© MDM INC.

WWW.MDMINC.COM

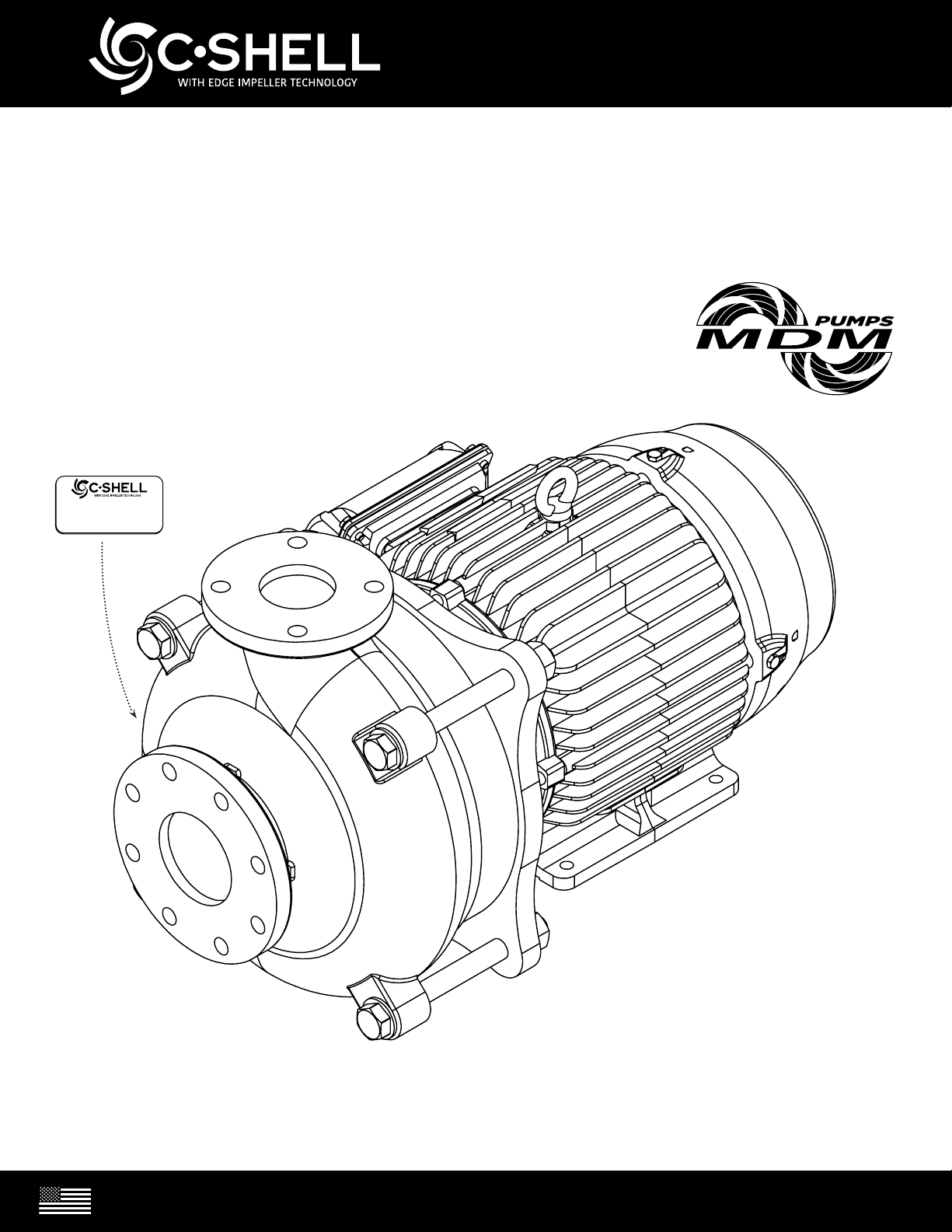

Generated from efficiency. Adapted for flow. Built for longevity.

Proudly Made

in the USA.

