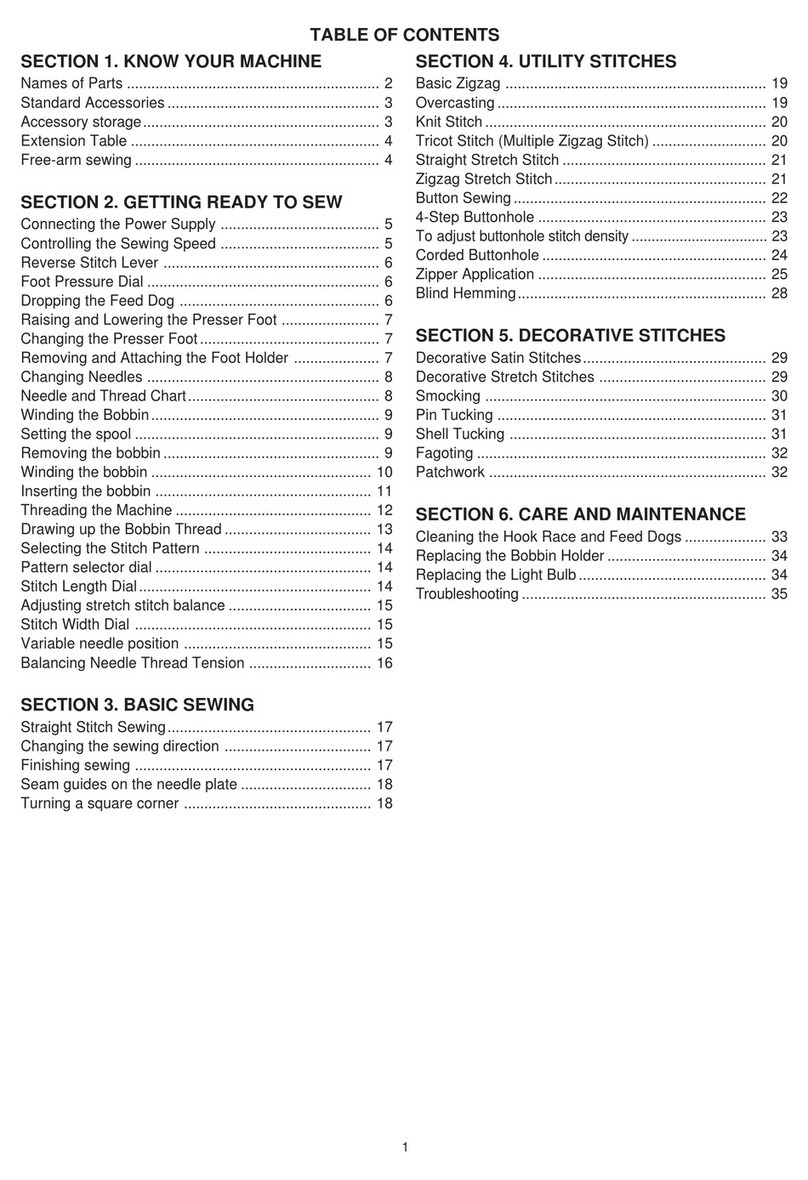

SERVICE ACCESS

FACE PLATE AND TOP COVER ............................................................................................................1

BELT COVER..........................................................................................................................................2

MACHINE BASE, BASE COVER AND BED COVER .............................................................................3

FREE-ARM COVER................................................................................................................................4

FRONT COVER ......................................................................................................................................5

REAR COVER ........................................................................................................................................6

