UsingtheTroubleshootCharts

Whenusing theTroubleshootingCharts,determinethesymptombyscreenobservationand

controlaction.ChecktheSymptomIndexandfind thesymptomthatmostcloselydescribesthe

problem.

ThepageindicatingthatkindofproblemhastheTroubleshootChartdealingwithit.

theTroubleshootChartslistadjustments,panelsandmodulestobechecked.Ifacheckresults

ina symptomchange,locatethenewsymptomintheIndexandfollowthechartdirections.

TwoGroundSystem

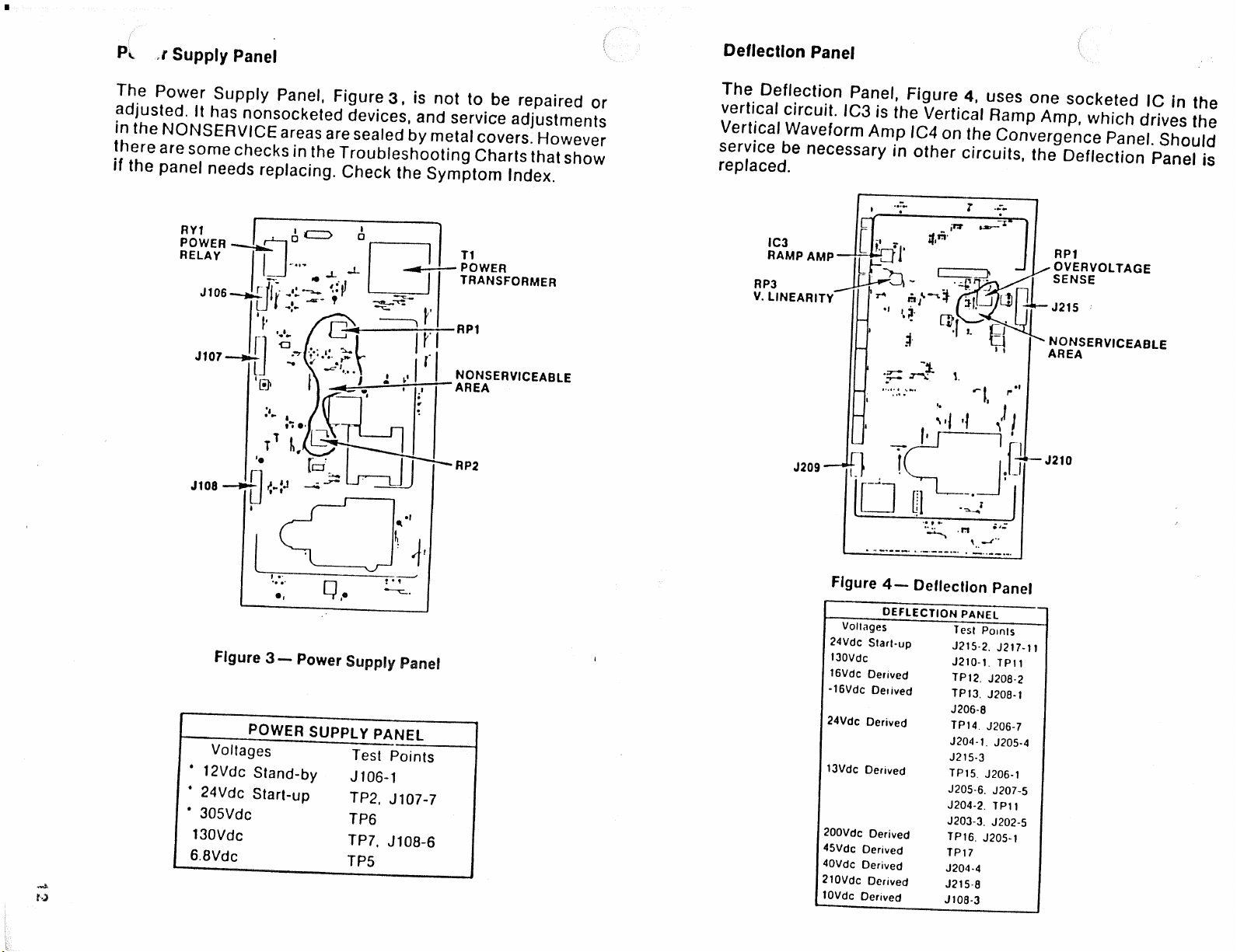

ThetwogroundsystemusedonthePowerSupplyPanelandDeflectionPanelare"AC"or

"Hot"groundand"Signal"or"Cold"ground.TestpointsTP3andTP9aremeasuringequip-

mentgroundsusedwhencheckingaclineconnectedcircuits."Signal"or"Cold"groundtest

pointsTP1andallshieldingonthesignalplugstopanelsandmodulesareusedfortestequip-

mentgroundswhenmeasuringcircuitsconnectedto"Signal"ground.

Isolationbetween"Hot"groundand"Cold"groundisdevelopedbyPowerTransformerTl,HV

TransformerT4,andOpticCoupler

IC1

onthePowerSupplyPanel.HorizontalDriveTrans-

formerTlandHorizontalOutputTransformerT2providetheisolationontheDeflectionPanel.

IsolationProtection

ItisimperativeanIsolationTransformerbeusedonthetwo-groundsystemtoprotectthetest

andmeasuringinstrumentsaswellasthesetelectronicsfrom mis-polarizedaclinecordplugs.

TVSystemOverview

WhenthePowerplugisconnectedtotheacline,Stand-byvoltageisfedtotheTS10PCon-

troller,Figure1,

and

regulatedto5VdctokeeptheMicrocomputeralive.A Power-Onkey

pressattheRemoteTransmitteroron-setKeyboardtunesthesettoChannel3,selectsthe

AntennaRFInput,andplacestheaudiosystemintheMonauralmode.TheTS10PController

displayson-screengraphicstoidentifythemode.TheMicrocomputeracceptsalldatafromthe

keyboard.Ifthechanneldataisincorrect,theTS10Pdisplayblinkssixtimesandontheseventh

blinkrevertstothepreviouschannelnumber.Incompletechannelnumbersreverttotheprevious

channeliftheseconddigitisnotenteredwithineightseconds.Zerocancellationisusedonall

numbersbelow10.Volumeiscontrolledin64steps.Soundismuteduntilthechannelistuned

andwhentheMutekeyispressedontheRemoteTransmitter.PresstheRemoteTransmitter

MutebuttonorVolumeUpbuttontoun-mute.

Figure2 showsthePanelandmodulefunctions,interconnectcables,plugs,andjacks.The

heavierlinesidentifythesignalflowfromtheRFSwitchertotheStereoSpeakerterrninalsand

theRed,GreenandBlueCRTs.Switchingsignals,controlvoltages,andotheroperationalvolt-

agesareshownwithlighterlines.

Adjustinga newCRT

AfterinstallinganewCRT,checkthepositionofthenewCRTrasteragainsttheCrosshair

patternoftheothertwoCRTsusing thefollowingprocedure.

1.

Placethealikemagneticringtabstogether.

2.

Rotatetheyoketopositionthecrosshairpatternstogether.Ifthepatternsdonot

match,

adjustthemagneticringtabstopositionthecrosshairpointstogether.

3.UseaCrosshatchpatterngeneratortochecktheoverallconvergence,andtouch

upconvergenceifnecessary.