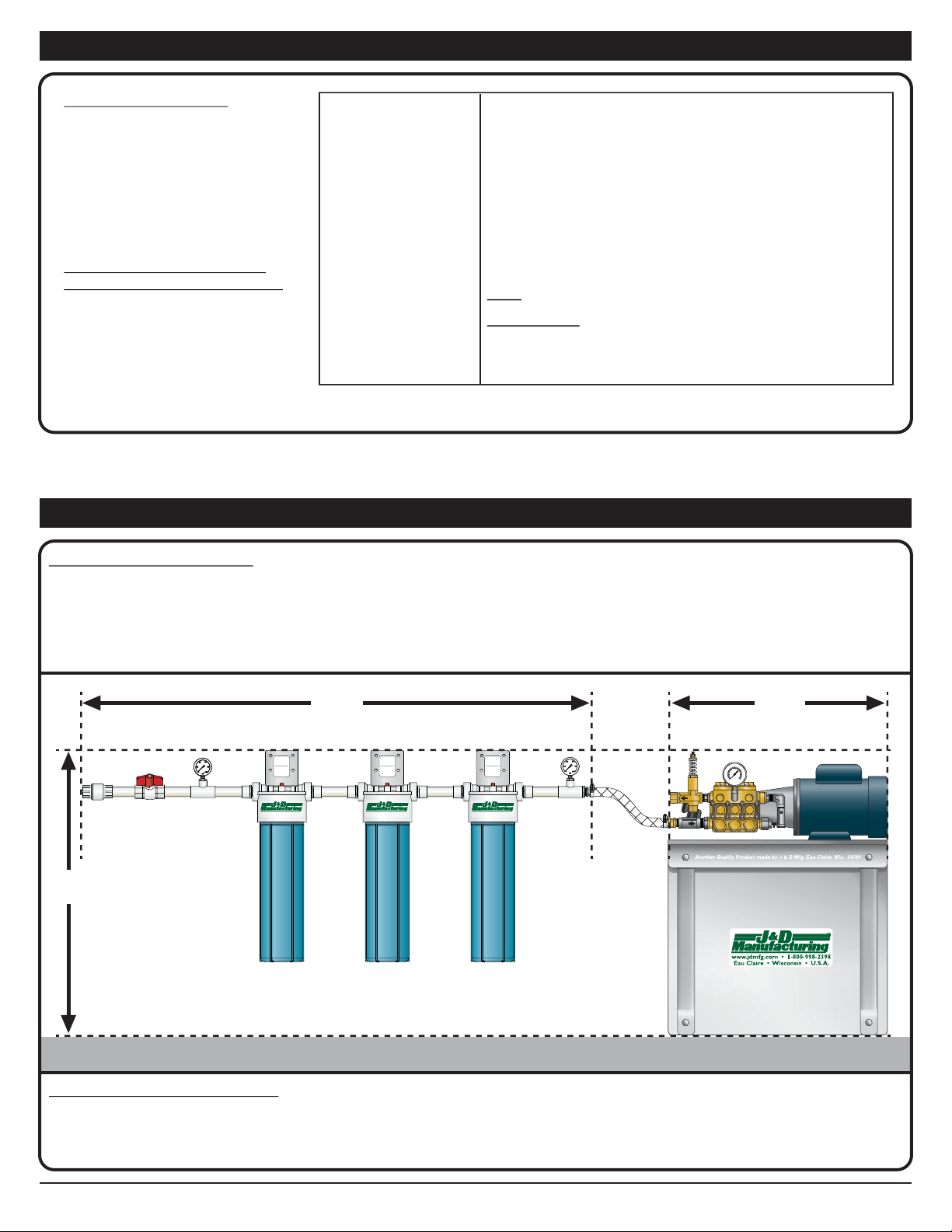

Filter & Motor Space Requirements

The minimum space requirements needed for the filtration assembly are 54” in width and 37” in height

The minimum space requirements for the motor and pump shelf assembly are 31” in width and 37” in height.

Provided 3/4” x 5’ Braided Hose for connecting filter assembly to pump allows for a 4’ distance between the filtration assembly and the motor pump shelf

assembly, however this distance can be extended if a longer (not provided) hose is acquired.

Filter & Motor Space Recommendations

Due to the nature of setup and maintenance of a filtration system, it is recommended that it be located in an area that has a floor drain or is some way protected

so that water will not damage materials or structure. Additional precautions should be taken to ensure that water will not come in contact with electrical cords

or outlets as this may result in severe injury or even death.

Water Quality Requirements

Thorough water testing and treatment of

your intended water supply by qualified

water treatment professionals is required

to minimize mineral deposits and corrosion

that may block or erode nozzles.

Shown are the basic parameters required

of your water supply.

Additional requirements by your water

treatment professionals may be justified.

Damage or clogging of nozzles or

other elements of J&D’s High Pressure

Fogging system due to insufficiently

treated water will not be covered by

warranty.

Test

Hardness

PH

Dissolved Metals

TDS

(Total Dissolved Solids)

Required Parameters

Less than 7gpg

(120 parts per million or milligrams per liter)

7.0 or higher

Listed are the most common and problematic.

Consult with your water specialist on what additional

dissolved metals you may need to correct.

Iron - Less than 0.3 parts per million

Manganese - Less than 0.05 parts per million

Less than 500 milligrams per liter

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

20

Micron

Filter

www.jdmfg.com • 1-800-998-2398

Eau Claire • Wisconsin • U.S.A.

OA128-08K 20

Micron

Filter

www.jdmfg.com • 1-800-998-2398

Eau Claire • Wisconsin • U.S.A.

OA128-08K 20

Micron

Filter

www.jdmfg.com • 1-800-998-2398

Eau Claire • Wisconsin • U.S.A.

OA128-08K

20

MICRON

REPLACEMENT

FILTER

5

MICRON

REPLACEMENT

FILTER

1

MICRON

REPLACEMENT

FILTER

37”

54” 31”

FloorFloor Floor Floor

* Indicates shown to scale for ease of identification.