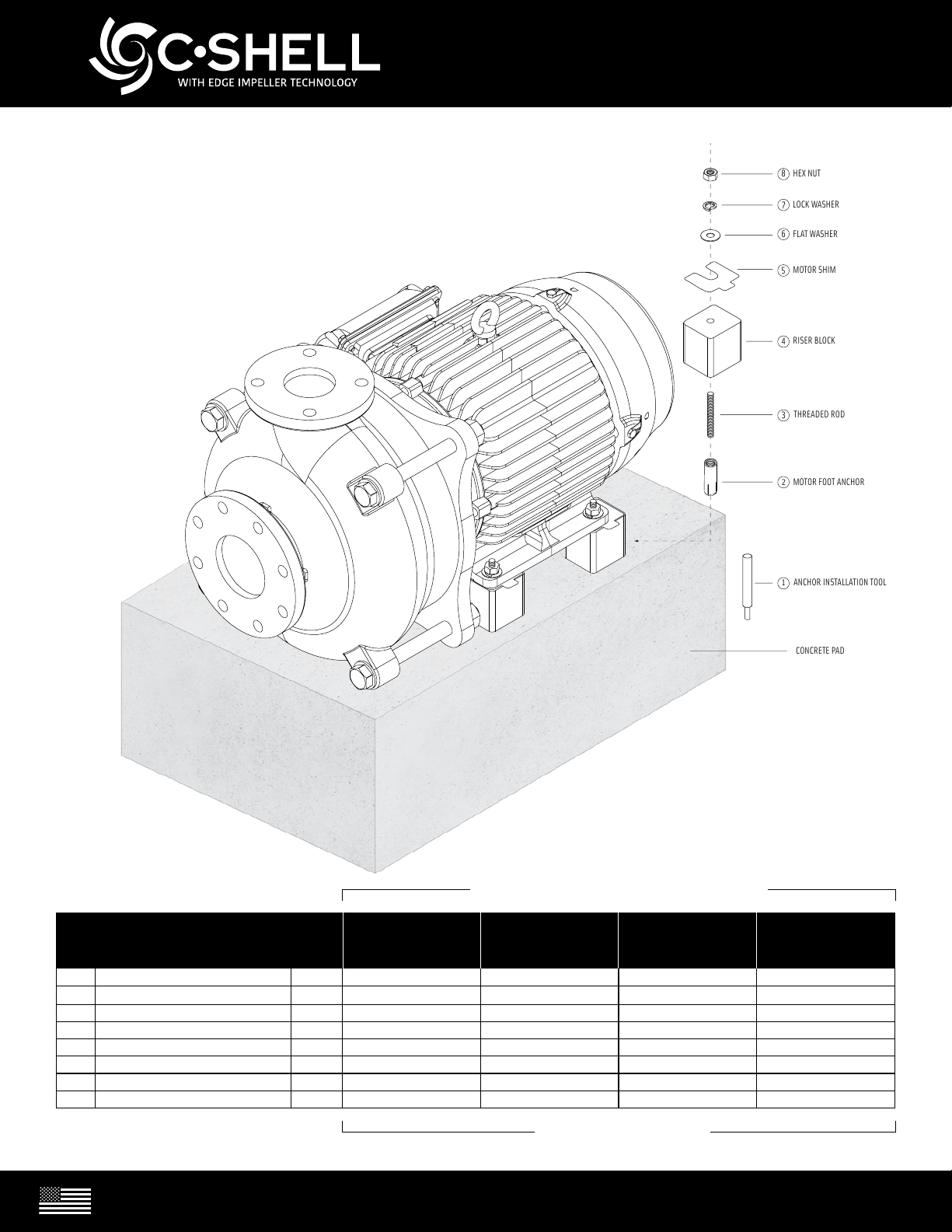

4X3 GENERAL ASSEMBLY

®

WARNING: EYE PROTECTION IS STRONGLY RECOMMENDED

We congratulate you on your choice of the C•Shell®Centrifugal Pump. It has been carefully designed using the advantages of today’s

technology and carefully constructed to give you the dependability of yesterday. To insure proper performance and longevity, we urge you

to carefully follow the instructions in this manual. If you have any questions, contact MDM for assistance.

PRIOR TO INSTALLATION

1. Once received from factory, store all crated pumps in a dry and covered location

2. Make certain all uncoated machined surfaces are coated with a dielectric or marine grease every seven day to prevent oxidation

3. Rotate motor shaft multiple times once a week

INSTALLATION

1. Locate the pump as near the fluid source as possible. A flooded suction situation is preferred.

2. Mount motor base to a secure, immobile foundation.

3. The pipe fittings should be self-supported and in neutral alignment with each port. (i.e. Fittings must not be forced into alignment which

may cause premature line failure or damage to the pump volute.)

4. Never restrict the intake. Keep both input and discharge lines as free of elbows and valves as possible. Always use pipe of adequate

diameter. This will reduce friction losses and maximize output.

5. The C•Shell®Pump is not self-priming. It must not be run dry. We recommend a flooded suction installation.

6. For additional plumbing tips, review MDM’s website: www.mdminc.com for pump installation recommendations.

ELECTRICAL HOOK-UP

WARNING: ALWAYS SHUT OFF ELECTRICAL POWER BEFORE INSTALLATION AND / OR SERVICING THIS PUMP!

All electrical wiring should meet state and local ordinances. Improper wiring may not only be a safety hazard but may permanently

damage the motor and/or pump! 50 HZ motors available - contact your supplier for information.

1. Check that supply voltages match the motor’s requirements.

2. Check motor wiring and connect, according to instructions on motor, to match supply voltage.

3. Verify motor rotation with rotation meter. Incorrect rotation can cause serious damage to pump and/or motor. MDM does not recommend

checking rotation by quickly switching power on and off because serious damage can occur.

4. Supply power wiring (load side) should be protected by conduit or by cable and be of proper gauge. Length should be no longer than necessary.

5. Power should be drawn directly from an enclosure with circuit breaker protection or with a fused disconnect switch.

PUMP END ASSEMBLY/DISASSEMBLY

Contact a factory authorized agent, service center, or factory directly before disassembly or assembly. MDM Incorporated factory hours are

7:30am - 4pm MST, Monday through Friday. You can reach us toll free at (800) 447-8342 or e-mail us at sales@mdminc.com.