Part No. 960-000165R_Rev. 1 © 2013, JCM American, Corporation

VEGA™ Banknote Acceptor JCM Training Overview July, 2013

Page

VEGA™Banknote Acceptor

Table of Contents

Overview.................................................................................. 3

VEGA Unit.................................................................................................3

VEGA Features ....................................................................... 4

User Precautions..................................................................... 5

Component Locations.............................................................. 6

Component Names.................................................................. 6

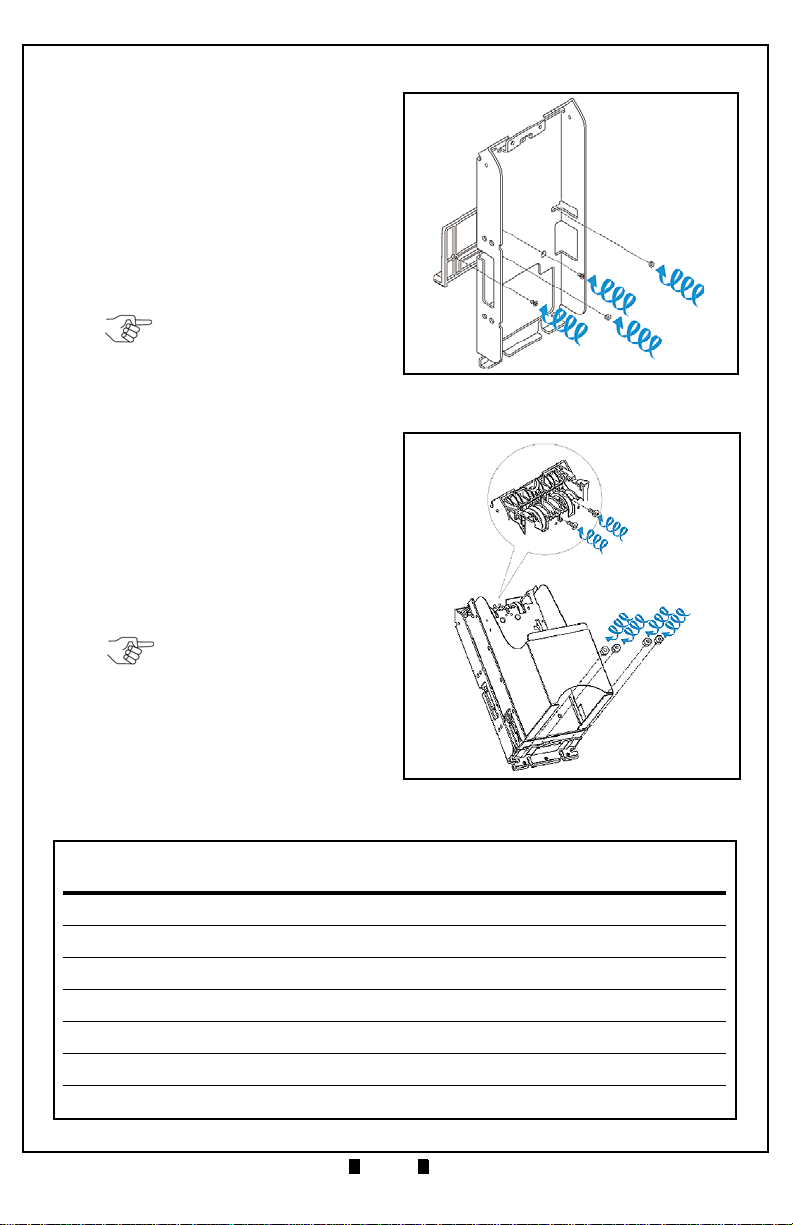

Installation................................................................................ 7

VEGA SH Unit...........................................................................................7

VEGA SU/SD Unit.....................................................................................7

VEGA SU/SD Unit (Continued 1)........................................................................8

VEGA SU/SD Unit (Continued 2)........................................................................9