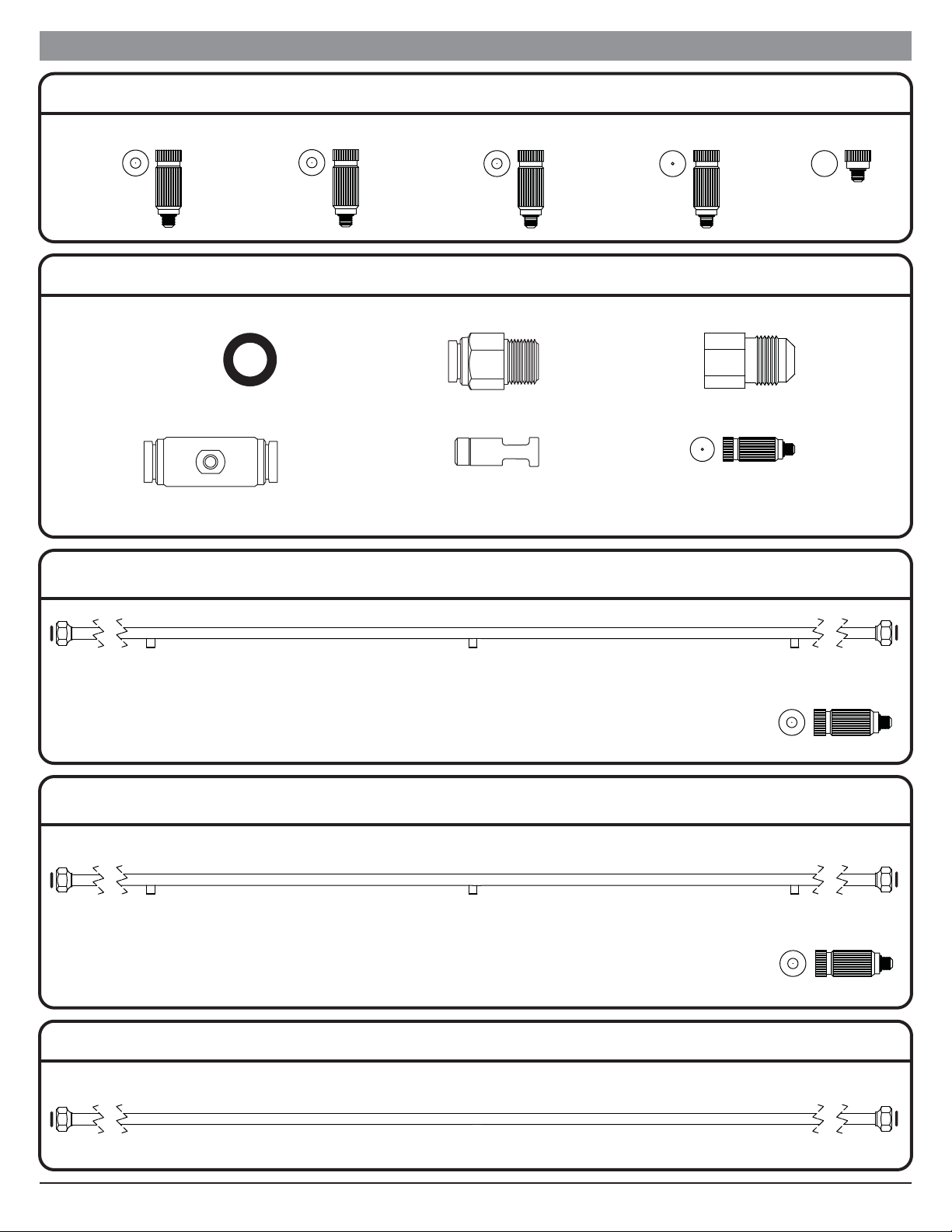

(2)

SS19

1/2”x1/4”

Reducer

(2)

SSOT

1”x1”x1/2”

Tee

(2)

VHPR145

Hose Clamp

(2)

VHPR149

Water Supply

Low Pressure

Gauge

(1)

SS01

1” Ball Valve

(1)

VHPR147

Male Adaptor

3/4” MPT x

3/4” Insert

(1)

VHPR146

1” Spigot x

3/4” FPT

Reducer Bushing

(1)

