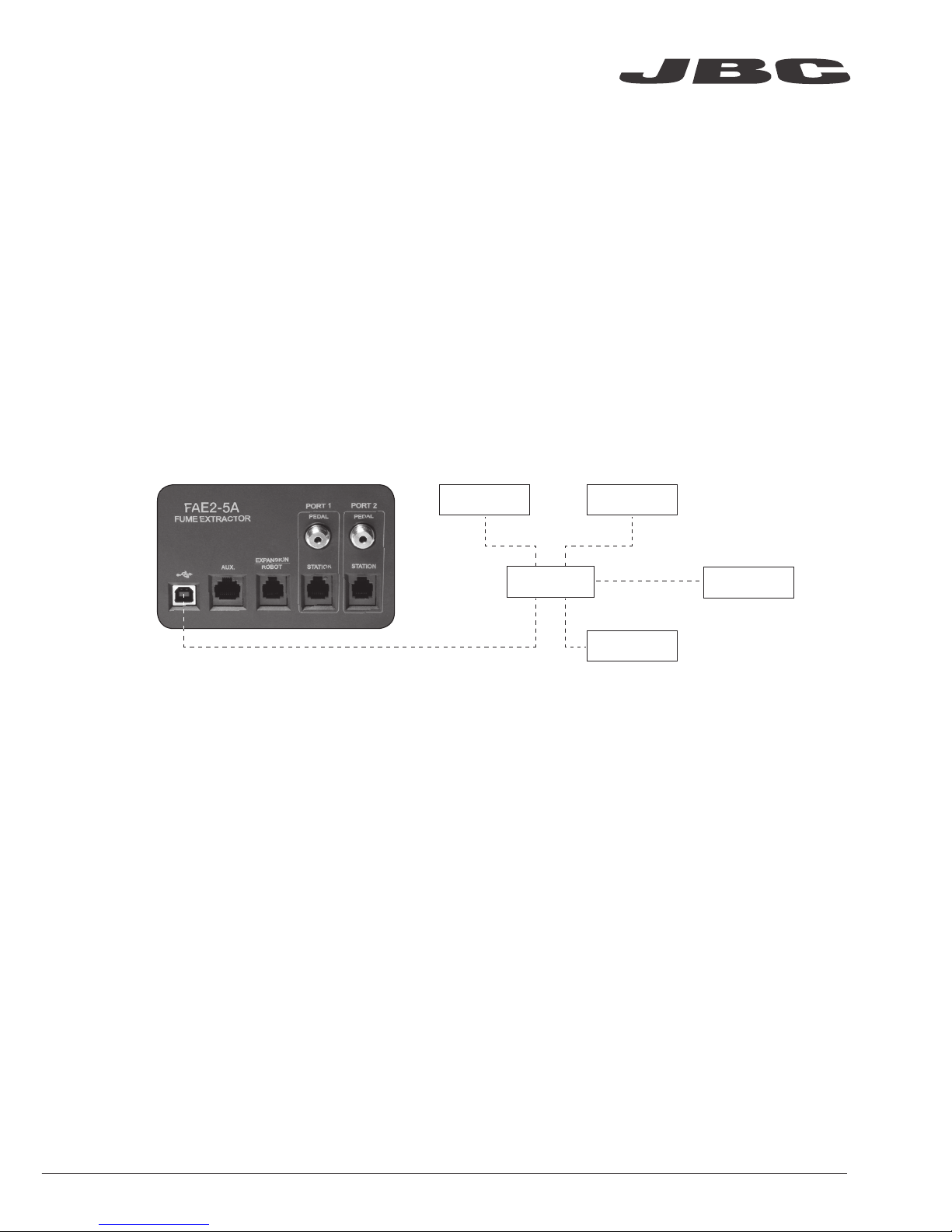

Aspiration ports control

For 2 work intakes configuration:

If only 1 station is connected to Port1, the

station will detect the 2 work intakes identified

as FAE_a (work1) and FAE_b (work2).

For 4 work intakes configuration:

If only 1 station is connected to Port1, the

station will detect the 4 work intakes identified

as FAE_a (work1), FAE_b (work2), FAE_c

(work3) and FAE_d (work4).

For 2 work intakes configuration:

If 1 station is connected to Port2, the station

will only detect the work2 intake identified as

FAE_a.

For 4 work intakes configuration:

If 1 station is connected to Port2, the station

will detect the 2 last work intakes identified as

FAE_a (work3) and FAE_b (work4).

The pedal connection takes precendence

over the RJ12 connection, the equipment

will only attend the Pedal port.

For 2 work intakes configuration:

When 2 stations are connected to Port1 and Port2, work intakes 1 and 2 are both detected as FAE_a

in the Peripherals menu of soldering stations.

For 4 work intakes configuration:

When 2 stations are connected to Port1 and Port2, work intakes 1 and 3 are detected as FAE_a and

work intakes 2 and 4 as FAE_b in the Peripherals menu of soldering stations.

8