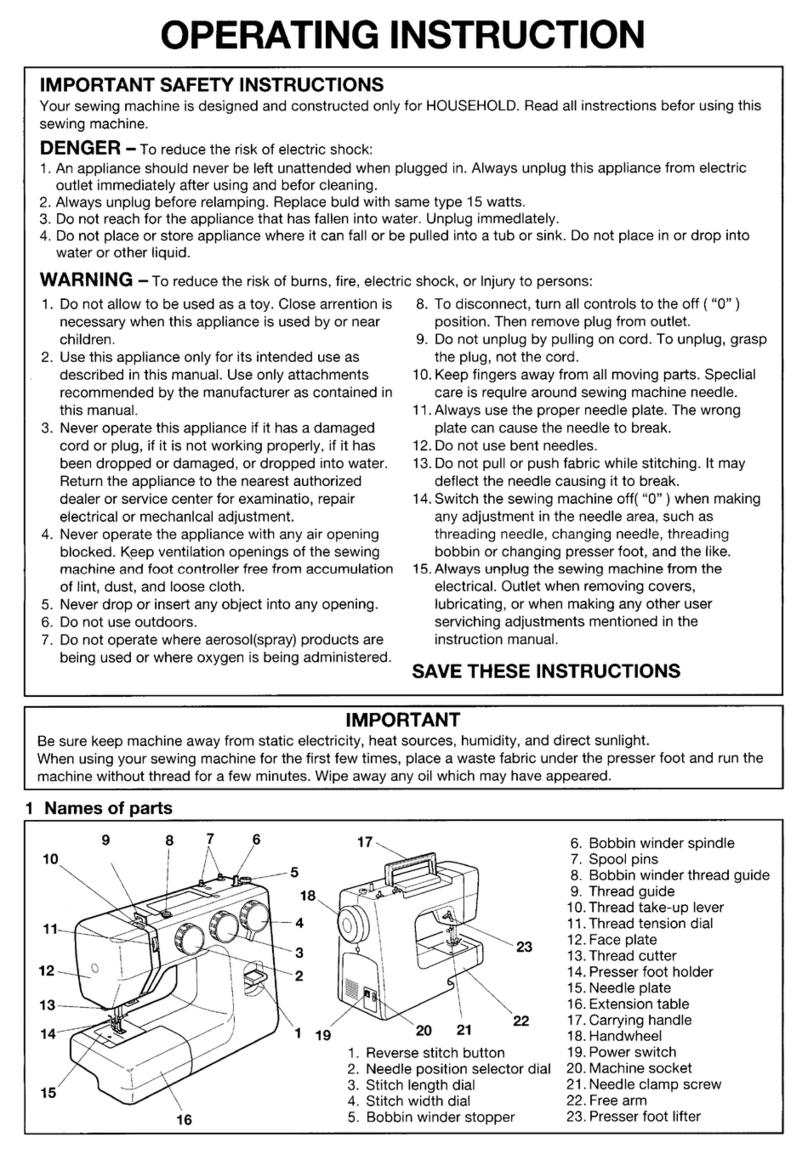

TABLE OF CONTENTS

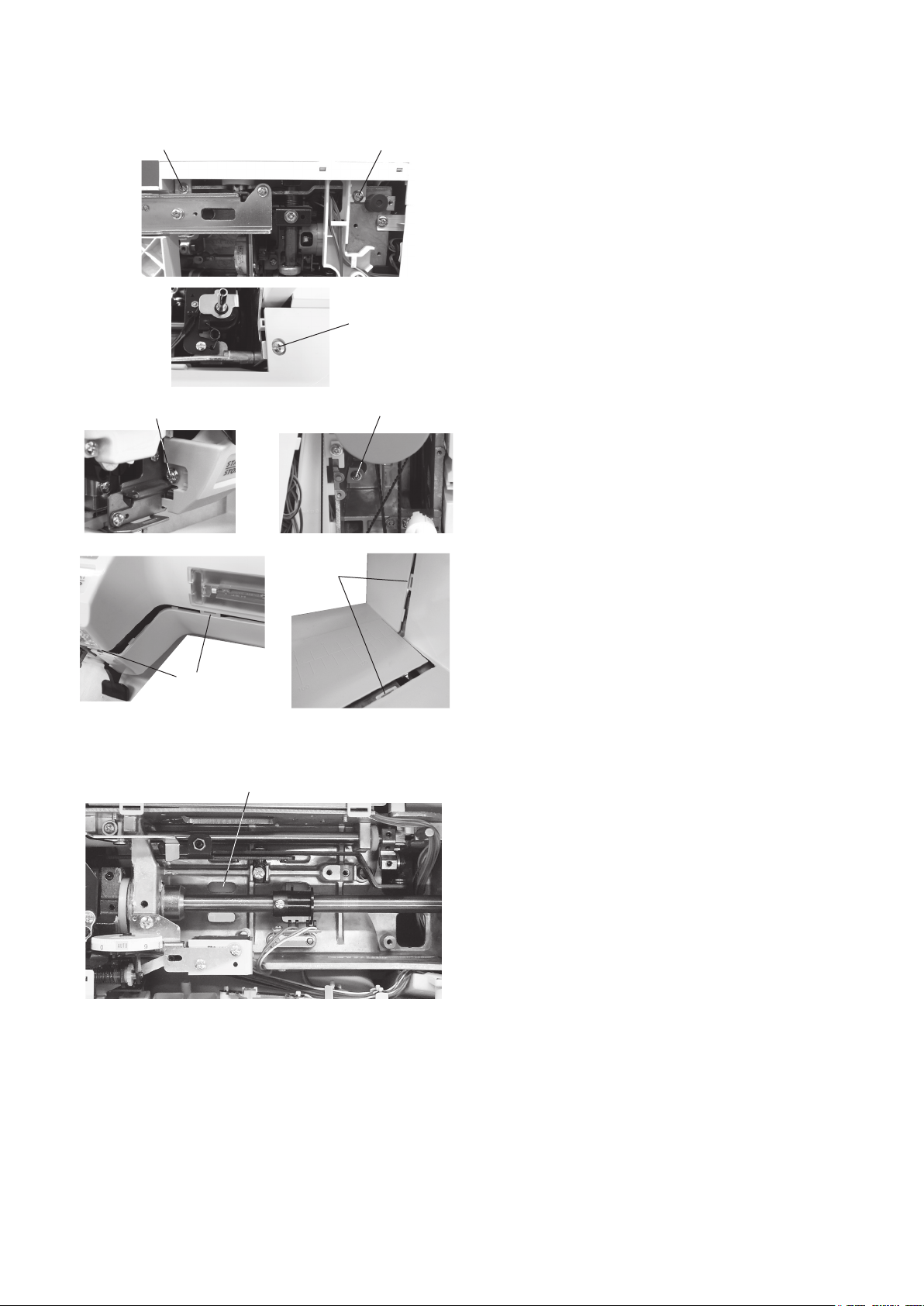

Replacing external parts

Face cover ......................................................................................................................................................... 1

Belt cover ........................................................................................................................................................... 1

Top cover ........................................................................................................................................................... 2

