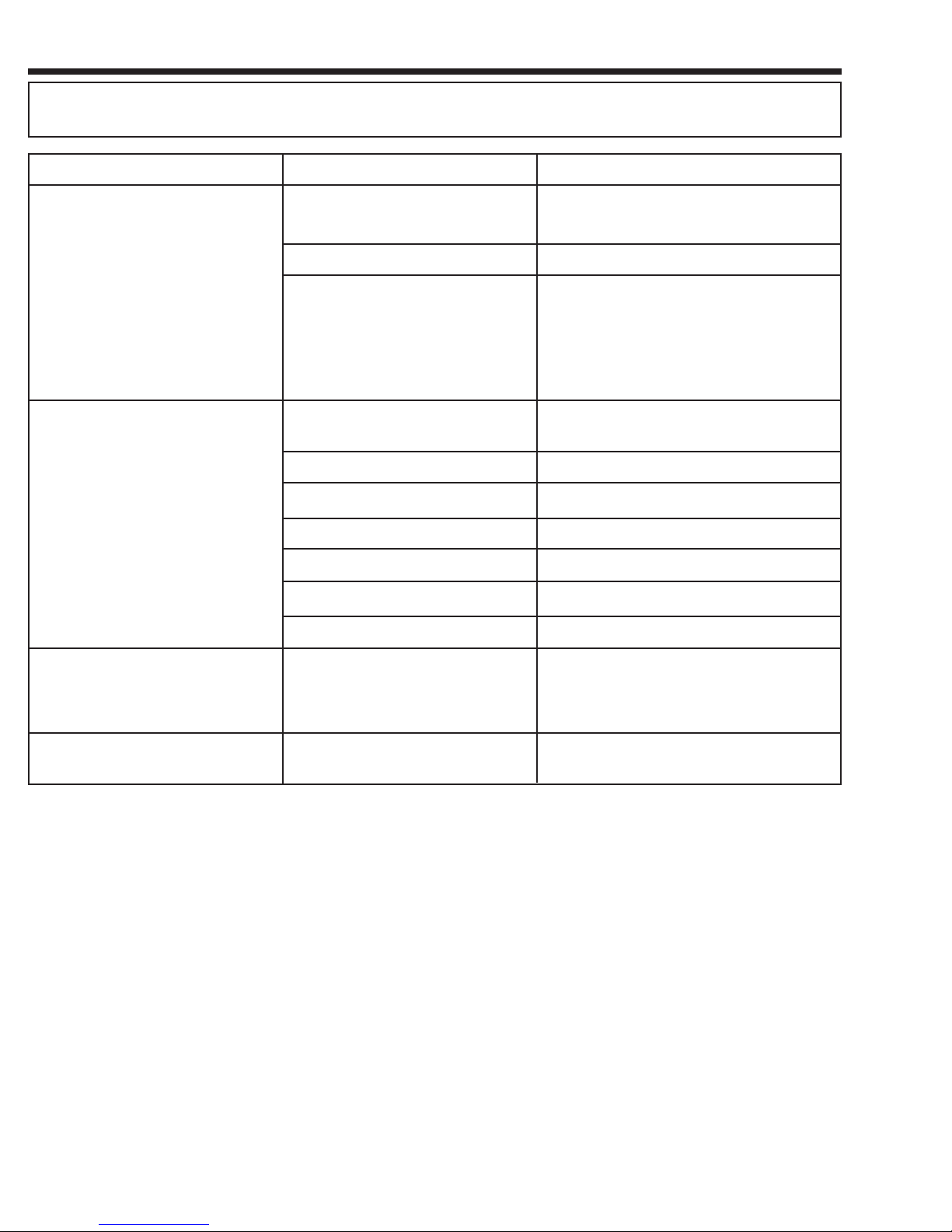

ROUBLESHOO ING

OPERATOR’S MANUAL FC-P30-UL

6.

