Standpipe

Manifold

FIGURE 1 - Snap-Fit Detail

Snap Fit

Lateral

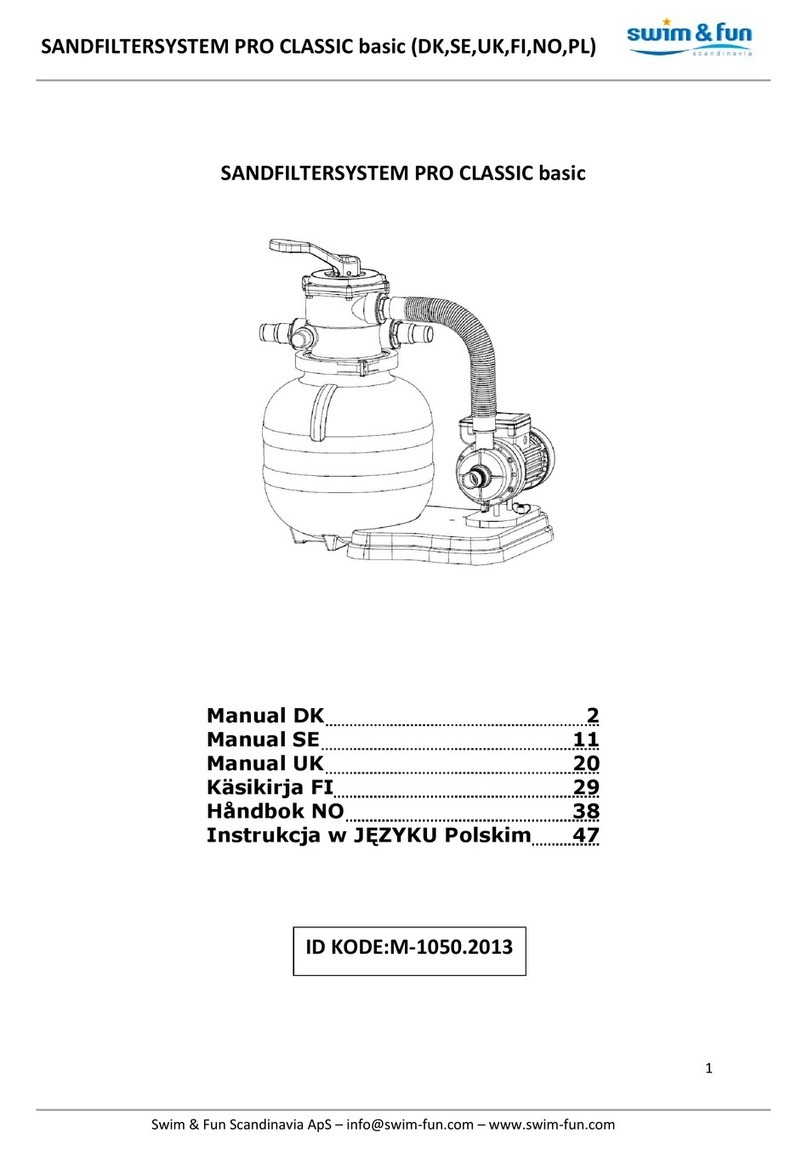

Table (installation in a private home)

FILTER MODEL MAXIMUM FLOW RATE

gpm EU/sq. ft. (m3h/m2)FILTRATION RATE

gpm (I/min)

SAND REQUIRED

WEIGHT LBS

(KILOGRAMS)

MAXIMUM

PRESSURE

PSI

SFTM22 25,0 (60) 66 (250) 250 (215) 35

SFTM25 25,0 (60) 83 (314) 350 (160) 35

TO BE LEFT WITH OWNER

Before installation be sure to read all instructions and warnings carefully.

Refer to product label(s) for additional operation instruction and specifications.

IMPORTANT: This product has been carefully inspected and packed at our factory.

As the carrier has assumed full responsibility for its safe arrival, any claim for

damage to the shipment, either visible or concealed, must be made to the carrier.

Make sure that you have received the correct equipment for the installation.

