JEANTIL PR 2000 R GT User manual

1

INSTRUCTION MANUAL

07/2006

PLEASE READ CAREFULLY AND UNDERSTAND BEFORE USING THE

EQUIPMENT

Mounted straw blower

PR 2000 R

PR 2000 R GT

3-Point linkage

Semi-trailer straw blower

PR 2000 R

PR 2000 R GT

Rigid axle

JEANTIL

Rue de la Tertrais

ZI La Hautière BP1

35590 L’HERMITAGE France

Tel: 00 33 (0)2.99.64.04.04

Fax: 00 33 (0)2.99.64.19.56

Spares shop Tel: 00 33 (0)2.99.64.04.02

2

E-mail: [email protected] –internet Site: www.jeantil.com

1. Aim of the Instruction Manual

a) General

This manual concerns all users of the equipment and anyone tasked with

assembling, installing, operating, adjusting, servicing, repairing or transporting

the equipment and its accessories.

It contains practical information for the correct and safe operation, handling,

adjusting and maintenance of your equipment.

Read carefully and ensure you understand the content before using the

equipment. Comply with the instructions and the safety-related advice.

b) Warning symbols

This warning symbol identifies important advice that must be followed for

your safety. When you see this symbol, take care as there is a potential risk of injury;

read the advice that follows carefully and inform other users.

c) Retention

Always keep this manual within easy reach or at your place of work (or

operating site).

Pass it on to any other user, including if you lend or sell the equipment.

d) Contact details (S.A.V.)

JEANTIL

Rue de la Tertrais

ZI de La Hautière

35590 L’HERMITAGE – France

Tel: 00.33. (0)2.99.64.04.04

Fax: 00.33. (0)2.99.64.19.56

Spares shop Tel: 00.33. (0)2.99.64.04.02

3

e) Statement of compliance with the European ‘Equipment’ directive

(Directive N°98/37/EC)

and to any relevant transposition regulations

Te manufacturer: JEANTIL

Rue de la Tertrais

ZI de La Hautière

35590 L’HERMITAGE – France

DECLARES THAT THE EQUIPMENT manufactured by JEANTIL as designated

below:

PR 2000 R

PR 2000 R GT

SERIAL N°: ……………

COMPLIES WITH:

1. Labour regulations

2. The revised European equipment directive N°98/37/EC

3. Revised EMC directive (electromagnetic compatibility) N° 89/336 EC

4. Specific safety standards: NF /EN 703 (mixers, straw blowers, silage feeders)

5. General safety standards: NF/EN/ISO 12100-1

NF/EN/ISO 12100-2

NF/EN 294

NF/EN 349

NF U 02-001-ISO 4254/1

NF EN 1553

NF EN 811

SIGNED AT HERMITAGE (DATE)

NAME OF SIGNATORY: Philippe JEANTIL

SIGNATURES:

4

2. Contents

1. Aim of the Instruction Manual

p.2

a. General p.2

b. Warning symbols p.2

c. Retention p.2

d. Contact details (S.A.V.) p.2

e. Statement of compliance with the “Equipment” directive p.3

2.