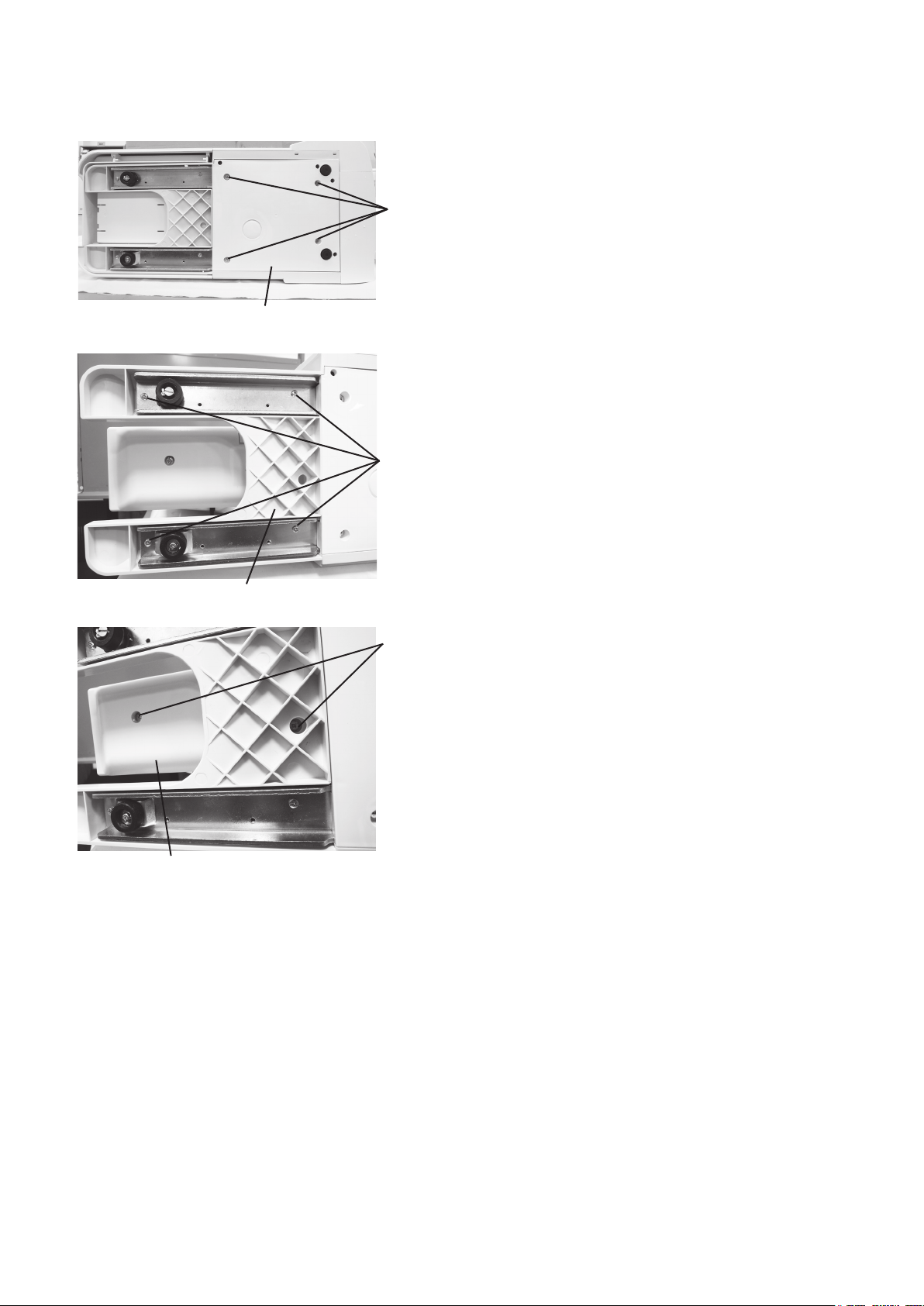

Machine base .................................................................................................................................................... 3

Base cover ......................................................................................................................................................... 3

Bed cover .......................................................................................................................................................... 3

