Jefferson Professional Tools & Equipment JEFCEMPETRED-L 2.0HP User manual

User Manual

v.1.1

JEFCEMPETRED-L

PETROL CEMENT MIXER

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

2

CONTENTS

Introduction 3

Specications 3

Assembly Procedure 3

Safety Guidelines 4

Operation Guide 5

Maintenance & Storage 5

Environmental Protection 5

Parts List & Diagram - Main Assembly 6

Parts List & Diagram - Cylinder Head 8

Parts List & Diagram - Crankcase 9

Parts List & Diagram - Crankcase Cover 10

Parts List & Diagram - Crankshaft / Piston / Connecting Rod 11

Parts List & Diagram - Gas Distribution Adjustment 12

Parts List & Diagram - Starter Sub-Assembly 12

Parts List & Diagram - Diversion Assembly 13

Parts List & Diagram - Carburetor 13

Parts List & Diagram - Flywheel / Ignition 13

Parts List & Diagram - Control System 14

Parts List & Diagram - Air Filter 15

Parts List & Diagram - Mufer 15

Parts List & Diagram - Fuel Tank 16

EC Declaration of Conformity 17

Limited Warranty Statement 18

ABOUT THIS DOCUMENT

This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for

the future reference.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure its correct and

safe use. We recommend that this manual is read before first use of the equipment or before performing any kind of maintenance. By following

all the general safety instructions contained in this manual you will help to ensure operator safety and extend the potential life-span of the

equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort

has been made to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make

modifications without prior warning.

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 3

• A powerful and reliable petrol driven cement mixer with quality 2.0HP Loncin engine

• Drum tilt action allows for easy pouring & cleaning

• Orange powder coated nish with UV-Protection

• Compact and portable for easy transportation

• Fitted with barrow height swivel

• Complete with tripod stand and rubber wheels

SPECIFICATIONS

Engine: Loncin 2.0HP Stage V OHV Petrol

Starting System: Recoil

Drum Capacity: 130L / 5ft³

Batch Output: 70L / 2.5ft³

Drum Diameter: 61cm

Drum Speed: 24rpm @ 2800rpm

Discharge Outlet Height: 104cm

Wheel Size: 25cm x 6.5cm

Operating Dimensions: 138cm x 110cm x 62cm

Storage Dimensions: 93cm x 66cm x 93cm

Weight: 75kg

Guaranteed Sound Power Level: 101db Lwa

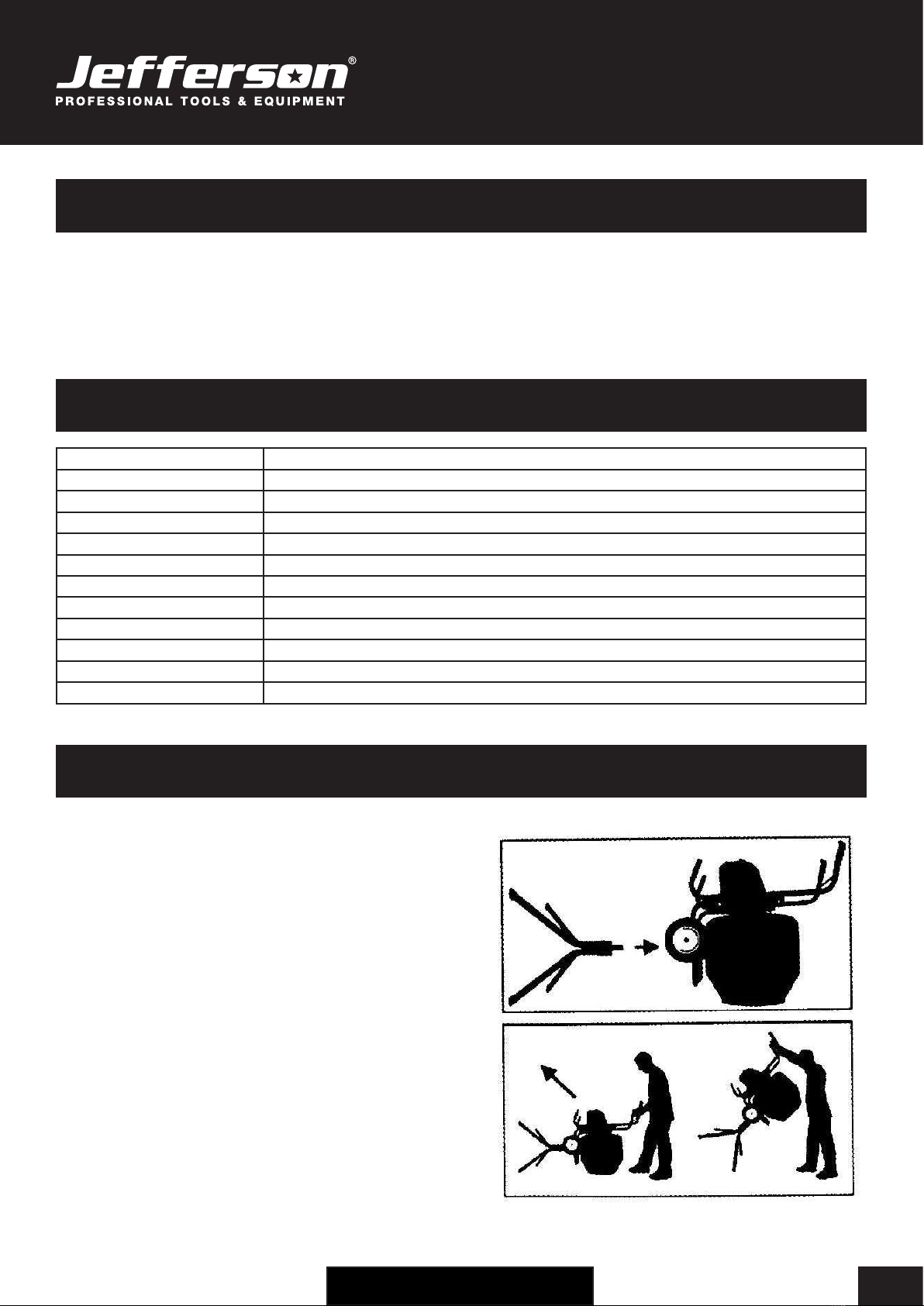

ASSEMBLY PROCEDURE

1. Remove all components from the packaging and check for

damage.

2. Place the frame on a level surface and slide both wheels onto

the main frame axle (secure with the R clips included in the

assembly kit.)

3. Remove the engine from its packing, attach the spacer key

pulley and washers to the crankshaft and fix with the relevant bolt

provided.

4. Remove the right hand section of the upper belt guard, a drive

belt is pre-installed under this cover.

5. Assemble the engine by first insuring that the belt is fitted on

the engine pulley. Fix the engine to the base plate using the 4mm x

6mm x 35mm nuts and bolts and washers provided.

