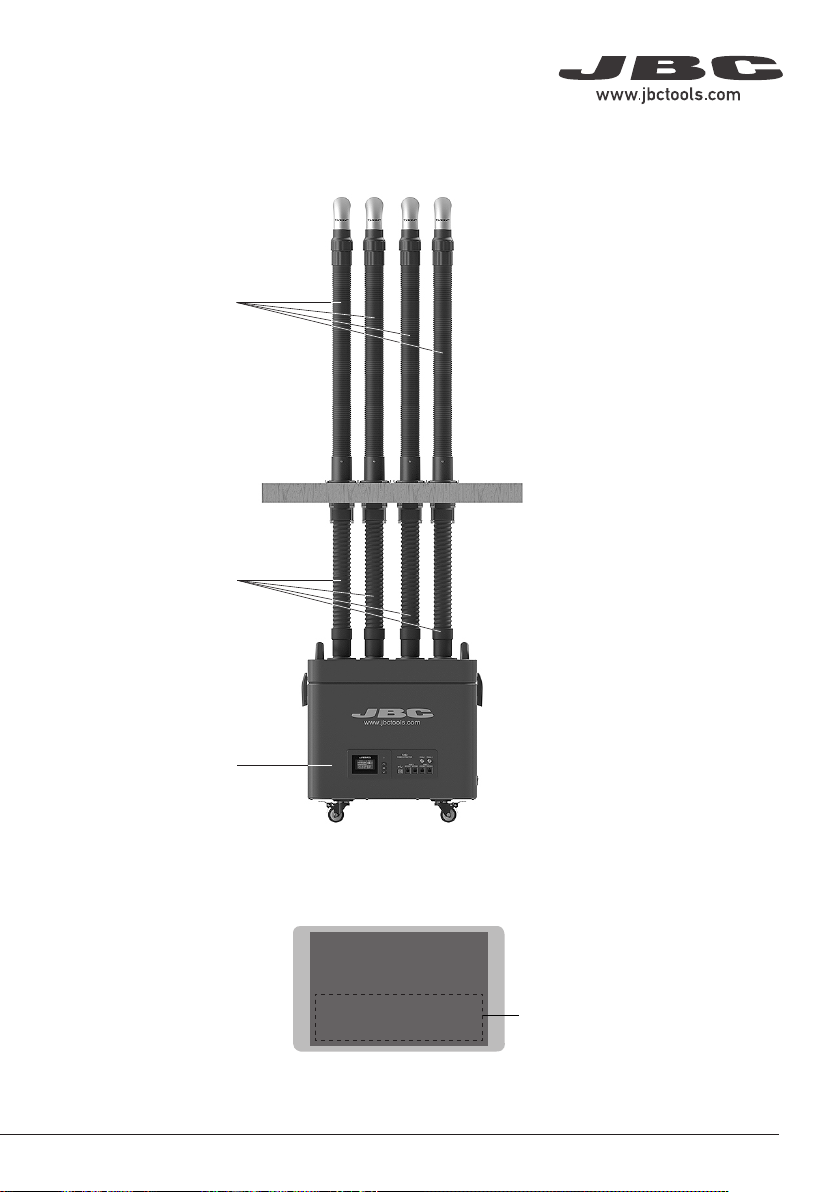

For 2 Workbenches Configuration:

Stations (Excellence or Advanced range) connected to RJ12 connectors station1 and station2 can

control flexible arm1/stand1 aspiration intakes, whereas those which are connected to station3 and

station4 can control flexible arm2/stand2 aspiration intakes.

For 4 Workbenches Configuration:

Each station connected to RJ12 connector stationX can control flexible armX aspiration intake (e.g.

station2 controls aspiration arm2).

Continuous mode

When continuous mode is enabled the 4 aspiration intakes are opened and fume extractor suction is

activated. Aspiration remains active until continuous mode is disabled or the equipment is powered

off. (See details on page 9).

Station Connections for Compact Range

Use the Compact Station Cable and the Adapter cable to connect JBC Soldering Stations. They

feature a USB-B port to the fume extractor in order to automatically activate the extraction when the

tools are in use.

Compact Station

Cable + Adapter

Equipment Software Update

JBC Updater

The fume extractor can be updated via the USB-B connection by means of JBC Updater software.

Download software from: www.jbctools.com/software.html.

Note: For the updating process the Premium Station Cable (RJ12) has to be disconnected. If a station

is connected to RJ12 connector the update process will not start.