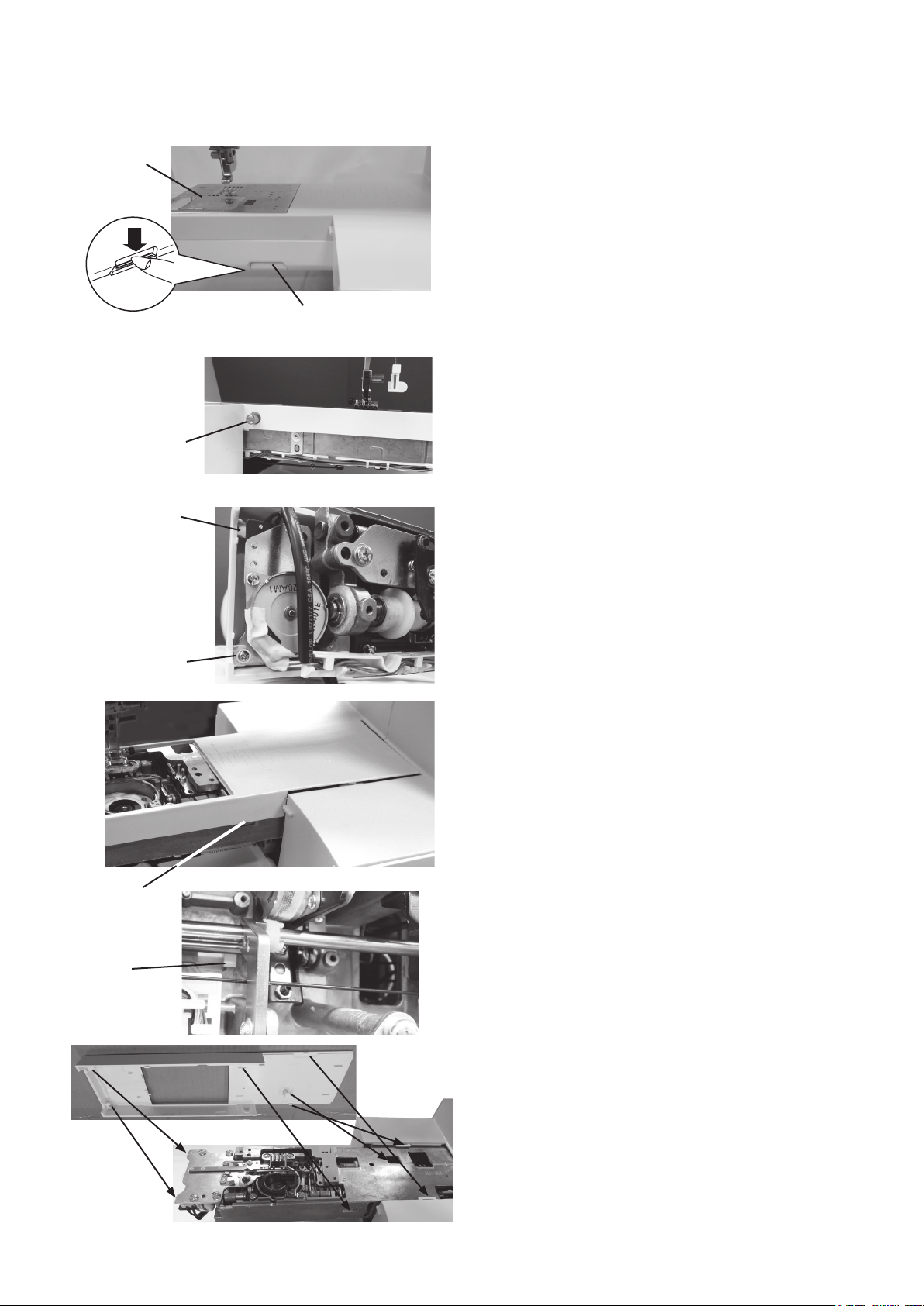

Free arm cover ................................................................................................................................................... 4