Important: After unpacking, inspect the equipment carefully and

ensure that the product is in perfect condition without any defects

or no damaged or worn parts.

Please dispose of all the packaging materials appropriately, recy-

cling all materials where facilities are available.

INTRODUCTION

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

4

Ensure that you have read and fully understand all of the operating instructions, safety precautions and warnings in this

manual before operating or maintaining this equipment. Most accidents are caused by the failure to observe basic safety

rules or precautions. Never use this equipment or modify it in any way that has not been specically recommended by the

manufacturer. Ensure that you check the equipment thoroughly to ensure it is safe and t for purpose before each use.

It is important that you inspect all plugs, sockets, power cables and electrical ttings for wear and damage and repair or

replace any defective components. Contact your nearest Jefferson dealer for advice on the repair of this equipment and

use only approved replacement parts. Service and maintain the equipment to keep it in good, safe working order.

1. Familiarise yourself with this equipment and its operation before use - read this user manual carefully before use. Save for future reference.

2. This appliance is for outdoor use only. Ensure that all bystanders are kept at a safe distance and that animals and children are kept from the

work area.

3. Never use this equipment if any part or accessory is damaged or malfunctioning.

4. Always shut the equipment off completely when not in use and if left unattended.

5. Ensure that the equipment is completely shutdown and disconnected from the mains before carrying out any servicing or repairs.

6. Only Jefferson approved engineers should carry out repairs and maintenance on this equipment. Only use Jefferson-approved replacement

parts to repair this equipment. Never modify the equipment in anyway. Ensure that the equipment is kept in good working order and cleaned and

serviced regularly. Check the external nuts and fixings regularly to ensure that they have not loosened from vibration during use.

7. Ensure that the electrical cable is fully protected and there is no danger of damage for equipment or materials. Always inspect the cable before

use and replace if any damage is apparent.

8. Do not wear jewellery or loose clothing that could be snagged by the rotating drum.

9. Keep your hands clear of the rotating drum at all times. Never put your hands inside of the drum when the machine is running.

10. Ensure that the safety guards are always used.

11. This equipment is heavy and requires two people to lift and assemble.

12. Ensure that the equipment is operated from a stable even surface.

13. Do not load the drum when the machine is switched off. Always ensure that the drum is rotating before gradually adding the mix. This will help

to preserve the motor and gearbox.

14. Do not allow water to come into contact with the motor or electrical components.

15. Do not operate under the influence of alcohol or drugs.

16. Keep the drum free from debris and mortar build up (clean after every use).

17. Keep all moving parts (wheel axles, swivel brackets etc.) lightly greased.

18. Petrol engines can become hot in use, do not refuel or touch hot engine parts until they have had a chance to cool down.

19. Wear appropriate Personal Protection Equipment as required.

SAFETY GUIDELINES

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 5

OPERATION GUIDE

Mixing Guidelines:

1. Start the mixer and ensure that the drum is rotating.

2. Add water to prevent contents sticking to the drum.

3. Add the cement.

4. Add the aggregate.

5. Mix to the consistency required.

6. Tilt the drum using the handles to pour when ready.

MAINTENANCE & STORAGE

Before Each Use:

Inspect the power cable to ensure that it is completely free from damage and that all ttings are tight and secure.

Periodically:

Inject a few drops of light oil onto the moving parts (wheel axles, swivel brackets etc.)

After each use:

Hose down the drum and stand with clean water. Take care to prevent any water entering the motor housing and electrical components by

protecting them with waterproof covering during the cleaning process.

Engine:

Check oil regularly and ll as required. Keep parts clean and service regularly.

Storage

Store in a safe dry environment away from children and animals.

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and requires disposal, drain off any

uids (if applicable) into approved containers and dispose of the product and the uids according to local regulations.