CD-S

CD-B

CA

CS

CDE-S

CDE-B

CP

OK

TOOL

EARTHING FUSE

AUX

USE ONLYWITH A 250 V FUSE

OK

ºC

ºF

A

OK

Language

Mode

Exit

Language

Mode

Exit

Language

Mode

Exit

Maximum temp

Minimum temp 200ºC

350ºC

8886698

PIN

Sound

Date&Time

02/06/2021, 15:01

ºC

On

O

Red limit 40%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

180

Sleep

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

Selected

Min 200 Max 400

350

º

C

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

180

Sleep

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

Selected

Min 200 Max 400

350

º

C

0.5s/div

Ok to set up soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to set up soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

2.4s

13W·s

ºC

95%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.2s

18W·s

2.4s

17W·s

ºC

94%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

1.3s

8W·s

ºC

38%

19:29

19:29

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

1.3s

8W·s

ºC

38%

19:29

1s/div

150 Time

C210-008 Ref. .

4.5s ---

ºC

SOLDERING JOINT INFO 1/3

Sel. temp.

Cartridge

Time

Max temp

Min temp

Energy

Result

Last Ref. Diff.

350ºC 350ºC

C245907

2.4s

350ºC

335ºC

13W·s

2.3s

C245907

-2%

350ºC +0%

340ºC -1%

14W·s +29%

95%

1s/div

150 Time

C210-008 Ref. .

4.5s ---

ºC

SOLDERING JOINT INFO 1/3

Sel. temp.

Cartridge

Time

Max temp

Min temp

Energy

Result

Last Ref. Diff.

350ºC 350ºC

C210009

2.4s

350ºC

335ºC

13W·s

2.3s

C210009

-2%

350ºC +0%

340ºC -1%

14W·s +29%

95%

C21

00

09

Cartridge

Language

Mode

Exit

Cartridge

Language

Mode

Exit

Hiberna�on

ºC

25% 75%

Power C245907

50%

19:29

325

º

CSel. temp.

325ºC

25% 75%

Power C245907

50%

Sleep

ºC

25% 75%

Power C245907

50%

19:2919:29

Hiberna�on

ºC

25% 75%

Power

50%

19:29

325

º

CSel. temp.

325ºC

25% 75%

Power

50%

Sleep

ºC

25% 75%

Power

50%

19:2919:29

TOOL

EARTHING FUSE

AUX

USE ONLY WITH A 250 V FUSE

Language

Mode

Exit

Language

Mode

Exit

Language

Mode

Exit

Maximum temp

Minimum temp 200ºC

350ºC

8886698

PIN

Sound

Date&Time

02/06/2021, 15:01

ºC

On

O

Red limit 40%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

180

Sleep

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

Selected

Min 200 Max 400

350

º

C

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

180

Sleep

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

Selected

Min 200 Max 400

350

º

C

0.5s/div

Ok to set up soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to set up soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

2.4s

13W·s

ºC

95%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.2s

18W·s

2.4s

17W·s

ºC

94%

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C245907 Ref.

2.3s

14W·s

1.3s

8W·s

ºC

38%

19:29

19:29

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

---

---

ºC

19:29

0.5s/div

Ok to reset soldering Ref.

20

16

12

8

4

355

350

345

340

335

350

Sel. temp. 350ºC

W% ºC

Time

Energy

C210009 Ref.

2.3s

14W·s

1.3s

8W·s

ºC

38%

19:29

1s/div

150 Time

C210-008 Ref..

4.5s ---

ºC

SOLDERING JOINT INFO 1/3

Sel. temp.

Cartridge

Time

Max temp

Min temp

Energy

Result

Last Ref. Diff.

350ºC 350ºC

C245907

2.4s

350ºC

335ºC

13W·s

2.3s

C245907

-2%

350ºC +0%

340ºC -1%

14W·s +29%

95%

1s/div

150 Time

C210-008 Ref..

4.5s ---

ºC

SOLDERING JOINT INFO 1/3

Sel. temp.

Cartridge

Time

Max temp

Min temp

Energy

Result

Last Ref. Diff.

350ºC 350ºC

C210009

2.4s

350ºC

335ºC

13W·s

2.3s

C210009

-2%

350ºC +0%

340ºC -1%

14W·s +29%

95%

C21

00

09

Cartridge

Language

Mode

Exit

Cartridge

Language

Mode

Exit

Hiberna�on

ºC

25% 75%

Power C245907

50%

19:29

325

º

CSel. temp.

325ºC

25% 75%

Power C245907

50%

Sleep

ºC

25% 75%

Power C245907

50%

19:2919:29

Hiberna�on

ºC

25% 75%

Power

50%

19:29

325

º

CSel. temp.

325ºC

25% 75%

Power

50%

Sleep

ºC

25% 75%

Power

50%

19:2919:29

JBC

Updater

Cable USB AB

7

40 mm

50 mm

60 mm

80 mm

100 mm

130 mm 130 mm

para manuales - color gris

200 mm

300 mm