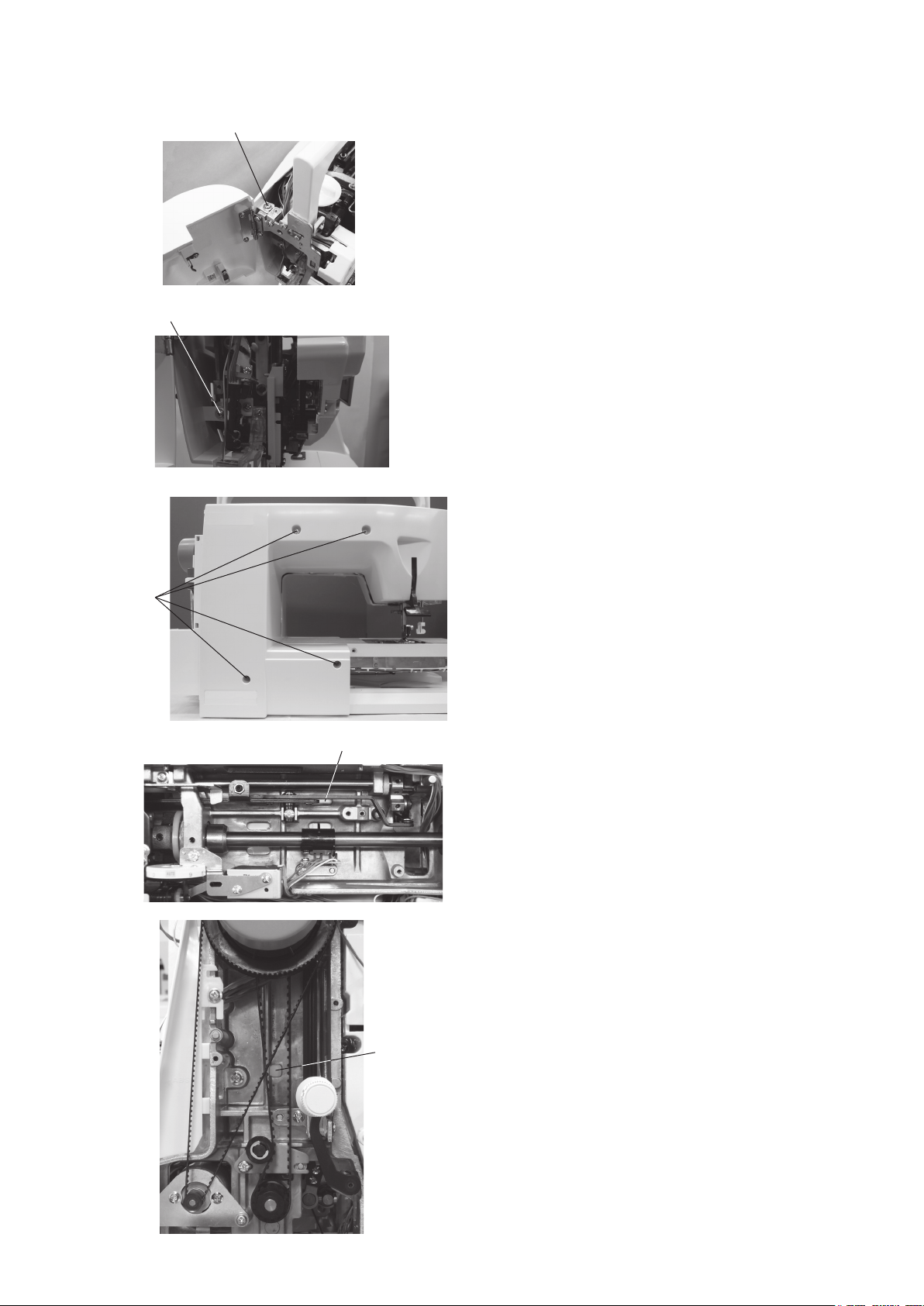

Front cover ......................................................................................................................................................... 5

Rear cover .......................................................................................