Pump is hard to turn or poor flow Filter is incorrect size for type of

fuel

Filter is clogged Replace filter

Loose filter Inspect and tighten

Replace with correct size filter 1 micron for

E85. 10 micron for gasoline, 30 micron for

diesel/kerosene

Pump is difficult to prime Hose not submerged in fuel when

trying to prime

Check hose and reposition hose in vehicle

fuel tank

Fuel level gauge does not work Float positioned diagonally across

tank

Remove red plastic nut and indicator cap.

Remove float mechanism and position so that

float is position across tank. Replace cap and

nut.

Ground wire is damaged or will not

clamp

Damaged Replace

Leak in hose fittings Check fittings and tighten

Vane sticking Check vanes for contamination

Excessive vane wear Check vanes for excessive wear and replace

Damaged, kinked, or cracked hose Replace with hose assembly

Inside of pump is dry or rusted from

extended periods of non-use

Remove pump out hose by loosening the 90°

elbow swivel fitting on top of pump. Spray

WD-40 or other light oil into the pump out

port. At the same time, turn handle in the

opposite direction of the arrow to lubricate

the pump. ust turn opposite direction of

arrow to prevent pumping fuel from tank.

Leak at fittings or pump mount Check fittings and tighten as required.

CONDI ION POSSIBLE CAUSE SOLU ION

OPERATOR’S MANUAL FC-P30-UL

3.

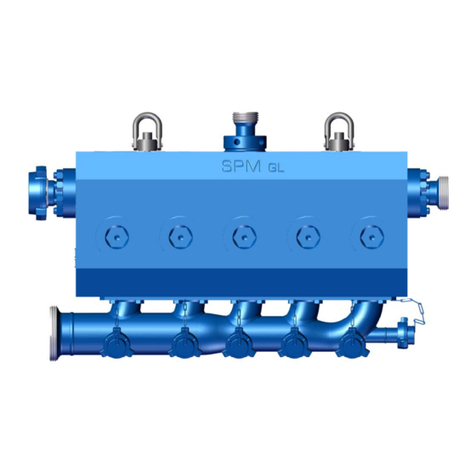

GENERAL PRODUCT DESCRIPTION

The Gas Caddy is designed and approved to safely transfer

fuel to and from a vehicle. It may be used to safely store fuel

during vehicle service. It is approved for use with unleaded

gasoline, diesel, kerosene, and E85 (ethanol) fuels.