Contents

p.4

3. Equipment identification

p.6

4. Standard operating conditions

p.7

a. Applications of the equipment p.7

b. Operator qualification p.7

c. Definition of work stations p.7

d. Environmental conditions p.7

e. Manufacturer’s and user’s responsibilities p.8

5. Technical characteristics

p.8

6. General safety rules

p.11

1) General p.11

2) Warnings / labels p.12

3) Coupling p.16

4) PTO / Drive shaft p.16

5) Clogging (or blockage of the equipment) p.17

6) Maintenance and repair p.17

6. a / General p.17

6. b / Welding operations p.18

6. c / Servicing the tyres p.18

6. d / Electrical servicing p.18

6. e / Hydraulic servicing p.19

6. f / Repair

p.19

7. Environmental protection

p.19

8. Fitting and installation

p.20

1- Attachment p.20

2- Drive shaft p.20

3- Hydraulics p.20

4- Electrical p.21

9. Adjustments and maintenance

p.22

1- 3-point attachment p.22

2- Attaching the electric control unit p.22

3- Universal chute p.23

5

4- Shredder p.24

5- Chain tension p.24

6- Shredder safety bolts p.25

7- Tyre pressures p.26

8- Lubrication p.26

9- Feed conveyor reducer gear p.26

10- Gearbox p.26

11-Hydraulic hoses p.27

10. Start up and operation

p.27

1- Loading p.27

2- Mulching p.29

3- Spreading using round wrapped bales of silage and hay p.31

11. Additional equipment information

p.32

1- Hydraulic flow divider for tractor flow rates exceeding 45 l / min. p.32

2- 1 m door extension p.32

3- Semi-trailer kit (axle-wheels + drawbar) p.32

12. Cleaning

p.33

13. List of technical documents

p.34

I. Supplier spare parts

p.34

II. JEANTIL spare parts

p.34

6

3. Equipment identification

Type

N° de

série

Année de

construction

P.T.A.C.

Réceptionné

Masses

maximales

admissibles

Anneau

Essieu 1

Essieu 2

kg

kg

kg

kg

20 kg

Essieu 3

35590 L'HERMITAGE - FRANCE

Ref: 892 770

Manufacturer’s plate to EC standards.

Never remove the manufacturer’s plate and the EC marking fixed

to the equipment.

NON

7

4. Standard operating conditions

a) Applications of the equipment:

1.

This equipment is intended exclusively for use in agricultural work off the public

highway, i.e.: loading, shredding, distributing products such as straw, silage, hay,

wrapped silage in the form of round or square bales, wrapped blocks of 0.30m short

straw silage.

2.

Any other use falls outside normal usage and is therefore forbidden.

3.

For all other uses, please contact the manufacturer.

b) Operator qualification:

1.

The equipment must only be used, maintained and repaired by trained operators; see

page 2 “Aim of the Instruction Manual”.

2.

Before using your equipment, familiarise yourself with all controls and their correct

operation.

3.

All users, prior to using the straw blower, must have carefully read this Manual, have

understood it and applied all the safety instructions. Once working, it will be too late to

do this.

c) Definition of work stations:

1.

The work station for the equipment is the tractor driver’s cab.

2.

Never leave the driver’s station when the engine of the tractor and the equipment are

operating.

3.

To access the work station, use the access devices provided by the manufacturer (ladder,

footholds).

d) Environmental conditions

1.

Never approach or remain in those areas that are dangerous when the equipment is in

operation.

2.

Adapt your speed and driving style to the terrain, roads and tracks; be alert and take

care!

3.

Do not operate vehicles on ground that slopes longitudinally or laterally where there is a

risk of tipping or overturning.

4.

Do not start or brake abruptly.

5.

Operate your equipment with sufficient light to ensure safety; use appropriate artificial

light if necessary (contact your dealer or mechanic).

8

e) Manufacturer’s and user’s responsibilities

1.

Follow all advice contained in this manual concerning levels of knowledge, installation

procedures, operation, adjustment, maintenance and repair.

2.

Only use spare parts and accessories that comply with the manufacturer’s

recommendations.

3.

Do not carry out any modifications yourself and do not allow others to modify your

equipment and its accessories (mechanical, electrical, hydraulic or pneumatic

characteristics) without requesting prior written approval from the manufacturer.

4.

Failure to comply with these requirements may make the machinery dangerous. The

manufacturer disclaims any responsibility if damage or injury arises from such action.

5. Technical characteristics

1 Dimensions of variants: Mounted

-FP MAX = maximum push force (daN)

-FT MAX = maximum tractive force (daN)

C.D.G

En charge maxi

3

rd

upper point

25 mm dia. shaft

MAX WEIGHT = Kg

daN

F.P. MAX

F.T.