................................................................... 6

Replacing mechanical parts

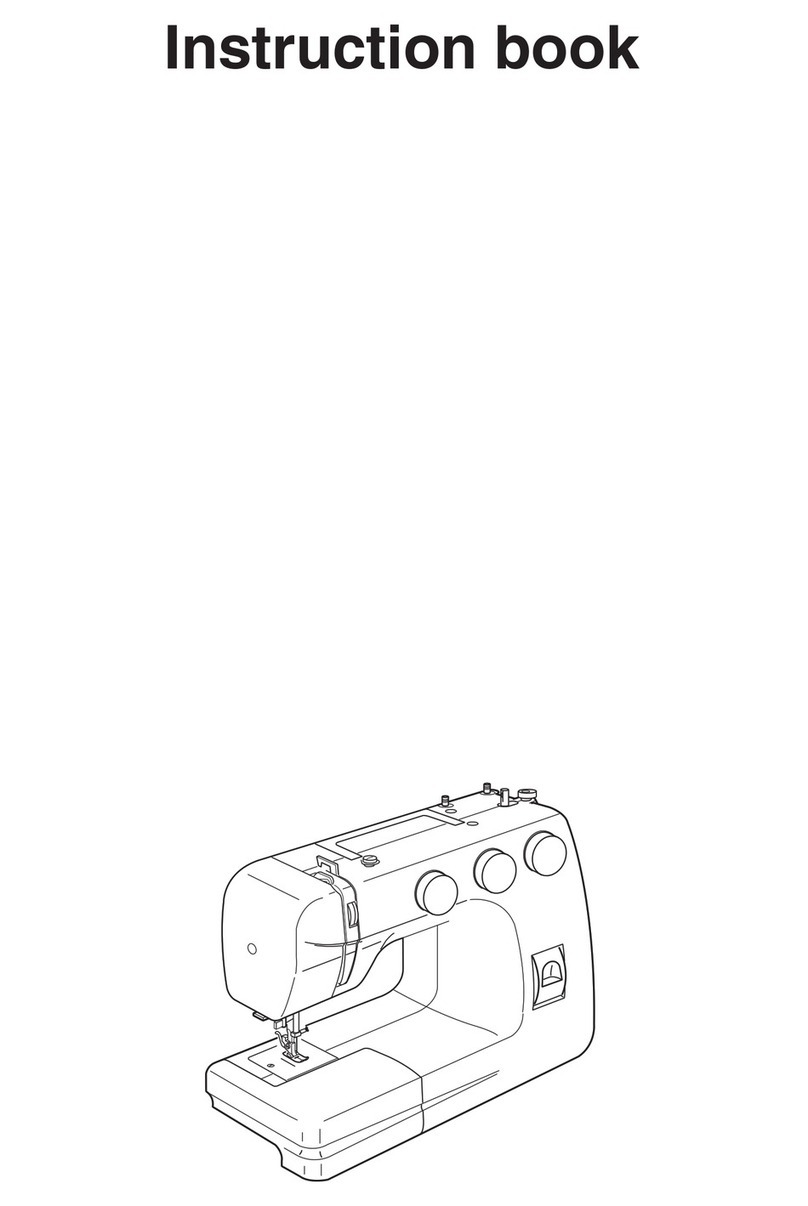

Needle threader hook position .......................................................................................................................... 7