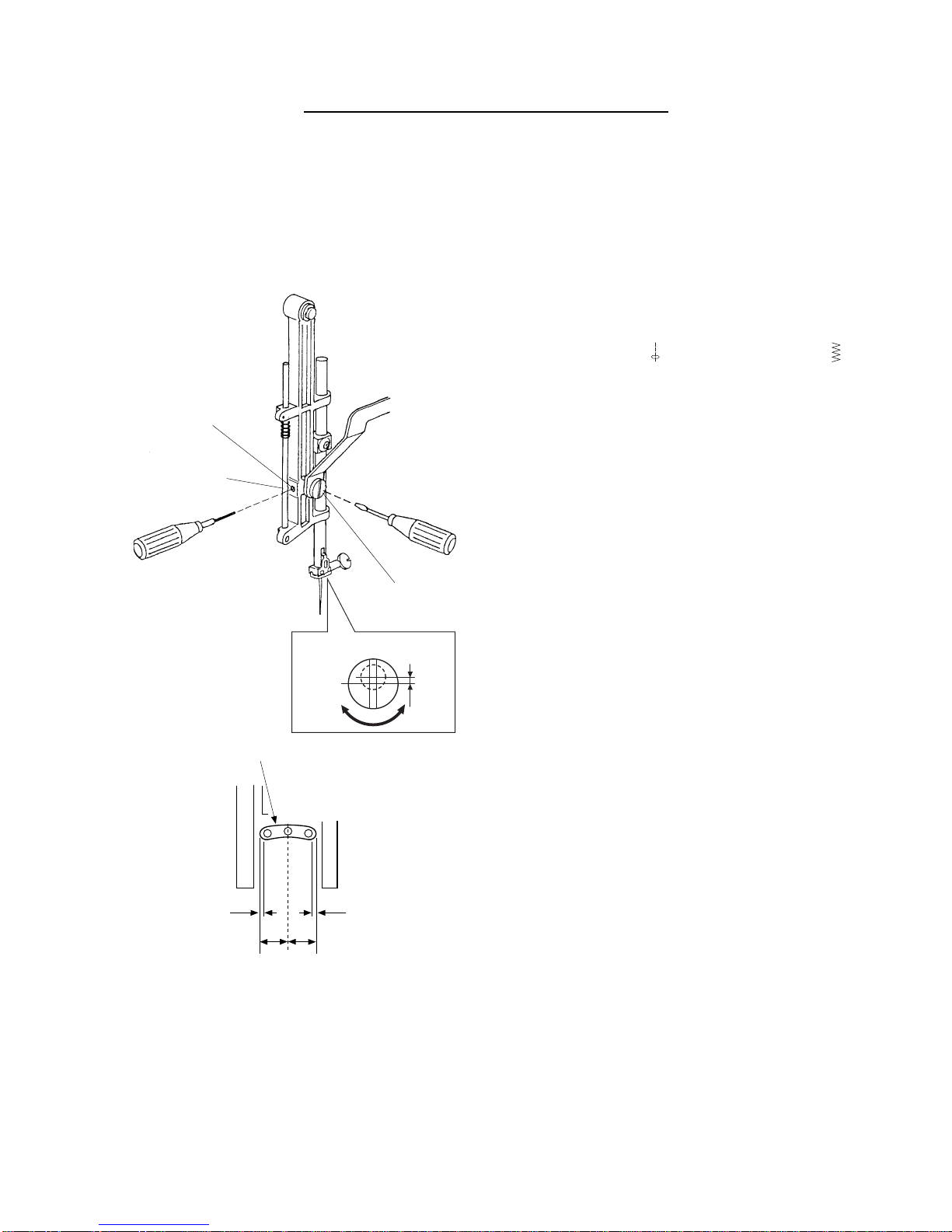

MECHANICAL ADJUSTMENT

NEEDLE DROP POSITION ....................................................................................................................7

PRESSER BAR HEIGHT AND ALIGNMENT ................................................................................... 8-10

HOOK TIMING ......................................................................................................................................11

NEEDLE BAR HEIGHT.........................................................................................................................12

CLEARANCE BETWEEN NEEDLE AND ROTARY HOOK ...................................................................................

13

BACKLASH OF HOOK AND LOWER SHAFT GEARS ........................................................................14

FEED DOG HEIGHT.............................................................................................................................15

UPPER THREAD TENSION .................................................................................................................16

THREAD TENSION UNIT REPLACEMENT .........................................................................................17

THREAD TENSION MECHANISM .......................................................................................................18

CIRCUIT BOARD “F” REPLACEMENT ................................................................................................19

CIRCUIT BOARD “A” REPLACEMENT ................................................................................................20

CONNECTOR DIAGRAM .....................................................................................................................21

NEEDLE THREADER PLATE REPLACEMENT ...................................................................................22

THREAD TENSION DRAWING LEVER ...............................................................................................23

UPPER FEED DOG ADJUSTMENT (1) ......................................................................................... 24-25

UPPER FEED DOG HEIGHT ...............................................................................................................26

DRIVING MOTOR.................................................................................................................................27

UPPER SHAFT SHIELD PLATE POSITION.........................................................................................28

CENTER NEEDLE POSITION ADJUSTMENT ....................................................................................29

BUTTONHOLE LEVER POSITION.......................................................................................................30

PRESSER BAR LIFTER SWITCH POSITION......................................................................................31

THREAD CUTTER SENSOR POSITION .............................................................................................32

SWITCHING POWER SUPPLY REPLACEMENT ................................................................................33

SOLENOID POSITION .........................................................................................................................34

STRETCH STITCH FEED BALANCE...................................................................................................35

DIAGNOSIS TEST ......................................................................................................... 36-39

INDEXINDEX

INDEXINDEX

INDEX