MAX

daN

2 lower points 28 mm dia.

shaft

3-point linkage, Category 2

NFU 14-032 / ISO 730

C of G

at maximum load

9

Semi-trailer

2. Schéma de préhension et d’arrimage

FA MAX = Max force on drawbar eye (daN)

TYPE PR 2000 R

PR 2000 R GT

Capacity 2m

3

2m

3

Maximum mulching range 18m 18m

B: Overall length 2.70m 2.70m

A: Internal length of container, door closed 1.70m 1.70m

C: Internal length of container, door open 3.00m 3.00m

D: Internal width of container 1.35m 1.35m

E: Overall width 1.79m 1.79m

F: Width with chute folded 1.91m 1.91m

G: Width with chute deployed 2.04m 2.04m

H: Container internal height 1.10m 1.10m

I: Overall height, chute deployed 2.42m 2.42m

J: Overall height, chute folded 2.21m 2.21m

K: Minimum spreading height 1.22m 1.22m

L: Maximum spreading height 2.42m 2.42m

M: Length with draw bar 3.82m

3.82m

N: Width with wheels 2.00m

2,00m

Empty weight

Kg

Kg

MAXIMUM GROSS WEIGHT

Kg

Kg

F.A. MAX

daN

C of G

at maximum load

F.E. MAX

daN

Drawbar eye dia 50 mm ISO 5692 / DIN 9678

On axle hook or tractor strong point

Or,

TOWING YOKE on tractor coupling bar (check that the coupling bar will support FA

MAX)

MAX WEIGHT

Kg

10

2 Lifting and tie down diagram:

Mounted

Semi-trailer

ISO 3767-1 standard lifting point, symbol 7.29.

ISO 3767-1 standard attachment point, symbol 7.34.

C of G

C of G

11

6. General safety rules

1) General

1. Never forget that knowledge, awareness and caution are the best way to ensure your

safety.

2. Regulations and rules relating to accident prevention, health and safety at work, and the

operation of vehicles on the public highway must be observed at all times.

3. Chapter 4 (Standard operating conditions) of this Instruction Manual, contains basic

directives that must be followed for the sake of your safety.

4. Make sure that no person, animal or obstruction is located near the equipment before it

is set in motion and throughout its operation or any other manoeuvre.

5. Children must never be allowed near the equipment.

6. Never carry passengers on the equipment.

7. Do not step on the cowlings or on any other part of the equipment, apart from any areas

provided for this purpose (ladder, platform, and means of access to the work station).

8. Before carrying out any work on the equipment, ensure that it cannot be started up

accidentally.

9. All controls (cords, cables, push-rods, hoses, etc.) must be positioned in the locations

provided for them so that they cannot accidentally initiate a manoeuvre likely to cause

an accident or damage.

10. Before use, after any adjustment or maintenance, ensure that all protective devices are in

position and in good condition, and that their latches are engaged.

11. Before use, check tightness of screws, nuts, connectors and wheels. Retighten if

required.

12. Do not wear loose clothing, long untidy hair and jewellery that might get caught in the

moving parts of the equipment.

13. Keep your hands, arms and feet well away from any moving parts, even those that are

slow-moving. Keep well away from moving parts.

14. If you detect any unusual noise or vibration, shut down the equipment and identify and

eliminate the cause of the incident before resuming work. Contact your dealer if

required.