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

6

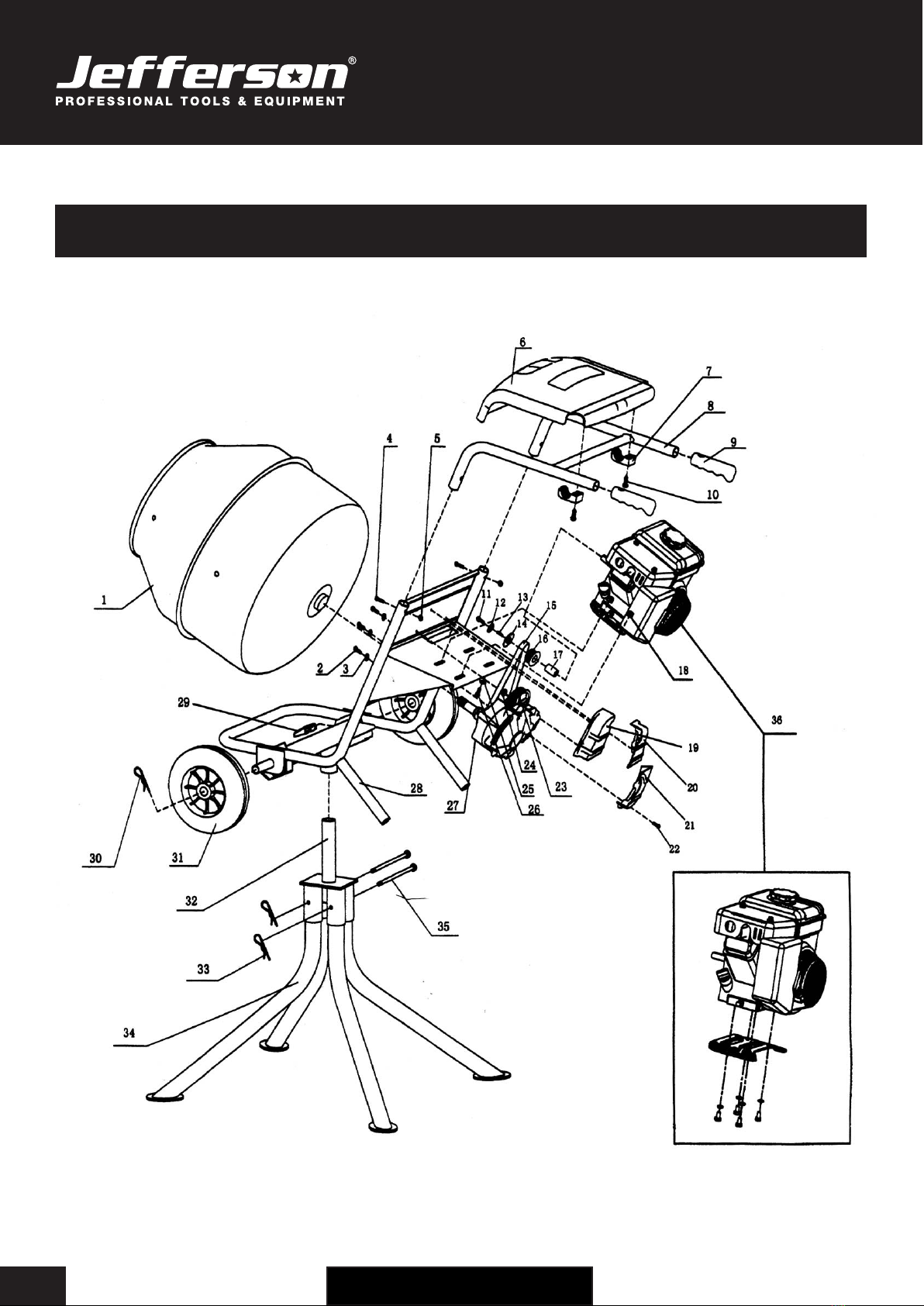

PARTS LIST & DIAGRAM - MAIN ASSEMBLY

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 7

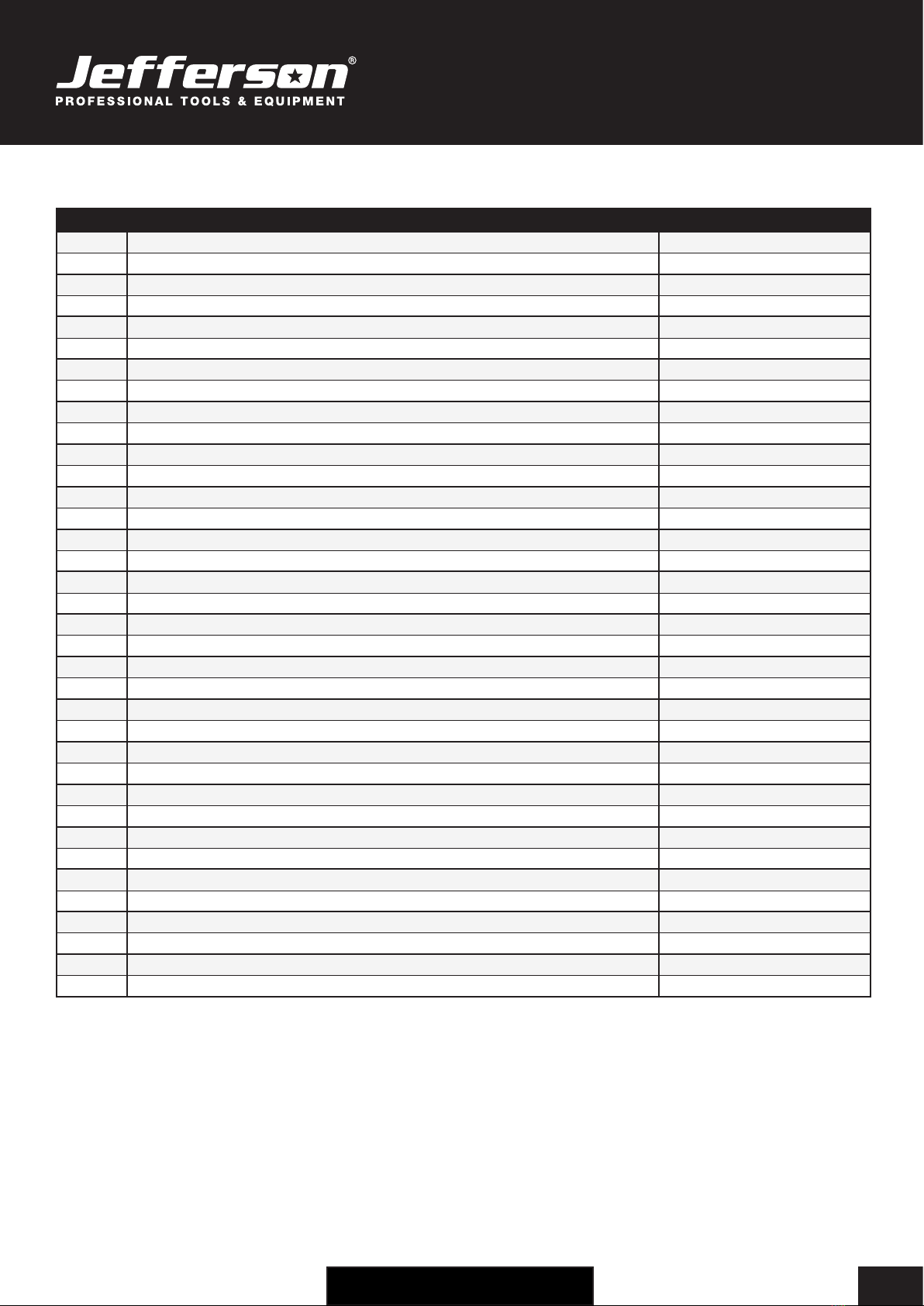

# Description Quantity

1Drum 1

2Bolt (M10 X 25) 4

3Washer (10) 4

4Bolt (M8x40) 2

5Nut (M8) 2

6Engine Cover 1

7Block 2

8Handle 1

9Cover 2

10 Screw 1

11 Bolt (M6 X 25) 1

12 Washer 1

13 Key (5x18) 1

14 Set Washer 1

15 Flat Toothed Belt 1

16 Driver 1

17 Pipe Box 1

18 Nut M8 4

19 Strap Cover-L 1

20 Strap Cover-R 1

21 Strap Cover-U 1

22 Screw (M5x10) 6

23 Pulley 1

24 Spring Washer 13 1

25 Washer (8) 4

26 Bolt (M8 X 15) 8

27 Gear Box 1

28 Brackets 1

29 Stop Bolt 1

30 Pin 2

31 Wheel 2

32 Shaft Housing 1

33 Pin 2

34 Stand 4

35 Pin 2

36 Engine Assy. 1

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

8

PARTS LIST & DIAGRAM - CYLINDER HEAD

# Description Quantity

1Hexagon Bolt With Flange 4

2Cable Cleat 1

3Cylinder Head Cover Assy 1

4Gasket For Cylinder Head Cover 1

5Hexagon Bolt With Flange 4

6Spark Plug 1

7Outlet Gasket 1

8Stud 2

9Cylinder Head 1

10 Gasket For Cylinder Head 1

11 Location Pin 2

12 Stud 2