VHPR151

1” PVC Tubing

2’ Stick

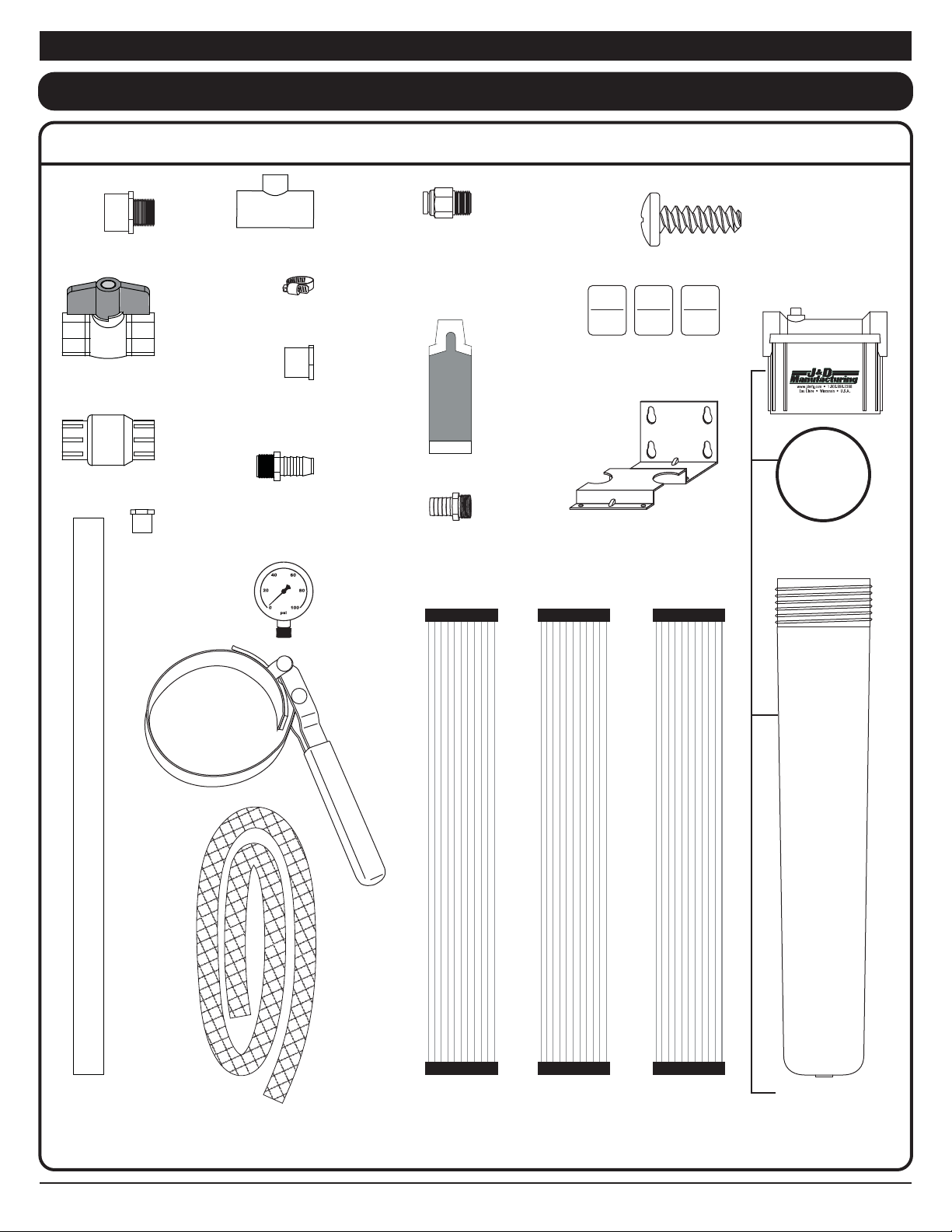

VHPF2520C - 3 Stage 2½” Filter Kit

*(12)

HD10464

Phillips Pan Head Screw

#14–10 x 3/4”

(6)

PP10461

3/4”x1”

Adapter

(1)

VHPR138

1 Micron

2-1/2” Filter

(1)

VHPR137

5 Micron

2-1/2” Filter

(1)

VHPR136

20 Micron

2-1/2” Filter

(3)

VHPR142

Mounting Bracket for

2-1/2” Filter Housing

(1)

VHPR133

2-1/2” Filter

Housing

Wrench

(3)

VHPR135

2-1/2” Filter

Housing Assembly

20

MICRON

REPLACEMENT

FILTER

5

MICRON

REPLACEMENT

FILTER

1

MICRON

REPLACEMENT

FILTER

Set of 3 Filter Size Labels

for Mounting Brackets

SS05R

O-Rings for

2-1/2” Filter Housing

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 1/8

Section D

Parts IdentificationSection D

(1)

SS03

1” One Way

Check Valve

(1)

VHPR148

Brass Adaptor

3/4” ID Barb x

3/4” Male

Hose Thread

(1) PP10815

Anti-Seize

Lubricant

2 Gram

Single Use

Pouch

(1)

VHPR152

3/4” Braided Hose

5’ Length

(1)

VHPR123

Adapter

3/8” Slip Lock

x 3/8” MIPT

(1)

VHPR151

1” PVC Tubing

2’ Stick

(1) PP10815

Anti-Seize Lubricant

2 Gram

Single Use Pouch

(1)

VHPR140

20 Micron

4-1/2” Filter

(3)

VHPR139

4-1/2” Filter

Housing Assembly

(1)

VHPR144

5 Micron

4-1/2” Filter

(1)

VHPR141

1 Micron

4-1/2” Filter

(1)

VHPR132

4-1/2” Filter

Housing Wrench

(6)

VHPR143

1”x1” Adapter

(2)

SS19

1/2”x1/4” Reducer

(2)

SSOT

1”x1”x1/2” Tee

(2)

VHPR145

Hose Clamp

(2)

VHPR149

Water Supply

Low Pressure Gauge

(1)

SS01

1” Ball Valve

(1)

VHPR148

Brass Adaptor

3/4” ID Barb x

3/4” Male Hose Thread

(1)

VHPR147

Male Adaptor

3/4” MPT x 3/4” Insert

(1)

VHPR146

1” Spigot x 3/4” FPT

Reducer Bushing

(1)

VHPR152

3/4” Braided Hose

5’ Length

(3)

VHPR153

Mounting Bracket for

4-1/2” Filter Housing

VHPF4520C - 3 Stage 4½” Filter Kit

*(12)

HD10464

Phillips

Pan Head

Screw

#14–10 x 3/4”

(1)

SS03

1” One Way

Check Valve

SS06R

O-Ring for

4-1/2” Filter Housing

20

MICRON

REPLACEMENT

FILTER

5

MICRON

REPLACEMENT

FILTER

1

MICRON

REPLACEMENT

FILTER

Set of 3 Labels Indicating Filter

Size for Mounting Brackets

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 2/8

Section DParts IdentificationSection D

(1)

VHPR123

Adapter

3/8” Slip Lock

x 3/8” MIPT

VHPRSHELF - Shelf for Motor and Pump

(1) Shelf

(1) Large J&D Manufacturing Label

(1) Narrow J&D Manufacturing Label

(2) Support Brackets

Hardware Packet Contents

Attaching Top of Brackets to Shelf Mounting Motor to ShelfAttaching Pump to Motor

*(4)

3/8”-16 x 1”

Hex Bolt

*(4)

3/8”-16 x 1”

Hex Bolt

*(4)

3/8”-16

Nylock Nut

*(2)

3/8”-16 x 1”

Hex Bolt

*(2)

3/8”-16

Nylock Nut

*(4)

5/16”-18x3/4”

Carriage Bolt

*(4)

5/16”-18

Nylock Flange Nut

*(4)

3/8”

Split Lock Washer

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 3/8

Section DParts IdentificationSection D

C-Face Motors

Each model of J&D C-Face pump motors will vary in size, configuration of components, and

appearance, however, the functionality and purpose of the components remain the same.

Single Phase

VHPM1

VHPM2

VHPM3

VHPM5

3 Phase

VHPM13

VHPM33A

VHPM53

VHPM103-CFACE

Mounting Foot

Shaft

Venting Bell

Pumps

Each model of J&D pumps will vary in size, configuration of components, and appearance, however, the functionality and purpose of the components remain the

same. For detailed pump information please refer to the separate pump manual.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 4/8

Section DParts IdentificationSection D

Breather Valve/Oil Dipstick

Breather Valve/Oil Dipstick

Adjustable

Pressure

Unloader

Adjustable

Pressure

Unloader

Adjustable

Pressure

Unloader

Adjustable

Pressure

Unloader

Flex Coupler

Flex Coupler

Flex Coupler

Breather Valve/Oil Dipstick

Breather Valve/Oil Dipstick

IN

OUT

VHPP57

IN

OUT

VHPP41

IN

OUT

VHPP13

VHPP30

IN

OUT

VHPP137

3/4” Female Hose Thread

3/4” Female Hose Thread

3/8” FIPT

3/8” FIPT

3/4” Female Hose Thread

3/4” Female Hose Thread

3/8” FIPT

3/8” FIPT

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 5/8

Section DParts IdentificationSection D

3/8” Slip Lock Connectors Compatible with

VHPR122 High Pressure Nylon Tube

1/2” Flare Connectors Compatible with

VHPR000, VHPR002, VHPR003 Stainless Steel Lines

VHPR120 - O-Ring

7/16” ID x

11/16” OD

VHPR123 - Adapter

3/8”