12

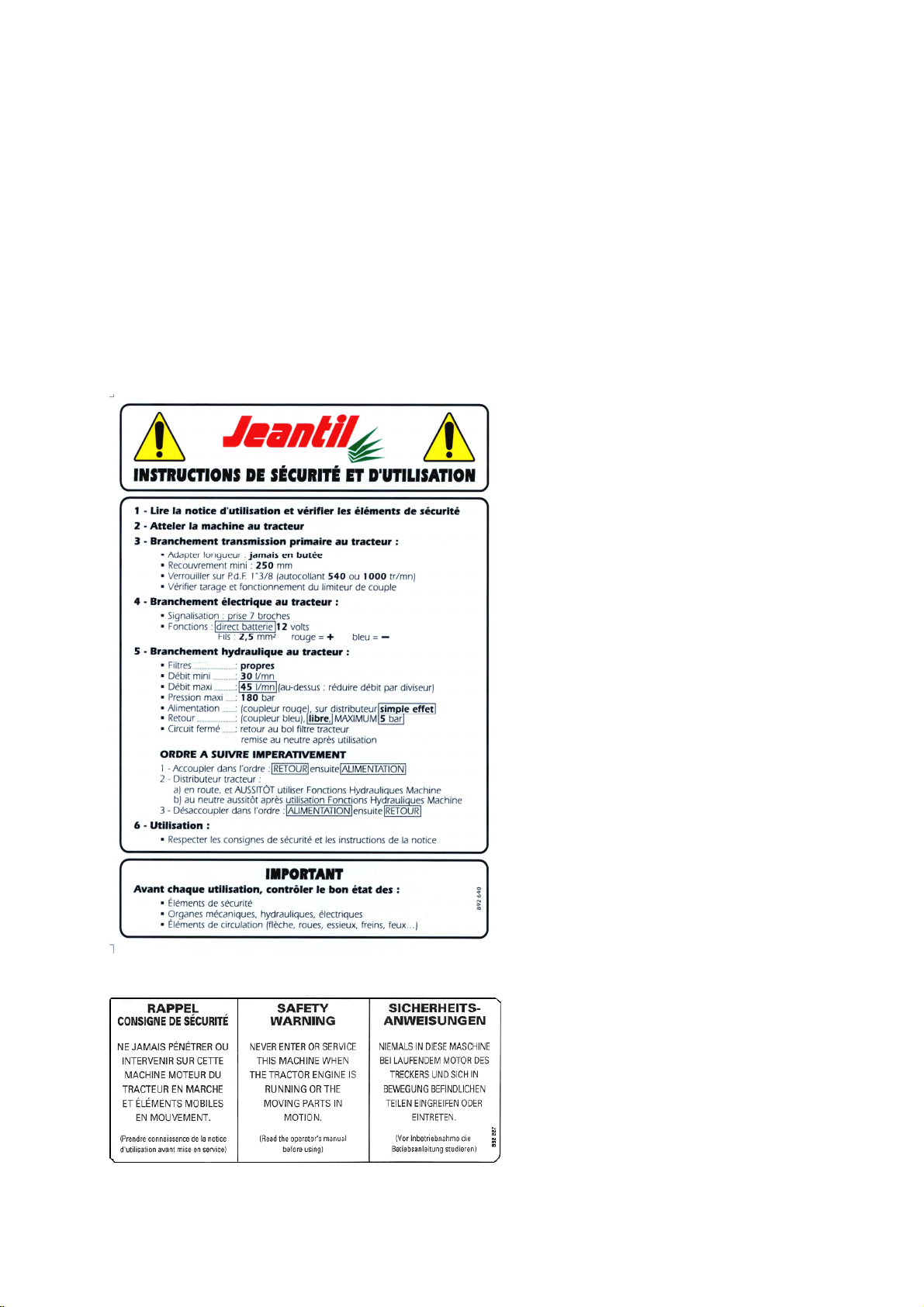

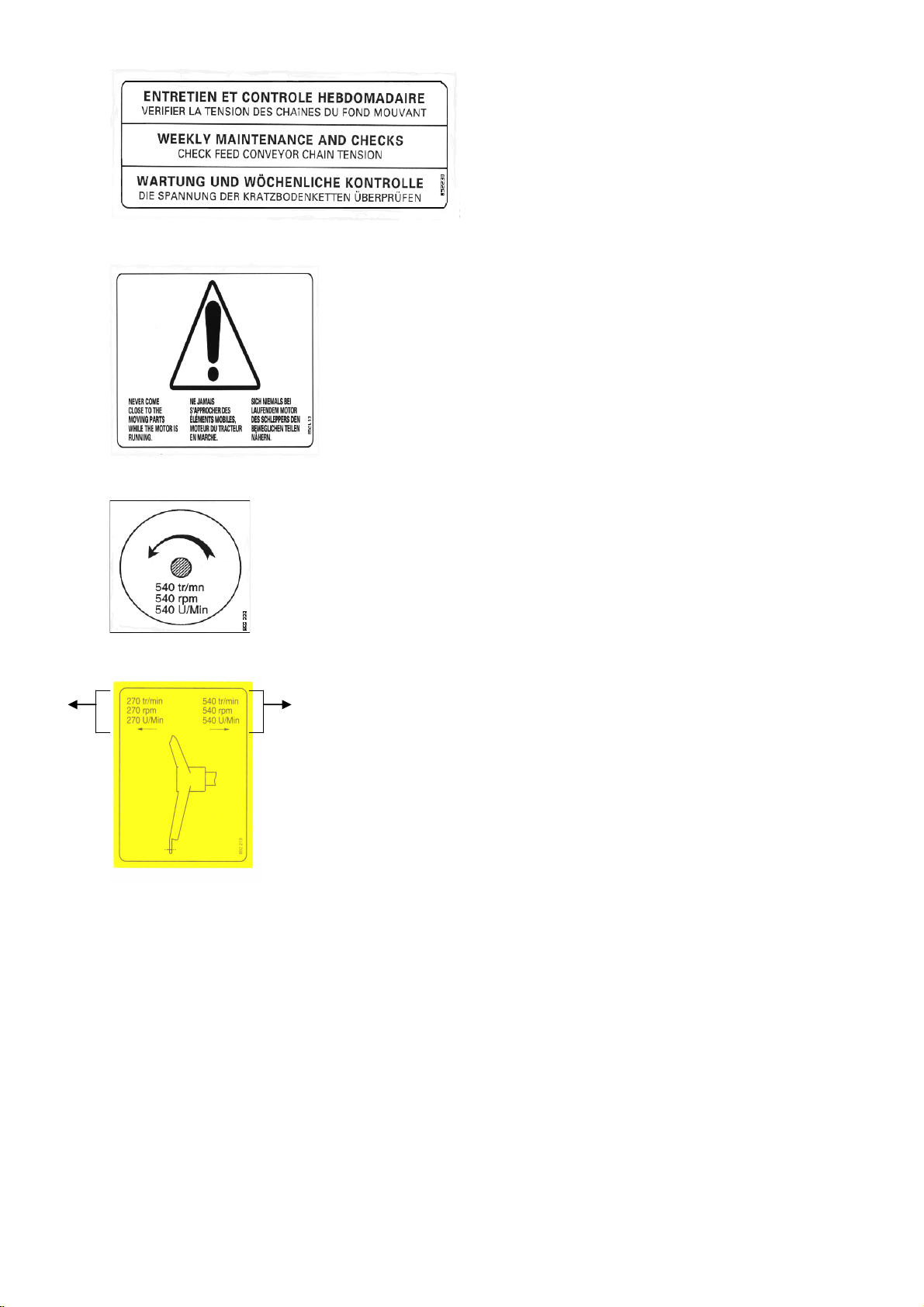

2) Warnings/Labels

1. Warnings and labels fixed to the equipment provide information about safety measures

to be taken that will contribute to the avoidance of accidents.

2. Make sure that these warnings and labels remain clean and legible. If they are damaged,

ask for new labels from the manufacturer (or agent).

3. If repairs are carried out, check that the replacement parts carry the same labels as those

that have been removed.

Ref: 892 640

Ref: 892 227

Ref: 892 230

Placed forward to R and L of the body

SAFETY AND OPERATING LABEL

CLEARLY mounted IN FULL VIEW on the

front of all items of equipment, close to those

components used to connect the unit to the

tractor.