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 9

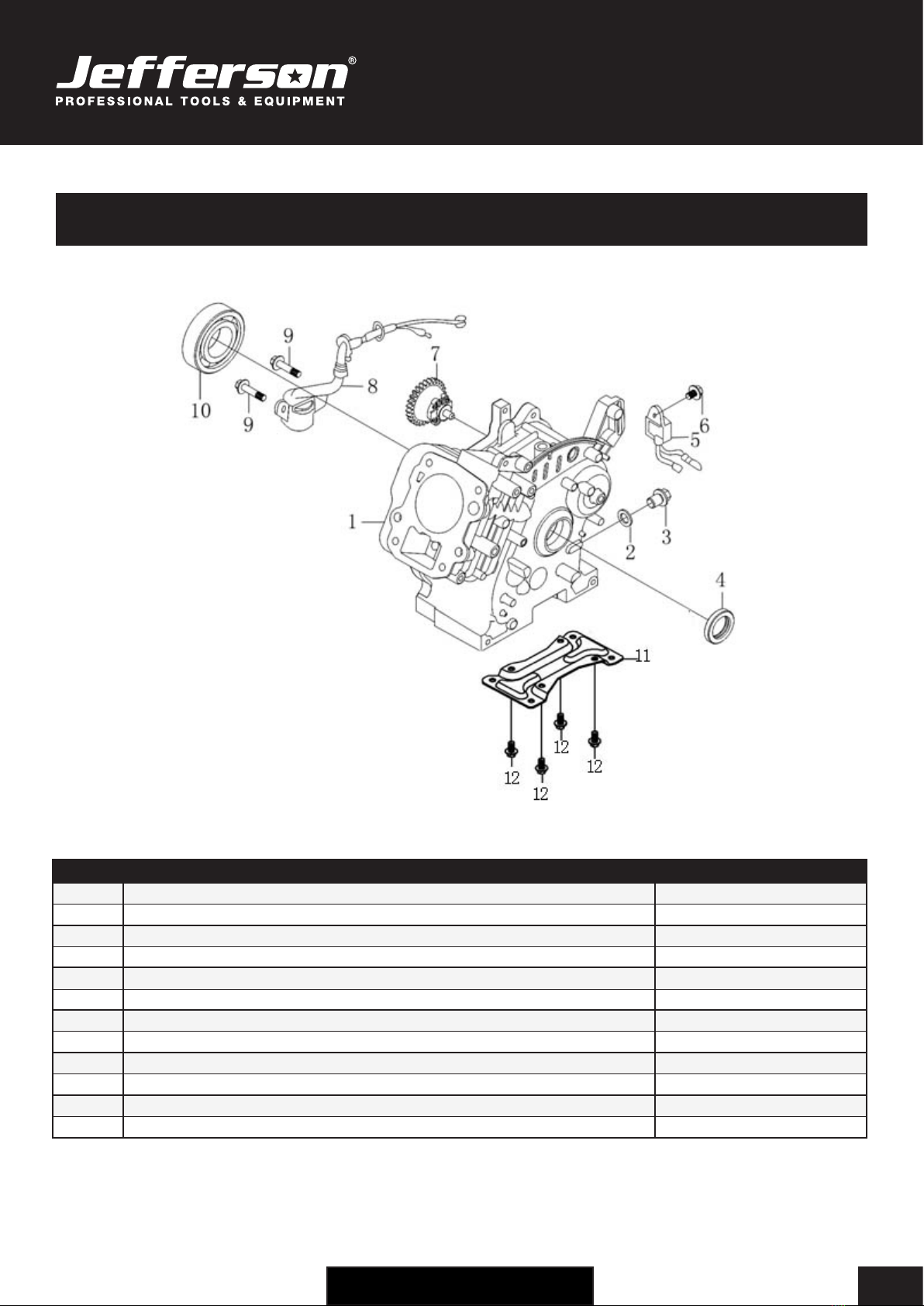

PARTS LIST & DIAGRAM - CRANKCASE

# Description Quantity

1Crankcase Body 1

2Flat Washer 1

3Sealing Plug Screw 1

4Oil Seal 1

5Engine Oil Protector 1

6Hexagon Bolt With Flange 1

7Components Of Governor Gear 1

8Oil Level Sensor 1

9Hexagon Bolt With Flange 2

10 Bearing 1

11 Engine Base 1

12 Hexagon Bolt With Flange 4

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

10

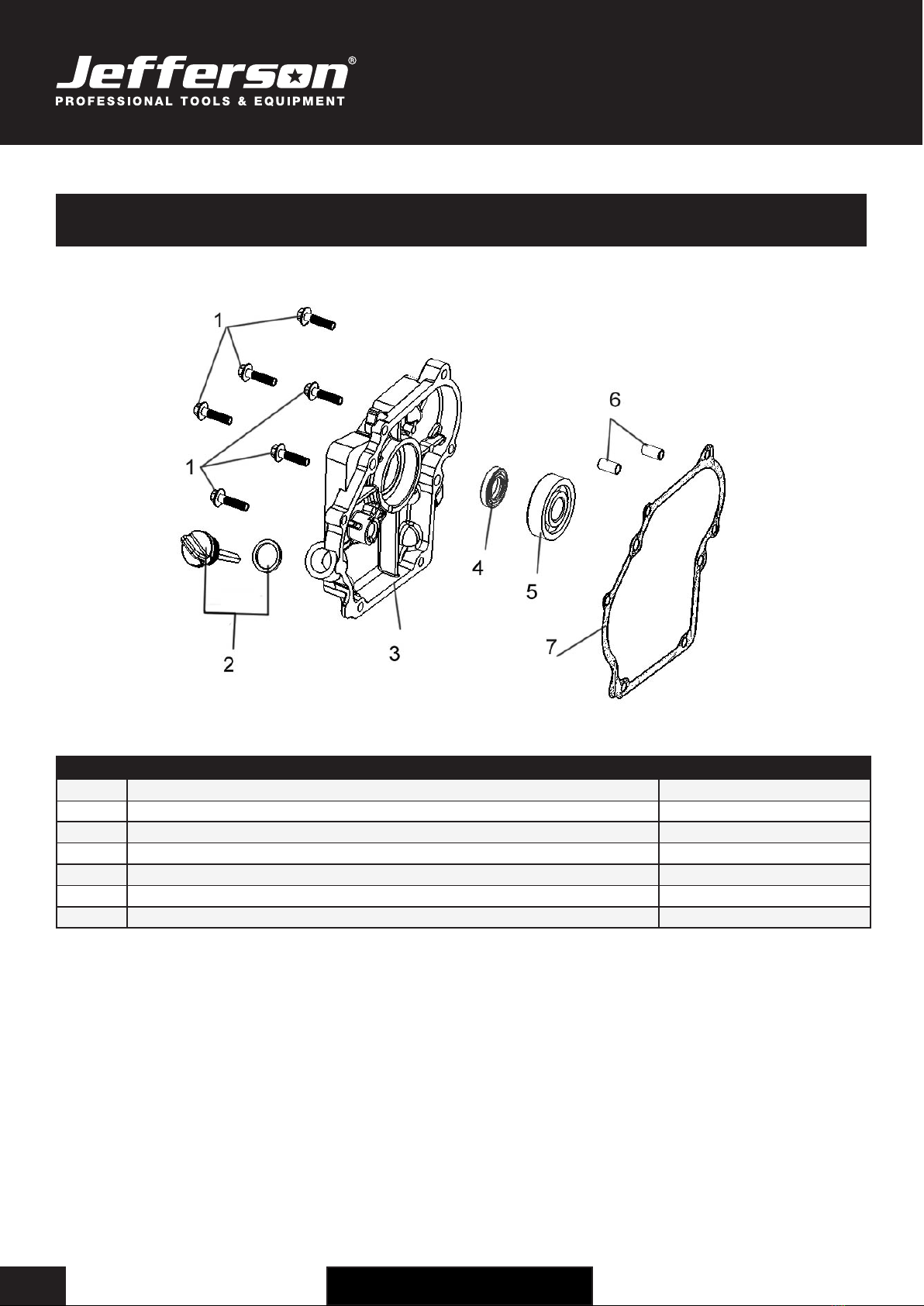

PARTS LIST & DIAGRAM - CRANKCASE COVER

# Description Quantity

1Hexagon Bolt With Flange 6

2Oil Rule Combination 1

3Crankcase Cover 1

4Oil Seal 1

5Bearing 1

6Location Pin 2

7Crankcase Cover Gasket 1

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 11

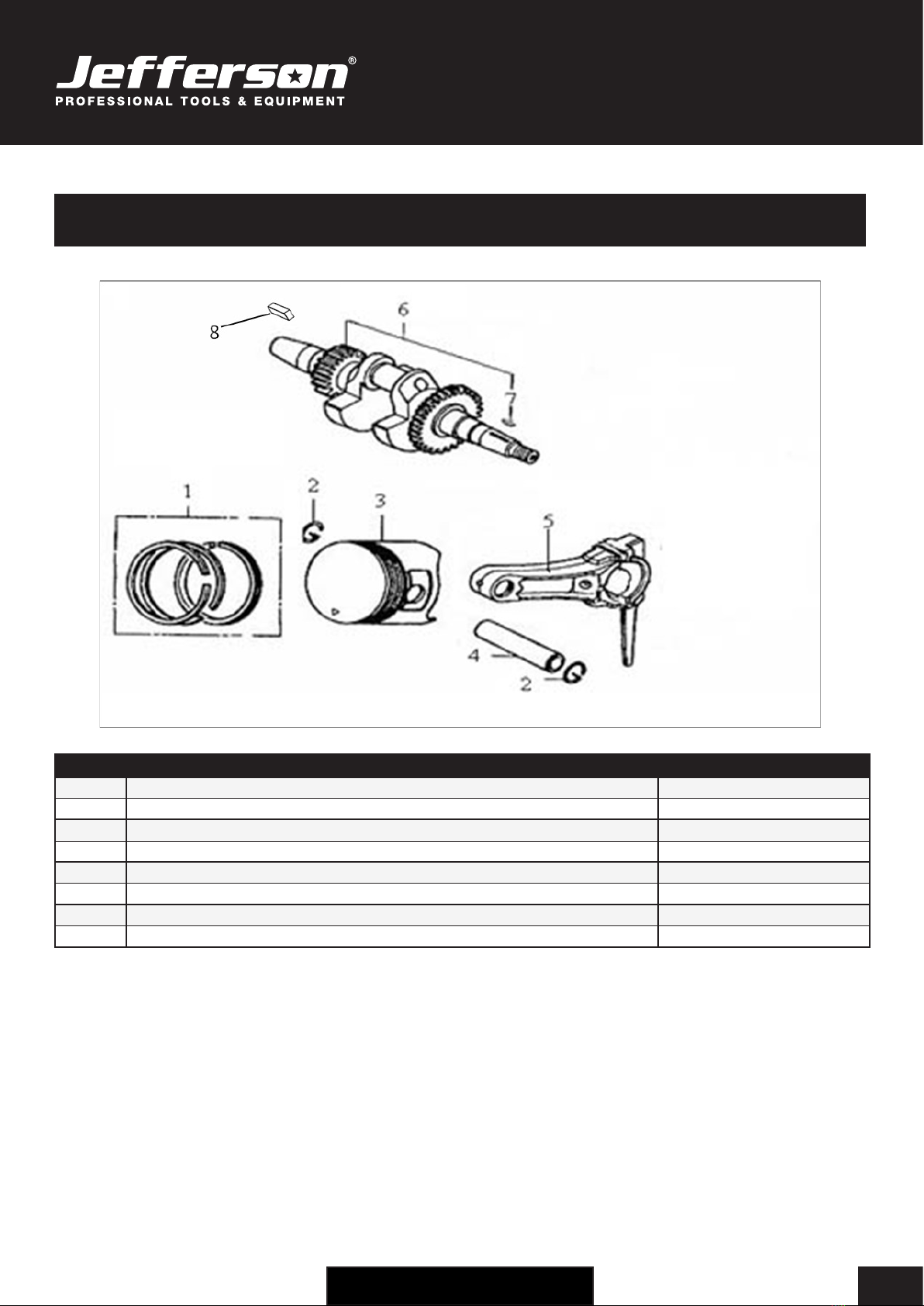

PARTS LIST & DIAGRAM - CRANKSHAFT / PISTON / CONNECTING ROD

# Description Quantity

1Piston Ring Combination 1

2Steel Cable Bafe Ring 2

3Piston 1

4Piston Pin 1

5Connecting Rod 1

6Crankshaft 1

7Key 1

8Key 1

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

12

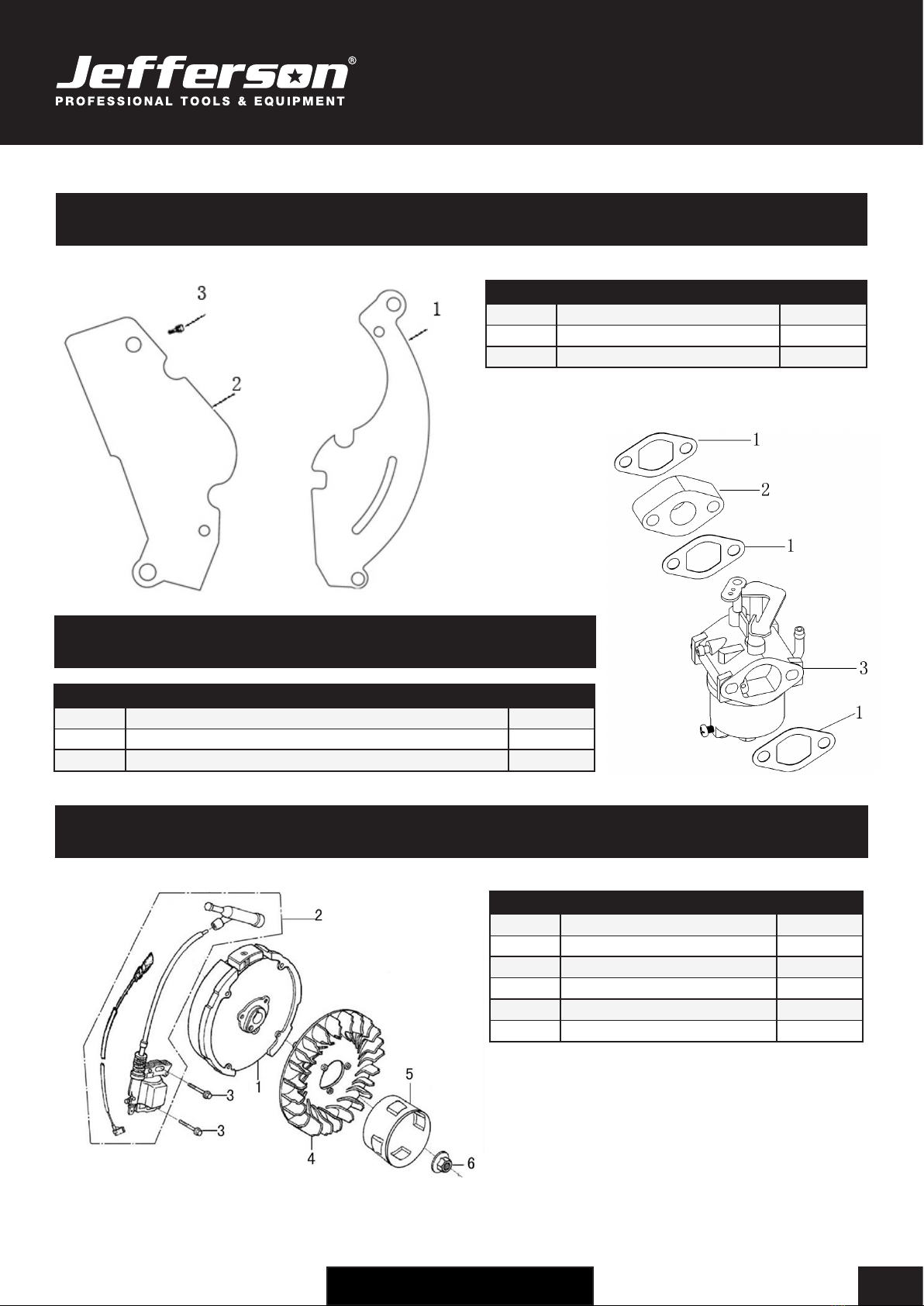

PARTS LIST & DIAGRAM - GAS DISTRIBUTION ADJUSTMENT

