General

Machine type –Compact Excavator

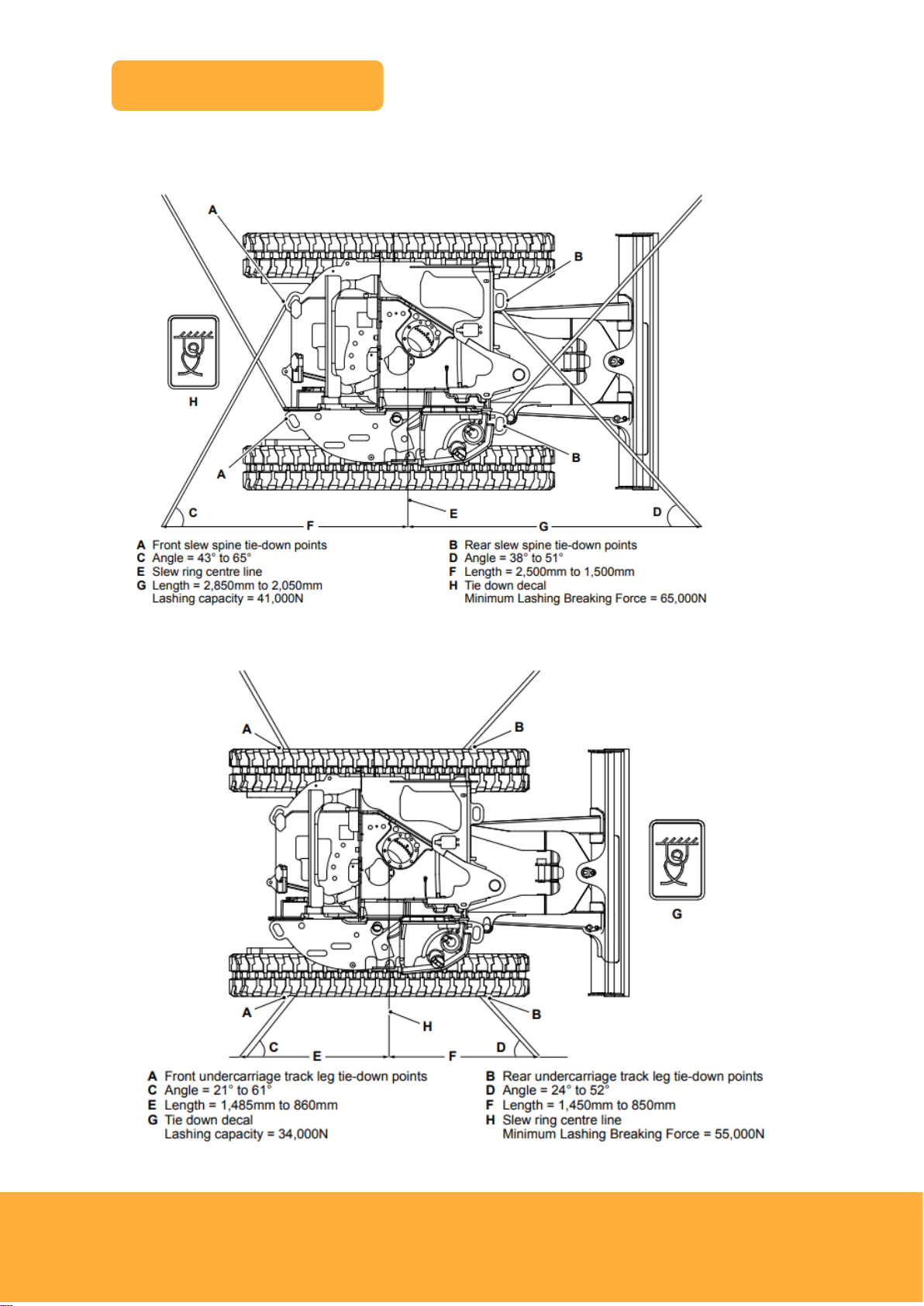

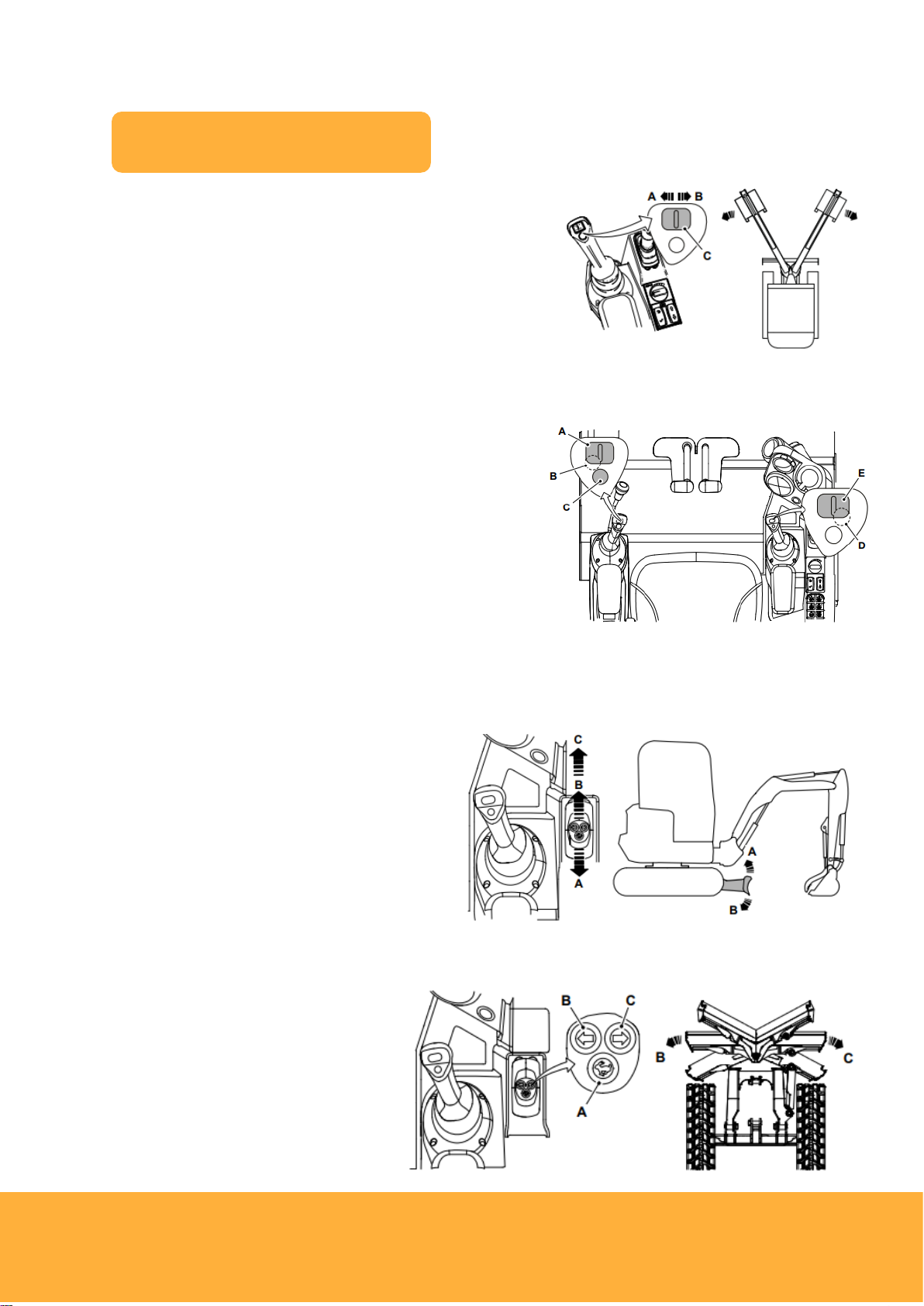

Self propelled machine with a tracked undercarriage

360° revolving upper structure with boom, dipper, bucket and slew mechanism

Intended Use

Machine intended to be used in normal conditions as detailed in the operators manual