13

Ref: 892 453

Ref: 892 229

Ref: 892 219

Placed on the metal

casing of the drive shaft

Placed to the rear R and L

on the sides of the body,

and on the forward face of

the equipment

Placed low down R and L on the sides of the body

Placed on the metal casing of

the drive shaft

Spreading

and mixing Mulching

14

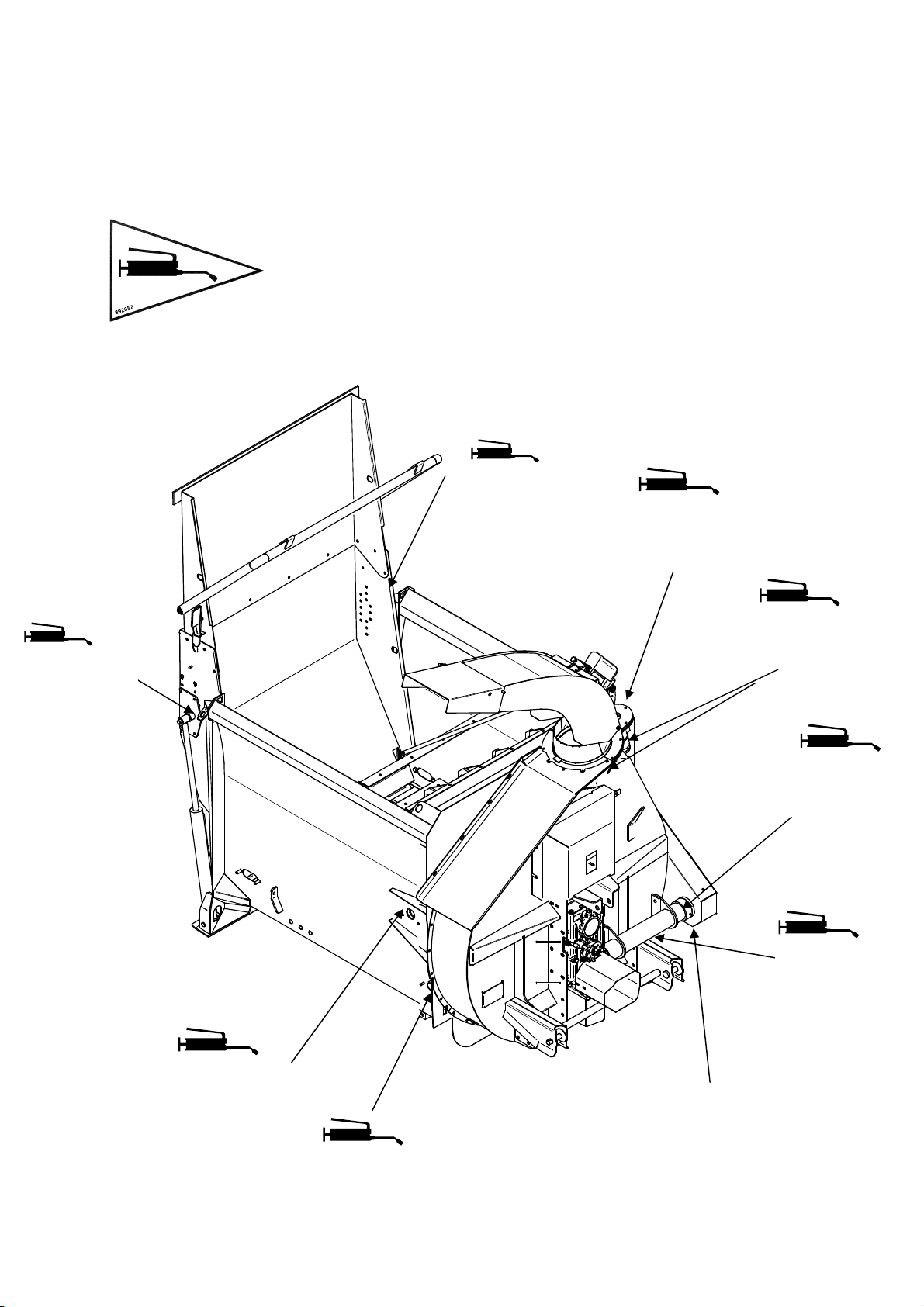

Lubrication chart

Ref: 892 652

Placed close the components to be greased

See diagram

Rotating

chute

greaser

Actuator

upper spindle

greaser

Shredder

bearing greaser

Feed conveyor

shaft bearing

greaser

Actuator

upper spindle

greaser

Gearbox

output shaft

greaser

Shredder

bearing

greaser

Feed conveyor

shaft bearing

greaser

The shredder drive chain is splash lubricated

from an oil bath inside its protective casing.

Unscrew the lower cover to check the oil level.