Slip Lock

3/8”

MIPT

VHPR134 - Elbow

3/8”

Slip Lock

3/8”

Slip Lock

VHPR154 - Splice

3/8”

Slip Lock

3/8”

Slip Lock

VIEC1000B - Tee

3/8”

Slip Lock

3/8”

Slip Lock

3/8”

Slip Lock

VIEC1000C - Tee

3/8”

Slip Lock

3/8”

Slip Lock

Nozzle

Port

VIEC1000G - Plug

Plug 3/8”

Slip Lock

1/2”

Flare

1/2”

Flare

1/2”

Flare

VHPR108 - Tee

VHPR125 - Coupling

3/8”

FIPT

1/2”

Flare

VHPR126 - Coupling

3/8”

FIPT

3/8”

FIPT

VHPR127 - Elbow

3/8”

FIPT

3/8”

FIPT

1/2”

Flare

1/2”

Flare

VHPR128 - Union

3/8”

MIPT

1/2”

Flare

VHPR129 - Union

1/2”

Flare

Plug

VHPR131 - Plug

VHPR124 - Coupler

1/2”

Female

Flare

Swivel

Nut

1/2”

Female

Flare

Swivel

Nut

3/8”

FIPT

3/8”

FIPT

VHPR122 - Tube 3/8” H.P. NylonVHPR163 - 2000 psi Ball Valve

NOTE: Spacing and quantity of nozzles is dependent on model purchased.

NOTE: Spacing and quantity of nozzles is dependent on model purchased.

VHPR123 - Adapter

3/8”

Slip Lock

3/8”

MIPT

VIEC1000C - Tee

3/8”

Slip Lock

3/8”

Slip Lock

Nozzle

Port

VIEC1000G - Plug

Plug 3/8”

Slip Lock

VHPR120 - O-Ring

7/16” ID x

11/16” OD

VHPR125 - Coupling

3/8”

FIPT

1/2”

Flare

VIEC1000I - Nozzle

Auto Drain

Valve Nozzle

VHPR2002 Series - 20’ Long SS Lines with 0.02 GPM Nozzles

VHPR2003 Series - 20’ Long SS Lines with 0.03 GPM Nozzles

VHPR2000 - 20’ Long SS Line (No Nozzles or Nozzle Ports)