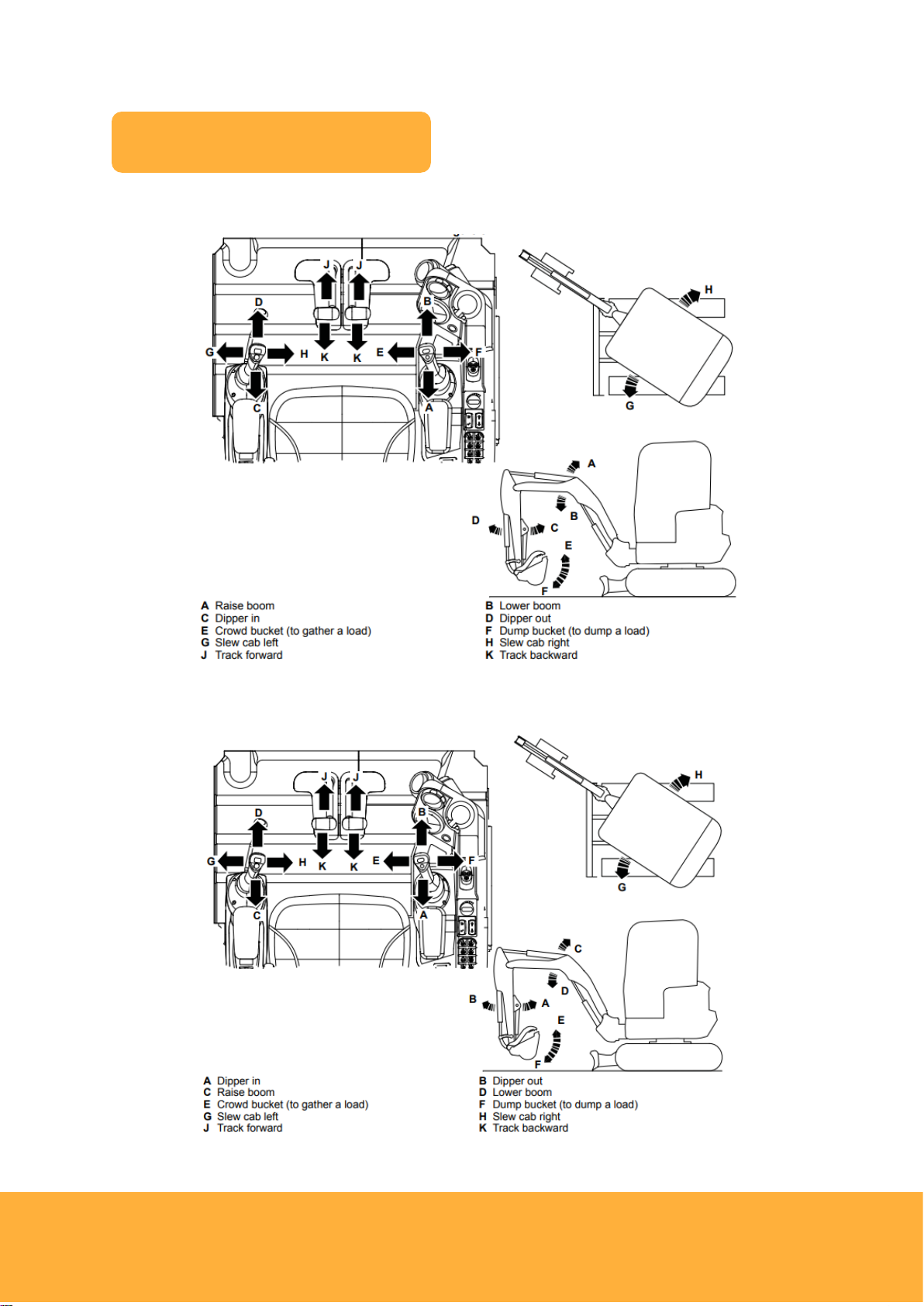

With bucket fitted, machine work cycle consists of digging, elevating, slewing and

discharging of materials

Applications include earthmoving, road construction, building and construction,

landscaping etc.

Can be used for object handling

Not intended for use in mining and quarrying applications, demolition, forestry, any use

underground and any explosive atmospheres.

Must not be used for forestry, used with attachments of unknown weight, used on

surfaces with unknown stability –list not exhaustive

PPE may be required in certain applications/environments e.g. high silica concentration

or asbestos

The machine should not be operated by any person without appropriate qualifications,

training or experience of using this type pf machine

Prior to use, the machines suitability should be considered with regards to the intended

applications and any hazards which may be present