15

Operating stickers (depending on equipment and options) placed on the electrical control unit, located on

the forward face of the unit:

Standard Electrical regulator Electrical distributor

Standard Electrical regulator Electrical distributor

16

3) Coupling

1. See chapter 5, Technical characteristics, page 8.

2. Attaching the unit to the tractor must only be carried out using the tractor’s rear

coupling points provided for this purpose.

3. Check compatibility of the unit with the tractor (minimum engine power, type of

coupling, tractor PTO characteristics, etc.). Keep clear of the area between the tractor

and the unit until you have stopped the tractor’s engine and removed the starter key.

4. Keep clear of the area between the tractor and the unit during any operation of the

tractor linkage, whether this is being controlled from the cab or from outside the tractor.

5. When manoeuvring, select the lowest possible tractor gear ratio. When coupling, attach

the equipment’s electrical control unit in the tractor cab, ensuring that it cannot move

during the operation.

6. Once the equipment has been coupled up, the hitch must be locked. Check correct

locking and the condition of the coupling before any movement.

7. Check that the equipment’s coupling does not create either an overload or poor weight

distribution on the tractor that might compromise stability:

-Do not exceed the maximum allowed loading for the tractor and equipment

attachment points.

-Where necessary, fit ballast weights to the mounts provided for this purpose in

accordance with the tractor manufacturer’s recommendations.

Couple the unit to a tractor whose linkage is equipped with lateral and vertical locking

devices.

4) Power Take Off (PTO) / Drive shaft

1. Read and learn the manufacturer’s instructions for the drive shaft, attached to the

transmission.

2. Check that the PTO guards are fitted and in good condition. Replace them immediately

if damaged.

3. Adjust the length between the tractor and the unit, retaining maximum engagement.

4. Minimum engagement length is 250mm. See white instruction stickers fitted on the

front of the unit, n° 892 640 (page 10).

Before each operation, check that the drive shaft is in good condition and that it is fitted

and locked correctly.

5. Only use the drive shaft provided with the equipment or recommended by the

manufacturer.

6. Check before each use that the speed and rotational sense of the tractor PTO are

compatible with the planned usage of the equipment.

17

5) Clogging (or blockage of the equipment)

If the chute or turbine become blocked:

1. Declutch the tractor PTO.

2. Raise the chute to maximum.

3. Operate the feed conveyor in reverse to clear the inlet to the shredder and turbine.

4. Open the rear door.

5. Lower the straw blower fully to the ground.

6. Stop the tractor engine and remove the starter key.

7. Select the turbine gearbox to neutral.

8. Clear the chute by hand.

9. Check if the turbine blades are clogged; if necessary clear then by hand.

10. After cleaning, re-engage the turbine gearbox:

Low gear 270 rpm for spreading

High gear 540 rpm pour mulching

11. Enter the tractor cab.

12. Start the tractor.

13. Close the rear door.

14. Engage the tractor PTO while rotating the turbine at low rpm and accelerate up to a PTO

speed of 540 rpm.

15. Continue the operation that was interrupted, mulching or spreading.

16. If the blockage has not been cleared, repeat the operation from paragraph 1.

6) Maintenance and repair

6. a / General:

1. Maintenance and repair operations must only be carried out by qualified personnel.

2. Always maintain the equipment and its accessories in perfect working order to ensure

safe and efficient operation.

3. Check the cleanliness of the oil.

4. Respect maintenance periods.

18

Before any servicing or repair:

5. Check the stability of the unit and its components.

6. Lower the unit to the ground.

7. Fit any stability devices provided (stand etc).

8. Check that all moving parts are stopped.

9. Declutch the tractor PTO.

10. Disconnect the hydraulic hoses between the tractor and the unit.

11. Stop the engine and remove the starter key; disconnect the battery (or the electrical

supply).

12. Apply the hand brake.

13. Select the equipment gear ratio selector to neutral.

14. Allow any component likely to be at a high temperature to cool.

6. b / Welding operations:

1. When carrying out any welding operation on the equipment, disconnect the electrical

supply and the tractor battery.