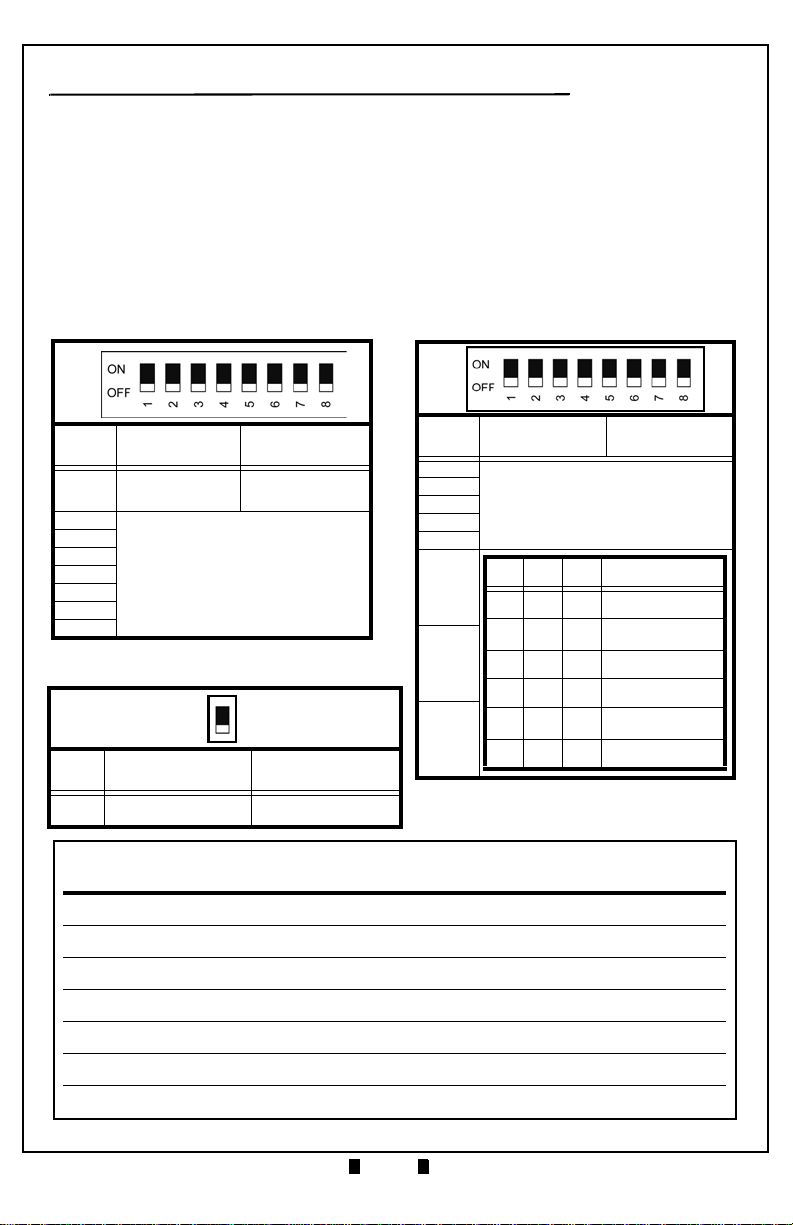

DIP Switch Settings............................................................... 10

Functional Testing...................................................................11

DIP Switch Test.......................................................................................11

Feed Motor Forward Rotation Test..........................................................11

Feed Motor Reverse Rotation Test .........................................................12

Stacker Motor Test ..................................................................................12

Aging Test ...............................................................................................13

Sensor Test.............................................................................................13

Sensor Test (Continued) ...................................................................................14

Software Download Procedure.............................................. 15

Software Download Procedure (Continued 1).........................................16

Software Download Procedure (Continued 2).........................................17

Non-PC Calibration Procedures ............................................ 18

Non-PC Calibration Procedures (Continued)..........................................19

Off-Line Banknote Acceptance Test........................................................20

Error and Reject Code Tables..........................................................................20

Error and Reject Code Tables (Continued) ......................................................21

VEGA Parts List..................................................................... 22