VHPR162 - Auto Drain Kit

VHPR110 - Nozzle

0.02 GPM

Anti Drip

Nozzle

2

VHPR111 - Nozzle

0.03 GPM

Anti Drip

Nozzle

3

Nozzles

VIEC1000I - Nozzle

Auto Drain

Valve Nozzle

VHPR110 - Nozzle

0.02 GPM

Anti Drip

Nozzle

2

VHPR111 - Nozzle

0.03 GPM

Anti Drip

Nozzle

3

VHPR106 - Nozzle

0.05 GPM

Anti Drip

Nozzle

5

VHPR107 - Nozzle

Nozzle

Plug

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 6/8

Section DParts IdentificationSection D

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 7/8

Section DParts IdentificationSection D

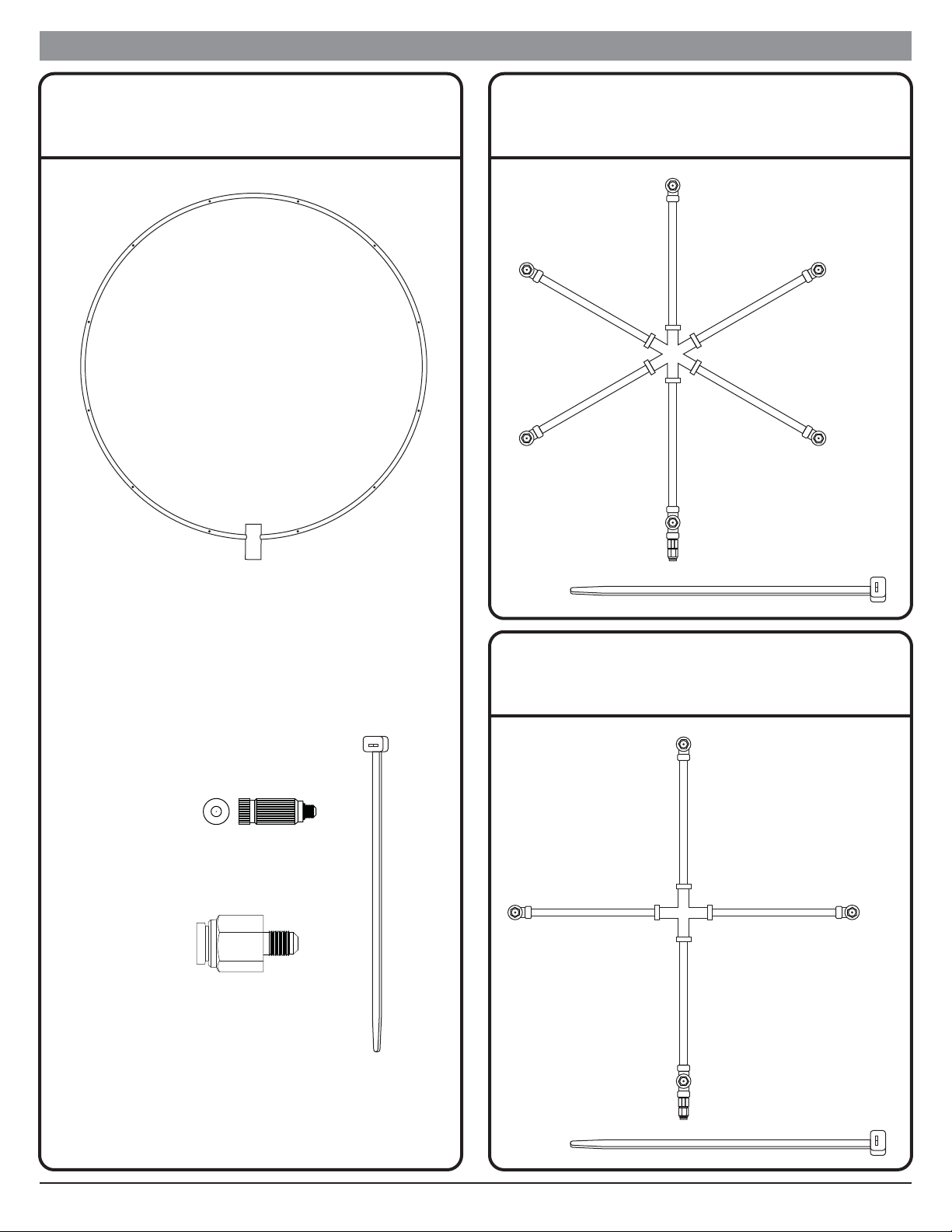

SS3012

30” Stainless steel

panel fan ring kit

with hose connector

and (12) 0.02 GPM

Nozzles

VHPR121

3/4” ID

Cable Clamp for

Tube and Pipe

VHPR160

18”

Mounting Rod

with Hardware

to use with

VHPR159

Mounting Clip

(6)

Cable Ties

SS3012 - 30” High Pressure

Fog Ring Kit with X-Frame

Pipe / Tube Mounting

VHPR110 - Nozzle

0.02 GPM

Anti Drip

Nozzle

2

VHPR159

(10)

Black Poly

Mounting

Clip for

1/2” OD

HPF Line

VIEC1000M

3/8”

Slip Lock

1/4”

Flare

Hanging Pegs

SS3011

30” Stainless steel

panel fan ring kit

with hose connector

and (12) 0.02 GPM

Nozzles

SS36SH6

13” Stainless steel

fogging cross with

hose connector and

(6) 0.008 nozzles

SS36SH

13” Stainless steel

fogging cross with

hose connector and

(4) 0.008 nozzles

(6)

Cable Ties

(4)

Cable Ties

(6)

Cable Ties

SS3011 - 30” High Pressure

Fog Ring Kit

SS36SH6 - 13” 6 Way

High Pressure Fog Cross

SS36SH - 13” 4 Way

High Pressure Fog Cross

VHPR110 - Nozzle

0.02 GPM

Anti Drip

Nozzle

2

VIEC1000M

3/8”

Slip Lock

1/4”

Flare

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section D - Page 8/8

Section DParts IdentificationSection D

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section E - Page 1/2

Section E

Guidelines for Assembling ComponentsSection E

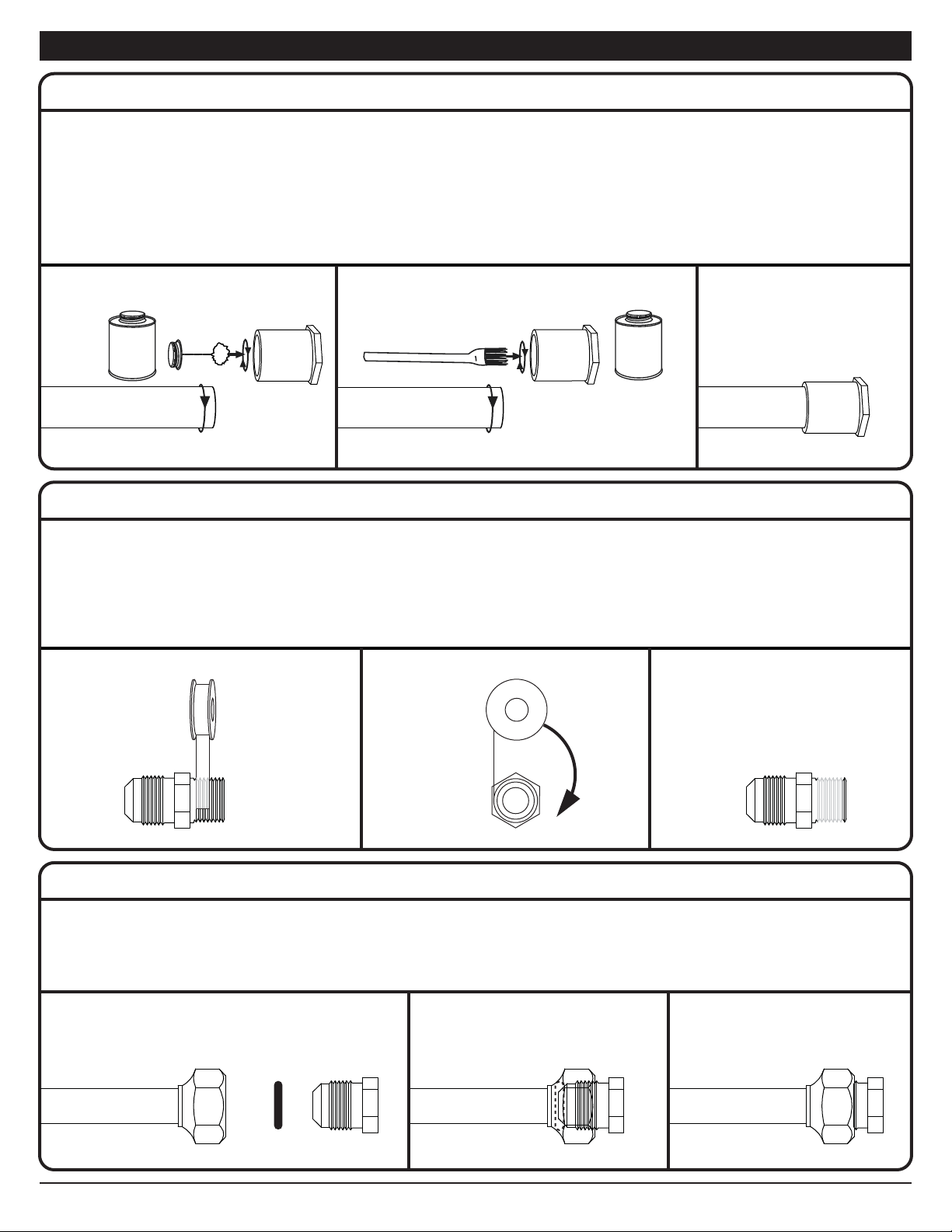

PVC Gluing Guidelines

PTFE

Tape

3/8”

MIPT

1/2”

Flare

3/8”

MIPT

1/2”

Flare

PTFE

Tape

Wipe primer around the pipe end and into the fitting to prepare it for the glue/cement. Let it dry about 10 seconds. Spread an even layer of glue/cement on the

same surfaces. To keep excess glue/cement from being pushed into water piping, don't apply too much to the inside of the socket on the fitting. At this point

you have to work fast to complete the assembly. Align the fitting and pipe about a quarter turn from their final orientation. Then twist the fitting a quarter turn

as you press it onto the pipe. Twisting the fitting helps spread the glue/cement evenly to ensure a solid joint. Hold the pipe and fitting together for about 30

seconds until the cement grabs. If you let go to soon, the pipe may push out of the fitting, resulting in a weak joint.