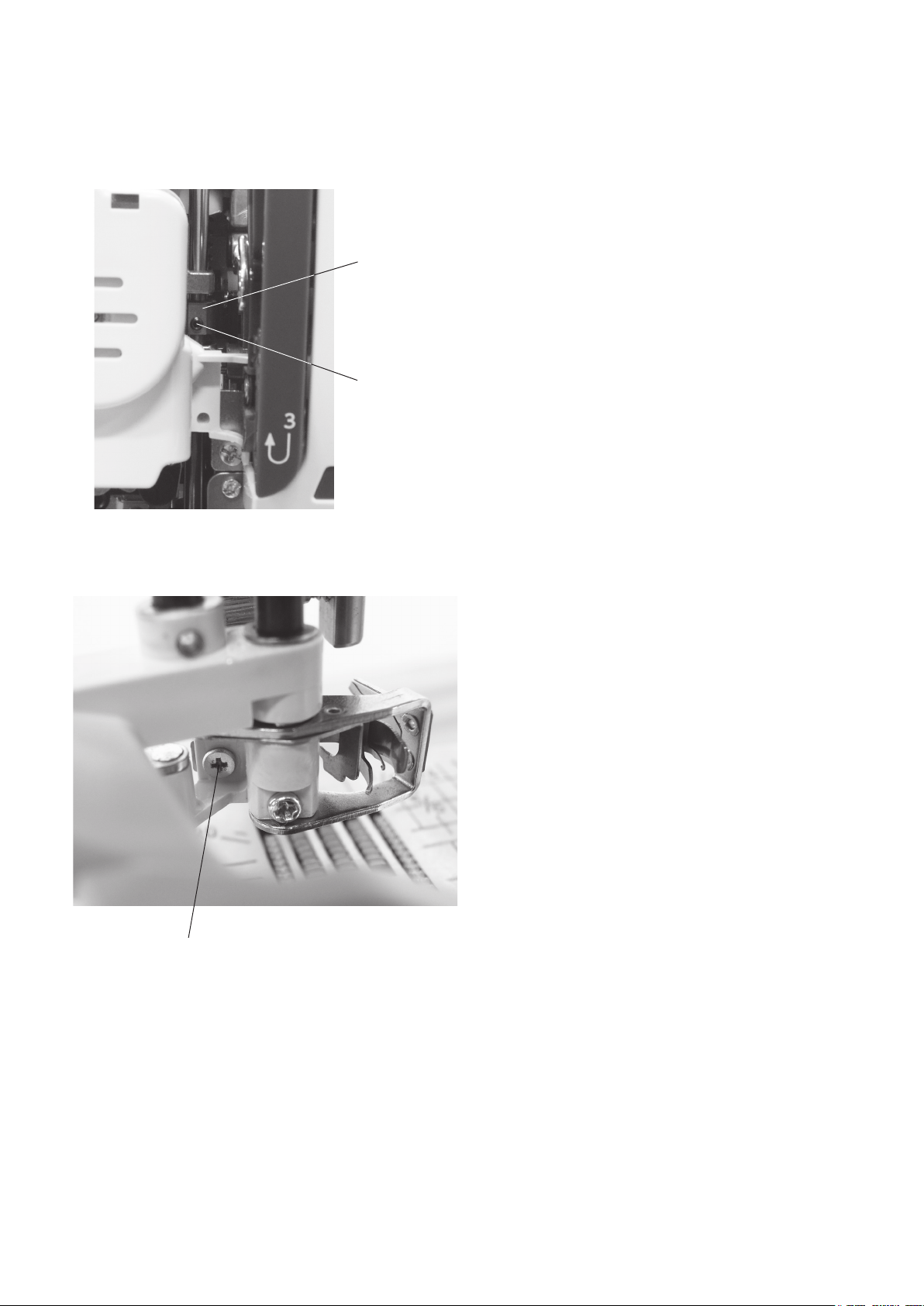

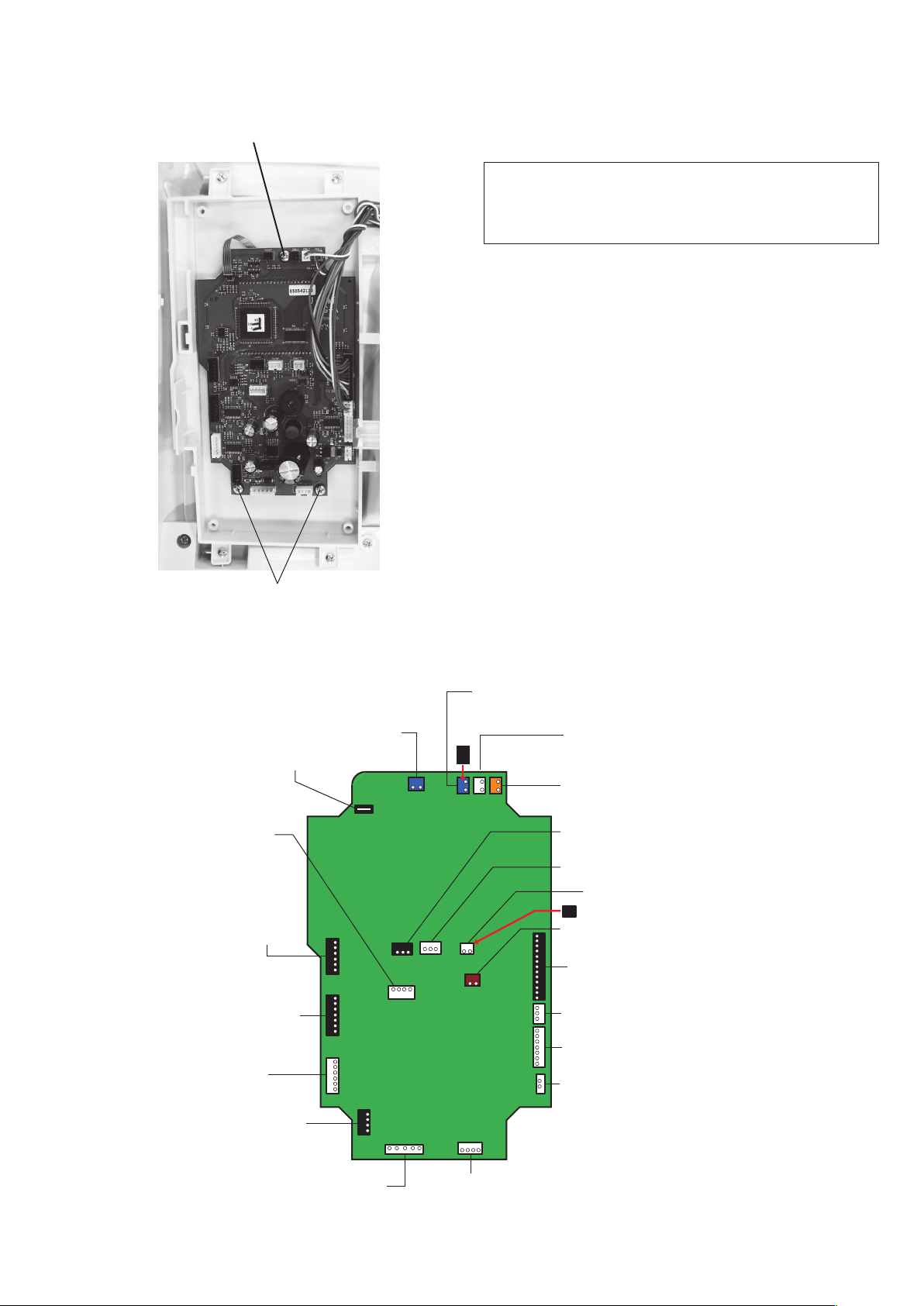

Replacing electronic components

Printed circuit board A ....................................................................................................................................... 8

Printed circuit board F ....................................................................................................................................... 9

Speed control slider ........................................................................................................................................... 9

Switching power supply unit ............................................................................................................................ 10

DC motor ......................................................................................................................................................... 11

Thread tension unit .......................................................................................................................................... 12

Mechanical adjustment

Feed dog height ............................................................................................................................................... 13

Needle drop position ....................................................................................................................................... 14

Presser bar height ............................................................................................................................................ 15

Hook timing ..................................................................................................................................................... 16

Needle bar height ............................................................................................................................................ 17

Clearance between needle and tip of the rotary hook ................................................................................ 18-19