# Description Quantity

1Valve Rocker Combination 2

2Plate, Push Rod Guide 1

3Push Rod 2

4Lifter, Valve 2

5Camshaft Assy 1

6Valve Adjustment Cap 2

7Retainer, Valve Spring 2

8Inner Spring Of Valve 2

9Valve Kit 1

10 Valve Oil Seal 1

PARTS LIST & DIAGRAM - STARTER SUB-ASSEMBLY

# Description Quantity

1Manual Starting Components 1

2Fan Cover Comp. 1

3Hexagon Bolt With Flange 3

4Manual Starting Assembly 1

5Stop Switch 1

6Hexagon Bolt With Flange 4

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 13

PARTS LIST & DIAGRAM - DIVERSION ASSEMBLY

# Description Quantity

1 Side plate 1

2 Side plate 1

3 Hexagon bolt with ange 1

PARTS LIST & DIAGRAM - CARBURETOR

# Description Quantity

1Carburetor Gasket 3

2Heat Insulating Pad For Carburetor 1

3Carburetor 1

PARTS LIST & DIAGRAM - FLYWHEEL / IGNITION

# Description Quantity

1Flywheel Comp 1

2Coil Assy / Ignntion 1

3Hexagon Bolt With Flange 2

4Impeller 1

5Starting Disc 1

6Hexagon Nut With Flange 1

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

14

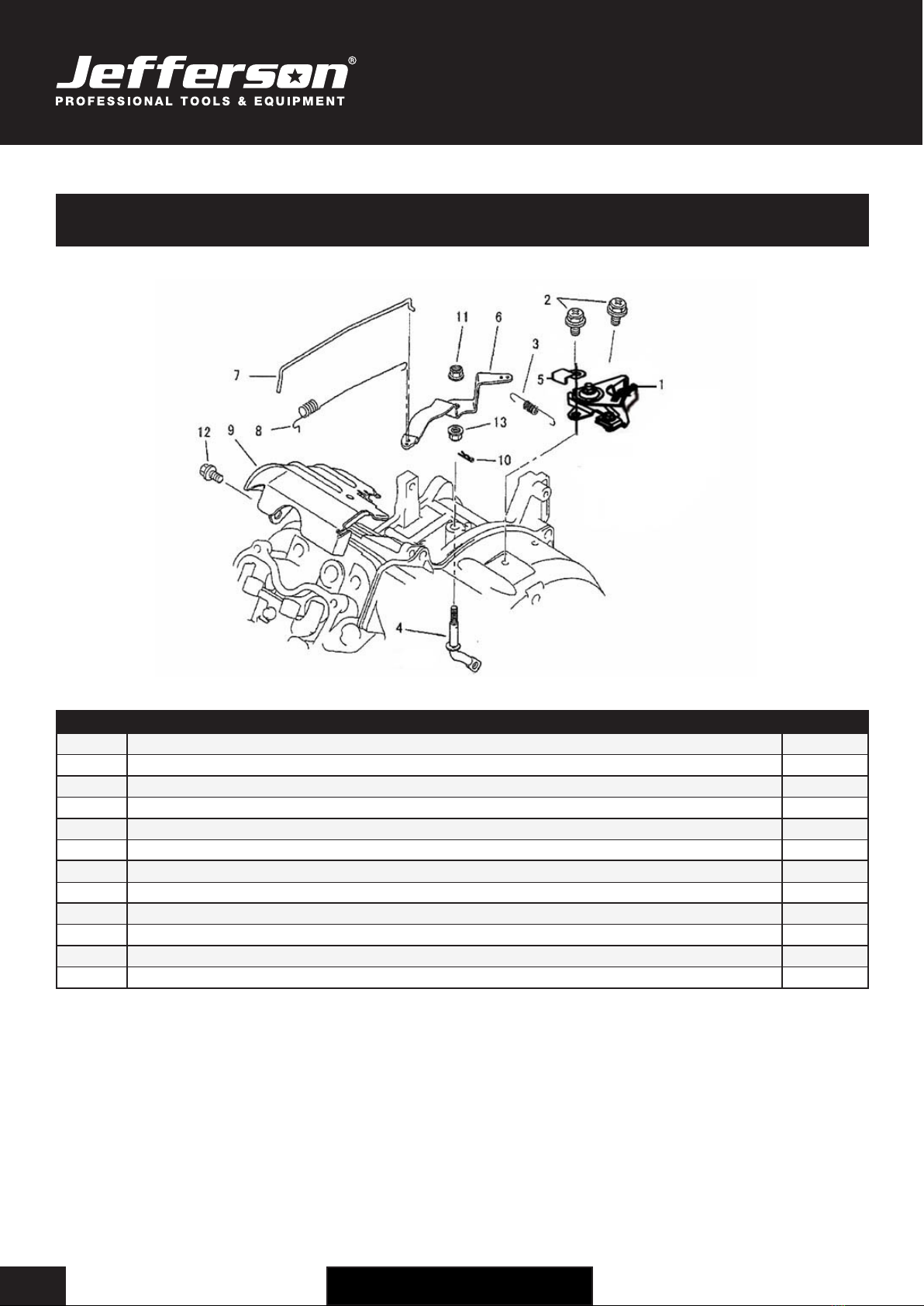

PARTS LIST & DIAGRAM - CONTROL SYSTEM

# Description Quantity

1Throttle Handle Combination 1