NOTE: PVC primer and PVC glue/cement are not included. When purchasing make sure both are for use with PVC.

Read the PVC primer and PVC glue/cement manufacturer’s directions and warnings before using and apply all safety recommendations.

PVC

Primer / Cleaner

PVC

Cement / Glue

PTFE Tape & Tightening Guidelines

Hold the fitting and starting at the inner end of the threads, wrap PTFE tape tightly and evenly clockwise and upwards in a helical fashion until all but the end

thread is covered. Leaving the end thread bare makes it easier to get the thread started during assembling of joints. Continue to wind the thread clockwise and

downwards back to where you started then once more towards end of fitting. This method will provide industry standard of three layers of PTFE tape.

Screw the male thread into the female union by hand until tight, then using a wrench rotate the fitting an additional 1-2 turns, DO NOT OVER TIGHTEN.

NOTE: Some fittings may come with a layer of dried white PTFE sealant that was previously applied to the threads by the manufacturer of the connector.

DO NOT add additional PTFE tape to these fittings; just assemble as is.

1/2” Flare Connector with Required O-Ring Guidelines

1/2” flare connector ends require an o-ring to complete the union. Insert the o-ring into the union and position it so it does not block the waterway. With o-ring

in place screw the male thread into the female union by hand until tight; using a wrench rotate the fitting an additional 1/2 to 1 turn. DO NOT OVER TIGHTEN.

NOTE: Stainless steel line ends have a 1/2” flare nut on each end and include the required o-rings needed for this connection. The purchase of additional

o-rings (VHPR120) is only required for replacement if needed or when the 1/2” male flare connector is used with other 1/2” female flare connectors.

1/2”

Male Flare

1/2”

Female Flare

VHPR120

O-Ring

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section E - Page 2/2

Section EGuidelines for Assembling ComponentsSection E

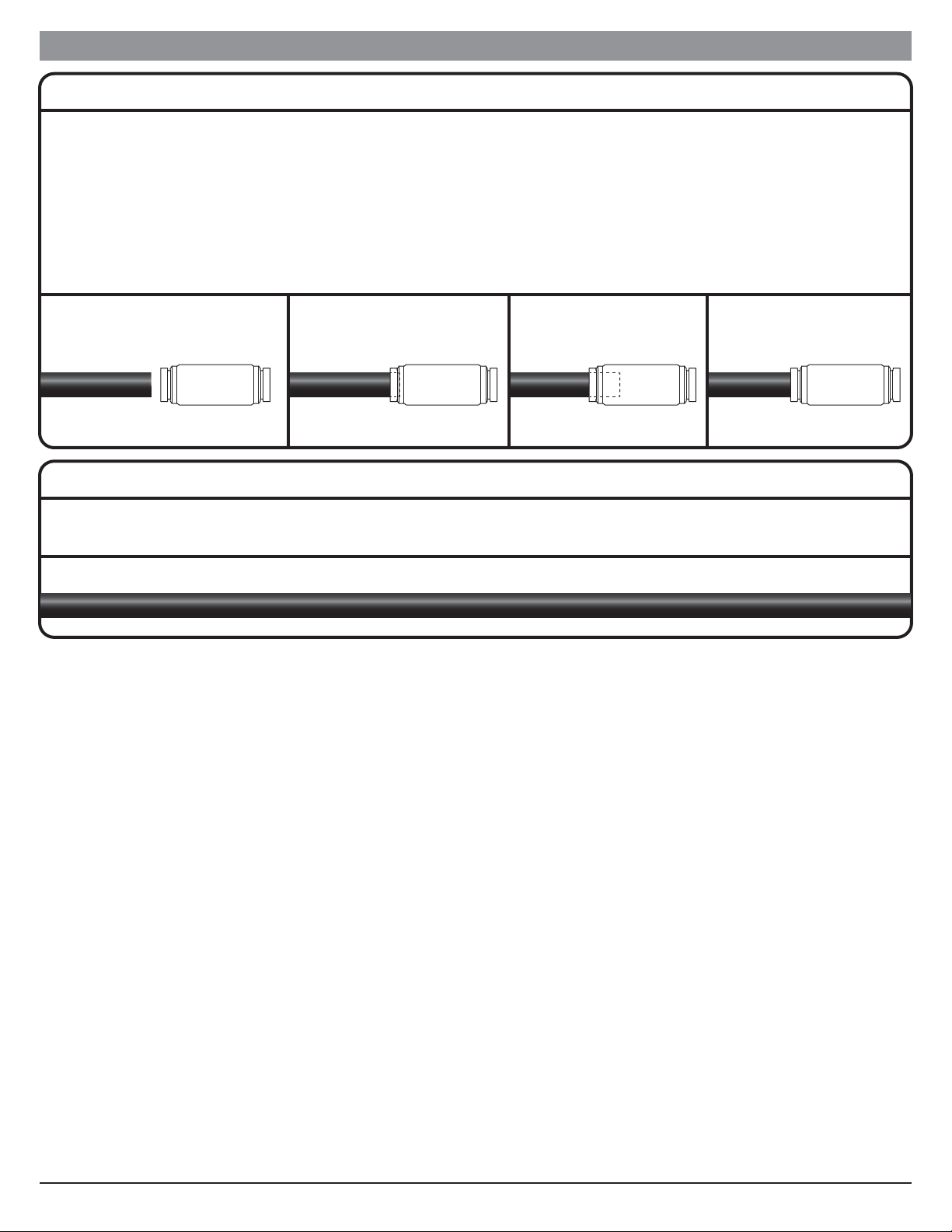

Slip Lock Guidelines

Slip lock connectors requires the nylon tube be cut straight, cleanly, and without crimping or deforming the tube while cutting.

If the other end of the fitting is not a slip lock, connect that first.

Insert the end of the nylon tube into the slip lock until you meet some resistance then push it in another 1/2” or so until it stops.