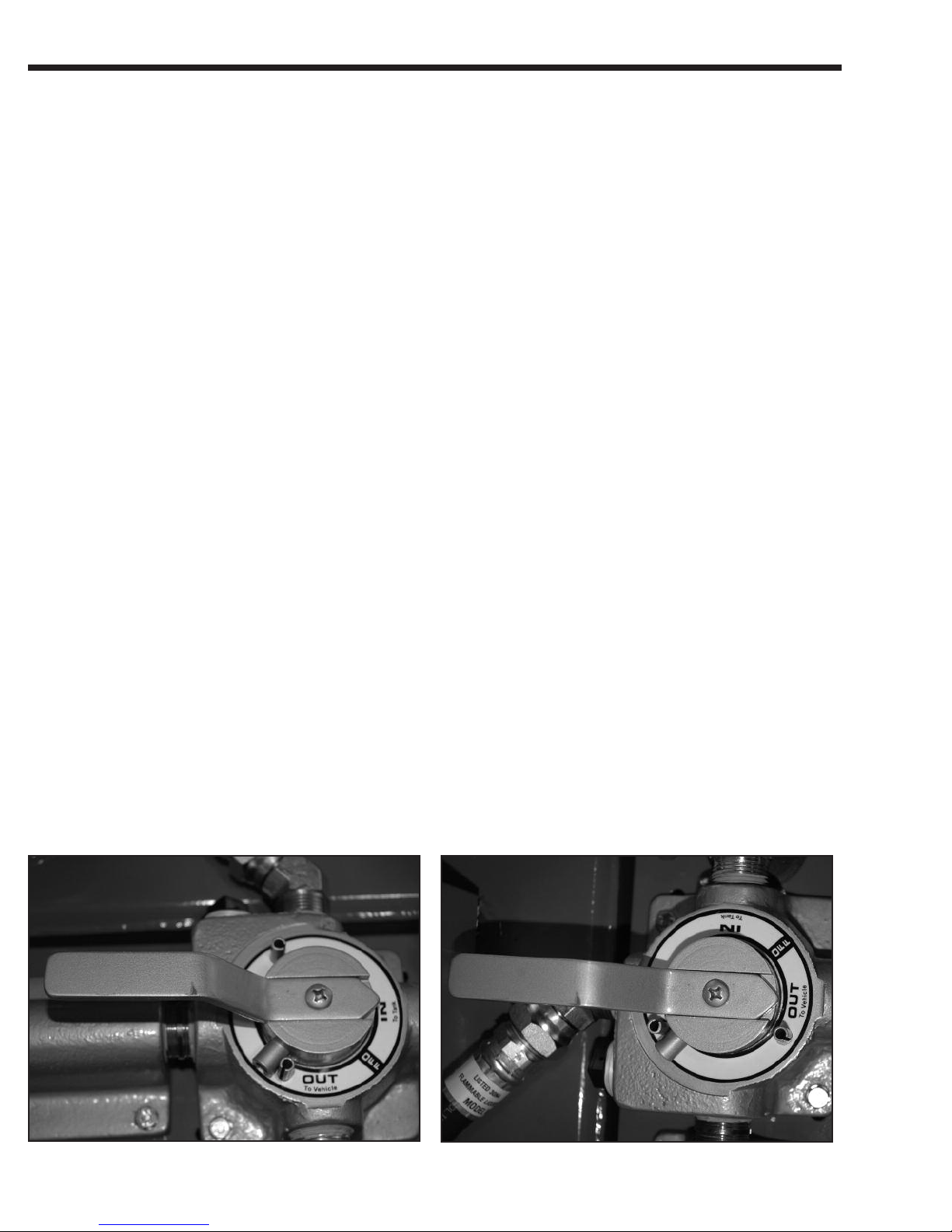

The direction of flow is controlled by a 4-way valve to assure

that fuel is filtered in both directions. Caution: urning the

pump in the opposite direction will pump the fuel, but this

will cause contaminates inside the filter to be introduced

into the fuel stream. Always use the valve to control the

direction of flow.

The FC-P30 comes standard with a 10 micron filter for use

with gasoline. Other filters are available for other fuels. Select

the correct filter for the intended application. Proper filter

selection is critical to achieving maximum pumping efficiency

and to properly remove contaminates from the fuel.

Refer to the table shown in REPLACE ENT PARTS AND

ACCESSORIES if you intend to pump different fuels.