2. Disconnect and protect any hoses (particularly rubber) and any electrical cables to

ensure that they are not damaged by incandescent particles that could cause fluid loss

or a short circuit.

6. c / Work on tyres:

1. Only carry out work on tyres if you have the necessary special tools and experience.

2. Incorrect fitting could seriously compromise your safety.

3. If in doubt, call in qualified personnel.

4. Do not fit tyres of different characteristics from those recommended by the

manufacturer.

5. Ensure that the tyres are inflated to the pressures recommended by the tyre

manufacturer (see sticker page 16).

6. d / Electrical servicing:

Before carrying out any work on the electrical system, disconnect the electrical supply.

19

6. e / Hydraulic servicing:

1. Select all hydraulic spool valves to neutral (rest).

2. Stop the engine and remove the starter key.

3. Before working on the hydraulic system, check that the installation is not pressurised.

4. Eliminate pressure before disconnecting hydraulic lines.

5. Before restoring pressure in hydraulic lines, check that all connectors are fully

tightened and that the hydraulic hoses are in good condition and correctly protected.

6. f / Repairs:

1. Any failure that might compromise safety must be eliminated.

2. Carry out immediate repairs to any leak or failure affecting the hydraulic or electrical

systems. These must be done by qualified personnel.

3. Do not attempt to find a hydraulic fluid leak (when pressurised) using the fingers.

4. Damaged or defective protective devices or casings must be replaced immediately.

5. The operation of any original protective device fixed to the equipment must not be

modified.

6. Hydraulic hoses that originate from another hydraulic system must not be re-used.

7. Rigid hydraulic lines must not be welded. When a rigid or flexible line is damaged, it

must be replaced immediately.

8. Repairs affecting components under pressure or electrically powered require special

tools and procedures. They must be carried out by qualified personnel.

7. Environmental protection

Ground pollution:

1. Take care not to spill or discard in any drainage system any used lubricating oil or

other substances such as hydraulic fluid.

2. Collect used fluids in sealed, clean containers designed for the purpose. Avoid using

containers used for foodstuffs or drinks bottles.

3. Used tyres. It is against the law to store tyres or to dump them, dispose of them in the

natural environment or burn them in the open air. Take them to a dealer or an

approved collector.

20

8. Fitting and Installation

Linkage with the tractor

1 - COUPLING

1. See page 8 technical characteristics / and page 20 coupling.

2. Read the warning notice on page 12: Ref: 892 640.

3. Couple the ring on the drawbar of the straw blower to the attachment point or axle

hook on the rear of the tractor.

4. Check that it is latched.

2 - DRIVE SHAFT

PRIMARY DRIVE SHAFT

1. See page 14: PTO / Drive shaft

2. Read the warning notice on page 12 Ref: 892 640.

3. Read the manufacturer’s instructions concerning the drive shaft, attached to the

transmission.

4. Check condition of the safety guard. If it shows any sign of damage, it must be

replaced before the equipment is used.

5. The drive shaft links the tractor to the straw blower.

6. Fit the primary straw blower drive shaft to the tractor rear PTO outlet, and adjust its

length, retaining maximum engagement. Minimum engagement length is 250 mm.

7. Ensure than both jaws have engaged correctly.

8. The primary drive shaft must be connected to the 540 rpm rear PTO of the tractor; see

adjacent sticker Ref: 892 229.

3 – HYDRAULICS

1. See page 19: Hydraulic servicing and repairs

2. Read the warning notice on page 12: Ref: 892 640.

3. Straw blowers are designed to operate with a maximum fluid flow rate of 45

l/min at a maximum pressure of 180 bars.

This manual suits for next models

1

Table of contents

Popular Blower manuals by other brands

Craftsman

Craftsman 358.798940 Operator's manual

KRESS

KRESS KG560E Series Safety and operating manual

Echo

Echo PB-200 - 02-09 Operator's manual

ST. SpA

ST. SpA AB 500 Li 48 Operator's manual

Gaggenau

Gaggenau AR 400 741 installation instructions

Howden

Howden Roots Tri-RAM 617 Installation, operation & maintenance manual