If you need to remove the nylon tube from the slip lock, the system must be depressurized. Then push the metal slip lock collar back into the fitting and pull the

nylon tube out.

NOTE: Once the nylon tube has been fully inserted into a slip lock and is removed, even for a short time, 1” of nylon tube (the amount that was inserted into

the slip lock) must be trimmed off or it will not seal properly. Keep this in mind if you intend to disassemble your system seasonally as you will want

to provide additional tubing to those sections to allow for yearly trimming until you are required to replace your nylon tubing.

3/8”

Slip Lock

3/8” High Pressure

Nylon Tube

High Pressure Nylon Tube Guidelines

When system is running the high pressure nylon tube will vibrate and jump causing nearby sharp or abrasive surfaces to cut or wear a hole in the nylon tube.

Rubber grommets, pieces of rubber mats, etc., should be used to protect the tube.

3/8” High Pressure Nylon Tube

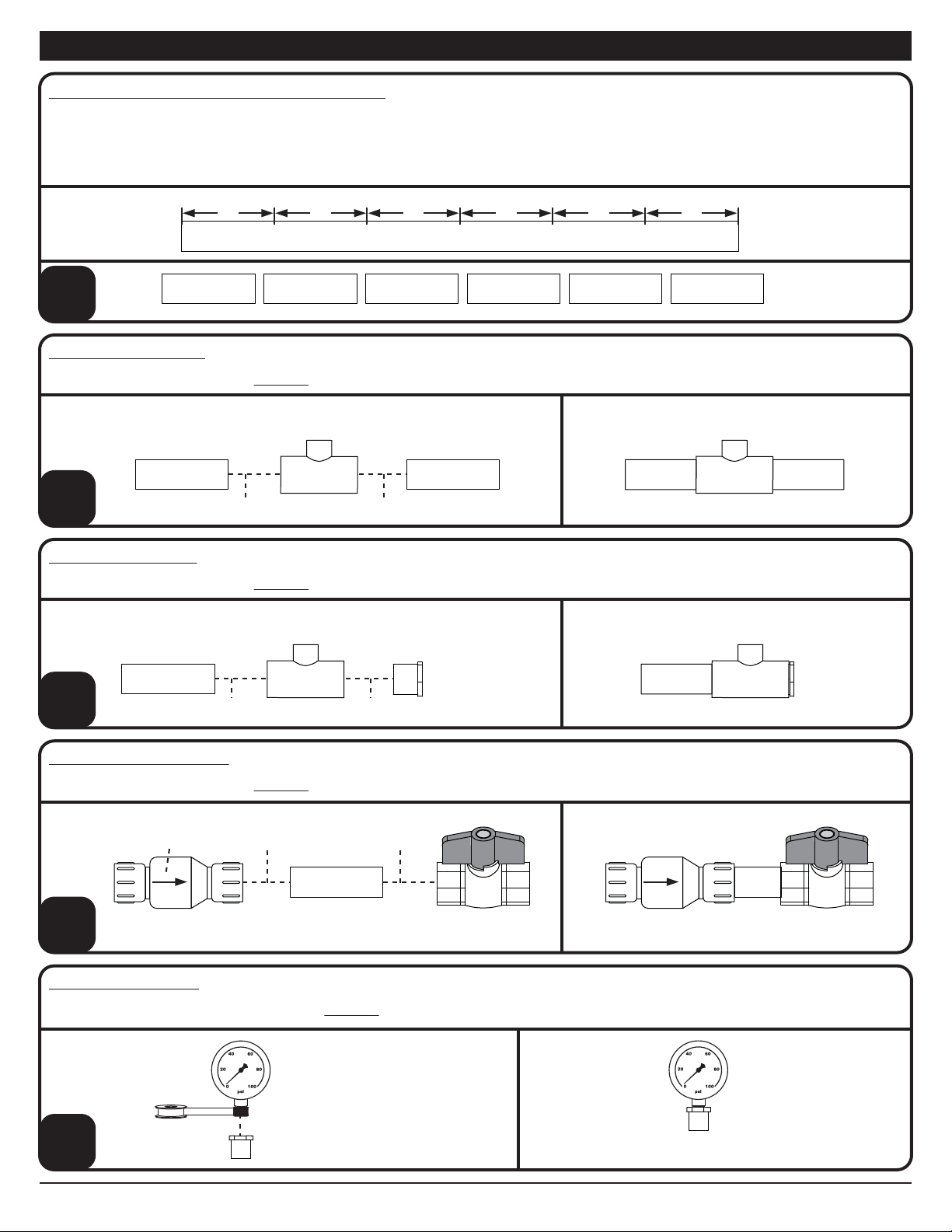

Preparing 1” PVC Tubing 2’ Stick (VHPR151) for Assembly

Measure and mark the tube into (6) 4” sections.

Using the marks just made and a fine toothed saw cut tubing into sections.

Clean and deburr each end of cut tube.

Before Filter Tee Assembly

Following the PVC Gluing Guidelines in Section E, prime and glue a section of 4” tube, tee (SSOT), and another section of 4” tube as shown below.

After Filter Tee Assembly

Following the PVC Gluing Guidelines in Section E, prime and glue a section of 4” tube, tee (SSOT), and reducer bushing (VHPR146) as shown below.

Check and Ball Valve Assembly

Following the PVC Gluing Guidelines in Section E, prime and glue check valve (SS03), a section of 4” tube, and ball valve (SS01) as shown below.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 1/6

Section F

Filter System Assembly & InstallationSection F

4”

4” 4” 4” 4” 4” 4”

4” 4” 4” 4” 4”

4”

SS01

Ball Valve

Prime & Glue Prime & Glue

SS03

Check Valve Check and Ball Valve Assembly

SSOT

Tee

VHPR146

Reducer Bushing

Prime & Glue

4”

Prime & Glue After Filter Tee Assembly

4”

Prime & Glue

4”

Prime & Glue

SSOT

Tee

Before Filter Tee Assembly

1

2

3

4

Pressure Gauge Assembly

Following the PTFE Tape & Tightening Guidelines in Section E, tape and assemble both pressure gauges (VHPR149) to a reducer (SS19) as shown below.

SS19

Reducer

VHPR149

Pressure Gauge

PTFE

Tape Pressure Gauge Assembly

5

Arrow on valve indicates

water flow direction

2-1/2” Filter Cap Assembly

Remove the caps from each of the filter housings (VHPR135).