Fuel Type Filter Type

Unleaded Gasoline 10 micron

Diesel and Kerosene 30 micron

E85 Ethanol 1 micron

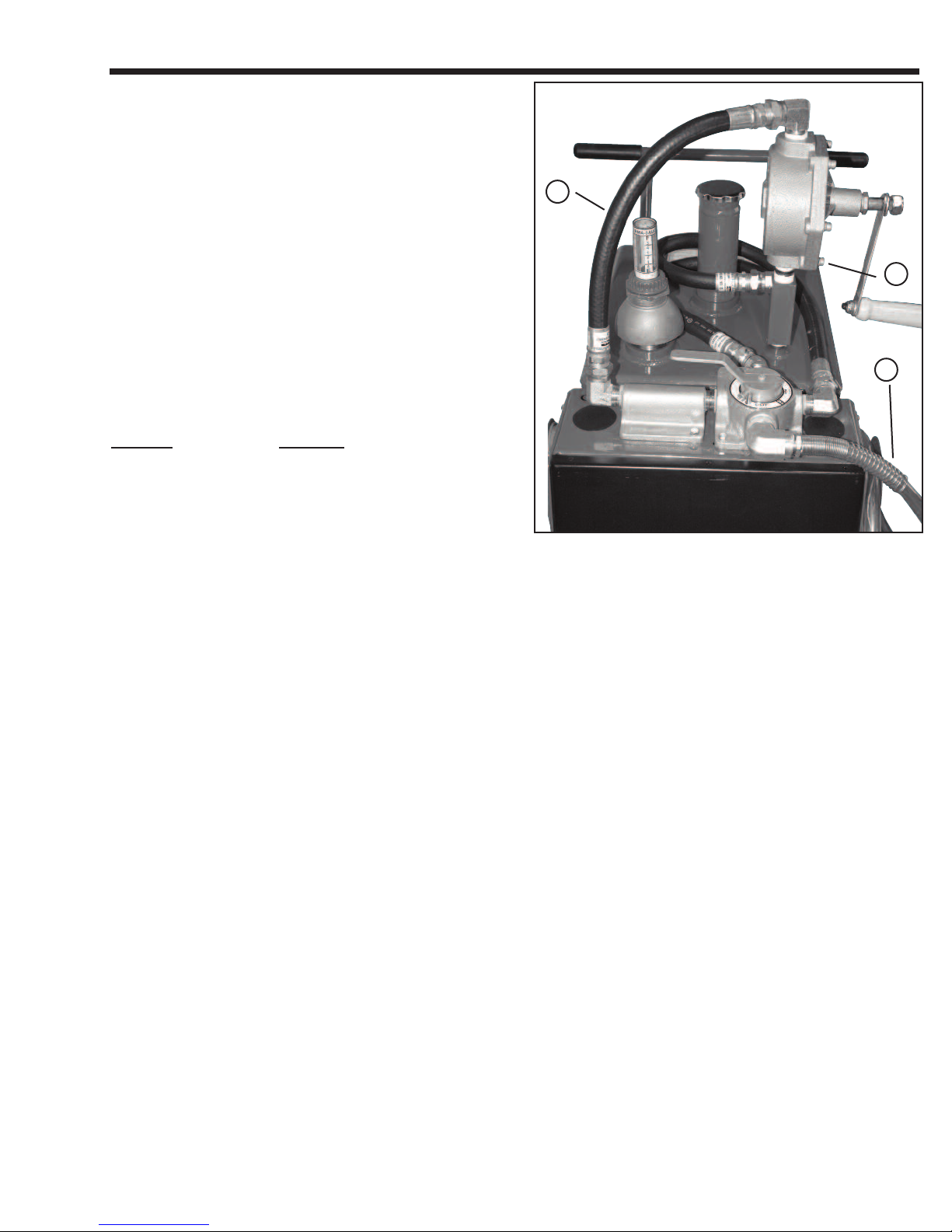

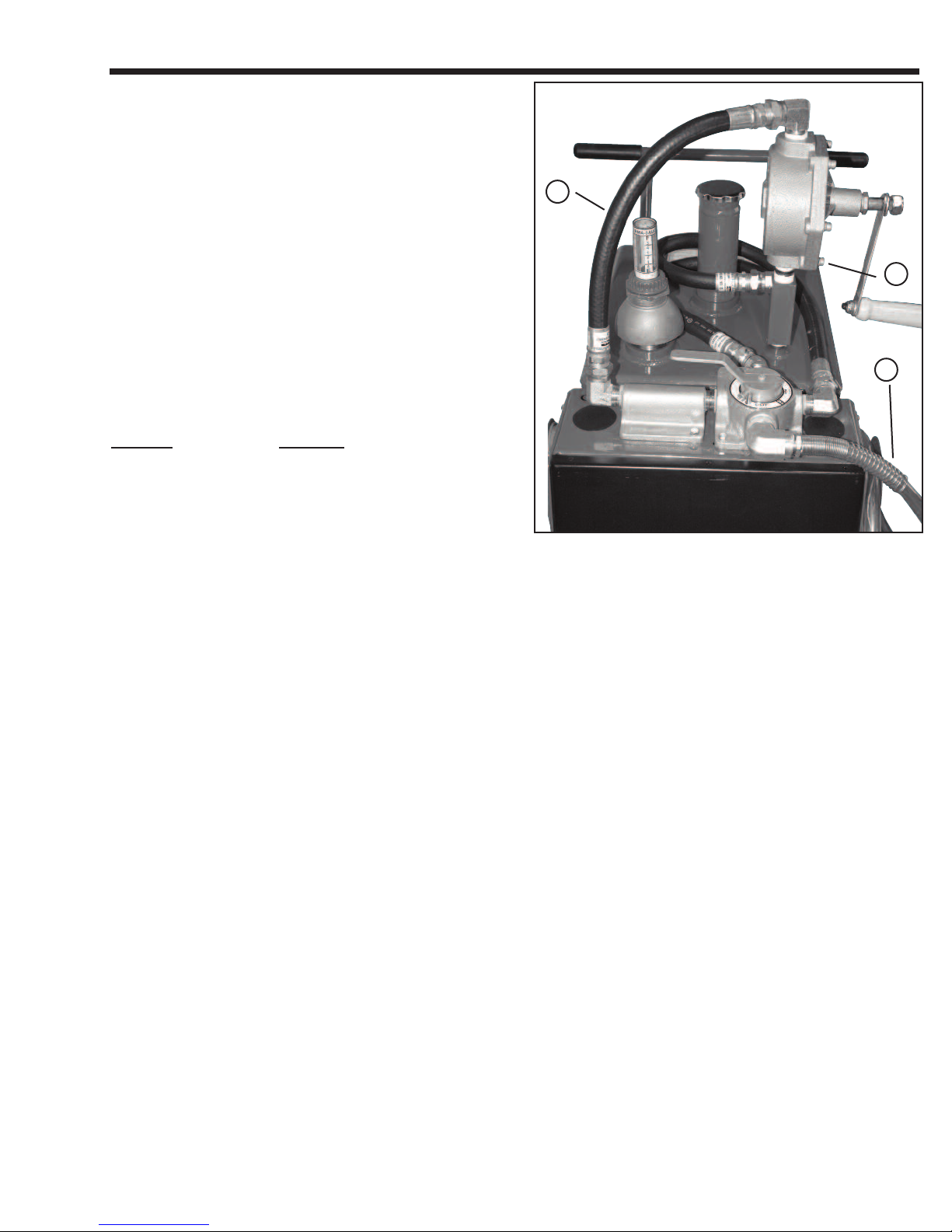

ASSEMBLY

1. Wrap 2 inch NPT thread on fill tube 4-6 wraps with PTFE

tape wrapping clockwise.

2. Assemble pump “A” onto tank by threading the “IN” side the

pump onto the 3/4 close nipple. Hold the manifold with a

1-1/2 inch adjustable wrench to prevent turning. Turn pump

until threads tighten with the final turn positioning the pump.

3. Position the handle to the left side of the tank as shown in

Figure 1.

4. Assemble the pressure hose “B” to the 90° swivel fitting on

top of the pump and to the 90° swivel fitting on the filter

support. Place a 1-1/16 inch open end wrench on the hose

and tighten the swivel using a 1-1/14 inch open end wrench.

Tighten securely to prevent leaks. Note: when tight the swiv-

el will not rotate.

5. Assemble the discharge hose “C” by threading the 3/4 NPT

fitting into 90° fitting located on the front of the valve assem-

bly. Pace a 1-1/16 inch wrench on the hose and tighten.

Tighten with wrench.

6. Coil and hang the discharge hose on the hose hanger

bracket on the side of the tank.

7. Thread the 2 inch fill pipe and cap assembly onto the fitting

in the center of the tank. Tighten snugly by hand until secure.

Tools and Supplies (not included):

• TPFE tape • 1-1/2 inch open end wrench

• 1-1/16 inch open end wrench

• 1-1/4 inch open end wrench.

10. Remove tape from top of fuel gauge and install plastic

indicator cap and plastic nut onto float assembly. Align

indicator mark to point diagonally across tank so that float is

free to move full range. Tighten nut by hand to secure cap

and fuel gage.

Fig. 1

B

A

C