PUMP SELECTION

A full line of pool pumps are available for installation with these filters. For those

installations where the equipment will be placed above the water level, a

self-priming pump should be selected. Ask your dealer to determine the proper

size and distance from pool or spa and friction losses (restrictions) of associated

equipment. The filter system is assembled at the site from a filter module and a

pump module. This method allows you to choose a pump providing an optimal

CIRCULATION RATE for a commercial installation (20 U.S. gallons per minute per

square foot of filtration surface) or for a residential installation (25 U.S. gallons per

minute per square foot of filtration surface or 61 cubic meters per hour per square

meter of filtration surface).

To reduce risk of injury, do not permit children to use this product unless they

are closely supervised at all times.

Locate the system at least five feet (1.5 m) from the pool to prevent it being used

as a means of access to the pool by young children. (See ANSI/NSPI-8 1996

“Model Barrier Code For Residential Swimming Pools, Spas and Hot Tubs”).

The filter module is equipped with a dial valve which works as follows:

1). FILTER gives a downward flow through the filter bed. Dirt accumulates in the

sand as filtering proceeds, and gradually restricts the flow of water until back-

washing is necessary. This position can also be used for vacuuming.

2). BACKWASH gives an upward flow through the filter bed that removes the dirt

from the sand and carries it to the waste.

3). DRAIN is for pumping water from the pool. It allows the flow from the pump to

bypass the filter and go directly to the waste. You can also use this position to

vacuum heavy concentrations of debris.

4). WHIRLPOOL bypasses the filter to obtain the optimum performance from a

hydro-air fitting fed by the filter pump. (No filtration occurs in this position).

5). WINTERIZE allows air to leave or enter the tank to help priming and draining.

Only to be used when pump is off.

6). RINSE gives a downward flow that settles the filter bed after backwashing and

carries any remaining loose dirt to the waste.

7). TEST prevents only backflow of water from pool during pump maintenance if

filter is below water level.

FILTER SAND

The outstanding filtration and superior dirt-holding capacity of this filter depends

on the use of the proper grade of filter sand. It should meet the following specifica-

tions: The filter sand must be free of clay, loam, dirt and organic matter, and must

consist of hard, durable, rounded or sub-angular grains of silica sand with no more

than 1% of flat or micaceous particles. The grains should have an effective size of

0.44mm with a uniformity coefficient of 1.35. DO NOT USE “SANDBOX” SAND. The

filter sand is NOT included in the filter module and must be purchased separately.

Refer to the table for the quantity required. Do not fill the tank with sand before

the filter is in its final position. Keep the sand dry for easy installation. Use only the

approved filter sand, otherwise the system may not work satisfactorily.

INSTALLATION LOCATION

LOCATION : System should be installed in accordance with the standards and in-

structions in effect in your country or municipality, preferably in a dry, shaded, and

well-ventilated area (See previous warning). Locate the system on a hard, level

surface, preferably in a dry, shaded, and well-ventilated area. Give consideration

to the following: Position of suction, return, and waste connections; Access for

backwashing and servicing; Protection from the sun, rain, splashing, etc; Drainage

of filter room or pit; Ventilation and protection of the motor.

ASSEMBLY OF SYSTEM

1). Place the empty tank in position on the base. Press the tank down until it

engages the base.

2). If the laterals are not installed, hold the standpipe/manifold assembly so that

the manifold is located in the middle of the tank. Take one of the lateral flow tubes

in your other hand and lower it into the tank, sliding it down the tube and into one

of the grooves in the manifold until a snap-fit is obtained. Repeat this action until

all eight lateral flow tubes are installed, then lower the complete assembly down

to the bottom of the tank. Press it down to ensure that the central tube is seated in

the depression in the base of the tank. See figure 1.

OPERATION/INSTALLATION INSTRUCTIONS

SFTM SERIES FILTERS FOR IN-GROUND AND

ABOVE-GROUND SWIMMING POOLS

NEVER attempt to assemble, disassemble or adjust the filter

when there is pressurized air in the system.

Starting the pump while there is any pressurized air in the

system can cause product failure or also cause the dial

valve to be blown off, which can cause death, serious

personal injury or property damage.

Never start the pump while standing within five (5) feet of

the filter.

To prevent the possibility of personal injury and equipment damage, always

turn the pump OFF before changing the position of a backwash valve.

DO NOT operate filter at water temperatures above 104º F (40º C). Water

temperature above the manufacturer’s recommendations will shorten the

life span of the filter and void the warranty.

4