2Hexagon Bolt With Flange 2

3Governing Spring 1

4Speed Regulating Arm 1

5Cable Cleat 1

6Speed Regulating Bracket 1

7Throttle Rod 1

8Throttle Return Spring 1

9Air Deector 1

10 Pin Clip 1

11 Hexagon Nut With Flange 2

12 Hexagon Bolt With Flange 1

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 15

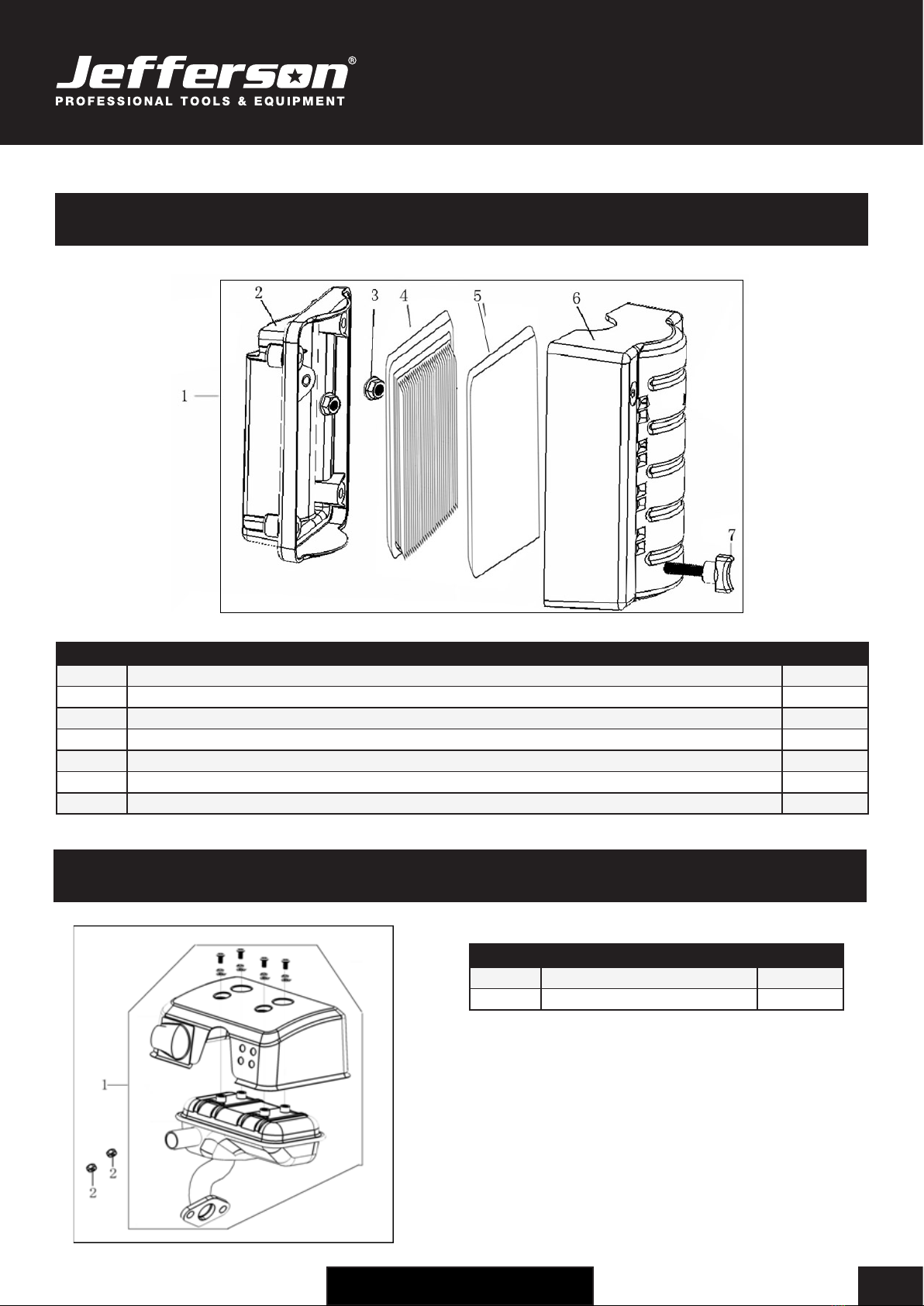

PARTS LIST & DIAGRAM - AIR FILTER

# Description Quantity

1Air Filter 1

2Air Filter Seat 1

3Hexagon Nut With Flange 2

4Air Filter Element 1

5Air Filter Element 1

6Air Filter Casing Cover 1

7Lock Bolt For Air Filter Cover 1

PARTS LIST & DIAGRAM - MUFFLER

# Description Quantity

1Mufer 1

2Hexagon Nut 2

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

16

PARTS LIST & DIAGRAM - FUEL TANK

# Description Quantity

1Tank Cover 1

2Pouring Orice Filter Screen Combination 1

3Tank 1

4Tank Oilout 1

5Oil Tube 1

6Protective Sleeve 1

7Pipe Clip 4

8Hexagon Shaft Shoulder Bolt 3

9Tank Damping Cushion 3

10 Oil Tube 1

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 17

We, Jefferson Professional Tools & Equipment, as the authorised European Community representative of the manufacturer, declare

that the following equipment conforms to the requirements of the following standards and directives:

Directive: Description:

2000/14/EC (as amended) Noise Emission in the Environment by Equipment for Use Outdoors

2014/30/EU (as amended) Electromagnetic Compatibility

2014/35/EU (as amended) Low Voltage Directive

(EU) 2016/1628 (as amended) Non-Road Mobile Machinery

Equipment Category: Petrol Concrete Mixer (Item 11)

EC-Type Approval Number: e13*2016/1628*2016/1628SHB2/P*0412*00

Product Name:

Model:

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

Guaranteed Sound Power Level: 101dB

The conformity assessment procedure followed was in accordance with Annex VI of

the Outdoor Noise Directive

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 25 October 2019

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way,

Chester Business Park,

Chester, United Kingdom,

CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

EC DECLARATION OF CONFORMITY

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

18

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations, improper care, service

or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• JEFCEMPETRED-L - 2.0HP Petrol Cement Mixer

