2

• Avoid situations where loads are not directly centered on the

cylinder plunger. O-center loads produce considerable strain

on cylinders and plungers. In addition, the load may slip or fall,

causing potential danger.

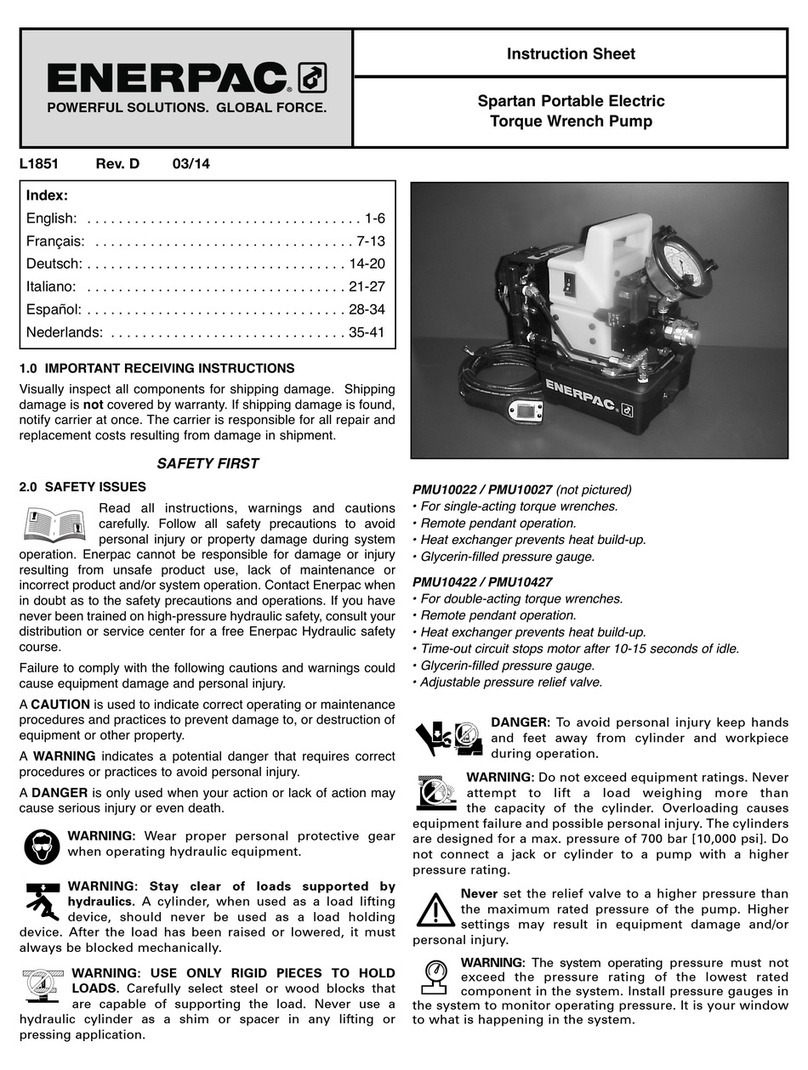

• The system operating pressure must not exceed the pressure

rating of the lowest rated component in the system. Install

pressure gauge(s) in the system to monitor operating pressure.

It is your window to see what is happening in the system.

• Do not exceed equipment ratings. Never attempt to lift a load

weighing more than the capacity of the cylinder. Overloading

causes equipment failure and possible personal injury

• Wear personal protective gear when operating hydraulic

equipment. Always wear eye protection. Safety equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal

injuries.

• Be sure setup is stable before lifting load. Cylinders should

be placed on a flat surface that can support the load. Where

applicable, use a cylinder base for added stability. Do not weld

or otherwise modify the cylinder to attache a base or other

support.

CAUTION

Failure to observe and comply with the following precautions

could result in minor or moderate personal injury. Property

damage could also occur.

• Avoid damaging hydraulic hose. Avoid sharp bends and kinks

when routing hydraulic hoses. Using a bent or kinked hose

will cause severe back-pressure. Sharp bends and kinks will

internally damage the hose, leading to premature hose failure.

• Do not drop heavy objects on hose. A sharp impact may cause

internal damage to hose wire strands. Applying pressure to a

damaged hose may cause it to rupture.

• Distribute the load evenly across the entire saddle surface.

Always use a saddle to protect the plunger.

• Do not lift hydraulic equipment by the hoses or swivel couplers.

Use the carrying handle or strap.

• Keep hydraulic equipment away from flames and heat.

Excessive heat will soften packings and seals, resulting in

fluid leaks. Heat also weakens hose materials and packings.

For optimum performance, do not expose equipment to

temperatures of 150˚F [65˚C] or higher. Protect all hydraulic

equipment from weld spatter

• Immediately replace worn or damaged parts with genuine

Enerpac parts. Enerpac parts are designed to fit properly and

to withstand high loads. Non-Enerpac parts may break or

cause the pump to malfunction.

NOTICE

• Hydraulic equipment must only be serviced by a qualified

hydraulic technician. For repair service, contact the Enerpac

Authorized Service Center in your area.

2.3 Battery Operated Pump Safety Precautions

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Do not operate the pump in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. The pump

creates sparks which may ignite the dust or fumes.

• Do not expose the pump to rain or wet conditions. Water

entering the pump will increase the risk of electric shock and

may damage the motor and other components.

• Do not exceed 25 percent duty cycle. Allow sucient time for

the pump to cool between operations.

• To avoid accidental starting, ensure that the trigger safety lock

is in the locked position before carrying or moving the pump.

Do not carry the pump with your hand or fingers on the trigger.

• Do not use the pump if the trigger switch does not turn it on

and o. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired before being used.

• Remove the battery pack from the pump before making any

adjustments, performing maintenance or storing the pump.

Such preventative safety measures reduce the risk of starting

the pump accidentally.

• Ensure the trigger lock is in the locked position before inserting

battery pack.

• Recharge battery pack only with the charger specified by the

battery manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

• Use the Enerpac XC Series pump only with MILWAUKEE

M28™Li-Ion battery packs. Use of any other battery packs

may create a risk of injury and fire.

• When battery pack is not in use, keep it away from other metal

objects like paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one

terminal to another. Shorting the battery terminals together

may cause burns or a fire.

• Under abusive conditions, liquid may be ejected from the

battery pack. Avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

• A separate manual (published by Milwaukee Electric Tool

Corp.) is provided with the battery pack and battery charger.

Read and understand all information contained in this

manual. Observe and comply with all communicated safety

precautions. If the manual is lost, obtain a replacement copy

before using the battery pack or charger.

• The battery pack and battery charger have no serviceable

parts. Do not attempt to disassemble or repair these items.