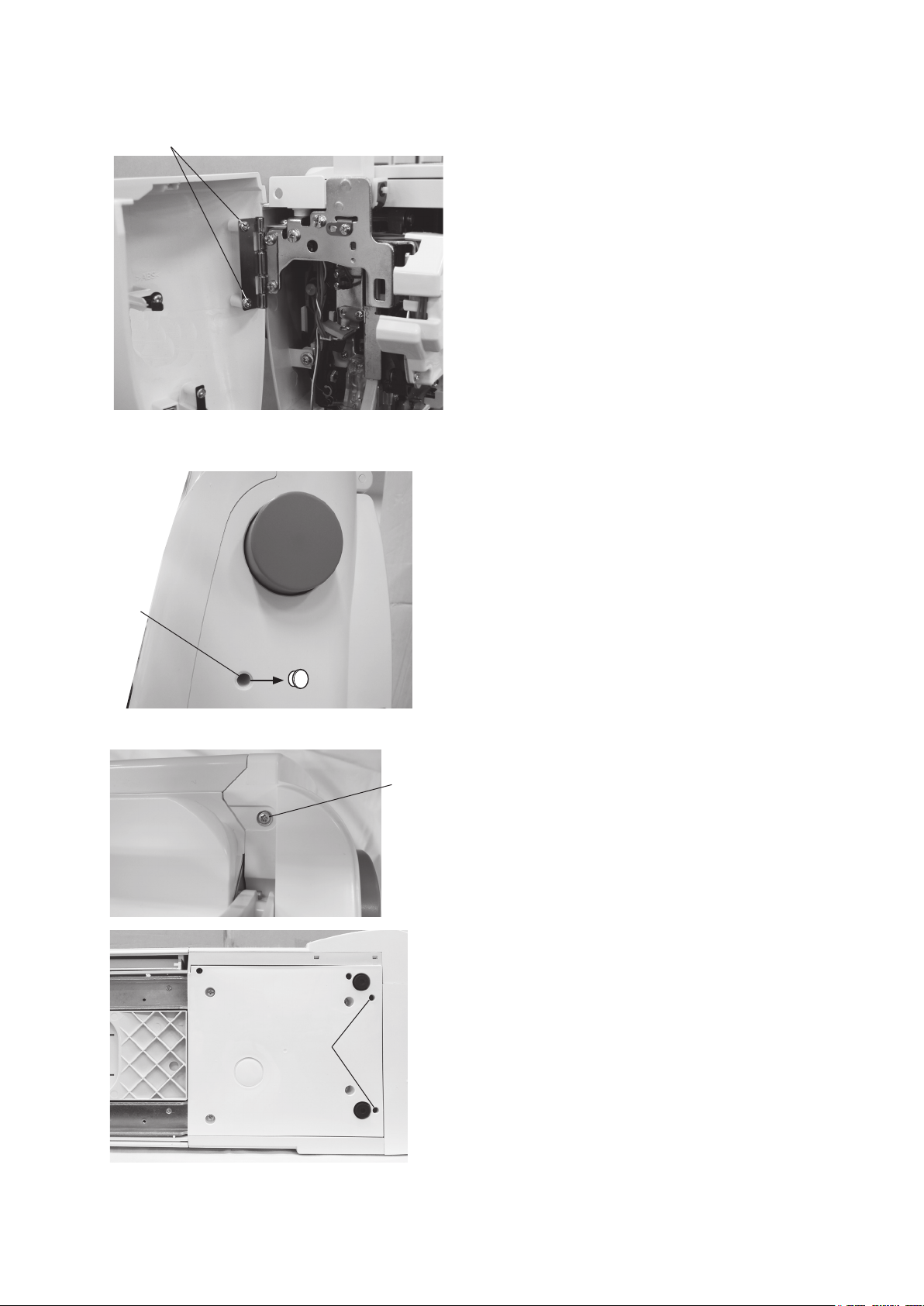

Presser bar lifter switch position adjustment ................................................................................................... 20

Backlash between hook drive gear and lower shaft gear ................................................................................ 21

Upper shaft shield plate position ..................................................................................................................... 22

Upper thread tension........................................................................................................................................ 23

Buttonhole lever adjustment ............................................................................................................................ 24

Thread cutter ................................................................................................................................................... 25

Solenoid position adjustment .......................................................................................................................... 26

Upper feed dog ........................................................................................................................................... 27-29

Stretch stitch feed balance .............................................................................................................................. 30

Needle plate switch ................................................................................................................................... 31-32

Knee lifter posotion .......................................................................................................................................... 33

Diagnosis test ............................................................................................................................................ 34-39

PARTS LIST...................................................................................................................................................... 40-61