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the

remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the need to

provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this

warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by

the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its

products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

USER MANUAL V1.1

JEFCEMPETORG-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com 19

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of

the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus return

carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to warranty@

jeffersontools.com

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

USER MANUAL V1.1

JEFCEMPETRED-L

2.0HP Petrol Cement Mixer

www.jeffersontools.com

20

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

www.jeffersontools.com

Table of contents

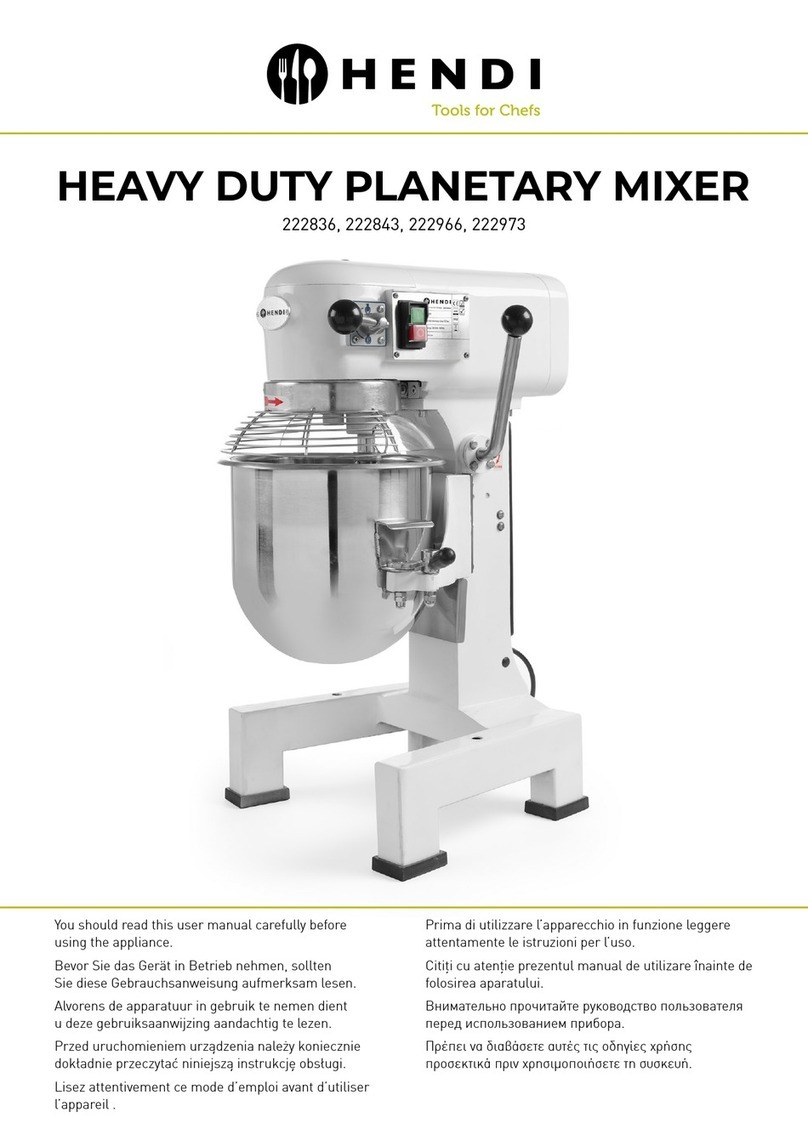

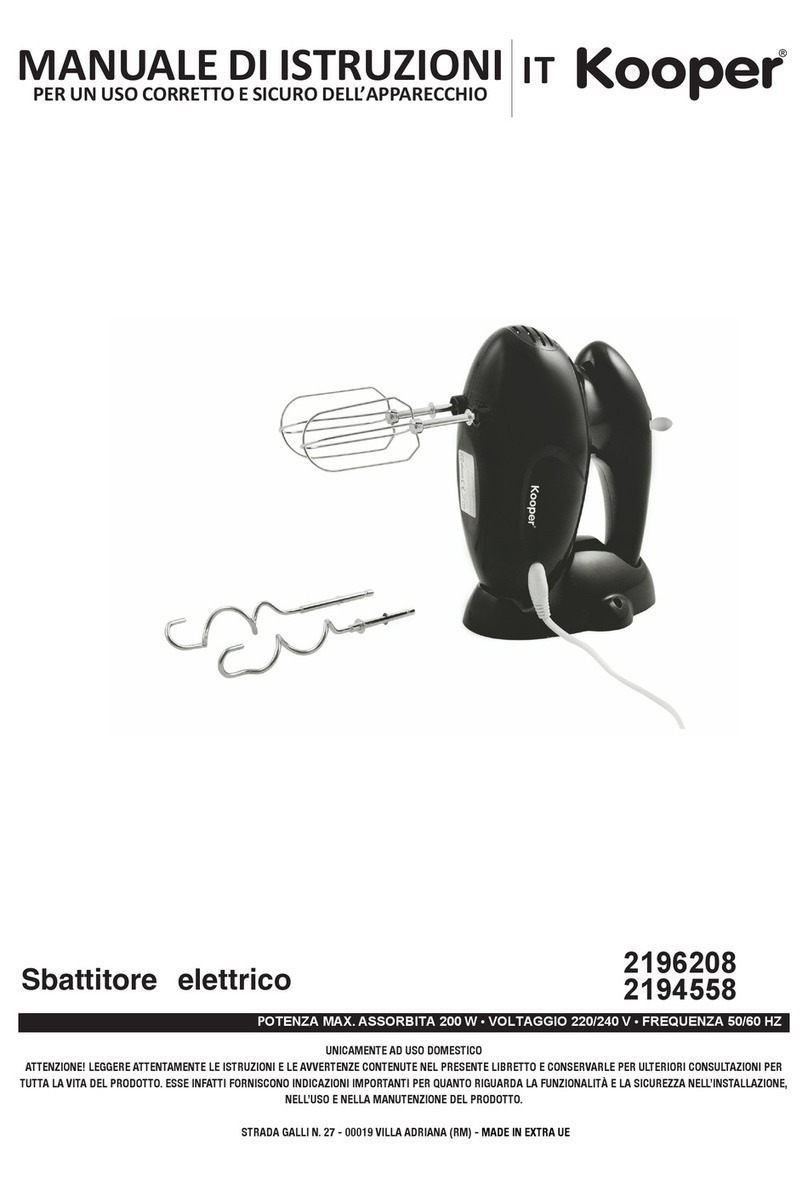

Popular Mixer manuals by other brands

Millipore

Millipore NovAseptic GMP ATEX Installation and user guide

Team International

Team International TEAM MS 17 operating instructions

better chef

better chef IM-815WC Use and care book

Hendi

Hendi Kitchen Line 222836 user manual

Kenwood

Kenwood Chef KM400 series user manual

Kooper

Kooper 2196208 User instructions