Following the PTFE Tape & Tightening Guidelines in Section E, tape and assemble two threaded adapters (PP10461) to each filter housing cap as shown below.

Set all three caps on a flat surface and arrange caps so IN and OUT are as shown below.

Following the PVC Gluing Guidelines in Section E, prime and glue a section of 4” tube between each cap as shown below.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 2/6

Section FFilter System Assembly & InstallationSection F

IN OUT IN OUT IN OUT

4”

Prime & Glue Prime & Glue Prime & Glue Prime & Glue

4”

2-1/2” Filter Cap Assembly

PP10461

Adapter

PTFE

Tape

PTFE

Tape

PP10461

Adapter

Cap Only - VHPR135

2-1/2” Filter Housing

6

If your filter system uses 4-1/2” filter housings, proceed to Step 8.

Attaching Brackets to 2-1/2” Filter Cap Assembly

Using either a #3 phillips head hand driven screwdriver or a #3 phillips head drill bit and drill with its clutch/torque adjusted to not strip the holes, secure the three

filter mounting brackets (VHPR142) to the filter cap assembly using (4) #14–10 x 3/4” phillips pan head screws per bracket as shown below.

7

If your filter system uses 2-1/2” filter housings, proceed to Step 10.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 3/6

Section FFilter System Assembly & InstallationSection F

4-1/2” Filter Cap Assembly

Remove the caps from each of the filter housings (VHPR139).

Following the PTFE Tape & Tightening Guidelines in Section E, tape and assemble two threaded adapters (VHPR143) to each filter housing cap as shown below.

Set all three caps on a flat surface and arrange caps so IN and OUT are as shown below.

Following the PVC Gluing Guidelines in Section E, prime and glue a section of 4” tube between each cap as shown below.

PTFE

Tape

PTFE

Tape

VHPR143

Adapter

VHPR143

Adapter

4”

Prime & Glue Prime & Glue Prime & Glue Prime & Glue

4”

IN OUT IN OUT IN OUT

4-1/2” Filter Cap Assembly

8

Attaching Brackets to 4-1/2” Filter Cap Assembly

Using either a #3 phillips head hand driven screwdriver or a #3 phillips head drill bit and drill with its clutch/torque adjusted to not strip the holes, secure the three

filter mounting brackets (VHPR153) to the filter cap assembly using (4) #14–10 x 3/4” phillips pan head screws per bracket as shown below.

9

From this point in the instructions only the 4-1/2” filter assembly will be shown in the illustrations however the same

steps must be applied to the 2-1/2” filter system as the remaining instructions are the same.

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 4/6

Section FFilter System Assembly & InstallationSection F

Mounting Filter Cap Assembly

To provide the space needed to access and service the filters once system is installed, measure and mark 37” from the floor as shown below. Align the top of the

filter mounting plates to this mark and prepare the (4) locations per bracket indicated below for the installation hardware (not included). Secure the mounting

plate to your chosen location.

NOTE: Mounting location and installation hardware (not included) must be able to withstand the weight of 90lbs, the assembled unit when in use and full

of water.

Mounting

Holes

10

37”

FloorFloor Floor

Assembling Tees to Mounted Filter Assembly

Following the PVC Gluing Guidelines in Section E, prime and glue the Before Filter Tee Assembly from Step 2 to the IN side of the Filter Cap Assembly and

the After Filter Tee Assembly from Step 3 to the OUT side of the Filter Cap Assembly as shown below.

Assembling Gauges to Tees

Following the PVC Gluing Guidelines in Section E, prime and glue one of the Pressure Gauge Assemblies from Step 5 to the Before Filter Tee Assembly and

the other Pressure Gauge Assembly from Step 5 to the After Filter Tee Assembly as shown below.

Install pressure gauge so

it can be easily viewed.

Install pressure gauge so

it can be easily viewed.

Pressure

Gauge

Assembly

Pressure

Gauge

Assembly

Prime & Glue Prime & Glue

Tee must

point up

Tee must

point up

Prime & Glue Prime & Glue

After Filter

Tee Assembly

Before Filter

Tee Assembly

Filter Cap Assembly

11

12

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 5/6

Section FFilter System Assembly & InstallationSection F

Assembling Check & Ball Valve to Mounted Filter Assembly

Following the PVC Gluing Guidelines in Section E,prime and glue the Check & Ball Valve Assembly from Step 4 to the Before Filter Tee Assembly as shown

below.

Install ball valve with the lever away from the

wall so lever can be turned without interference.

Prime & Glue

Check & Ball Valve Assembly

13

Assembling Adapter to Mounted Filter Assembly

Following the PTFE Tape & Tightening Guidelines in Section E, tape and assemble male adapter (VHPR147) to Before Filter Tee Assembly as shown below.

14

Attaching Labels to Bracket of Mounted Filter Assembly

Attach the labels that indicate filtration size to the mounting brackets as shown below, this will aid in filter maintenance and replacement in the future.

15

Connecting Water Source to Mounted Filter Assembly

With water shut off and following the PVC Gluing Guidelines in Section E, connect the water source to the check valve.

16

PTFE

Tape

VHPR147

Male Adapter

Connect water

source here

20

MICRON

REPLACEMENT

FILTER

5

MICRON

REPLACEMENT

FILTER

1

MICRON

REPLACEMENT

FILTER

20

MICRON

5

MICRON

1

MICRON

20

MICRON

REPLACEMENT

FILTER

5

MICRON

REPLACEMENT

FILTER

1

MICRON

REPLACEMENT

FILTER

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section F - Page 6/6

Section FFilter System Assembly & InstallationSection F

IS275-17L J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com Section G - Page 1/3

Section G

Motor & Pump Shelf Assembly & InstallationSection G

If your structure has studs 24” on center, proceed to Step 4.

Mounting Shelf Assembly to Structure that has Studs 16” On Center

Prepare the (8) locations indicated below for the installation hardware (not included) and secure the mounting shelf to your chosen location as shown below.

NOTE: Mounting location and installation hardware (not included) must be able to withstand the weight of 145 lbs, the assembled shelf with motor and

pump assembly.

1

Assemble Shelf Support Brackets

Using a 9/16” wrench and 9/16” socket and socket wrench assemble (2) shelf braces so the mounting tabs are behind the shelf lip and secure with (2) 3/8”-16 x

1” Hex Bolts and (2) 3/8”-16 Nylock Nuts as shown below.

2

Table of contents