@ INITIAL START-UP

1. Fan Blade Does Not Spin 1.

2. Blade Spins but No Mist 2.

3. Hard To See Mist Output 3.

SPORADIC or NO MIST

1. Stiff/Locked Motor Shaft 1.

2. Reduced Mist Output 2.

3. No Mist at Low Output 3.

4. Worn/Bad Sump Pump 4.

5. Clogged Fan Blades 5.

OTHER

1. Does Not Sweep 1.

2. Tank Overowing 2.

3. No Auto Shut-Off 3.

4. Drain Plug Leaking 4.

5. Plumbing Leaks 5.

6. Squeaky/Hot Motor 6.

7. Control Box Not Working 7.

8. Elect. Breaker Tripping 8.

Issue

Tips On What To Check

TROUBLESHOOTING

Check power supply. Turn power switch to ON position mode. Check for a

damaged/cut power cord. Check for loose wires inside junction boxes.

Make sure there is enough water to completely submerge the pump. The mist

switch needs to be activated showing a green light. Throttle the ow control

valve to maximum mist to prime out any air bubbles. Test Pump and check

plumbing lines.

Fine mist output is generally difcult to see without having a dark

background. Fine mist particles also evaporate quickly (within seconds) in

dry air. This is a good thing as this causes evaporative cooling to occur.

If motor smells, doesn’t start (with a direct power supply) or shaft will not

loosen up. The motor is bad and should be replaced.

Check pump’s output by disconnecting tubing, check pump’s sediment

screen. Then move up the plumbing lines looking for kinks or clogs.

Indicates a clogged ow restrictor tube. Remove, clean or replace.

Sump pumps can go bad if operated for lenghty periods of time out of water.

If the pump has little to no output ow. Replace as needed.

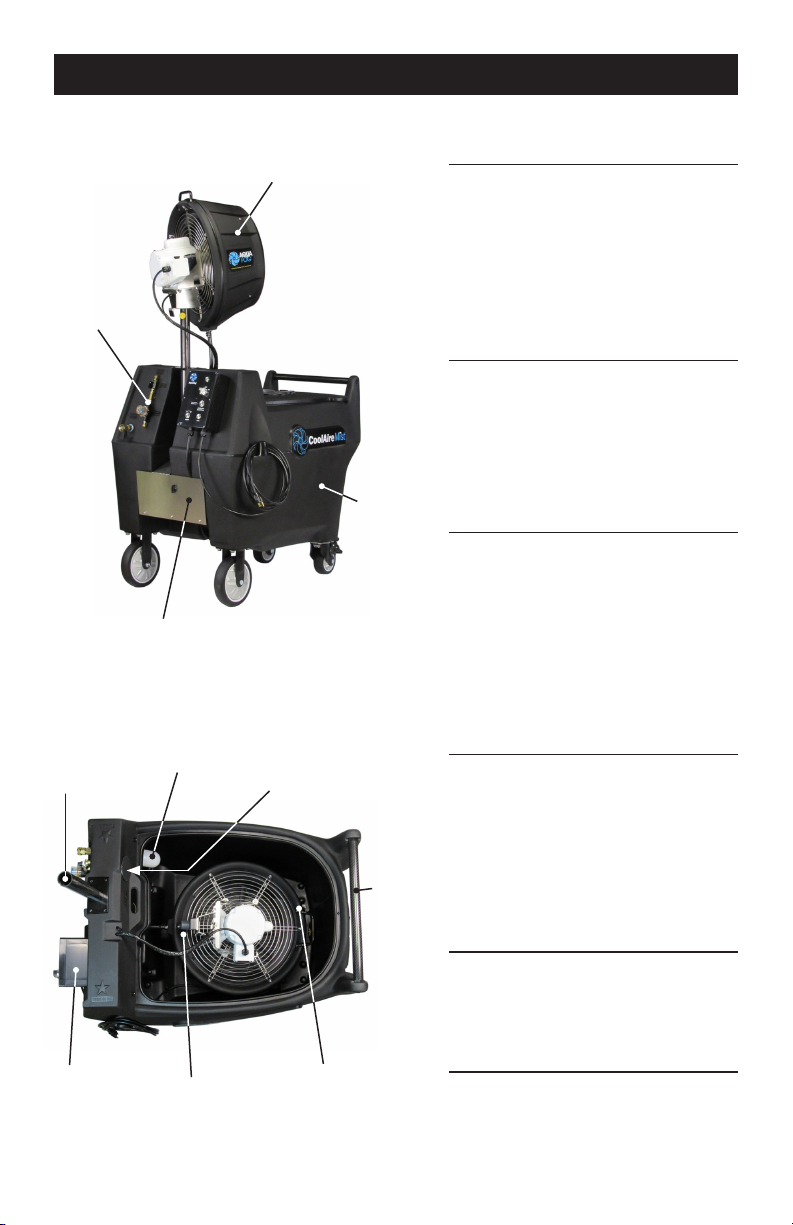

If there is a lot of calcium build-up near the end of your atomizing fan blades.

Remove and clean by soaking the blade assembly in bath of (CLR) calcium

dissolving solution.

Check the sweep switch, also check the oscillator motor.

This indicates a bad oat valve. Check, service or replace.

This mode requires water in the tank to activate the uid level switch. If still

not working, test the uid level switch and replace if needed.

If any deep scratches or dents occurs where the drain plug seals against the

tanks wall, this can cause leaking. Attempt to smooth the walls of the hole

with sandpaper. Check the plug for any damage or cracked seals.

If there is a persistent plumbing leak. Use both thread tape (rst) with some

pipe sealant on top of tape to ensure a leak-proof connection.

If motor makes squeaky noise, smells and gets excessively hot. These are

signs of a motor going bad. Replace motor early to avoid future issues.

Check power supply and power cord. Check inside control box for loose

connections. Consult an electrician or replace the control box assembly.

Turn off all other devices connected to the same circuit. If the breaker

continues to trip, the fan motor is probably bad and in need of repair.

Consult an electrician for professional evaluation.

6

WARNING! BEFORE

INSPECTION AND/OR SERVICE

DISCONNECT AND LOCK OUT

POWER SOURCE